Sishintsha ngokuzimela isigubhu se-brake ku-VAZ 2107

Okuqukethwe

Akekho odinga ukuchaza ukuthi abaluleke kangakanani amabhuleki athembekile emotweni. Lokhu kusebenza kuzo zonke izimoto, futhi i-VAZ 2107 ayifani. Amabhuleki ezigubhu ayehlale efakwe emasondweni angemuva "ayisikhombisa". Yilolu hlelo lwesigubhu, ngenxa yokuklama kwayo okungaphumeleli kakhulu, okunikeza abanikazi bezinkinga "eziyisikhombisa" eziningi. Ngenhlanhla, kungenzeka kakhulu ukushintsha amabhuleki anjalo ngokwakho. Ake sibone ukuthi kwenziwa kanjani.

Anjani amabhuleki angemuva ku-VAZ 2107

Amabhuleki angemuva "ayisikhombisa" aqukethe izakhi ezimbili ezibalulekile: isigubhu sebhuleki kanye nomshini wokubhuleka otholakala kulesi sigubhu. Ake sicabangele isici ngasinye ngokuningiliziwe.

Isigubhu sebhuleki

Uma ushayela, izigubhu zamabhuleki ezixhunywe emasondweni angemuva zizungeza nazo. Lezi izingxenye zensimbi ezinkulu ezinezimbobo zezigxivizo ezigxunyekwe eceleni komjikelezo wesigubhu. Lezi zigqoko zibamba zombili izigubhu namasondo angemuva eVAZ 2107.

Nazi izilinganiso eziyinhloko zesigubhu samabhuleki esijwayelekile "esiyisikhombisa":

- ububanzi bangaphakathi - 250 mm;

- ububanzi obuvumelekile, uma kucatshangelwa isicefe, yi-252.2 mm;

- ukuphakama kwangaphakathi kwesigubhu - 57 mm;

- ukuphakama kwesigubhu esiphelele - 69 mm;

- ububanzi obukhulayo - 58 mm;

- inani lezimbobo ezifakwe isondo - 4;

- isamba sezimbobo ezifakwayo siyisi-8.

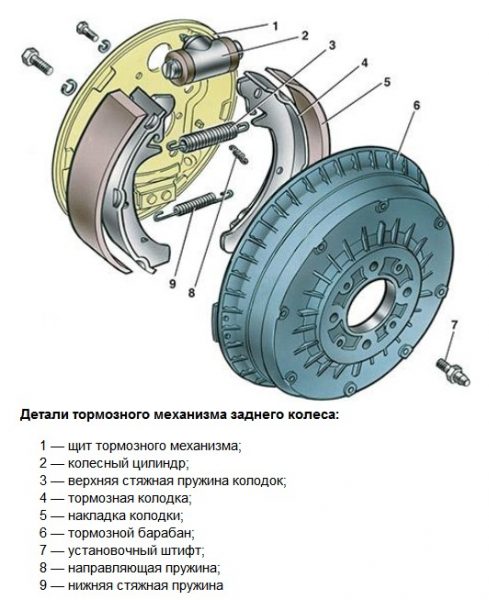

Indlela yamabhuleki

I-braking mechanism ye "eziyisikhombisa" igxilwe kusihlangu esikhethekile se-brake, futhi lesi sihlangu, siboshwe ngokuphephile kuhabhu lamasondo. Nazi izici eziyinhloko ze-VAZ 2107 brake mechanism:

- i-pair of brake pads enamaphedi enziwe ngezinto ezikhethekile;

- i-cylinder ye-brake ezinhlangothini ezimbili (igama elithi "izinhlangothi ezimbili" lisho ukuthi lesi silinda asinaso esisodwa, kodwa ama-piston amabili asuka emikhawulweni ehlukene yedivayisi);

- iziphethu ezibuyayo ezimbili;

- ikhebula lebhuleki lesandla;

- i-hand brake lever.

Amaphedi amabili kumshini wamabhuleki angemuva adonswa ndawonye ngama-return springs. Phakathi kwalawa maphedi kukhona isilinda esinezinhlangothi ezimbili. Ukulandelana kokusebenza kwe-brake mechanism imi kanje. Umshayeli ushaya amabhuleki. Futhi uketshezi lwamabhuleki luqala ukugeleza ngokushesha lusuka kusilinda oluyi-hydraulic luya kusilinda esinezinhlangothi ezimbili esigubhu. Ama-piston anezinhlangothi ezimbili anwebeka futhi acindezele amaphedi, nawo aqala ukuhlukana futhi aphumule odongeni lwangaphakathi lwesigubhu, elungisa ngokuphephile idivayisi. Lapho umshayeli esusa imoto “ebhulekini lesandla”, umfutho we-brake fluid ohlelweni lwehla kakhulu, futhi ama-pistons esilinda esisebenzayo abuyele emzimbeni wedivayisi. Ama-return springs adonsa amaphedi abuyele endaweni yawo yokuqala, adedele isigubhu futhi avumele isondo elingemuva ukuthi lijikeleze ngokukhululeka.

Ziyini izigubhu

Isigubhu samabhuleki siyingxenye ebalulekile, futhi izidingo zaso ziphezulu kakhulu. Amapharamitha abaluleke kakhulu yilezi ezilandelayo:

- ukunemba kwejometri yesigubhu;

- i-coefficient of friction yodonga lwangaphakathi;

- amandla

Enye ipharamitha ebalulekile yizinto okwenziwa ngazo isigubhu sebhuleki. Lesi sici singaba insimbi ekhonjiwe noma i-alloy esekelwe ku-aluminium. Kulezi "eziyisikhombisa", kuye ngonyaka wokukhiqiza umshini, ungathola kokubili izigubhu ze-iron ne-aluminium.

Izigubhu zensimbi zale moto zibhekwa njengelungile (ekukhishweni kokuqala kwe-VAZ 2107, kwakuyizigubhu zensimbi eziphonswe). I-Cast iron inenhlanganisela engcono kakhulu yamandla, ukwethembeka kanye ne-coefficient ephezulu yokungqubuzana. Ngaphezu kwalokho, izigubhu zensimbi ezisansimbi ziyathengeka futhi kulula ukuzikhiqiza. I-Cast iron ine-drawback eyodwa kuphela: ukuqina okukhulayo, okubaluleke kakhulu lapho ushayela emigwaqweni yethu enzima.

Ukuxazulula le nkinga, abakhiqizi be-VAZ 2107 bathatha isinyathelo esilandelayo: baqala ukubeka izigubhu ezenziwe ngama-alloys asekelwe ku-aluminium kamuva "eziyisikhombisa" (ngaphezu kwalokho, kusukela kuma-alloys - le nsimbi ithambile kakhulu ngendlela ehlanzekile). Futhi ukuze kugcinwe i-coefficient ephezulu yokungqubuzana kwezindonga zangaphakathi, ukufakwa kwe-cast-iron kwaqala ukufakwa ezigubhu ze-aluminium. Kodwa-ke, isisombululo esinjalo sobuchwepheshe asizange sihlangane nokuqonda phakathi kwabashayeli bezimoto. Kuze kube yilolu suku, abanikazi abaningi be "isikhombisa" babheka izigubhu zensimbi njengenketho engcono kakhulu, hhayi i-alloy.

Izimbangela nezimpawu zokuhluleka kwamabhuleki angemuva

I-VAZ 2107 yangemuva ye-brake mechanism inesici esisodwa esingathandeki kakhulu: ishisa kalula. Lokhu kungenxa yokuklanywa kwalo mshini, ongenawo umoya omuhle kakhulu. Ngokusho kwabakhiqizi, amabhuleki angemuva "ayisikhombisa" angaqiniseka ukuthi ahamba ayizinkulungwane ezingu-60 km ngaphandle kokulungiswa, kanti amabhuleki angaphambili angahamba kuphela ayizinkulungwane ezingu-30 km. Eqinisweni, ngenxa yokushisa okungenhla, i-mileage ye-brake yangemuva iphansi kancane, cishe izinkulungwane ezingama-50 km. Ngemva kwalokho, umshayeli nakanjani kuyodingeka abhekane nezimo ezilandelayo:

- amaphedi kumshini wamabhuleki aguga kancane noma ngokuphelele, futhi ukuguga kungabonwa ohlangothini olulodwa nakuzo zombili;

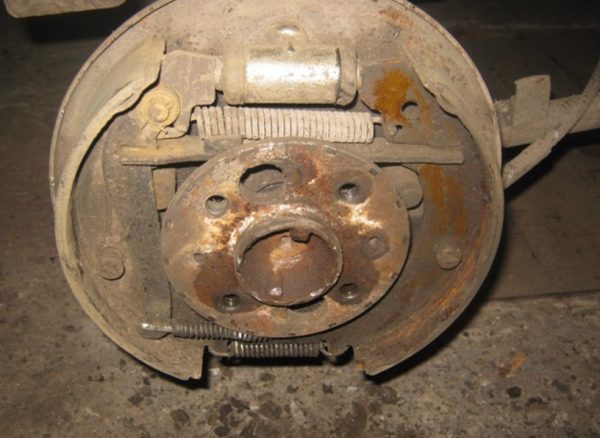

Amaphedi angemuva agqokwa cishe phansi.

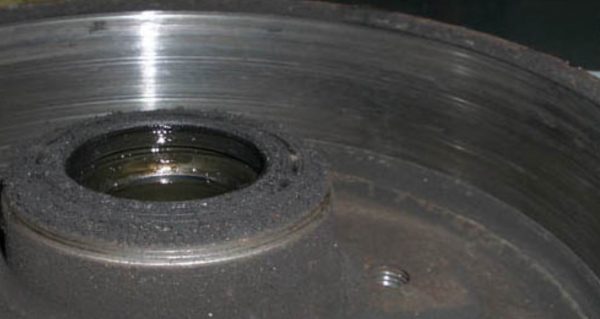

Amaphedi angemuva agqokwa cishe phansi. - izimpawu ku-cylinder esebenzayo ngenxa yokushisa okuphezulu, ngenxa yalokho ukuqina kwedivayisi kuphukile, okuholela ekuvuzeni kwe-brake fluid kanye nokwehla okubukhali ekusebenzeni kahle kwe-braking;

- iziphethu ezibuyayo ku-brake mechanism zigqwalile (ezimweni ezimbi kakhulu, enye yazo ingase iphule, okungaholela ekugxumeni kwesondo elingemuva);

- ikhebula lebhuleki lesandla liyaguga. Lapho ikhebula liguga, liyanwebeka futhi liqala ukucwila kakhulu. Ngenxa yalokho, ngemva kokubeka imoto "ibhuleki lesandla", ama-brake pads abeka ingcindezi encane kakhulu odongeni lwesigubhu, futhi amasondo angemuva alungiswa ngokungathembeki.

Ngawo wonke la maphuzu engqondweni, kunconywa kakhulu ukuhlola umshini we-brake wangemuva njalo ngamakhilomitha ayizinkulungwane ezingu-20 futhi, uma kunesidingo, ufeze ukuvimbela kwayo. Kufanele kuqashelwe ngokukhethekile amabhuleki angemuva lapho kuvela izimpawu ezilandelayo eziyisixwayiso:

- lapho ubhuleka, ukudlidliza okunamandla kwemoto kubonakala, umshayeli azizwa ngokoqobo ngomzimba wakhe wonke;

- ngemuva kokucindezela amabhuleki, kwenzeka i-creak eqinile, okuthi ngokuhamba kwesikhathi iphenduke i-rattle evala izindlebe;

- lapho ushayela, kukhona "ukushaya" okunamandla kokubili kwesondo lokuqondisa kanye ne-brake pedal;

- ukusebenza kahle kwamabhuleki kwehle kakhulu, futhi nebanga lokubhuleka selilikhulu kakhulu.

Zonke lezi zimpawu zibonisa ukuthi amabhuleki adinga ukulungiswa ngokushesha noma ukunakekelwa okukhulu. Akunakwenzeka neze ukushayela ngamabhuleki anjalo.

isigubhu sebhuleki ephukile

Imifantu iyisihluku sangempela sazo zonke izigubhu zamabhuleki, hhayi kuphela "kuyisikhombisa", kodwa nakweminye imishini eminingi enamabhuleki ezigubhu. Iningi lezimpawu eziyisixwayiso ezibalwe ngenhla zivela ngqo ngemva kokuqhekeka kwesigubhu. Lokhu kwenzeka kaningi ngezigubhu zensimbi. Iqiniso liwukuthi i-cast iron iyingxube yensimbi ne-carbon, lapho i-carbon iqukethe ngaphezu kwe-2.14%. Ikhabhoni yenza insimbi eyinsimbi ibe lukhuni ngendlela emangalisayo, kodwa insimbi egayiwe iba brittle. Uma umshayeli engenaso isitayela sokushayela esiqaphile futhi ethanda ukugibela emigodini eheleza umoya, ukuqhekeka kwezigubhu zamabhuleki kuyindaba yesikhathi nje.

Enye imbangela yokuqhekeka kwezigubhu yilokho okubizwa ngokuthi ukukhathala kwensimbi. Uma ingxenye ingaphansi kwemithwalo eshintshashintshayo ye-cyclic isikhathi eside, ehambisana nokushintsha okungazelelwe kwezinga lokushisa (futhi isigubhu se-brake sisebenza ngaphansi kwezimo ezinjalo), khona-ke ngokushesha noma kamuva i-microcrack yokukhathala ivela kuleyo ngxenye. Akunakwenzeka ukuyibona ngaphandle kwesibonakhulu se-electron. Ngesinye isikhathi, lokhu kuqhekeka kusakazeka ekujuleni kwengxenye, futhi ukusakazeka kuhamba ngesivinini somsindo. Ngenxa yalokho, kuvela ukuqhekeka okukhulu, okungenakwenzeka ukungaboni. Isigubhu esiqhekekile asikwazi ukulungiswa. Okokuqala, imishini ekhethekile namakhono adingekayo ukushisela insimbi ensimbi egalaji, futhi okwesibili, amandla esigubhu esinjalo ngemva kokushisela azoncishiswa kakhulu. Ngakho-ke umnikazi wemoto unenketho eyodwa kuphela esele: buyisela isigubhu sebhuleki esiphukile ufake esisha.

Gqoka izindonga zangaphakathi zesigubhu

Ukugqokwa kwezindonga zangaphakathi zesigubhu kuyinqubo yemvelo, imiphumela yayo ibonakala ngokucacile ngemva kokuba imoto isidlulile kumakhilomitha ayizinkulungwane ezingu-60 amenyezelwe ngenhla. Njengoba izindonga zangaphakathi zesigubhu zithinteka ngezikhathi ezithile amandla okungqubuzana adalwa ama-friction linings ezicathulweni zamabhuleki, ububanzi bangaphakathi besigubhu bukhula ngokungenakugwenywa ngokuhamba kwesikhathi. Kulokhu, ukusebenza kahle kwe-braking kuncishisiwe, ngoba ama-brake pads awacindezelwe kancane ngokumelene nesigubhu. Imiphumela yokuguga kwemvelo iqedwa ngokulungisa kabusha isigubhu sebhuleki bese kulungiswa indlela yokubhuleka ukuze kuqinisekiswe ukulingana okufanele kwamaphedi ezindongeni zangaphakathi.

Ama-grooves endaweni engaphakathi yesigubhu

Ukubonakala kwama-grooves ebusweni obungaphakathi besigubhu kungenye inkinga evamile abanikazi be "sevens" abavame ukubhekana nayo. Iqiniso liwukuthi amabhuleki angemuva ku-"seven" aklanywe ngendlela yokuthi ngezinye izikhathi kungene uthuli namatshe amancane esigubhuni, ikakhulukazi uma umshayeli eshayela ikakhulukazi emigwaqweni ewubhuqu. Itshe elilodwa noma ngaphezulu lingagcina liphakathi kwesicathulo sebhuleki nodonga lwangaphakathi lwesigubhu. Lapho iphedi licindezela itshe endaweni engaphakathi yesigubhu, licindezelwa ngokujulile kulwelwesi olushayisanayo esicathulweni sebhuleki futhi lihlale lilapho (impahla ye-friction lining ithambile impela). Ngokubhuleka ngakunye okulandelayo, amatshe abhajwe ebhulokhini aklwebha udonga lwangaphakathi lwesigubhu.

Ngokuhamba kwesikhathi, ukuklwebheka okuncane kuphenduka umsele omkhulu, okungeke kube lula ukuwususa. Indlela yokuxazulula le nkinga inqunywa ukujula kwama-grooves avele. Uma umshayeli ewabonile kusenesikhathi, futhi ukujula kwawo akudluli imilimitha eyodwa, ungazama ukuwaqeda ngokuguqula isigubhu. Futhi uma ukujula kwama-grooves kungamamilimitha amabili noma ngaphezulu, khona-ke kunendlela eyodwa kuphela yokuphuma - esikhundleni sesigubhu sebhuleki.

Mayelana nokuphendula izigubhu zamabhuleki

Njengoba kushiwo ngenhla, ezinye iziphambeko eziye zavela ngesikhathi sokusebenza kwezigubhu ze-brake zingaqedwa ngokusebenzisa okuthiwa yi-groove. Kufanele kushiwo ngokushesha ukuthi akunakwenzeka ukugaya isigubhu ngokwakho egaraji. Ngoba lokhu, okokuqala, udinga i-lathe, futhi okwesibili, udinga ikhono lokusebenza kulo mshini, futhi ikhono linzima. Umshayeli wezimfundamakhwela ngeke aziqhenye ngokuba nomshini egaraji lakhe kanye namakhono ahambisana nawo. Ngakho-ke, unenketho eyodwa kuphela: ukufuna usizo ku-turner ofanelekayo.

Ngakho-ke yini i-drum groove yebhuleki? Ngokuvamile kuhlanganisa izigaba ezintathu:

- isigaba sokulungiselela. Umjikijeli ususa cishe ingxenye yemilimitha yensimbi ezindongeni zangaphakathi zesigubhu. Ngemva kwalokho, umshini uvaliwe, futhi isigubhu sihlolwe ngokucophelela ukuze kutholakale amaphutha angaphakathi. Isiteji sokulungiselela sikuvumela ukuthi unqume izinga eliphelele lokugqoka isigubhu kanye nokwenzeka komsebenzi oqhubekayo. Ngezinye izikhathi, ngemva kwesiteji sokulungiselela, kuvela ukuthi i-groove ayisizi ngenxa yokugqoka okunzima, futhi isigubhu silula ukushintshwa kunokugaya;

- isiteji esikhulu. Uma, ngemva kokwelashwa kwangaphambili, kwavela ukuthi isigubhu asizange siguge kakhulu, khona-ke isigaba esiyinhloko sokuphenduka siqala, lapho i-turner ibushelelezi futhi igaya yonke imifantu emincane nemifantu. Phakathi nalo msebenzi, cishe u-0.3 mm wensimbi uzokhishwa ezindongeni zangaphakathi zesigubhu;

- Isigaba sokugcina. Kulesi sigaba, indawo enesihlabathi ipholishwa nge-paste ekhethekile. Le nqubo iqeda ngisho neziphambeko ezincane kakhulu ezingabonakali ngeso lenyama, futhi ubuso buba bushelelezi ngokuphelele.

Kumele futhi kuqashelwe lapha ukuthi i-groove izosiza ukuqeda ukukhubazeka kwangaphakathi ku-drum, kodwa ngeke kube yize uma i-drum geometry iphukile. Isibonelo, isigubhu sasonteka ngenxa yomthelela noma ngenxa yokushisa ngokweqile. Uma isigubhu siyinsimbi ephonswe, khona-ke kuzodingeka sishintshwe, ngoba kunzima kakhulu ukuqondisa i-brittle cast iron ngosizo lwamathuluzi okufaka amapayipi. Uma isigubhu "sesikhombisa" siyi-alloy ekhanyayo, ungazama ukuyiqondisa. Futhi kuphela emva kwalokho qhubekela ku-groove.

Ukushintsha isigubhu sangemuva ku-VAZ 2107

Ezimweni eziningi, ukushintshwa kwezigubhu kuwukuphela kwendlela yokuphuma kumnikazi wemoto. Okuhlukile yizimo ezibalwe ngenhla, lapho inkinga ingalungiswa nge-groove. Kodwa njengoba kude nabo bonke abashayeli bezimoto bane-turner ejwayelekile efanelekayo, abaningi bakhetha ukungazihluphi ngokubuyisela ingxenye engasebenzi, kodwa bavele bathenge izigubhu ezintsha bese bezifaka. Ukufaka sidinga izinto ezilandelayo:

- isigubhu esisha se-VAZ 2107;

- isethi yezipanela;

- i-sandpaper eyindilinga;

- ujack.

Ukumiselela ukulandelana

Ngaphambi kokuqala umsebenzi, elinye lamasondo angemuva omshini liyakhishwa futhi likhishwe. Ngaphambi kokuqala lo msebenzi wokulungiselela, qiniseka ukuthi umshini uqiniswe ngokuvikelekile nezinsimbi zamasondo.

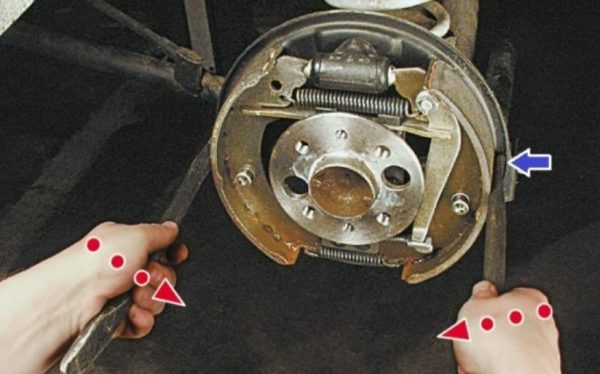

- Ngemva kokukhipha isondo, ukungena kusigubhu kuyavuleka. Ihlala phezu kwezikhonkwane zomhlahlandlela, eziphawulwe ngemicibisholo ebomvu esithombeni. Amantongomane ezikhonkwaneni azikhohliwe. Ngemuva kwalokho, isigubhu kufanele sidonswe kancane sibheke kuwe, futhi sizophuma kubaqondisi.

Amantongomane akuzikhonkwane zomhlahlandlela akhishwe ngesikrini esingu-12

Amantongomane akuzikhonkwane zomhlahlandlela akhishwe ngesikrini esingu-12 - Ngokuvamile kwenzeka ukuthi isigubhu asiphumi kuma-guide, kungakhathaliseki ukuthi umshayeli wenza kanzima kangakanani. Uma isithombe esinjalo sibonwa, khona-ke udinga ukuthatha ama-bolt ambalwa ku-8, uqale ukuwafaka kunoma yiziphi izimbobo zamahhala emzimbeni wesigubhu. Njengoba amabhawodi efakwa phakathi, isigubhu sizoqala ukuhamba eduze kweziqondiso. Bese-ke ingakhishwa izikhonkwane zomhlahlandlela ngesandla.

Kudingeka amabhawodi ambalwa kuphela angu-8 ukususa isigubhu esibhajwe.

Kudingeka amabhawodi ambalwa kuphela angu-8 ukususa isigubhu esibhajwe. - Ngemva kokukhipha isigubhu, ukufinyelela ku-flange ku-axle shaft kuyavuleka. Uma amabhuleki engazange ashintshwe isikhathi eside, khona-ke le flange izombozwa ngongqimba obukhulu bokugqwala nokungcola. Konke lokhu kufanele kuhlanzwe ku-flange nge-sandpaper eqinile.

Kungcono ukuhlanza i-flange nge-sandpaper enkulu kunazo zonke

Kungcono ukuhlanza i-flange nge-sandpaper enkulu kunazo zonke - Ngemuva kokuhlanza okuphelele, i-flange kufanele igcotshwe nge-LSTs1. Uma ibingekho eduze, ungasebenzisa igrisi ye-graphite evamile.

- Manje kufanele uvule i-hood yemoto, thola i-reservoir nge-brake fluid futhi uhlole izinga layo. Uma izinga le-liquid liphezulu (lizoba uphawu lwe-"Max"), khona-ke udinga ukukhulula ipulaki bese uthela cishe "ama-cubes" oketshezi ethangini. Indlela elula yokwenza lokhu ukusebenzisa isirinji yezokwelapha evamile. Lokhu kwenzelwa ukuthi lapho ama-brake pads encipha kakhulu, uketshezi lwebhuleki lungaphumi ngaphandle kwechibi.

Khipha uketshezi oluthile endaweni yokugcina amabhuleki

Khipha uketshezi oluthile endaweni yokugcina amabhuleki - Ngaphambi kokufaka isigubhu esisha, ama-brake pads kufanele ahlanganiswe. Lokhu kwenziwa kusetshenziswa ama-mounts amabili. Kufanele zifakwe njengoba kukhonjisiwe emfanekisweni futhi ziphumule ngokuqinile ngokumelene nepuleti yokufaka amabhuleki engemuva. Ngemuva kwalokho, usebenzisa ama-mounts njengama-levers, kufanele uhambise ama-pads eduze komunye nomunye.

Uzodinga ama-pry bar ambalwa ukuze uhambise amaphedi.

Uzodinga ama-pry bar ambalwa ukuze uhambise amaphedi. - Manje konke sekumi ngomumo ukufaka isigubhu esisha. Ifakwa ezikhonkwaneni zomhlahlandlela, emva kwalokho uhlelo lwamabhuleki luphinde luhlanganiswe.

Ngemva kokugudluza amaphedi, kufakwa isigubhu esisha

Ngemva kokugudluza amaphedi, kufakwa isigubhu esisha

Ividiyo: ukushintsha izigubhu ezingemuva ku-"classic"

Ngakho-ke, ukushintsha isigubhu sebhuleki "eyisikhombisa" kuwumsebenzi olula. Kungaphakathi kwamandla ngisho nomshayeli we-novice, owake wabamba intaba kanye ne-wrench ezandleni zakhe. Ngakho, umshayeli uzokwazi ukonga ruble mayelana 2 XNUMX. Lokhu kubiza malini ukushintsha izigubhu ezingemuva emsebenzini wezimoto.