Idivayisi nenqubo yokusebenza kwe-multi-plate friction clutch

Okuqukethwe

Ekuchazeni imininingwane yezobuchwepheshe yama-SUV amaningi nezinye izimoto zabagibeli ezinokulungiswa okuhlukile kokudluliswa kwamasondo amane, ungathola umqondo we-clutch yamapuleti amaningi. Le nto yokushayisana iyingxenye yalokho okubizwa nge-plug-in all-wheel drive. Ukusebenza kwalesi sici kwenza kube nokwenzeka, uma kunesidingo, ukwenza i-eksisi engasebenzi ibe ehamba phambili. Lo mklamo uyasetshenziswa, ngokwesibonelo, ohlelweni lwe-xDrive, okukhona ngalo isihloko esihlukile.

Ngaphezu kwezimoto, imfucuza yamapuleti amaningi isetshenziswa ngempumelelo kumadivayisi ahlukahlukene womshini lapho kususwa khona amandla kwenzeka phakathi kwezinqubo ezimbili ezihlukile. Le divayisi ifakiwe njengengxenye yenguquko, ilinganisa futhi ivumelanisa ukushayela kwezinqubo ezimbili.

Cabanga ngomgomo wokusebenza kwale divayisi, yiziphi izinhlobo, kanye nobuhle nobubi babo.

Isebenza kanjani i-clutch

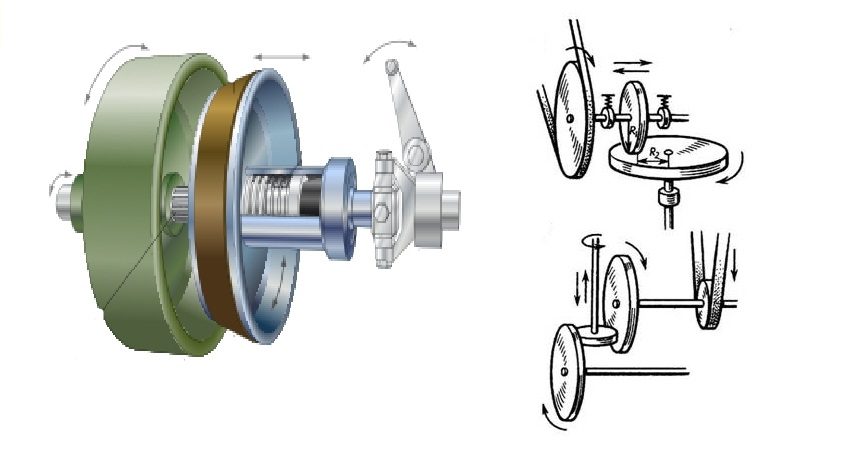

Ama-clutch clutch wokuqubuka amaningi angamadivayisi avumela indlela eqhutshwa ukukhipha amandla enkosini. Idizayini yayo ifaka phakathi idiski (kusetshenziswa izingxabano kanye nezinhlobo zensimbi zezingxenye). Isenzo somshini sinikezwa ngokucindezela ama-discs. Imvamisa ezimotweni, lolu hlobo lwe-clutch lusetshenziswa njengenye indlela yomehluko wokukhiya (le ndlela ichazwa ngokuningiliziwe kokunye ukubuyekeza). Kulokhu, ifakiwe ecaleni lokudlulisa (mayelana nokuthi liyini nokuthi kungani lidingeka ekudlulisweni, funda lapha) futhi uxhuma shaft eqhutshwa ohlangothini lwesibili, ngenxa yokuthi i-torque idluliselwa emasondweni angasebenzi, futhi ukudluliswa kuqala ukuwajika. Kepha enguqulweni elula, idivayisi enjalo isetshenziswa kubhasikidi we-clutch.

Umsebenzi omkhulu walezi zinqubo ukuxhuma / ukunqamula amayunithi amabili asebenzayo. Ngenkathi yokuxhuma idrayivu nama-disc aqhutshwa, i-clutch yenzeka ngokushelela ngokwanda okuqhubekayo kwamandla kuyunithi lokushayela. Ngokuphambene nalokho, imikhuba yokuphepha inqamula amadivayisi lapho i-torque idlula inani elivunyelwe kakhulu. Izindlela ezinjalo zingakwazi ukuxhuma ngokuzimela amayunithi ngemuva kokuba umthwalo omkhulu usususiwe. Ngenxa yokunemba okuphansi kwalolu hlobo lokuhlanganiswa, zisetshenziswa ezinhlelweni lapho kutholakala khona ukulayishwa okuningi okuhloniphekile, kepha isikhathi esifushane.

Ukuze uqonde isimiso sokusebenza kwale ndlela, kwanele ukukhumbula ukuthi i-clutch yegearbox (umakhenikha noma irobhothi), noma ubhasikidi obamba. Imininingwane ngale unit yemoto ichaziwe ngokwehlukana... Ngamafuphi, isiphethu esinamandla sicindezela idiski lapho libhekene nopulangwe. Ngenxa yalokhu, amandla asuswa kuyunithi yamandla ayiswa kushaft yokufaka ka-gearbox. Le ndlela isetshenziselwa ukunqamula okwesikhashana ukudluliswa kusuka kwinjini yomlilo yangaphakathi, futhi umshayeli ukwazile ukushintshela egiyeni oyifunayo.

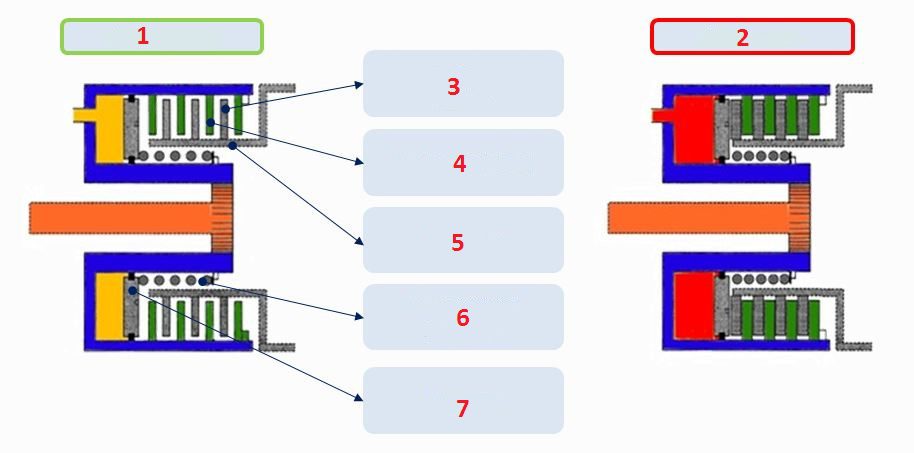

Umehluko omkhulu phakathi kwe-clutch yamapuleti amaningi nomehluko wokukhiya ukuthi indlela ebhekwayo inikezela ukuxhumana okushelelayo kwedrayivu kanye nemiphini eqhutshwa. Isenzo senziwa ngumbutho wokuphikisana, ohlinzeka ngokunamathela okuqinile phakathi kwama-disc namandla kuthathwa kuyunithi eqhutshwa. Ngokuya ngocingo olucindezela amadiski, ingcindezi yazo ingahlinzekwa yisiphethu esinamandla, i-servo kagesi noma umshini wokubacindezela.

I-coefficient ye-torque ilingana ngqo namandla okucindezela ama-disc. Lapho ukudluliswa kwamandla kushaft eqhutshwa kuqala (i-disc ngayinye icindezelwa kancane kancane, futhi i-clutch iqala ukusonteka shaft eqhutshwa), ukungqubuzana phakathi kwama-actuators kunika ukwanda okushelelayo kwamandla asebenza kushaft ye-secondary mechanism. Ukusheshisa kubushelelezi.

Futhi, amandla e-torque ancike kwinani lamadiski ku-clutch. Ukubukwa kwama-multi-disc kunokusebenza kahle okukhulu ekudluliseni amandla ku-node yesibili, ngoba indawo yokuxhumana yezinto zokuxhumana iyanda.

Ukuze idivaysi isebenze kahle, kuyadingeka ukugcina igebe phakathi kwendawo yamadiski. Le pharamitha isethwe ngumenzi, ngoba onjiniyela babala amandla okumele asetshenziswe ukuze indlela yokudlulisa kahle i-torque. Uma imvume yediski ingaphansi kwepharamitha ebekiwe, idrayivu yedrayivu izoshintshanisa nezinto eziqhutshwayo, ngaphandle kwesidingo sokuthi zisebenze.

Ngenxa yalokhu, ukumbozwa kwama-disc kuguga ngokushesha (kushesha kangakanani kuye ngobukhulu begebe). Kepha ukwanda kwebanga phakathi kwama-disc nakanjani kuzoholela ekugqokeni ngaphambi kwesikhathi kwedivayisi. Isizathu ukuthi ama-disc ngeke acindezelwe ngamandla amakhulu, futhi njengoba amandla ajikelezayo anda, i-clutch izoshelela. Isisekelo sokusebenza okulungile kokuhlanganiswa ngemuva kokulungiswa kwaso ukusetha ibanga elifanele phakathi kwezindawo zokuxhumana zezingxenye.

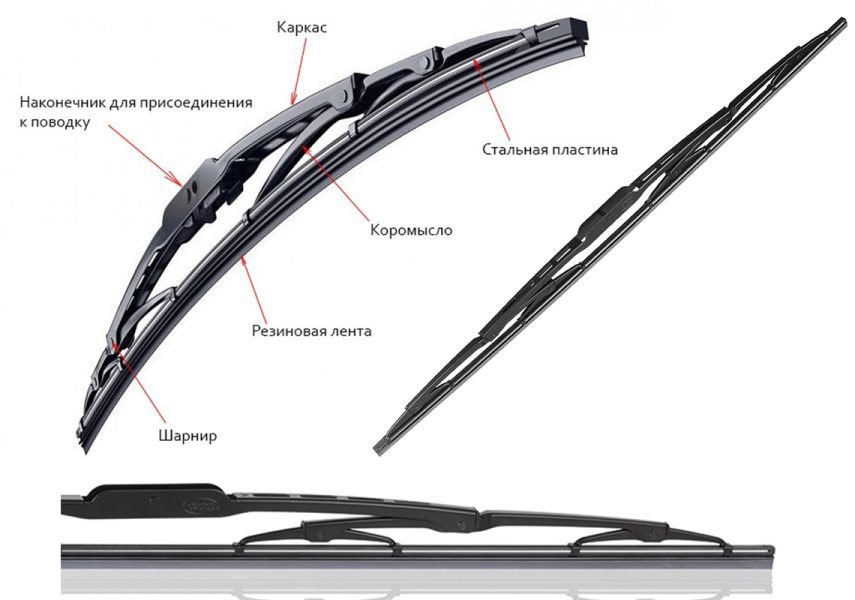

Idivayisi nezinto eziyinhloko

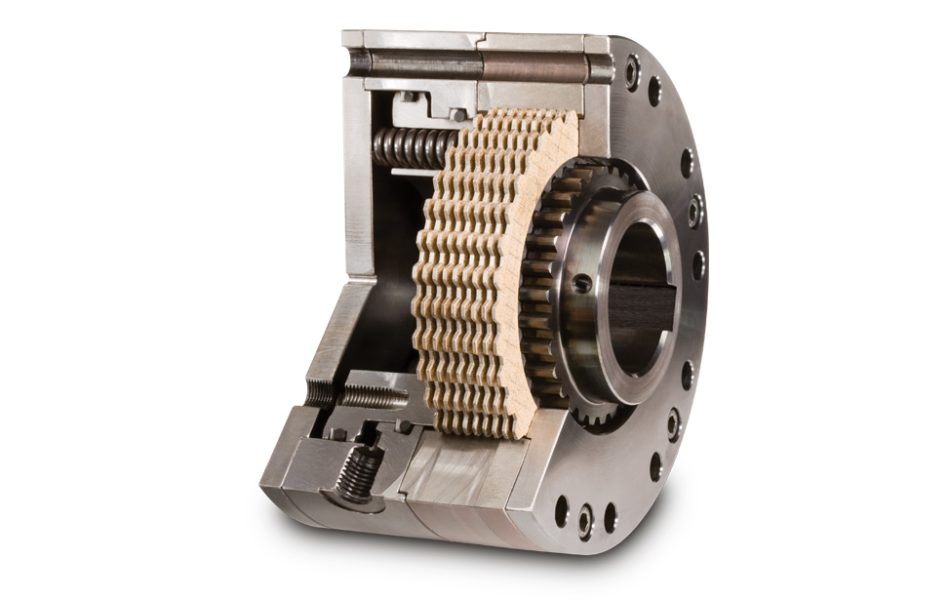

Ngakho, bamba siqukethe isakhiwo steel. Kukhona ama-discs amaningi wokushayisana kuwo (inani lalezi zakhi lincike ekuguqulweni kwemishini, kanye namandla wesikhashana lapho kufanele idlulise khona). Ozakwabo bensimbi bafakiwe phakathi kwalawa madiski.

Izinto zefutheni zixhumana nama-analogs wensimbi abushelelezi (kwezinye izimo, kukhona ukuhlohla okuhambisanayo kuzo zonke izingxenye zokuxhumana), kanye nebutho lokushayisana elinikezwe ngento yokumboza (kuvunyelwe ukusebenzisa izinto zobumba, njengoba ngamabhuleki e-ceramic, Kevlar, izinto ezihlanganisiwe zekhabhoni, njalonjalo), ikuvumela ukuthi udlulise amandla adingekayo phakathi kwezinqubo.

Ukuguqulwa okuvame kakhulu kokuguqulwa kwamadiski kuyinsimbi, lapho kufakwa khona ikhethelo elikhethekile. Okungajwayelekile kakhulu kunezinketho ezifanayo, kepha zenziwe ngepulasitiki enamandla amakhulu. Iqembu elilodwa lama-disc ligxiliswe kuhabhu ledrayivu shaft, kanti elinye kushaft eqhutshwa. Amadiski wensimbi abushelelezi ngaphandle kwesendlalelo sokungqubuzana aqondiswa kusigubhu se-shaft esiqhutshwa.

Kusetshenziswa ipiston nesiphethu sokubuyisa ukucindezela ama-disc ngokuqinile. I-piston ihamba ngaphansi kwengcindezi yedrayivu (ama-hydraulic noma imoto kagesi). Esikhathini se-hydraulic version, ngemuva kokucindezela kohlelo, intwasahlobo ibuyisela amadiski endaweni yawo, futhi i-torque iyeka ukugeleza.

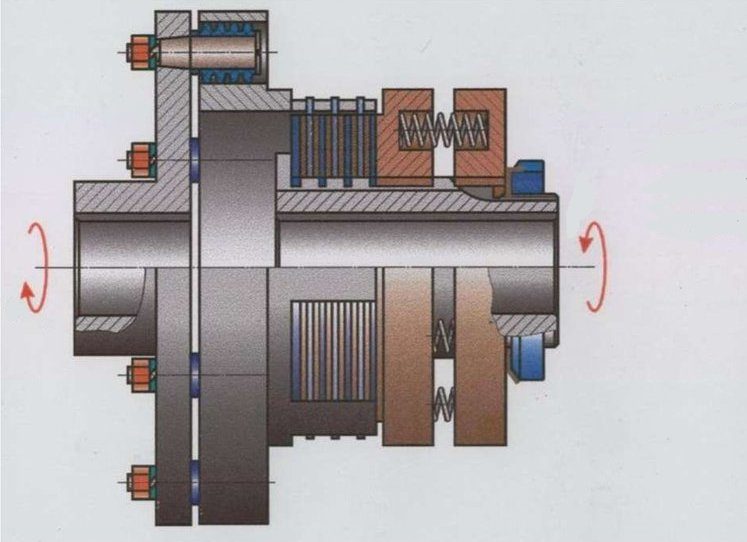

Phakathi kwazo zonke izinhlobo zamabhande amaningi, kunezinhlobo ezimbili:

- Yomile... Kulokhu, amadiski esigubhini anendawo eyomile, ngenxa yokuthi kufinyeleleke inani eliphakeme lokungqubuzana phakathi kwezingxenye;

- Imvula... Lezi zinguquko zisebenzisa inani elincane lamafutha. I-lubricant iyadingeka ukuze kuthuthukiswe ukupholisa kwama-disc kanye nokugcoba izingxenye zomshini. Kulokhu, kuzokwehla ukwehla okuphawulekayo ku-coefficient of friction. Ukunxephezela lokhu kusilela, onjiniyela banikeze idrayivu enamandla kakhudlwana yale clutch, ecindezela amadiski ngokuqinile. Ngokwengeziwe, ungqimba lokushayisana kwezingxenye luzofaka izinto zesimanje nezisebenza kahle.

Kunezinhlobonhlobo zamaklaski e-disc friction, kepha inqubo yokusebenza iyafana kubo bonke: i-disc yokuxubana icindezelwe kakhulu ebusweni be-analogue yensimbi, ngenxa yokuthi imiphini ye-coaxial yamayunithi ahlukene nezindlela zixhunywe / inqanyuliwe.

Izinto ezisetshenziswa ekwakheni

Ngokwesiko, i-disc yensimbi yenziwa ngensimbi ephezulu ene-anti-corrosion agent. Ezimotweni zesimanje, inketho eyenziwe ngezinto zokwenziwa kwekhabhoni noma i-Kevlar ingasetshenziswa. Kepha okuphumelela kakhulu namuhla izinketho ezivamile zokushayisana.

Abakhiqizi basebenzisa izinto ezahlukahlukene ukwenza leyo mikhiqizo, kepha imvamisa yile:

- I-Retinax... Ukwakheka kwento enjalo kufaka phakathi i-barite, i-asbestos, i-phenol-formaldehyde resins kanye ne-shavings yethusi;

- I-Tribonite... Le nto yenziwa ngenhlanganisela yemikhiqizo ethile kaphethiloli nezinto ezihlanganisiwe. Imikhiqizo enjalo imelana kakhulu nokusabela kwe-oxidative, ngenxa yokuthi idivayisi ingasetshenziswa ezimeni eziphezulu zomswakama;

- Inhlanganisela ecindezelwe... Ngaphezu kwezinto ezibalulekile eziqinisekisa ubuqotho bomkhiqizo, le nto iqukethe imicu yamandla ephezulu ekhulisa impilo yomkhiqizo, evimbela ukugqoka ngaphambi kwesikhathi.

Ifomu lokukhishwa kwengxenye

Njengoba kushiwo ngaphambili, i-multi-plate clutch inama-disc okungenani amabili. Lokhu kuyimikhiqizo ekhiqizwa ngendlela yamapuleti, lapho kufakwa khona ukugcotshwa okukhethekile noma ukugoqwa kwemihlobiso (nakho kwenziwa ngezinto ezibalulwe ngenhla). Kukhona nokuguqulwa okungajwayelekile kwezingxenye ezikwazi ukuhlinzeka ngokuhlanganiswa okungalungile kwamayunithi.

Ukuhlukahluka kwezinhlobo

Ngokuya ngemishini lapho kusetshenziswa khona imikhuba eminingi yamapuleti, kungafakwa ukulungiswa okuhlukile ekwakhiweni kwabo. Ake sicabangele ukuthi yiziphi izici ezihlukile. Ngamafuphi, ziyehluka ngosayizi, ukuma, inani lamadiski wokuxhumana kanye ne-torque edluliswa yidivayisi.

Njengoba sesibonile, izakhi eziyinhloko zedivayisi zivame ukuba ngamadiski. Kepha njengenye indlela futhi ngokuya ngesenzo esidingekayo, izigubhu, izingxenye ezi-tapered noma ze-cylindrical zingasetshenziswa. Ukuguqulwa okunjalo kusetshenziswa kulawo mayunithi lapho i-torque idluliswa khona ngemodi engajwayelekile, ngokwesibonelo, uma imiphini yamayunithi ingahambelani.

Idiski

Lolu hlobo lokuhlanganiswa luyinto evame kakhulu. Ekuklanyweni kokuguqulwa okunjalo, kukhona isigubhu lapho i-drive shaft iqondiswa khona. Ama-analogs emikhuhlane afakiwe phakathi kwama-disc wensimbi, agxiliswe kushaft eqhutshwa. Ngayinye yalezi kitshi inamathiselwe kwiyunithi eyodwa kusetshenziswa isitendi (noma izibopho eziningi).

Ukusetshenziswa kwama-disc couplings kunezici eziningana:

- Okokuqala, ukushayela okuningi kungasetshenziselwa ukuthuthukisa ukuthembeka nokusebenza kahle;

- Okwesibili, ukwakheka kwamadiski kungaba yinkimbinkimbi, ngakho-ke, ukukhiqizwa kwawo kungahlotshaniswa nemfucuza ehlukahlukene eyengeziwe, ngenxa yokuthi kunezinhlobonhlobo zamanani ezinto ezifanayo ezibonakalayo;

- Okwesithathu, enye yezinzuzo zalezi zinto ubukhulu obuncane bengxenye.

Okuyindilinga

Ukuhlanganiswa kwesigaxa kuvame ukusetshenziselwa izindlela zokubamba. Lokhu ukuhluka okusetshenziswa kumadivayisi e-drive ahlukahlukene adlulisa ngokuqhubekayo inani elikhulu le-torque kusuka entweni yokushayela iye entweni eqhutshwa.

Idivayisi yale ndlela iqukethe imigqomo eminingana exhunywe yipuleti. Izimfoloko ezikhipha izakhi zinosayizi abehlukene. Okucacile kwalokhu kuguqulwa ukuthi amapuleti engxenye eqhutshwa yensimbi angazungeza ngokuqinile, futhi iminwe ifakwa kulowo mshini engela elithile.

Izici zalokhu kuguqulwa kokuhlanganiswa kufaka phakathi:

- Ubushelelezi obukhulu bokukhuphuka kwe-torque;

- Izinga lokunamathela okuphezulu;

- Isikhathi esifushane, lo mklamo ukuvumela ukuthi ulungise ijubane lokujikeleza lamayunithi we-mated. Ukuze wenze lokhu, udinga nje ukushintsha amandla wokucindezela wezinto zokungqubuzana.

Naphezu kokusebenza kahle okuphezulu, lo mkhiqizo unesakhiwo esiyinkimbinkimbi, ngakho-ke, izindleko zezindlela ziphakeme kakhulu uma kuqhathaniswa ne-analogue yangaphambilini.

Ukwakhiwa kwesakhiwo

Lokhu kuguqulwa akuvamile kakhulu ezimotweni. Zivame ukusetshenziselwa ompompi. Ububanzi besigubhu sokushayela kudivayisi bukhulu, futhi ama-rack angaba ngosayizi abahlukene. Izikhonkwane zokuxina nazo zinkulu, futhi amabhele amaningi angafakwa kulokho. Okuhlukile kwalolu hlobo lokuhlanganiswa ukuthi bayakwazi ukumelana nemithwalo esindayo.

Ekwenziweni kwemikhiqizo enjalo, kusetshenziswa izinto ezingamelana namazinga okushisa aphezulu. Okubi kakhulu kulezi zindlela ngosayizi wazo omkhulu.

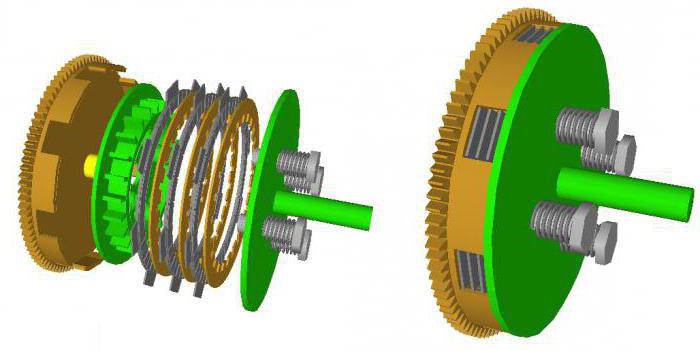

Ukubukwa kwama-disc amaningi

Njengoba sekushiwo, imvamisa yamapuleti amaningi isetshenziswa ezimotweni. Idivayisi yento enjalo ifaka isigubhu esisodwa lapho kufakwa khona amapuleti amathathu. Ama-Gaskets afakiwe kuzikhonkwane zokubopha. Ngokuya ngemodeli yedivayisi, ukwesekwa okungaphezu koyedwa kungasetshenziswa esakhiweni. Kunezinketho ezimbili zentwasahlobo. Zinikela ngamandla amakhulu nezimfoloko zinkulu ngobubanzi. Ngokuvamile lezi zinhlobo zokuhlanganiswa zifakwa kudrayivu. Umzimba walesi sici sokungqubuzana unciphisiwe.

Lokhu kuguqulwa kokuhlanganiswa kuvumela ubukhulu bezinto zedivayisi ukuthi banciphiswe ngaphandle kokunikela ngokusebenza. Nazi izinto ezibalulekile ezisebenza kulokhu kuguqulwa:

- Bavumela ukunciphisa ubukhulu bokusetshenziswa kwedivayisi, kodwa ngasikhathi sinye bandise umkhiqizo womshini;

- Amadivayisi anjalo asetshenziswa ngempumelelo ekuthuthweni kwemithwalo;

- Inani lezinto zokungqubuzana likuvumela ukuthi wandise amandla wokuphambana, ngenxa yokuthi kungenzeka ukudlulisa i-torque yamandla amakhulu (idivaysi ingaba nobukhulu obungenamkhawulo);

- Ama-clutches anjalo angomile noma abe manzi (ngama-discs wokukhuphisana okugcotshisiwe).

Izinhlobo zesigubhu esisodwa

Kulokhu kuguqulwa, ipuleti elilodwa noma amaningi atholakala ngaphakathi kwesigubhu. I-Downforce ilungiswa ngezikhonkwane ezilayishwa entwasahlobo. Izindlela ezifanayo zisasetshenziswa kwezinye izinhlobo zezimoto, kepha zivame ukutholakala kuma-cranes. Isizathu salokhu yikhono lokumelana nemithwalo esindayo ye-ekseli.

I-plug yokufakwa esakhiweni ifakiwe eduze kwesisekelo sayo. Ama-disc friction ahamba phambili, kanti lawo aqhutshwa ayapholishwa, futhi angazungeza ngejubane elikhulu. Izici zale mikhiqizo zifaka:

- Usayizi omncane;

- Ukuntuleka kokungqubuzana noma izinto ezihuqayo (ezinhlotsheni eziningi);

- Idizayini ivumela ukunciphisa ukushisa ngesikhathi sokusebenza kwedivayisi;

- Uma usebenzisa i-analog yokungqubuzana, ungakhuphula amandla we-torque.

Izinhlobo ezinama-reels amaningi

Imvamisa ungathola i-clutch yezokuphepha yohlobo lokushayisana, ukwakheka kwayo kufaka phakathi izigubhu eziningana. Izinzuzo zalolu hlobo lwedivayisi zifaka ukusebenza ngamandla okuphezulu, ukugcizelelwa kwekhwalithi ephezulu, kanye nokukwazi ukubhekana nemithwalo esindayo. Kulezi zinguquko, izimbondela azivamile ukusetshenziswa.

Amamodeli anezigubhu eziningi asebenzisa i-pinion gear enkulu, kanti amanye amamodeli asebenzisa izikhonkwane zokungezwani kanye ne-rack kabili. Ipulaki yokuxhuma itholakala ngaphambili kwedivayisi.

Lezi zinguquko zedivayisi azisetshenziswanga kumadrayivu, ngoba anokuxhumeka okuhamba kancane. Abakhiqizi abaningana bakhiqize izinhlobo zemodeli yesigubhu esiningi esebenzisa idiski ekhishwayo. Kulesi sakhiwo, isiqu sinqamule futhi iminwe incane.

Lezi zinguquko zisebenza kahle kakhulu. Izigubhu zijikeleza kuphela ohlangothini olulodwa. IDiski yedrayivu ingatholwa ngaphambi kwepuleti lokukhishwa noma ngemuva kwayo.

Bushings

Lokhu kuguqulwa kusetshenziswa kuphela kuma-clutches. Kwesinye isikhathi zingafakwa esitimeleni sokushayela. Basebenzisa iziphethu zokukhulula, okufakwa kuzo izikhonkwane zokubopha, futhi ngaphakathi kungaba nokuhlukaniswa okuningi. Ipuleti ngalinye lomshini lisendaweni evundlile, futhi ukufakwa phakathi kwehlukaniso (ngaphezu kwalokho, kusebenza njenge-damper).

Ububi balokhu ukuguqulwa kokuhlanganiswa kungukucindezelwa okubuthakathaka kwama-disc. Ukuzungezisa okuqinile kushaft akumele kuvunyelwe okwamanje. Ngalezi zizathu, amadivayisi akulesi sigaba awasetshenziswa kumadrayivu.

I-Flanged

Inzuzo yokuhlanganiswa kwe-flange ukuthi isigubhu asigugile kangako kuzo. Ama-disc alungiswa ngemuva kwe-rack. Ukuhlukaniswa ngaphakathi komkhiqizo kuncane. Ukuze i-rack ibe sendaweni eyodwa, ihlanganiswe ngocwecwe olukhethekile. Imvamisa, iziphethu zokuhlanganisa okunjalo zifakwa ezansi kwesakhiwo. Okunye ukuguqulwa kungabhangqwa nedrayivu. Idrayivu shaft ixhunywe kudivayisi nge-plug. Kwesinye isikhathi kunezinketho ezisebenzisa i-disc squeeze ebanzi. Le ndlela incane ngosayizi, futhi umzimba wenziwe ngesigaxa.

Ukuhlanganiswa kwe-Flange kulula ukufaka nokugcina. Imikhiqizo enjalo inempilo ende yokusebenza futhi inokwethenjelwa okuphezulu. Ngaphandle kokuxhaphaka kwamadivayisi anjalo, awafakwa ngaso sonke isikhathi.

Kushiwo

Lokhu kuguqulwa kokuhlanganiswa kungasetshenziswa kumadrayivu anamandla ahlukile. Umklamo womshini onjalo usebenzisa ukwahlukanisa okubanzi (kungahle kube khona ama-notch kuwo) neminwe emifushane. Ama-disc alungiswa phansi kwamapuleti. Umzimba walolu hlobo lwedivayisi ungaba nosayizi abahlukene, kuya ngobukhulu bezinto zabo. Izikhonkwane eziqinisayo zifakwe phambi kweraki.

Ukususwa kwamandla yidivayisi enjalo ngqo kuya ngobukhulu besigubhu. Ngokuvamile, udonga lwawo lubanzi. Imiphetho yayo ayihlangani nama-disc ngenxa yokulola nokusetshenziswa kwamahinji.

I-Cam

Ukuhlanganiswa kwalolu hlobo kusetshenziswa emishinini yezimboni. Izinguquko eziningi ziyakwazi ukumelana nemithwalo esindayo, kepha lokhu kuya ngobukhulu besigubhu. Kunezinhlobonhlobo lapho isigubhu silungiswa ngokwahlukaniswa, futhi amapuleti nawo angaba khona ekwakhiweni kwawo. Ukugcina izingxenye zihlangene, umzimba wenziwa ngesigaxa.

Izinguquko ezivame kakhulu zinama-discs cindezela. Kulokhu, isigubhu sizoba sincane. Imfoloko kule modeli ixhunywe nezinduku. Ezinye izinhlobo zokuhlangana zisebenzisa lezi zinhlobo zokuhlanganiswa. Ukulungiswa kwezikhonkwane zokubopha (izingxenye ezincane zisetshenzisiwe) kungenzeka eduze kwesisekelo sokwahlukanisa. Ubuhle balezi zinhlobo zokuhlanganiswa ukuthi isigubhu esiqhutshwa cishe asigugi.

Umgomo wokusebenza kokuguqulwa okunje umi kanje:

- Lapho idrayivu isenziwa, ama-cams atholakala engxenyeni eyodwa yokuhlanganisa afaka ukuphuma kwesinye isigamu sokuhlanganisa. Ukuxhuma kwezinto ezimbili kuqinile;

- Ingxenye yokusebenza ihamba eduze kwe-eksisi isebenzisa ukuxhumana kwe-spline (esikhundleni se-spline, enye into yomhlahlandlela nayo ingasetshenziswa);

- Ukuze ukugqoka okuncane kumshini, ingxenye ehambayo kufanele ifakwe kushaft eqhutshwa.

Kukhona ukulungiswa lapho ama-cams engunxantathu, ama-trapezoidal futhi engunxande. Amakhamela enziwe ngensimbi eqinile ukuze akwazi ukumelana nemithwalo esindayo. Kwezinye izimo, iphrofayli ye-asymmetrical ingasetshenziswa.

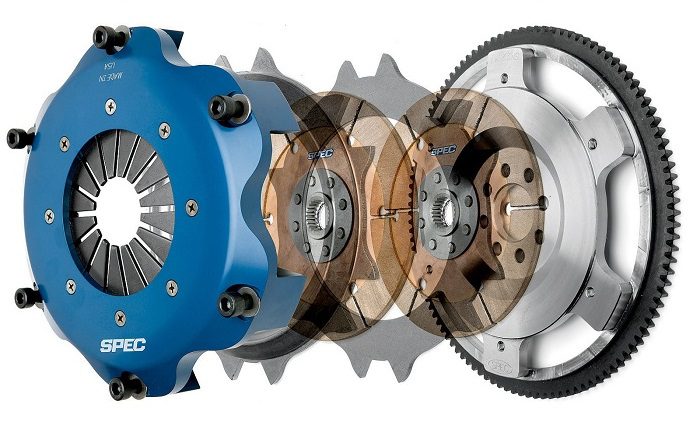

Izinketho zeDrayivu

Ezinhlelweni zokushayela, kusetshenziswa imikhuba enjalo yamapuleti amaningi, lapho kungasetshenziswa khona isigubhu esisodwa nezimbalwa. Kulezi zinguqulo, isiqu sikulungele ukukhweza kushaft encane. Isigubhu sibekwe sibheke phezulu. Eziningi zalezi zinhlanganisela zisebenzisa ama-aluminium disc (noma ama-alloys awo). Futhi, izindlela ezinjalo zingaba nezinto ezilayishwe entwasahlobo.

Esimweni sakudala, idrayivu bamba unamadiski amabili anwebekayo, okufakwa kuwo ipuleti. Isihlahla sinamathiselwe ngemuva kwenduku yethuluzi. Ukuze isigubhu singagugi ngaphambi kwesikhathi, ukwakheka komshini kuhlinzeka ngobukhona bokubamba.

Amamodeli asetshenziswa ekufakweni kwamandla aphakeme anomklamo ohluke kancane. Kufakwa ukwahlukanisa eduze kwediski yokukhama, kanti isigubhu esiqhutshwa sima kumugqa omkhulu. Iziphethu zingafakwa othayi. Imfoloko ilungiswa esisekelweni. Umzimba wokunye ukuguqulwa uthayishiwe. Idivayisi yezinqubo ingafaka amapuleti amancane okusebenza.

Umkhono wemikhono

Ukuhlanganiswa kweminwe ehlathini nakho kuvamile. Zisetshenziswa ekwakheni izindlela ezahlukahlukene. Izici zalokhu kuguqulwa zifaka izici ezilandelayo:

- Ezimweni eziningi, le mikhiqizo yenziwa ngokuya ngamazinga athile, ukuze ukwazi ukukhetha kalula imodeli efanelekile yokunyakaza okuthile;

- Lapho uhlela lo mshini, ungalanda izinketho eziningi zemidwebo eningiliziwe kwi-Intanethi;

- Izinto ezahlukahlukene zingasetshenziswa ngokuya ngenhloso yokuhlangana.

Imvamisa, lezi zinhlobo zokuhlanganiswa zisetshenziswa njengamafiyuzi.

Ukugcwala

Ama-clution clutches asetshenziswa kulezo zindlela lapho kufanele kuqinisekiswe ukudluliswa kwe-torque ngokushelelayo, kungakhathalekile ukuthi ijubane lokushintshana kwemiphini yokushayela nelishaywayo. Futhi, lokhu kuguqulwa kukwazi ukusebenza ngaphansi komthwalo. Ukucaca kokusebenza kahle komshini kulele kumandla aphezulu wokuphikisana, aqinisekisa amandla amakhulu okusuka.

Izici zemikhuhlane yokushayisana zifaka phakathi izinto ezilandelayo:

- Ayikho imithwalo eshaqisayo, ngoba ukubandakanyeka kwenzeka ngokushelela ngokushelela ngesikhathi sokuxhuma kwama-disc. Lokhu kuyinzuzo esemqoka yalokhu kuguqulwa;

- Ngenxa yengcindezi eqinile yamadiski phakathi kwabo, ukushibilika kuyancipha, futhi namandla okuxubana ayanda. Lokhu kuholela ekwandeni kwe-torque kuyunithi eqhutshwa kuze kube yilapho izinguquko zemiphini zifana;

- Ijubane lokujikeleza kushaft eliqhutshwa lingalungiswa kusetshenziswa amandla okucindezelwa kwama-disc.

Ngaphandle kwalezi zinzuzo, imikhuhlane yokushayisana nayo inezinkinga ezinkulu. Esinye sazo ukugqokwa okwandayo kwendawo equbuzanayo yamadiski okuxhumana. Ngaphezu kwalokho, njengoba amandla okuxabana ekhuphuka, ama-discs angashisa kakhulu.

Izinzuzo nokungalungi

Izinzuzo zokuhlangana kwamapuleti amaningi zifaka:

- Ubukhulu bomklamo ohlangene;

- Iyunithi uqobo, lapho kusetshenziswa khona ukuhlangana okunjalo, nayo izoba ncane;

- Ukwandisa i-torque, asikho isidingo sokufaka i-disc enkulu. Ngalokhu, abakhiqizi basebenzisa idizayini enkulu ngama-disc amaningi. Ngenxa yalokhu, ngosayizi onesizotha, idivayisi iyakwazi ukudlulisa inkomba ehloniphekile ye-torque;

- Amandla anikezwa kushaft yedrayivu ngokushelela, ngaphandle kokudlikiza;

- Kungenzeka ukuxhuma imiphini emibili endizeni eyodwa (uxhumano lwe-coaxial).

Kepha le divayisi inezinkinga ezithile. Iphuzu elibuthakathaka kulomklamo izindawo zokungqubuzana kwama-disc, aphela ngokuhamba kwesikhathi kusuka kuzinqubo zemvelo. Kodwa uma umshayeli enomkhuba wokucindezela kakhulu i-pedal yegesi lapho esheshisa imoto noma endaweni engazinzile, khona-ke i-clutch (uma idluliswa nayo) izoguga ngokushesha.

Ngokuphathelene nezinhlobo ezimanzi zokuhlangana, i-viscosity kawoyela ithinta ngqo amandla okuxabana phakathi kwama-disc - okunamandla kokuthambisa, ukunamathela kubi kakhulu. Ngenxa yalesi sizathu, kumishini efakwe imigoqo yamapuleti amaningi, kubalulekile ukushintsha uwoyela ngesikhathi esifanele.

Ukubhangqa uhlelo lokusebenza

Ama-clutch clutch amaningi angasetshenziswa ezinhlelweni ezahlukahlukene zezimoto. Nazi izindlela namayunithi angafakwa kule divayisi:

- Emabhasikithini e-clutch (lokhu kungukuguquguquka kokuhlukahluka lapho kungekho siguquli se-torque);

- Ukudluliswa okuzenzakalelayo - kule yunithi, i-clutch izodlulisa i-torque kumagiya eplanethi;

- Kuma-gearbox amarobhothi. Yize kungeyona i-clutch yamapuleti amaningi yakudala esetshenziswa lapha, iklatshi elomile kabili noma elimanzi lisebenza kumgomo ofanayo (ukuthola eminye imininingwane ngamabhokisi wamagiya akhethiwe, funda kwesinye isihloko);

- Kuzo zonke amasondo drive izinhlelo. I-multi-plate clutch ifakiwe ecaleni lokudlulisa. Kulokhu, lo mshini usetshenziswa njenge-analogue yokuvimba umehluko wesikhungo (ukuthola imininingwane yokuthi kungani kungadingeka ukuvinjwa kwale divayisi, funda ngokwehlukana). Kuleli lungiselelo, imodi ezenzakalelayo yokuxhuma i-ekseli lesibili izothamba kunasesimweni sokukhiya okwehlukile;

- Kwezinye izinguquko zokuhluka. Uma i-multi-plate clutch isetshenziswa kumshini onjalo, khona-ke inikeza ukuvimba okuphelele noma okuyingxenye kwedivayisi.

Ngakho-ke, yize iqiniso lokuthi izindlela zakudala zithathelwa indawo kancane kancane ngama-hydraulic, kagesi noma ama-pneumatic analogs, ezinhlelweni eziningi akukwazeki ukukhipha ngokuphelele ubukhona bezingxenye ezisebenza ngokwesisekelo semithetho yemvelo, ngokwesibonelo . Ukubanjwa kwamapuleti amaningi kuwubufakazi balokhu. Ngenxa yobulula bokuklama, isafunwa ngamayunithi amaningi, futhi kwesinye isikhathi ingena esikhundleni samadivayisi ayinkimbinkimbi ngokwengeziwe.

Ngaphandle kokuthi lezi zinto zihlala zidinga ukulungiswa noma ukushintshwa, abakhiqizi abakwazi ukuzishintsha ngokuphelele ngezisebenza kahle kakhulu. Ukuphela kwento eyenziwe ngonjiniyela ukwenza ezinye izinto ezihlinzeka ngemikhiqizo emikhulu yokugqoka.

Ekupheleni kokubuyekezwa, sinikela ngevidiyo emfushane emayelana nokuhlangana okungqubuzanayo:

Ukulungiswa kwe-clutch yefriction

Kuye ngokuguqulwa nenjongo ye-friction clutch, ingalungiswa kunokuthenga entsha. Uma umkhiqizi wedivayisi enikeze ithuba elinjalo, khona-ke okokuqala udinga ukususa isendlalelo se-friction esigugile. Ingalungiswa esisekelweni ngama-rivets noma izinto ze-epoxy. Ngemuva kokudilizwa, ingaphezulu lesisekelo kufanele lihlanzwe kahle ku-adhesive residu noma lifakwe isihlabathi uma linama-burrs.

Njengoba ukuguga kwempahla ye-friction kwenzeka ngenxa yokushelela kwejoyinti ngaphansi kwamandla aphezulu, kungaba kuhle kakhulu ukungafaki umugqa omusha onama-rivets, kodwa ukuwuxhuma kusisekelo sensimbi sokuhlangana ngezinto ze-epoxy eziklanyelwe ukusebenza. emazingeni okushisa aphezulu.

Uma izinto zokungqubuzana zilungiswa ngama-rivets, njengoba lesi singqimba siguga, ama-rivets angakwazi ukunamathela endaweni yokusebenza yensimbi ye-disc ukuze ihlanganiswe, okuzoyenza ingasebenzi. Ukulungiswa okuthembekile kwesendlalelo sokungqubuzana esisekelweni, i-VS-UT glue ingasetshenziswa. Lokhu okunamathelayo kuqukethe izinhlaka zokwenziwa ezincibilika kuzincibilikisi zemvelo.

Ifilimu yalesi sinamathiseli inikeza ukulungiswa okuthembekile kwezinto eziphikisanayo ensimbi. Ifilimu iyaphikiswa, ayikho ngaphansi kokubhujiswa ngenxa yokuchayeka emanzini, izinga lokushisa eliphansi nemikhiqizo kawoyela.

Ngemuva kokulungisa i-clutch, udinga ukuqinisekisa ukuthi ungqimba lwe-friction luzothintana nendawo yokusebenza yediski yensimbi. Kulokhu, kusetshenziswa umthofu obomvu - upende we-orange. Iphoyinti lokuxhumana kufanele lihambisane ngokugcwele nendawo yesici sokungqubuzana se-clutch. Uma ngesikhathi sokusebenza into esezingeni eliphansi noma eyonakele ye-friction yonakalise ingaphezulu lediski yokucindezela (kuvele imihuzuko, ama-burrs, njll.), ngaphezu kokulungisa i-friction lining, indawo yokusebenza kufanele futhi ifakwe isihlabathi. Uma kungenjalo, i-friction lining izoguga ngokushesha.

Imibuzo nezimpendulo:

Iyini i-friction clutch? Isici esinjalo sinikeza ukunamathela kwezinqubo ezimbili usebenzisa ama-discs ane-friction kanye nendawo ebushelelezi. Isibonelo sakudala soxhumano olunjalo yibhasikidi ye-clutch.

Isebenza kanjani i-disc clutch? I-drive shaft enediski eyinhloko iyazungeza, ama-disc/disc aqhutshwa icindezelwa kuwo isiphethu esinamandla. Ingaphezulu le-friction, ngenxa yamandla e-friction, iqinisekisa ukudluliswa kwe-torque isuka kudiski iye ku-gearbox.

Kwenzekani uma i-friction clutch ihlanganyela? Lapho i-clutch ye-friction ibamba, idonsa amandla okusebenza (i-torque) bese iwadlulisela engxenyeni elandelayo yomshini. Lokhu kukhipha amandla okushisa.

Iyini i-multi-plate friction clutch? Lokhu ukuguqulwa komshini, inhloso yawo ukudlulisa i-torque. Umshini uqukethe iphakethe lama-disc (iqembu elilodwa liyinsimbi, kanti elinye liyi-friction), elicindezelwe ngokuqinile komunye nomunye.