Indlela Yokuhlanza I-Soldering Iron - Umhlahlandlela ophelele

Okuqukethwe

- Izimpawu zokuhlanza

- Yini ebangela inkinga?

- Kungani bedinga isondlo?

- Izindlela zokuhlanza

- Isiqophi

- Ungakuvimbela kanjani i-oxidation?

- Amathiphu okugcina ithiphu lakho lensimbi yokunamathisela lisesimweni esihle

- Kwenzekani uma ungayisevisi i-ayina yakho yokusoda?

- Izinzuzo zokunakekelwa okufanele kwe-iron soldering

- Izinkinga ezivamile ezenzeka lapho i-soldering iron ingagcinwa kahle

- Isikhathi sokushintsha ithiphu

- isiphetho

Akukho lutho olubi kakhulu kunensimbi ye-solder engapheli.

Namuhla sizoxoxa indlela yokuhlanza i-soldering iron kanye namathiphu athile wokuyigcina isesimweni esihle.

Uzobona izindlela ezintathu ezilula zokuhlanza ithiphu lakho lensimbi yokuhlanganisa ukuze kubukeke sengathi usanda kulithenga.

Izimpawu zokuhlanza

- Ayisebenzi kahle

Uma i-soldering iron ingasebenzi kahle, ngokuvamile kungenxa yokuthi ithiphu alihlanzekile. Uma ithiphu ingcolile, i-solder ngeke inamathele kuyo futhi uxhumano luzoba buthakathaka.

- Kuthatha isikhathi eside ukufudumala

Uma uqaphela ukuthi i-soldering iron yakho ishisa isikhathi eside, khona-ke ingxenye yayo ene-oxidized ayikuvumeli ukukhipha ukushisa. Kulokhu, ingxenye egqwalile isebenza njenge-insulator.

Kufana nokuzama ukungena ngomnyango wesilwane esifuywayo.

Lapha ungathola ukuthi i-soldering iron ishisa isikhathi eside kangakanani.

- Iyanuka uma ivuliwe

Lapho i-soldering iron iqala ukusebenza, iqala ngokushesha ukushisa ithiphu. Uma iqala ukunuka, ukushisa kushisa ingxenye engcolile phezulu. Lokhu kusho ukuthi i-oxidation isiqalile ukwakheka ekugcineni.

Yini ebangela inkinga?

Kunezizathu eziningi zokubangela i-oxidation. Lesi simo sibangelwa ukusetshenziswa kocingo lwe-solder olusezingeni eliphansi noma unamathisele othintana naye oqukethe izinsimbi ezihlukahlukene ezinamathele esihlokweni sensimbi yokunamathisela.

Ukusebenzisa i-soldering iron emazingeni okushisa aphezulu kuzolimaza ithiphu.

Futhi, i-soldering iron iyagqwala ngokuhamba kwesikhathi ngenxa yokuthi ayizange ihlanzwe isikhathi eside.

Kungani bedinga isondlo?

Isizathu esikhulu sokuthi ama-ayina asodayo adinga ukulungiswa ukuthi angangcola. Uma i-iron ingahlanjululwa njalo, ukungcola nokungcola kuzoqala ukunqwabelana, okuzogcina kuthinte ikhwalithi yamalunga akho e-solder.

Esinye isizathu sokuthi kufanele usebenzise insimbi yakho ye-soldering ukuthi ingathinta impilo yethuluzi. Ingabhidlika uma ungayihlanzi njalo futhi ungayithayitha insimbi yokunamathisela. Lokhu kuzonciphisa impilo ye-soldering iron futhi kungase kubangele ukuba iphuke.

Izindlela zokuhlanza

Inhlanganisela yesipontshi noboya bensimbi ihlanza ngokuphumelelayo ichopho lensimbi yokunamathisela. Ngaphezu kwalokho, ukusetshenziswa kwe-flux kanye nethuluzi elijikelezayo kungasiza ukubuyisela ukubukeka kokuqala okucwebezelayo.

isipontshi esimanzi

A isipontshi esimanzi lena indlela eshibhile nembi kakhulu. Ngaphambi nangemva kokusebenza nge-soldering iron, udinga ukuhamba izikhathi ezimbalwa ngesipontshi esimanzi.

Lokhu kuzosusa izingqimba ezimahhadla zokungcola, kodwa i-oxidation izohlala. Isipontshi esimanzi singasiza ekuqaleni, kodwa ngokuhamba kwesikhathi, lena akuyona inketho engcono kakhulu.

Isipontshi siyindlela enhle yamahhala.

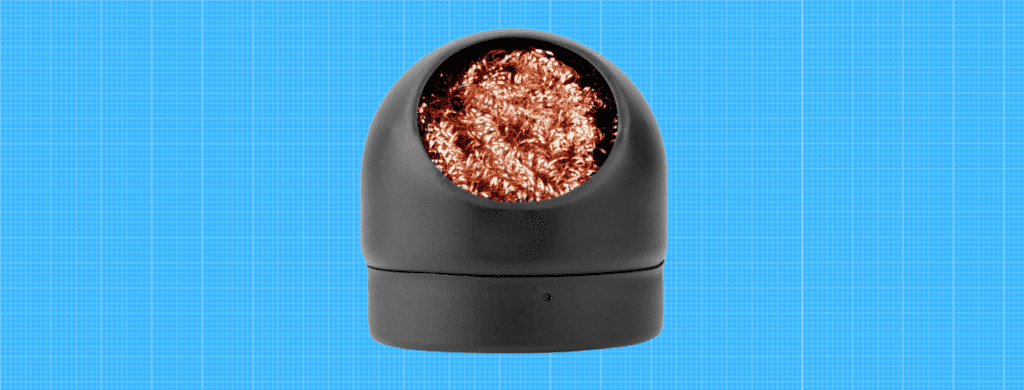

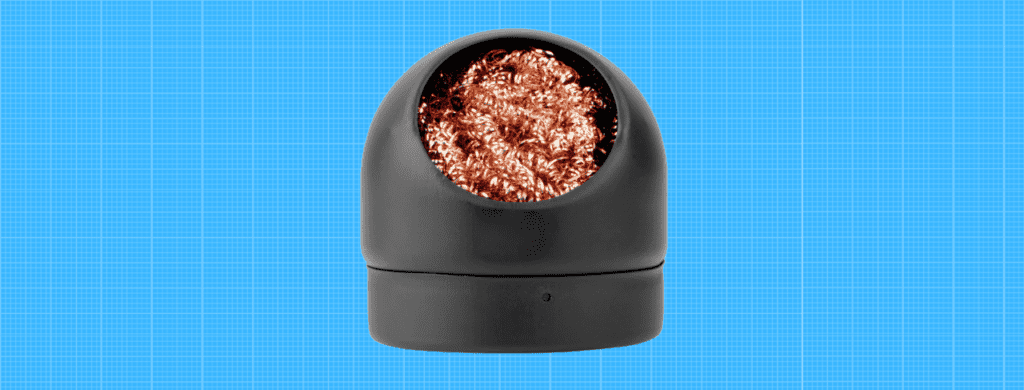

uboya bensimbi

uboya bensimbi Leli ithuluzi eliwusizo lokuhlanza ithiphu ye-soldering iron. Ukuze uhlanze ithiphu, vele uthathe ucezu lwensimbi bese uluhlikihla phezu kwethiphu kuze kube yilapho i-solder ingasekho.

Ngaphambi kokubeka i-iron soldering, qiniseka ukuthi ususa noma iyiphi imfucumfucu okungenzeka isele.

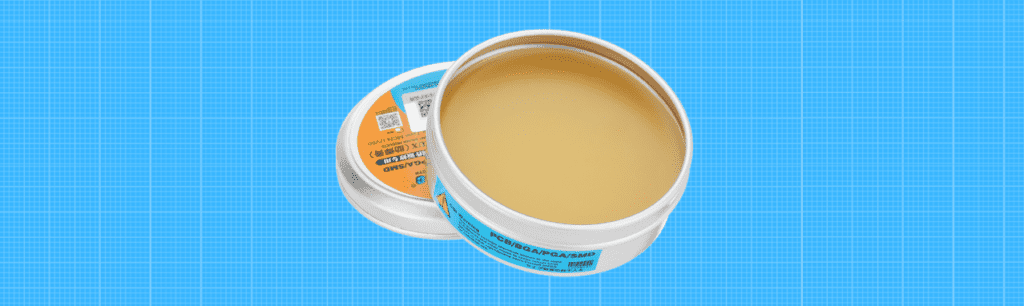

Ukugeleza

Ake sithathe ukugeleza noma thinta unamathisele bese ucwilisa insimbi eshisayo yokunamathisela kuzo. Lokhu kuzosusa kokubili ukungcola nenye ingxenye ene-oxidized. Le ndlela ifundiswa esikoleni.

Lokhu kuhle, kodwa futhi akwanele ukususa ingxenye egqwalile.

Ngoba kukhona izinsimbi ezincane ku-flux kanye nokunamathisela okuthintana okuzonamathela ku-ayini yakho ye-soldering futhi. Lapho i-soldering iron iphola, ingxenye ene-oxidized izovela futhi ngemva kwesikhashana.

Njalo sebenzisa i-tip flux yekhwalithi ephezulu.

ithuluzi elijikelezayo

Nakanjani indlela engcono kakhulu yokuthola i-doppelgänger yilapho usanda kuthenga i-soldering iron. Ingabe ukusebenzisa ithuluzi lokuhlanza elijikelezayo.

Nansi imfihlo. Sizoqala ngokususa ungqimba lokungcola kanye ne-oxidation ngezinye zalezi zandiso.

Ngaphambi kokuhlanza nokupholisha, i-soldering iron kufanele ipholile futhi yome ukuze isuse ngempumelelo zonke izinto ezingcolile kanye nezingxenye ze-oxidize.

Okokuqala, hamba ngokucophelela ingxenye ngayinye yethiphu yensimbi yokunamathisela. Ngokuvamile udinga iminithi noma amabili ukuze ususe imininingwane. Ungacindezeli, kodwa cindezela kancane phezulu eduze naphezulu.

Manje njengoba usususe ukungcola kanye nensimbi ene-oxidized enamathele ensimbi yakho yokuhlanganisa, sebenzisa elinye lala macebiso okupholisha. Lokhu kuzobuyisela insimbi yokunamathisela ekubukekeni kwayo kwasekuqaleni. Nweba ingxenye ngayinye ngokuningiliziwe. Ngeke udinge ngaphezu komzuzu womsebenzi.

Ithuluzi le-Rotary alibizi futhi lenza umsebenzi omuhle kangaka. Isincomo sami esithembekile: noma ngabe ungumuntu osaqalayo noma uthuthukile, bamba leli thuluzi ngoba lizokwenza umsebenzi wakho ube lula uma kufika isikhathi sokusevisa insimbi yakho yokuhlanganisa.

Isiqophi

Kule vidiyo, sizokukhombisa ukuthi ungayihlanza kanjani i-countertop futhi uyibuyisele ekubukekeni kwayo kwangaphambili okucwebezelayo.

Ungakuvimbela kanjani i-oxidation?

Ukwenza iseluleko sakho

ukubopha Isihloko se-soldering iron sisho ukumboza ngongqimba oluncane lwe-solder. Lokhu kuzosiza ukuthi i-solder igeleze ngokuphumelelayo futhi ivikele nethiphu kusuka ku-oxidation. Ukuze unamathisele ithiphu lensimbi ye-soldering, mane usebenzise inani elincane le-solder esihlokweni bese usula ngendwangu ehlanzekile.

I-solder izosiza ukugcina ithiphu ihlanzekile futhi izokwenza kube lula ukusebenzisa i-solder ekuhlanganyeleni. Qinisekisa ukuthi ufaka ithiphu lensimbi yokunamathisela ngaphambi kokusetshenziswa ngakunye.

Uma usuqedile ukusebenzisa i-soldering iron, qiniseka ukuthi uyayithina ithiphu futhi.

Ukugcina amathiphu ethini kuzoba namathiphu aphindwe kabili.

Amathiphu okugcina ithiphu lakho lensimbi yokunamathisela lisesimweni esihle

- Ukuhlanza njalo

Ukuhlanza njalo kuyindlela eyinhloko yokulondoloza insimbi yakho yokuhlanganisa. Ngemuva kokusebenza nge-soldering iron, thatha imizuzu embalwa ukuyihlanza.

- Amathiphu wokugcina

Ukugcina endaweni eyomile kuyadingeka. I-tip ye-soldering iron iyinsimbi, njenganoma iyiphi enye. Yingakho kufanele ibe sendaweni eyomile ukuze ingagqwali.

Uma i-soldering iron isendlini engaphansi noma ekamelweni elimanzi, yibeke ebhokisini ukuze uvimbele ukuthintana ngqo nomoya oswakeme. Ukumboza ngendwangu nakho kungasiza.

- Ikhwalithi ye-solder

Ikhoyili yekhwalithi kanye ne-flux izonciphisa ukugqwala kwe-soldering iron yakho. Ikhoyili eshibhile yenziwe ngezinto ezisezingeni eliphansi ezinamathela ku-soldering iron kunengxenye.

- Izinga lokushisa eliphezulu

Izinga lokushisa elilungile lensimbi yokunamathisela licishe libe ngu-600-650°F (316-343°C). Ake sithi izinga lokushisa lensimbi yokunamathisela liphansi kakhulu. Kulesi simo, i-solder ngeke igeleze kahle futhi uxhumano luzoba buthaka. Uma izinga lokushisa liphezulu kakhulu, i-solder ingancibilika ngaphambi kwesikhathi noma ilimaze izingxenye ezihlanganiswayo.

Ukugcina izinga lokushisa elilungile kuzosiza ukunweba impilo ithiphu lensimbi yakho yokuhlanganisa.

Kwenzekani uma ungayisevisi i-ayina yakho yokusoda?

Uma ungayinasi insimbi yakho yokusoda, ingase iyeke ukusebenza. Izinkinga ezinkulu ozobhekana nazo ukugqwala, ukugqwala kanye nokunqwabelana kokungcola nomsizi.

Izinzuzo zokunakekelwa okufanele kwe-iron soldering

Ukunakekelwa okufanele kwe-iron soldering yakho kunezinzuzo eziningana. Lokhu kubandakanya:

- Impilo yensimbi enwetshiwe

- I-soldering engcono

- Amathuba amancane okulimala kwensimbi ye-soldering noma izingxenye ezidayisiwe

Izinkinga ezivamile ezenzeka lapho i-soldering iron ingagcinwa kahle

Uma ungayigcini i-soldering iron yakho, kunezinkinga ezimbalwa ezivamile ezingase zenzeke. Lokhu kubandakanya:

- I-soldering iron ayishisi kahle

- I-Solder ngeke igeleze kahle

- I-solder joint izoba buthakathaka futhi ingaphuka kalula.

- I-soldering iron ingase iqale ukugqwala noma ukugqwala

- Ukungcola nokungcola kunganqwabelana esihlokweni se-soldering iron nezinye izingxenye zethuluzi. Lokhu kuzokwenza ukuthi i-soldering efanele ibe nzima futhi ingase ilimaze i-soldering iron.

Isikhathi sokushintsha ithiphu

Amathiphu ensimbi e-soldering agqwala ngokushesha futhi awakwazi ukuhlala unomphela. Ukuhlanza njalo kungandisa impilo yeshalofu. Kodwa uma ubona ukuthi izimbobo ezincane ziqala ukwakheka phezulu, sekuyisikhathi sokushintsha.

Izimbobo ezincane zakhiwa ngemva kokugqwala. Bafana nesifo sensimbi. Babhubhisa insimbi ezingeni elincane futhi ngaleyo ndlela badale izimbobo ezimise ngendlela engavamile. Ngemuva kwezinyanga ezimbalwa, uma uhlanza insimbi yokunamathisela, i-sting iqala ukugqwala futhi yenza izimbobo ngokwayo.

Khona-ke sekwephuze kakhulu ukuqala ukuhlanza, kodwa ungazama. Ukulimala ngokuhamba kwesikhathi kuzoholela ekudluliselweni kokushisa okuncane futhi okuncane, futhi insimbi ye-solder ngeke isebenziseke.

Kungakho kuhle ukuba namathiphu asele ethuluzi lakho lokunamathisela. Kubalulekile ukwazi ukuthi akuwona wonke ama-iron soldering anezeluleko ezengeziwe. Ngokuvamile ama-ayina ashibhile ashibhile awanawo amathiphu asele.

Izinsimbi ezisodayo ezilawulwa izinga lokushisa zibonise ukumelana kangcono nokugqokwa kune-ayina e-solder ngaphandle kokulawula izinga lokushisa.

isiphetho

Namuhla, wonke amathiphu enziwe ngensimbi. Insimbi iyinto ekwazi ukugqwala ngokushesha. Yingakho idinga ukunakekelwa njalo.

Ungavumeli insimbi yakho yokusoda ingcole ngemva komsebenzi. Uma kungenzeka, thola amathiphu ayisipele ukuze ungagcini usesimeni lapho udinga i-soldering iron engeke ilingane.

Futhi ungakhohlwa ukuthinta ithiphu uma usuqedile.