Ukuminyana kwamafutha e-Compressor

Okuqukethwe

Umqondo wokuminyana

Ukuminyana kukawoyela weCompressor kuyisilinganiso sevolumu ye-lubricant nesisindo sayo. Enye yemingcele ebaluleke kakhulu ethinta ukuhamba komsebenzi ngaphakathi kwesistimu.

Ukuphakama kwesisindo samafutha, kuphumelela kakhulu ukuvikela izingxenye kusuka ku-friction, kungcono kuvimbela ukwakheka kwe-carbon deposits nokukhululwa kwemikhiqizo yesibili. Igrisi engaminyene kangako ekuhambisaneni isebenza ngokunenzuzo lapho udinga ukusheshe usebenzise okokusebenza. Ingena khona manjalo ezakhini, igcobe ngempumelelo yonke ingxenye yazo.

Futhi uwoyela we-compressor okhethwe kahle ngobuningi obuthile:

- ukwandisa impilo yokusebenza kwemishini;

- kuyoba umsizi omuhle ukuqala uhlelo ngenkathi ebandayo;

- izonakekela ukusebenza kwe-compressor ngesikhathi sokusebenza kwayo isikhathi eside emazingeni okushisa aphakeme.

Ukuminyana kwamafutha e-compressor kukalwa kanjani futhi kumaphi amayunithi?

Ukuminyana kwamafutha kubalwa ekushiseni okuthile. Isilinganiso singu +20 degrees Celsius. Ukuze kubalwe, kuyadingeka ukuthatha inkomba yokushisa bese ususa inani eliphakathi kuso. Umehluko owumphumela ube usuphindaphindwa ngokulungiswa kwezinga lokushisa. Ukulungiswa kwangempela kwezinga lokushisa kuboniswa ku-GOST 9243-75. Kusele ukukhipha umkhiqizo ovela kupharamitha ye-density, eboniswa ekucacisweni kobuchwepheshe bomkhiqizo ngamunye othize wamafutha e-compressor.

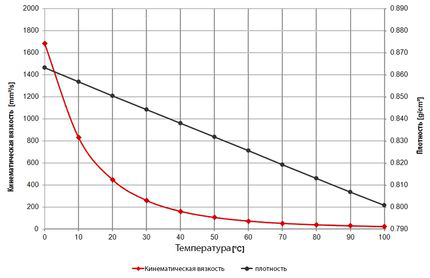

Ukuminyana kukalwa ngo-kg/m3. Amanani amaphakathi, ancike kumkhiqizo kanye ne-viscosity kawoyela oyi-compressor othize, asukela ku-885 kuya ku-905 kg/m.3.

Kungani udinga ukwazi inkomba yokuminyana?

Njengoba izinga lokushisa likhuphuka, ukuminyana kokuqala kwamafutha ezimboni kuncipha. Ngokuvumelana nalokho, ngokuncipha kombuso wokushisa, le nkomba iyanda futhi. Lolu lwazi lufanelekile kubasebenzi besevisi. Ukushintsha kokuminyana okunqunywe kusengaphambili kuthinta ukuwohloka kwezakhiwo zokuvala nokugcoba uwoyela we-compressor. Lokhu, futhi, kungabangela umswakama (i-condensate) ukungena ohlelweni futhi ukwandise ukungqubuzana ngesikhathi sokusebenza kwemishini ebusika, ngenkathi ebandayo. Ngenxa yalokho, idivayisi ingase imiswe ngenxa yokonakala noma ukuguga ngaphambi kwesikhathi.

Ukuba nolwazi mayelana nobuningi bamafutha we-compressor nokuthi le pharamitha incike kuphi, umphathi noma umqhubi womshini uzokwazi, ngokucabangela izimo zokusebenza zemishini, ukuthatha izinyathelo zokuvimbela ukungasebenzi kahle nokuguqula izakhiwo ze-lubricant.

Buka le vidiyo ku-YouTube