ICE piston. Idivayisi nenjongo

Ingxube kaphethiloli evutha kusilinda yenjini ikhipha amandla okushisa. Bese iphenduka isenzo somshini esenza i-crankshaft ijikeleze. Isici esiyinhloko sale nqubo i-piston.

Le mininingwane akuyona eyakudala njengoba ingase ibonakale ekuqaleni. Kungaba iphutha elikhulu ukumthatha njengomuntu ophushayo.

I-piston itholakala ku-cylinder, lapho ibuyisela khona.

Njengoba iqonda endaweni ephezulu efile (TDC), ipiston icindezela ingxube kaphethiloli. Enjinini kaphethiloli evuthayo yangaphakathi, ivutha ngokushesha eduze nomfutho omkhulu. Enjinini ye-diesel, ukuthungela kwenzeka ngokuqondile ngenxa yokucindezela okuphezulu.

Ukucindezela okukhulayo kwamagesi akhiwe ngesikhathi sokusha kusunduzela i-piston kwelinye icala. Kanye nepiston, induku yokuxhuma eshiwo nayo iyanyakaza, okwenza ijikeleze. Ngakho-ke amandla amagesi acindezelwe aguqulwa abe yi-torque, adluliselwe ngokudluliselwa kwamasondo emoto.

Ngesikhathi sokusha, izinga lokushisa lamagesi lifinyelela ku-2 XNUMX degrees. Njengoba ukusha kuqhuma, i-piston ibhekene nemithwalo enamandla yokushaqeka.

Ukulayisha okudlulele kanye nezimo zokusebenza eziseduze nezidlulele zidinga izidingo ezikhethekile zokuklama nezinto ezisetshenziselwa ukwenziwa kwayo.

Lapho uklama ama-pistons, kunamaphuzu amaningi abalulekile okufanele uwacabangele:

- isidingo sokuqinisekisa impilo ende yenkonzo, ngakho-ke, ukunciphisa ukugqoka kwengxenye;

- vimbela ukushiswa kwe-piston ekusebenzeni okuphezulu kokushisa;

- qinisekisa ukubekwa uphawu okuphezulu ukuvimbela ukuphumelela kwegesi;

- ukunciphisa ukulahlekelwa ngenxa yokungqubuzana;

- qinisekisa ukupholisa kahle.

I-piston material kufanele ibe nenani lezinto ezithile:

- amandla abalulekile;

- esiphezulu kungenzeka conductivity ezishisayo;

- ukumelana nokushisa kanye nekhono lokumelana nokushintsha okungazelelwe ekushiseni;

- i-coefficient yokwanda okushisayo kufanele ibe mncane futhi ibe seduze ngangokunokwenzeka ne-coefficient ehambisanayo yesilinda ukuze kuqinisekiswe ukubekwa uphawu okuhle;

- ukumelana nokugqwala;

- izakhiwo ze-antifriction;

- ukuminyana okuphansi ukuze ingxenye ingasindi kakhulu.

Njengoba impahla ehlangabezana kahle nazo zonke lezi zidingo ingakadalwa, umuntu kufanele asebenzise izinketho zokuvumelana. Ama-pistons ezinjini ezivuthayo zangaphakathi enziwe nge-grey cast iron nama-alloys e-aluminium ane-silicon (silumin). Kuma-piston ahlanganisiwe ezinjini ze-diesel, kwenzeka ukuthi ikhanda lenziwe ngensimbi.

I-Cast iron iqinile impela futhi ayigugi, ibekezelela ukushisa okuqinile, inezinto ezilwa nokungqubuzana kanye nokunwetshwa okuncane kokushisa. Kodwa ngenxa ye-thermal conductivity ephansi, i-cast iron piston ingashisa kufika ku-400 ° C. Enjinini kaphethiloli, lokhu akwamukelekile, njengoba kungabangela ukushiswa kwangaphambili.

Ngakho-ke, ezimweni eziningi, ama-pistons ezinjini zezimoto ezivuthayo zangaphakathi zenziwa ngokugxiviza noma ukuphonsa kusuka ku-silumin equkethe okungenani i-silicon engu-13%. I-aluminium ehlanzekile ayifaneleki, njengoba ikhula kakhulu uma ishisa, okuholela ekwandeni kokungqubuzana nokukhwabanisa. Lawa kungaba amanga ongahlangana nawo uma uthenga izingxenye eziyisipele ezindaweni ezingabazisayo. Ukuze uvimbele lokhu kungenzeki, xhumana nabathembekile.

I-aluminium alloy piston ilula futhi iqhuba kahle ukushisa, ukuze ukushisa kwayo kungabi ngaphezu kuka-250 ° C. Lokhu kuzilungele impela izinjini ezivuthayo ezisebenza ngophethiloli. Izakhiwo zokulwa ne-silumin nazo zinhle kakhulu.

Ngesikhathi esifanayo, le nto ayinazo izinkinga. Njengoba izinga lokushisa likhuphuka, liya ngokuya lihlala isikhathi eside. Futhi ngenxa yokwanda komugqa obalulekile lapho kushisa, kufanele kuthathwe izinyathelo ezengeziwe ukuze kulondolozwe uphawu eduze komjikelezo wekhanda futhi kunganciphisi ukucindezelwa.

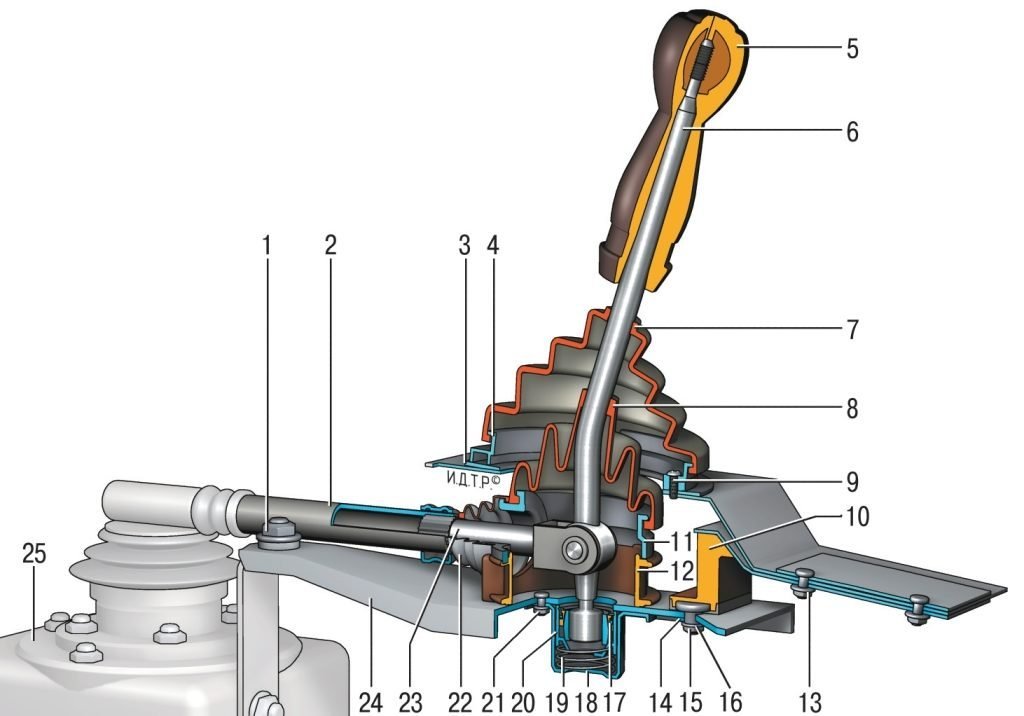

Le ngxenye inomumo wengilazi futhi inekhanda nengxenye yomhlahlandlela (isiketi). Ekhanda, futhi, kungenzeka ukuhlukanisa ingxenye engezansi kanye nengxenye yokuvala.

Ngezansi

Iyindawo eyinhloko yokusebenza ye-piston, yiyona ebona ukucindezela kwamagesi andayo. Ingaphezulu layo linqunywa uhlobo lweyunithi, ukubekwa kwemibhobho, amakhandlela, amavalvu kanye nedivayisi ethile ye-CPG. Kuma-ICE asebenzisa uphethiloli, yenziwa isicaba noma i-concave ngokusikwa okwengeziwe ukuze kugwenywe ukukhubazeka kwamavalvu. Iphansi le-convex linikeza amandla akhulayo, kodwa likhuphula ukudluliswa kokushisa, ngakho-ke akuvamile ukusetshenziswa. I-Concave ikuvumela ukuthi uhlele ikamelo elincane lomlilo futhi unikeze isilinganiso esiphezulu sokucindezela, okubaluleke kakhulu kumayunithi edizili.

Uphawu ingxenye

Lolu uhlangothi lwekhanda. Ama-grooves amasongo e-piston enziwa kuwo azungeze isiyingi.

Izindandatho zokucindezela zidlala indima yophawu, zivimbela ukuvuza kwamagesi acindezelwe, futhi ama-scrapers kawoyela asusa okokugcoba odongeni, okuvimbele ukuthi angangeni ekamelweni elivuthayo. Amafutha ageleza ngaphansi kwepiston emigodini esemseleni abese ebuyela ku-oyela sump.

Ingxenye yohlangothi olusemaceleni phakathi konqenqema lwendandatho engezansi nengaphezulu ibizwa ngokuthi indawo yomlilo noma indawo yokushisa. Nguye ozwa umphumela omkhulu wokushisa. Ukuze uvimbele ukutubeka kwepiston, leli bhande lenziwe laba banzi ngokwanele.

Ingxenye yomhlahlandlela

Ayivumeli i-piston ukuthi inyakaze ngesikhathi sokunyakaza okuhambisanayo.

Ukuze kunxeshezelwe ukwanda okushisayo, isiketi senziwe i-curvilinear noma i-cone-shaped. Eceleni, i-anti-friction coating ngokuvamile isetshenziswa.

Ngaphakathi kukhona abaphathi - ukungena okubili okunezimbobo zephini le-piston, lapho ikhanda libekwe khona.

Emaceleni, endaweni yabaphathi, ama-indents amancane ayenziwa ukuvimbela ukukhubazeka okushisayo kanye nokuvela kwamagoli.

Njengoba umbuso wokushisa we-piston ucindezela kakhulu, indaba yokupholisa kwayo ibaluleke kakhulu.

Amasongo e-piston ayindlela eyinhloko yokususa ukushisa. Ngabo, okungenani isigamu samandla ashisayo ngokweqile siyasuswa, adluliselwe odongeni lwesilinda bese ejazi lokupholisa.

Esinye isiteshi esibalulekile sikasinki wokushisa ukugcoba. Imfucumfucu kawoyela kusilinda, ukugcoba ngembobo endongeni yokuxhuma, kusetshenziswa ukufuthwa ngempoqo nge-nozzle yamafutha nezinye izindlela. Ukushisa okungaphezu kwengxenye eyodwa kwezintathu kungasuswa ngokujikeleza amafutha.

Ngaphezu kwalokho, ingxenye yamandla ashisayo isetshenziselwa ukushisa ingxenye entsha yengxube evuthayo engene kusilinda.

Amasongo agcina inani elifunekayo lokucindezela kumasilinda futhi asuse ingxenye yengonyama yokushisa. Futhi zenza cishe ingxenye yesine yakho konke ukulahleka kokungqubuzana enjinini yomlilo yangaphakathi. Ngakho-ke, ukubaluleka kwekhwalithi nesimo samasongo e-piston ekusebenzeni okuzinzile kwenjini evuthayo yangaphakathi akunakulinganiswa ngokweqile.

Ngokuvamile kuba namasongo amathathu - izindandatho ezimbili zokucindezela phezulu kanye ne-oyela scraper eyodwa phansi. Kodwa kunezinketho ezinenani elihlukile lamasongo - kusuka kwamabili kuya kwayisithupha.

I-groove yendandatho engenhla ku-silumin Kwenzeka ukuthi kwenziwa ngokufaka insimbi okwandisa ukumelana nokugqoka.

Izindandatho zenziwe ngamamaki akhethekile ensimbi ekhonjiwe. Amasongo anjalo abonakala ngamandla aphezulu, ukuqina, ukumelana nokugqoka, i-coefficient ephansi yokungqubuzana futhi agcine izakhiwo zawo isikhathi eside. Izengezo ze-molybdenum, i-tungsten nezinye izinsimbi zinikeza ukumelana nokushisa okwengeziwe kumasongo e-piston.

Ezintsha zidinga ukugaya. Uma usushintshile izindandatho, qiniseka ukuthi usebenzisa injini evuthayo yangaphakathi isikhathi esithile, ugweme izimo zokusebenza ezishubile. Uma kungenjalo, izindandatho ezingafakwanga zingase zishise futhi zilahlekelwe ukunwebeka, futhi kwezinye izimo zize ziphuke. Umphumela ungase ube ukwehluleka kophawu, ukuphelelwa amandla, okokugcoba kungena ekamelweni elivuthayo, ukushisa ngokweqile nokushiswa kwepiston.