Amabhuleki pads. Odinga ukukwazi

Ezimotweni zanamuhla, kusetshenziswa izinhlobo ezimbili zemishini yamabhuleki - idiski nesigubhu. Kuzo zombili izimo, kusetshenziswe indlela yokushayisana ye-braking, lapho ukwehla kokujikeleza kwamasondo kwenzeka ngenxa yokusebenzisana kwamapheya okushayisana. Kumabhangqa anjalo, enye yezingxenye iyagudluka futhi izungeza nesondo, enye imile. Ingxenye enyakazayo yi-brake disc noma isigubhu. Isici esinqunyiwe yi-brake pad, okuzoxoxwa ngayo kulesi sihloko.

Ngesikhathi sokubhuleka, ukucindezelwa kwamanzi kwakhiwa ohlelweni lwe-hydraulic noma emoyeni ocindezelwe uma i-pneumatics isetshenziswa njengedrayivu. Ukucindezela kudluliselwa kumasilinda okusebenza (amasondo), futhi ama-pistons awo, aqhubekela phambili, asebenze kuma-brake pads. Lapho amaphedi ecindezelwa kudiski noma isigubhu esizungeza nesondo, kuphakama amandla okungqubuzana. Amaphedi kanye nediski (isigubhu) kuyashisa. Ngakho-ke, amandla e-kinetic okunyakaza kwemoto aguqulwa abe amandla ashisayo, ijubane lokujikeleza kwamasondo liyancipha futhi imoto iyancipha.

Колодки для тормозных механизмов дискового и отличаются формой. В дисковых тормозах они плоские, в барабанных выполнены в виде дуги. Форму определяет поверхность, с которой колодки контактируют — плоская боковая поверхность диска либо внутренняя цилиндрическая рабочая поверхность барабана. В остальном принципиальных отличий в их конструкции нет.

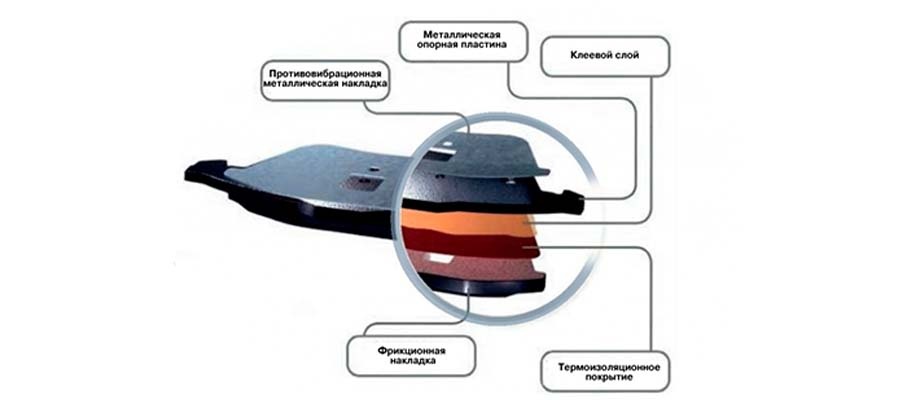

Isisekelo senziwa yi-metal bearing plate. Ngasohlangothini olungasebenzi, ine-primer edambisayo yokudambisa ukudlidliza nomsindo. Kweminye imiklamo, i-damper ingenziwa ngendlela yensimbi ekhishwayo.

I-friction lining ixhumana ngqo ne-disc noma isigubhu, esixhunywe esisekelweni nge-adhesive ekhethekile noma ngama-rivets. Kwenzeka ukuthi i-lining ingasuswa, kodwa ezimweni eziningi i-block ishintsha ngokuphelele.

I-lining iyingxenye ethakazelisa kakhulu ye-brake pad. Ukusebenza kahle kwe-Braking, kanye nempilo yesevisi kanye nentengo ye-pad ngokwayo, kuncike kakhulu kumingcele yayo kanye nokusebenza kwayo.

Между фрикционным слоем и опорной пластиной имеется термоизоляционная прослойка. Она предохраняет от чрезмерного нагрева, а от закипания.

Imvamisa, ama-chamfers kanye nesethi eyodwa noma isethi ye-slots yenziwa ohlangothini olusebenzayo lwephedi. Ama-chamfer anciphisa ukudlidliza nomsindo, kanti izindawo zokukhala zisebenza ukususa uthuli, futhi zithuthukisa nokunqamuka kokushisa.

I-lapping coating ivame ukusetshenziswa phezu kwesendlalelo sokungqubuzana ukuze kulungiswe ngokushesha ukungahambi kahle kwediski.

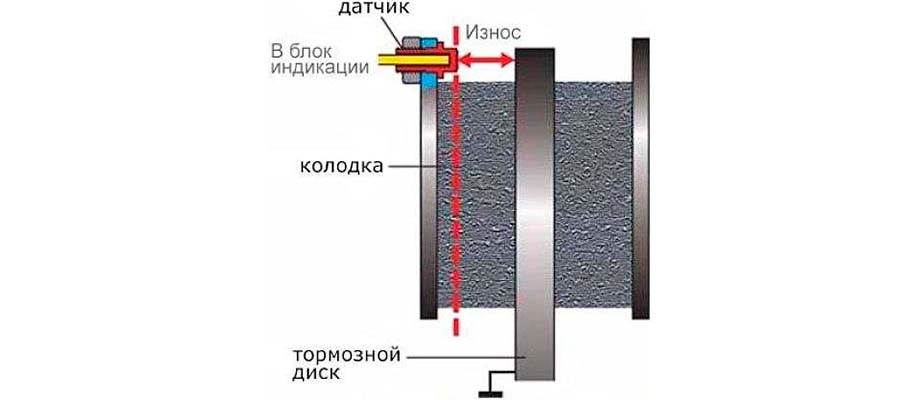

Ukuze usize umshayeli aqonde ukuthi i-block ifinyelele izinga elibucayi lokugqoka, abakhiqizi abaningi banikeza idivayisi yokubonisa imishini, okuyipuleti lensimbi eligxilwe ekugcineni. Lapho ungqimba lwe-friction lugugile kakhulu, unqenqema lwepuleti luzoqala ukuthinta i-brake disc futhi lukhiphe i-squeal ephezulu yesici.

Muva nje, ukulawula izinga lokuguga kwamaphedi, kusetshenziswa izinzwa zikagesi, uma kubasiwe, ukukhanya okuhambisanayo kudeshibhodi kuyakhanyisa. Zingaba ngaphandle noma eyakhelwe ngaphakathi. Esimweni sesibili, ukuze ushintshe, udinga ukuthenga amaphedi anezinzwa ezihlanganisiwe.

Isidingo esiyinhloko sama-linings ukunikeza ukusebenza okwanele kokubhuleka kuzo zonke izimo zomgwaqo, kuhlanganise nodaka kanye nomswakama ophezulu. Umswakama oveza inkinga enkulu ekusebenzeni okujwayelekile kwepheya yamabhuleki, udlala indima yokuthambisa kanye nokunciphisa i-coefficient of friction.

Ama-pads kumele agcine izakhiwo zawo zokusebenza eqhweni elinzima, amelane nokushintsha kwezinga lokushisa okungazelelwe kanye nokushisa okubalulekile, okuthi ngesikhathi sokungqubuzana kungafinyelela ku-200 ... 300 ° C nangaphezulu.

Izici zomsindo nazo zibaluleke kakhulu. Cishe eminyakeni eyikhulu edlule, lapho kusungulwa ama-disc brakes, ama-pads ayengenawo ama-pads futhi ukungqubuzana kwensimbi ensimbi phakathi nokubhuleka kwakuhambisana nokuhlengezela okubi kakhulu. Emabhulekini esimanje, le nkinga ayikho, nakuba amaphedi amasha angase answininize isikhashana aze agqoke.

Enye imfuneko ebalulekile yamaphedi isimo sengqondo esimnene ku-brake disc (isigubhu). I-friction pad ethambile kakhulu izonciphisa amandla okubhuleka adalwe ukungqubuzana, futhi inhlanganisela ye-friction eqinile "izodla" ngokushesha i-disc, ebiza kakhulu kunamaphedi.

Ukwengeza, i-fiction coating eqinile kakhulu ingase ivimbe ngokuphelele ukujikeleza kwamasondo ngaphambi kwesikhathi, lapho imoto ingakanciphisi ngokwanele. Kulesi simo, imoto ingahamba ishushuluze futhi ingalawuleki.

I-Friction linings yezimoto, njengomthetho, ine-coefficient ye-friction ebangeni lika-0,35 ... 0,5. Leli inani eliphelele elivumela ukubhuleka okufanele emigwaqweni yedolobha nasemigwaqweni yasemaphandleni futhi ngesikhathi esifanayo kusiza ukulondoloza insiza ye-brake disc. Kukhona amaphedi ane-coefficient ephakeme yokungqubuzana, kodwa ahloselwe kakhulu izimoto zezemidlalo ezidinga ukwehlisa ijubane njalo futhi ngokucijile kakhulu.

Ezikhathini zasendulo, i-asbestos yayisetshenziswa kakhulu ekukhiqizeni izintambo zokushayisana. Kodwa-ke, kwavela ukuthi uthuli lwe-asbestos lunezici ze-carcinogenic, ngakho-ke le nto yavinjelwa ngokuphelele e-European Union ngo-2005. Amanye amazwe alandela isibonelo sawo kancane kancane. Ngenxa yalesi sizathu, ama-brake pads aqukethe i-asbestos aya ngokuya engavamile futhi, yiqiniso, ukufakwa kwemikhiqizo enjalo kufanele kugwenywe.

I-asbestos yathathelwa indawo yizingxube eziqukethe ngezinye izikhathi izingxenye eziyi-15-20. Abakhiqizi abakhulu ngokwabo bathuthukisa izinto zokungqubuzana, belwela ukufeza izakhiwo ezingcono kakhulu zokusebenza.

Kuze kube manje, kunezinhlobo ezintathu eziyinhloko ze-lining yama-brake pads - eziphilayo, eziqukethe insimbi kanye ne-ceramic.

Ama-Organic ngokuvamile ayenziwa ngesisekelo se-graphite ngokufaka ama-binders kanye nezingxenye ezithuthukisa ukungqubuzana - ama-polymers, i-fiberglass, ithusi noma i-bronze shavings, nezinye izinto. Njengoba ukwakheka kuqukethe inani elincane lensimbi (kufika ku-30%), le nto ibizwa nangokuthi i-low-metal (i-low-metallic).

Amaphedi alolu hlobo asetshenziswa kabanzi ku-aftermarket yezimoto, abekezelela kahle isithwathwa futhi anenani elikhangayo. Ngakolunye uhlangothi, ama-rubber e-organic athambile, awanakho ukumelana nokugqoka okuphezulu futhi awalungile kakhulu ngaphansi kokucindezeleka okukhulu.

Ukufakwa kwenani elibalulekile lethusi, insimbi noma ezinye izinsimbi ekwakhiweni kwezinto zokungqubuzana kuthuthukisa ukudluliswa kokushisa, ngakho-ke lawa maphedi angakwazi ukumelana nokushisa okuphawulekayo kahle, isibonelo, esimweni sokushayela okunolaka. Izindwangu ezinensimbi azikho ngaphansi kokuguga kwazo, kodwa isethi isula i-brake disc kakhulu futhi inomsindo omncane. Abaningi babheka le nketho njengelungele ukusetshenziswa ezimotweni eziningi zabagibeli.

Izindwangu ezenziwe nge-ceramic zimelana kakhulu nokugqokwa futhi zisebenza kahle ngaphansi kokushisisa okuqinile, ngakho-ke ukusetshenziswa kwazo kufanelekile ezimotweni zomjaho, lapho ukubhuleka kungazelelwe kungabangela ukushisa kufikela ku-900-1000 °C. Kodwa-ke, azikulungele ukushayela okuvamile ukuzungeza idolobha noma uhambo lwezwe, njengoba zidinga ukushisa ngaphambi kokufika ku-200 ° C. Futhi i-ceramics engashiswanga ngeke ikwazi ukukhombisa izimfanelo zabo ezinhle kakhulu, kodwa ingasheshisa ukugqoka kwe-brake disc. Ngaphezu kwalokho, izindleko zamaphedi e-ceramic ziphezulu kakhulu.

Uma ibanga lokubhuleka liye landa, ukukhala kwenkomba yokugqoka kuzwakala, isilinda se-brake esisebenzayo sigxiliwe, i-caliper inamathele, sekuyisikhathi sokushintsha ama-pads. Kodwa-ke, kungcono ukuqapha ngezikhathi ezithile isimo sezinqubo zokubopha nama-pads, ngaphandle kokulinda izimpawu ezinjalo. Ungakwazi ukulinganisa izinga lokuguga kwamaphedi ngokubuka ngefasitela ku-caliper. Uma i-1,5 ... 2 mm ishiywe ungqimba lwe-friction, ama-pads adinga ukushintshwa. Futhi-ke, awukwazi ukuletha udaba ekusuleni okuphelele kwe-lining, ngoba kulokhu isisekelo sensimbi se-pad sizobhubhisa ngokushesha i-brake disc.

ukushintshwa, kufanele ucabangele uhlobo lwemoto, ubukhulu bayo, amandla enjini, izimo zokusebenza, isitayela sokushayela.

Khetha amaphedi alingana ncamashi namaphedi owashintshayo. Lokhu kuzosheshisa futhi kuthuthukise ukugaya kwabo, ikakhulukazi uma i-disc (isigubhu) inamaqhubu (amahlombe).

Ngokuhambisana okuphezulu, kuyancomeka ukuthi amaphedi namadiski avela kumkhiqizi ofanayo.

Qiniseka ukuthi ushintsha wonke amaphedi kuwo womabili amasondo e-ekseli efanayo. Uma kungenjalo, ukuziphatha komshini ngesikhathi sokubhuleka kungase kungabonakali.

Izingxenye ezithengiswayo zingahlukaniswa ngezigaba ezintathu:

- 1. Okwangempela, okungukuthi, lawo afakwe emishinini eshiya umugqa womhlangano. Zingaba ezibizayo, kodwa ngakolunye uhlangothi, uqinisekisiwe ukuthola ingxenye ikhwalithi yayo engalawulwa kuphela ngumkhiqizi oqondile, kodwa futhi ngumenzi we-automaker ngaphansi komkhiqizo wakhe okhiqizwayo. Ngakho, ungaqiniseka ukuthi into ihambisana ngokugcwele nezici ezimenyezelwe.

2. Ama-analogue (okubizwa ngokuthi i-aftermarket) izingxenye ezikhiqizwa inkampani efanayo nezangempela, kodwa ezithengiswa ngaphansi kohlobo lwazo. Bangase babe nokuchezuka okuthile kumapharamitha amenyezelwe. Ngo-1999, Ikhomishana Yezomnotho YaseYurophu yadinga abakhiqizi bezingxenye zesistimu yamabhuleki okungezona ezangempela ukuthi bahlangabezane nezidingo ze-automaker okungenani ngama-85%. Uma kungenjalo, imikhiqizo ayivunyelwe emakethe yaseYurophu. Lokhu kuvumelana kukhonjiswe ngokumakwa kwe-ECE R90.

Ngokwentengo, ama-analogue angasondela ezingxenyeni zangempela, kodwa ngokuvamile ashibhile ngo-20 ... 30%.

I-coefficient of friction yamaphedi e-analog ingaphansi kunawasekuqaleni, futhi ngokuvamile i-0,25 ... 0,4. Lokhu kuzothinta ijubane lamabhuleki kanye nobude bebanga lokubhuleka.

3. Imikhiqizo ehloselwe amazwe asathuthuka. Kulesi sigaba, ungathola amaphedi angabizi, kepha ikhwalithi yawo inenhlanhla njenganoma ngubani. Amaphedi ashibhile mancane amathuba okuthi ahlale isikhathi eside, kodwa angonakalisa i-brake disc. Ngakho-ke ukonga okunjalo kungabaza kakhulu, ikakhulukazi uma ukhumbula ukuthi sikhuluma ngokuvikeleka.

Kungcono ukuphendukela, kulokhu ngeke uwele inkohliso, okukhona okuningi, kodwa isakazwa ngokuyinhloko ezimakethe nasezitolo ezincane.