Ithebula lobukhulu bokupenda kwezimoto ezisuka efektri nangemuva kokulungiswa

Okuqukethwe

Ukuphakama kwesendlalelo kukalwa ngamaphuzu angu-4-5 phakathi nendawo kanye nasemiphethweni yendawo efundwayo. Ngokuvamile umehluko phakathi kwezingxenye eziseduze akufanele udlule ama-microns angu-30-40. I-LPC ikalwa endaweni engaphezulu ye-aluminium enegeji yokujiya elinganiselwe le nsimbi. Ukuze unqume ukuphakama kwesendlalelo sikapende epulasitiki, awukwazi ukusebenzisa idivayisi kazibuthe. Ukuze wenze lokhu, sebenzisa umshini wokulinganisa we-ultrasonic noma uhlole ukuchezuka kombala.

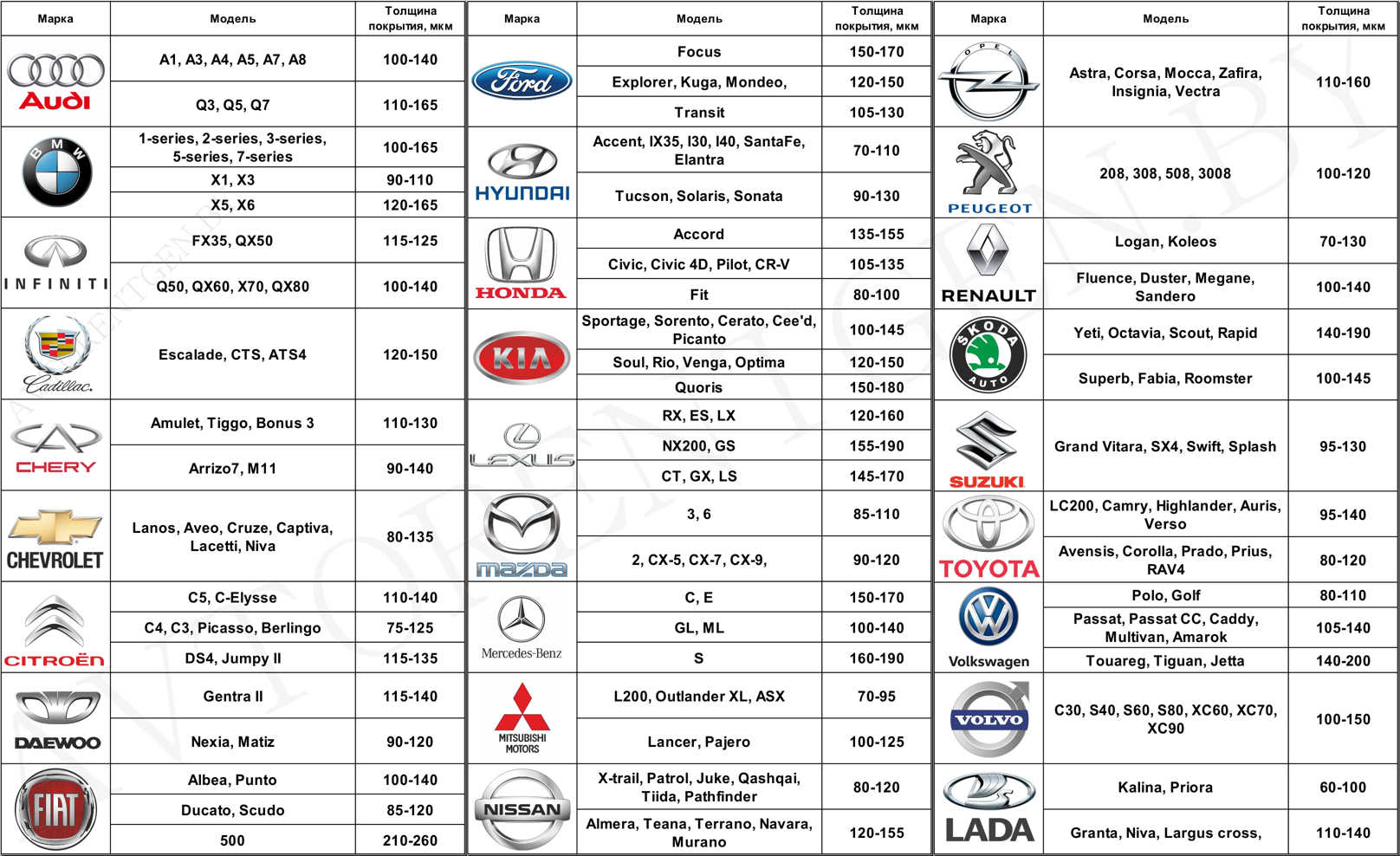

Isimo esihle sikapende emotweni endala ngokwemvelo sivusa izinsolo. Hlola ukushuba komsebenzi wokupenda ezimotweni ngokwetafula ukuze uthole imodeli ethile. Ukuchezuka kumanani ajwayelekile cishe kuhlobene nokulungiswa komzimba okwenziwe.

Ukunqunywa kobukhulu bepende yemoto

Ngokuvamile, lapho uthenga imoto esetshenzisiwe, ngaphezu kokuhlolwa kwangaphandle, bahlola umsebenzi wokupenda. Ukumbozwa okuphezulu kakhulu kungase kubonise ukulungiswa komzimba. Zingaki izingqimba zopende ezisetshenziswayo zincike kumodeli wemoto kanye nohlobo lomsebenzi wokupenda.

Izindlela zokunquma ukuphakama kwe-coating emzimbeni wemoto:

- Uzibuthe ohlala njalo ovame ukukhangwa kuphela endaweni yensimbi enongqimba oluncane lwe-koqweqwe lwawo kanye ne-varnish.

- Ukwembula ngokukhanya okuhle umehluko emithunzini yongqimba kapende wezigaba eziseduze emzimbeni wemoto.

- Igeji yokuqina kagesi esiza ukukala umsebenzi wokupenda wemoto ngokunemba okuphezulu.

Amadivayisi okunquma inani elifanele lopende ebusweni bomzimba nawo angama-mechanical, ultrasonic kanye ne-laser. Qhathanisa ubukhulu bomdwebo wezimoto ngokuya ngethebula lamanani ajwayelekile emodeli ethile.

Yiziphi izinto okufanele uzihlole kuqala

Ezingxenyeni ezihlukene zomzimba wemoto, ukuphakama kwesendlalelo sikapende kuhluke kancane. Lapho ukala, kuyadingeka ukuqhathanisa umphumela otholiwe nojwayelekile ovela etafuleni.

Ukuhlolwa komsebenzi wokupenda emzimbeni wemoto

Izingxenye zomzimba zomshini ziyehluka ngomklamo kanye nobukhulu bomhlaba. Uma kwenzeka ingozi, umonakalo uyingxenye engaphambili yemoto.

Ukulandelana kwezingxenye okunqunywa ukushuba komsebenzi wokupenda:

- uphahla;

- ama-racks;

- isigqoko;

- isiqu;

- iminyango;

- imibundu;

- ama-side pads;

- izindawo ezipendiwe zangaphakathi.

Ukuphakama kwesendlalelo kukalwa ngamaphuzu angu-4-5 phakathi nendawo kanye nasemiphethweni yendawo efundwayo. Ngokuvamile umehluko phakathi kwezingxenye eziseduze akufanele udlule ama-microns angu-30-40. I-LPC ikalwa endaweni engaphezulu ye-aluminium enegeji yokujiya elinganiselwe le nsimbi.

Ukuze unqume ukuphakama kwesendlalelo sikapende epulasitiki, awukwazi ukusebenzisa idivayisi kazibuthe. Ukuze wenze lokhu, sebenzisa umshini wokulinganisa we-ultrasonic noma uhlole ukuchezuka kombala.

Ithebula lokujiya ngopende

Abakhiqizi bezimoto bapenda umzimba nge-primer, i-koqweqwe lwawo kanye ne-varnish enezakhiwo ezahlukene. Isendlalelo esijwayelekile singahluka ngobude, kodwa amanani amaningi awela ebangeni lama-micron angama-80-170. Amatafula okuqina omdwebo wezimoto zezingxenye ezahlukene zomzimba aboniswa abakhiqizi ngokwabo.

Inani elingaphezu kwama-microns angu-200 ngokuvamile libonisa ukupendwa kabusha, kanye nama-microns angaphezu kuka-300 - okungenzeka kube yi-putty yomzimba wemoto ephukile. Kuhle ukwazi ukuthi amamodeli ezimoto zeprimiyamu anobukhulu bepende obufika ku-250 microns.

Ukupenda kwemoto uma kuqhathaniswa

Isendlalelo esincane sokumboza cishe singalimala futhi singandiza ngisho nalapho sigeza ngaphansi kwengcindezi. Amandla okuvikelwa kwezindawo zensimbi zomzimba nawo athinteka yizici zezinto. Kodwa inkomba enqumayo yekhwalithi yomdwebo wemoto ubukhulu bengubo.

Ngokuvamile, ukuze wonge imali, umenzi unciphisa ukuphakama kwesicelo ezingxenyeni zezimoto ezingavezwanga emiphumeleni eyingozi. Upende ophahleni, indawo yangaphakathi kanye ne-trunk ngokuvamile kuba mncane. Ezimotweni ezifuywayo nezaseJapan, ubukhulu bokupenda ngama-microns angama-60-120, futhi kumabhrendi amaningi aseYurophu naseMelika angama-microns ayi-100-180.

Imaphi amanani akhombisa izendlalelo ezengeziwe

Ukulungiswa komzimba wendawo ngokuvamile kwenziwa ngaphandle kokususa ngokuphelele upende. Ngakho-ke, ukuphakama kwe-coating entsha kukhulu kunokuqala okufakwe ku-conveyor. Ubukhulu bengqimba yoqweqwe lwe-koqweqwe lwawo kanye ne-putty ngemva kokulungiswa ngokuvamile buphakeme kuno-0,2-0,3 mm. Futhi efektri, ungqimba lukapende lusetshenziswa ngokulinganayo; umehluko wokuphakama ongama-microns angaba ngu-20-40 uthathwa njengowamukelekile. Ngokulungiswa komzimba okusezingeni eliphezulu, upende ungase ulingane nowokuqala. Kodwa umehluko ekuphakameni kwe-coating kufinyelela ku-40-50% noma ngaphezulu.

Yini ekhombisa ukungenelela

Imoto ephukile ngemva kokubuyiselwa komzimba ingase ibukeke njengentsha. Kodwa ukuhlola ngozibuthe noma idivayisi yokulinganisa kufanele kuveze kalula iminonjana yokuphazamisa.

Izimpawu zokulungisa nokupenda kabusha umzimba:

- umehluko phakathi kobukhulu bokupenda kwezimoto kusuka etafuleni lamanani ajwayelekile ngama-microns angu-50-150;

- ukuhluka kokuphakama kwe-coating engxenyeni eyodwa engaphezu kwama-micrometer angu-40;

- umehluko wendawo emthunzini wombala ebusweni bomzimba;

- ama-fasteners apendiwe;

- uthuli kanye nokufakwa okuncane kungqimba lwe-varnish.

Lapho ukala, kuyadingeka futhi ukucabangela ububanzi bokuchezuka etafuleni ukuze uthole imodeli ethile.

Isizathu somdwebo omncane wezimoto zesimanje

Iningi labakhiqizi bezimoto bazama ukonga kukho konke ukuze behlise intengo futhi banqobe umncintiswano. Ukunciphisa ukuphakama komsebenzi wokupenda ezingxenyeni zomzimba ezingabalulekile kungenye yezindlela zokunciphisa izindleko. Ngakho-ke, uma ungqimba wokupenda wefektri ku-hood kanye neminyango ngokuvamile i-80-160 microns, khona-ke ezindaweni zangaphakathi kanye nophahla - ama-microns angu-40-100 kuphela. Ngokuvamile, umehluko onjalo ekugqineni kokugqoka utholakala ezimotweni zasekhaya, zaseJapane naseKorea.

Umgomo wokusebenza kwegeji yokujiya

Lesi silinganiso sifanelekile, ngoba izindawo zangaphakathi nezingaphezulu zomzimba azithintani kancane nothuli lomgwaqo kanye nama-reagents kunalawo aphansi. Izinga elincane lopende lisetshenziswa kusetshenziswa izinto eziqinile ezisezingeni eliphakeme. Ukwakhiwa okuthuthukisiwe koqweqwe lwawo ngobuningi be-pigment ephezulu kuvumela ukunciphisa inani lezendlalelo zokudweba.

Esinye isizathu sokudweba umzimba wemoto emincane yizidingo zemvelo okumele abenzi bezimoto bahambisane nazo.