I-soldering iron ithatha isikhathi esingakanani ukushisa? Imiphumela yokulinganisa

Okuqukethwe

- I-soldering iron ithatha isikhathi esingakanani ukushisa?

- Amandla kuma-ayina e-soldering nokuthi kusithinta kanjani isikhathi sokushisa

- Kuthatha isikhathi esingakanani ukuthi i-soldering iron iphole?

- Wazi kanjani ukuthi i-soldering iron ishisa ngokwanele?

- Kungani i-ayini yami yokunamathisela ingashisi ngokwanele?

- Kuthatha isikhathi esingakanani ukuthi insimbi yokufaka engu-60W ishise?

- Kungani kubalulekile ukuba nensimbi yokushisisa esheshayo?

- I-soldering iron isebenza kanjani?

- isiphetho

Uma kuziwa ekufakweni kwe-soldering, enye yezinto ezibaluleke kakhulu ukuqinisekisa ukuthi i-soldering iron yakho isezingeni lokushisa elifanele ngaphambi kokuba uqale.

Uma ithiphu lingashisi ngokwanele, i-solder ngeke igeleze kahle futhi uzogcina une-solder embi kakhulu.

So i-soldering iron ithatha isikhathi esingakanani ukushisa? Sihlole izinhlobo ezahlukene zama-ayina e-solder, ake sibheke imiphumela.

I-soldering iron ithatha isikhathi esingakanani ukushisa?

Uma kuziwa ekutheni i-soldering iron ithatha isikhathi esingakanani ukushisa, ayikho impendulo eqondile. Kuya ngohlobo kanye nemodeli yensimbi, kanye nokuthi kushisa kangakanani.

Nokho, izinsimbi eziningi Imizuzwana engama-30 ukuya kumzuzu ukuwashisa. Uma ujahile, nanka amathiphu ambalwa ukusiza ukusheshisa inqubo.

Asibone Imiphumela ohlotsheni ngalunye lwe-soldering iron.

| Thayipha | Isikhathi | Temperature |

| Izinsimbi ezilula zikagesi | Imizuzwana engu-37,7 | I-300 ° C (572 ° F) |

| Soldering Station | Imizuzwana engu-20,4 | I-300 ° C (572 ° F) |

| I-Soldering iron | Imizuzwana engu-24,1 | I-300 ° C (572 ° F) |

| Insimbi yokufaka igesi | Imizuzwana engu-15,6 | I-300 ° C (572 ° F) |

| I-wireless soldering iron | Imizuzwana engu-73,8 | I-300 ° C (572 ° F) |

Izinsimbi ezilula zikagesi

Sithole umphumela wamasekhondi angu-45 wokufudumala kufika kuma-degree angu-300. Le nsimbi yokunamathisela inamandla angama-60W.

Siwutholile umphumela 37,7 amasekhondi okufudumala kuwo I-300 ° C (572 ° F). Le nsimbi yokunamathisela inamandla angama-60W.

I-soldering iron elula iqukethe ithiphu ye-alloy yensimbi, umqhubi wethusi, kanye nesici sokushisa. Isici sokushisisa sinikwa amandla ugesi oshisisa i-conductor bese kuba yithiphu ye-alloy.

Soldering Station

Isiteshi se-soldering sibonakale singcono kakhulu kunensimbi evamile yokunamathisela ngenxa yama-heaters asezingeni eliphezulu namandla amaningi.

Okudingayo nje isiteshi sokushisa Imizuzwana engu-20,4 ukufika ku-300°C (572°F). Okushesha ngokuphindwe kabili kunensimbi evamile yokuhlanganisa.

Lo mphumela ufinyelelwa ngenxa yezifudumezi ze-ceramic zekhwalithi ephezulu ezihlinzeka ngokugeleza kokushisa okusheshayo okunjalo.

I-Soldering iron

I-soldering iron ishisa ngokushesha kakhulu kune-solder iron iron. Wafinyelela izinga lokushisa 300°C (572°F) kumasekhondi angu-24,1 nje.

Isizathu esiyinhloko sokushisa ngokushesha kangaka yingoba bane-transformer eyehlayo eyehlisa i-voltage futhi ithumele inqwaba yamanje.

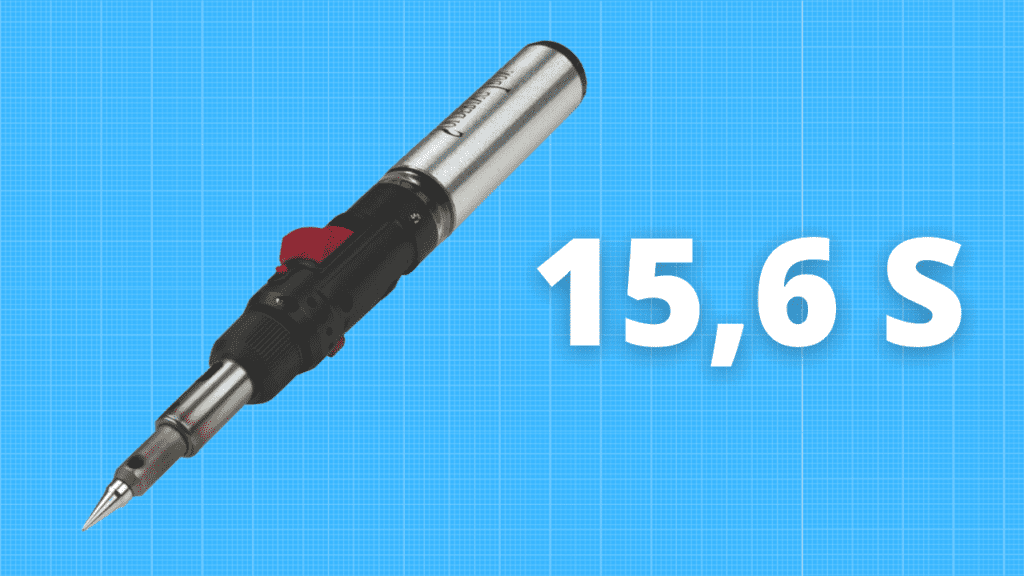

Insimbi yokufaka igesi

Ngaphandle kwenkinga enkulu, i-gas soldering iron yiyona eyawina ukuhlolwa kwethu. Izinga lokushisa lokusebenza lifinyelelwe I-300 ° C (572 ° F) ngemizuzwana engama-15,6 kuphela, okuyiyona eshesha kunazo zonke ezinye izinhlobo.

I-gas soldering iron isebenzisa ithangi elincane le-propane noma i-butane ukushisa ithiphu. La magesi avuthayo ashisisa ichopho lensimbi ewuketshezi ngokushesha okukhulu.

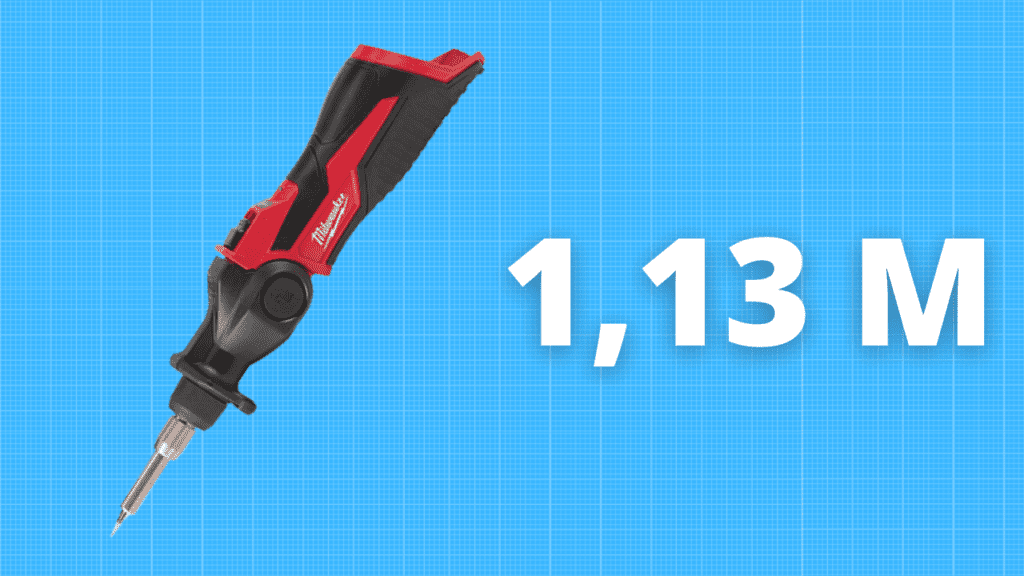

I-wireless soldering iron

Izinsimbi ezingenazintambo ezisodayo zigcina phakathi kwama-ayina asodayo athatha isikhathi eside kakhulu ukufudumala. Kuthathe 73,8 imizuzwana yokushisa ithiphu ukuya ku-300°C (572°F).

Lokhu kuvamile kulolu hlobo lwe-soldering iron, inzuzo yabo eyinhloko ingenantambo.

Amandla kuma-ayina e-soldering nokuthi kusithinta kanjani isikhathi sokushisa

Izinsimbi zokugoqa ziza ngamakhono ahlukene. I-wattage ye-soldering iron inquma ukuthi ishisa ngokushesha kangakanani nokuthi ikhipha ukushisa okungakanani.

A i-soldering iron enamandla amaningi ishisa ngokushesha futhi ikhiqize ukushisa okungaphezulu kunensimbi efakwe emanzini e-soldering ephansi.

Kodwa-ke, insimbi enamandla kakhulu ye-soldering ayidingeki ngaso sonke isikhathi. Uma usebenza kuphrojekthi encane, insimbi yokudambisa amandla aphansi kuya naphakathi iyokwanela.

Uma usebenza kuphrojekthi enkulu noma udinga ukudayisa izintambo ezisindayo, uzodinga insimbi enamandla amakhulu.

Ama-ayina e-soldering atholakala ngamawathi ahlukahlukene ukusuka ku-20W kuye ku-100W. Insimbi yokudambisa ejwayelekile inesilinganiso samandla esingu-40W ukuya ku-65W.

Kuthatha isikhathi esingakanani ukuthi i-soldering iron iphole?

Ukupholisa phansi i-soldering iron kungathatha noma yikuphi ukusuka emaminithini ambalwa ukuya ehoreni, kuye ngosayizi namandla ensimbi yokunamathisela. Kuma-ayina amancane, kungathatha imizuzu emihlanu nje ukuthi ukushisa kuphele.

Nokho, ama-ayini amakhulu angathatha ihora ukuze aphole ngokuphelele. Kubalulekile ukuvumela i-ayina e-soldering ukuthi iphole ngokuphelele ngaphambi kokuyigcina, njengoba ukugcina insimbi eshisayo kungayilimaza.

Wazi kanjani ukuthi i-soldering iron ishisa ngokwanele?

Uma usebenzisa i-soldering iron, kubalulekile ukuqinisekisa ukuthi ishisa ngokwanele ukuze umsebenzi wenziwe kahle. Uma insimbi ingashisi ngokwanele, i-solder ngeke inamathele ensimbi futhi ngeke ukwazi ukuqedela iphrojekthi.

Kunezindlela eziningana zokuhlola ukuthi insimbi ishisa ngokwanele yini. Enye indlela ukusebenzisa i-solder engenamthofu. I-solder kufanele iqale ukuncibilika ngokushesha nje lapho ithinta insimbi.

Uma i-solder ingancibiliki, insimbi ayishisi ngokwanele futhi udinga ukukhulisa izinga lokushisa.

Enye indlela yokuhlola ukushisa ngesipontshi. Uma umanzisa isipontshi futhi usithinta ensimbi bese kuphuma isitimu, insimbi kufanele ishise ngokwanele ukuyisebenzisa.

Futhi, uma une-multimeter ekwazi ukushisa, ungabona ukuthi ithiphu ishisa ngokwanele yini.

Kungani i-ayini yami yokunamathisela ingashisi ngokwanele?

Kungaba nezizathu eziningana zokuthi kungani i-soldering iron yakho ingashisi ngokwanele.

Uma i-soldering iron isindala, isici sokushisa singase siguge futhi sidinga ukushintshwa.

Uma i-ayina e-soldering ingalinganiswa kahle, ingase ingafinyeleli izinga lokushisa elifanele. Qinisekisa ukuthi usebenzisa uhlobo olulungile lwe-solder kuphrojekthi osebenza kuyo nokuthi ithiphu lensimbi yokunamathisela lihlanzekile futhi alifakwanga i-oxidized.

Okokugcina, uma usebenzisa i-soldering iron kagesi, qiniseka ukuthi ixhunyiwe futhi inamandla.

Uma ungaqiniseki ngesimo se-soldering iron yakho, kutuswa ukuthi ubuyisele ithiphu lensimbi yokunamathisela.

Kuthatha isikhathi esingakanani ukuthi insimbi yokufaka engu-60W ishise?

Kuye ngokuthi iyiphi imodeli oyisebenzisayo, ikhwalithi ye-heater, ubukhulu bethiphu, njll. isikhathi esimaphakathi imizuzwana engama-30.

Kungani kubalulekile ukuba nensimbi yokushisisa esheshayo?

Amathuluzi e-soldering ayingxenye ebalulekile yokuphila kwabantu abaningi njengoba asetshenziselwa yonke into kusukela ekulungiseni ugesi kuya ekudaleni ubuciko.

Kodwa-ke, esinye sezici ezibaluleke kakhulu zethuluzi le-soldering izinga lokushisa kwalo.

Ithuluzi lokushisa elisheshayo lisho ukuthi ungaqala ngokushesha ngaphandle kokulinda ithuluzi ukuthi lishise. Lokhu kubalulekile ngoba uma uqala ukusebenza kuphrojekthi yakho ngokushesha, ungashesha ukuyiqeda. Namuhla sonke sibambekile esikhathini.

Futhi, ithuluzi elishisisa ngokushesha lisho ukuthi uchitha isikhathi esincane ulinde ithuluzi ukuthi liphole ngaphambi kokuthi ulibeke. Lokhu kubaluleke kakhulu uma usebenza kuphrojekthi edinga izikhathi eziningi zokuhlanganisa.

I-soldering iron isebenza kanjani?

I-soldering iron iyithuluzi lesandla elisebenzisa ukushisa ukuze lihlanganise izingcezu ezimbili zensimbi.

Isihloko se-soldering iron siyashisisa bese sisetshenziselwa ukuncibilikisa i-solder, okuwuhlobo lwensimbi olunephuzu eliphansi lokuncibilika. Khona-ke i-solder encibilikisiwe isetshenziswa endaweni ephakathi kwezingcezu ezimbili zensimbi, ezincibilika futhi zizihlanganise ndawonye.

isiphetho

Incazelo yegolide yokufudumala i-soldering iron isuka kumasekhondi angu-20 kuya kwangu-60.

Ama-ayina e-soldering afika ngamakhono ahlukene, futhi ngayinye inesikhathi sokushisa esihlukile. I-ayoni enamandla amaningi ishisa ngokushesha kunensimbi enamandla amancane.

Indlela engcono kakhulu ukuhlola insimbi yakho yokuhlanganisa ukuze uthole ukuthi kuthatha isikhathi esingakanani ukuthi ithiphu lishise.