I-Carburetor Vaz 2101: inhloso, idivayisi, ukungasebenzi kahle nokuqedwa kwabo, ukulungiswa komhlangano

Okuqukethwe

- ICarburetor VAZ 2101

- Izimpawu ze-carburetor engasebenzi kahle

- Ukulungisa i-carburetor VAZ 2101

- Ithebula: ukumakwa kwejethi ye-carburetor ye-VAZ 2101

Enye yezinto eziyinhloko eziqinisekisa ukusebenza okuzinzile kwenjini ye-carburetor kuzo zonke izindlela yi-carburetor. Esikhathini esingengakanani esidlule, izimoto ezifuywayo zazifakwe uhlelo lokuhlinzeka ngophethiloli zisebenzisa le divayisi. Ngakho-ke, cishe wonke umnikazi "we-classic" kufanele abhekane nokulungiswa nokulungiswa kwe-carburetor, futhi ngenxa yalokhu akudingekile ukuthintana nesevisi, ngoba izinqubo ezidingekayo zilula ukuzenza ngezandla zakho.

ICarburetor VAZ 2101

Imoto Vaz 2101, noma kubantu abavamile "penny", ifakwe carburetor injini umthamo 59 amalitha. Nge. nomthamo 1,2 amalitha. Idivayisi efana ne-carburetor idinga ukunakekelwa nokulungiswa ngezikhathi ezithile, ngaphandle kwalokho injini izozinza, kungase kube nezinkinga ngokuqala, kanye nokwanda kokusetshenziswa kukaphethiloli. Ngakho-ke, ukuklama nokulungiswa kwale node kufanele kucatshangelwe ngokuningiliziwe.

Kwenzelweni

I-carburetor inemisebenzi emibili eyinhloko:

- Ukuxuba uphethiloli nomoya bese ufafaza ingxube ewumphumela.

- Ukwakhiwa kwengxube ye-fuel-air engxenyeni ethile, okudingekayo ekushiseni kwayo okuphumelelayo.

I-jet yomoya kanye nophethiloli ifakwa ngesikhathi esisodwa ku-carburetor, futhi ngenxa yomehluko ngesivinini, uphethiloli uyafuthwa. Ukuze uphethiloli uvuthe ngokuphumelelayo, kufanele uhlanganiswe nomoya ngezilinganiso ezithile. Ezimweni eziningi, lesi silinganiso singu-14,7:1 (umoya kuya kuphethiloli). Ngokuya ngezindlela zokusebenza zenjini, izilinganiso zingahluka.

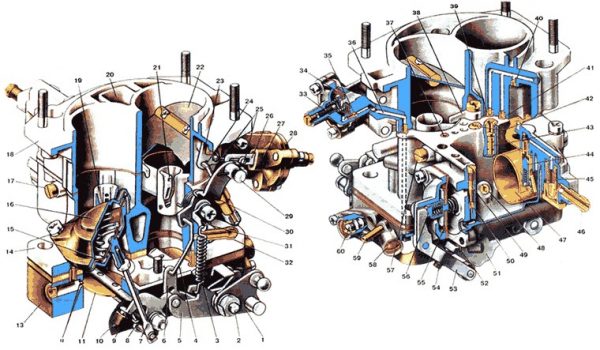

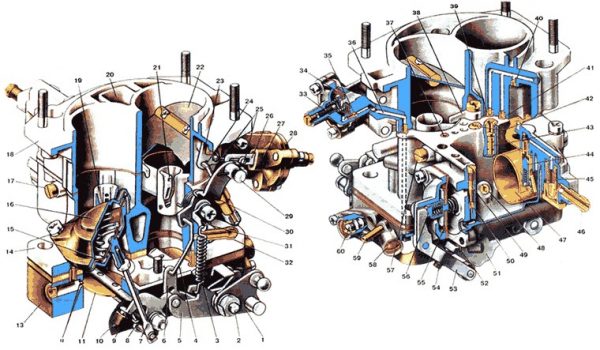

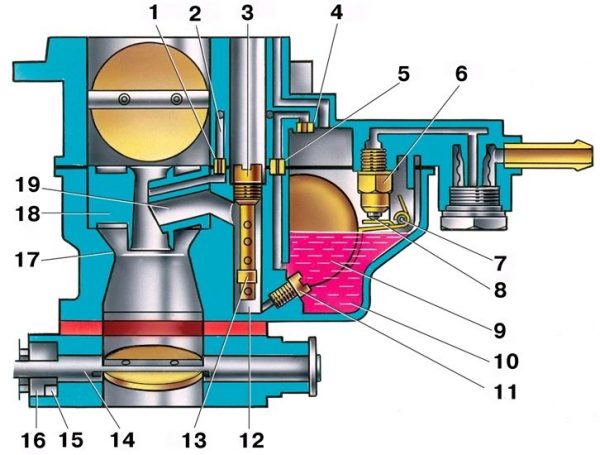

Idivayisi ye-Carburetor

Kungakhathaliseki ukuguqulwa kwe-carburetor, amadivaysi ahluke kancane komunye nomunye futhi ahlanganisa izinhlelo eziningana:

- amasistimu okugcina nokulungisa izinga likaphethiloli;

- ukuqalisa injini kanye nezinhlelo zokufudumala;

- amasistimu angasebenzi;

- iphampu ye-accelerator;

- uhlelo lokudosa oluyinhloko;

- i-econostat kanye ne-economizer.

Ake sicabangele lezi zinhlelo ngokuningiliziwe ukuze siqonde kangcono ukusebenza kwe-node.

Uhlelo lokugcinwa kwezinga lamafutha

Ngokwesakhiwo, i-carburetor inegumbi lokuntanta, futhi i-float etholakala kuyo ilawula izinga likaphethiloli. Umklamo walesi simiso ulula, kodwa ngezinye izikhathi izinga lingase lingalungile ngenxa yokuvuza kwe-valve yenaliti, okubangelwa ukusetshenziswa kwephethiloli yekhwalithi ephansi. Inkinga ixazululwa ngokuhlanza noma ukufaka esikhundleni se-valve. Ngaphezu kwalokho, i-float idinga ukulungiswa ngezikhathi ezithile.

Isistimu yokuqala

Uhlelo lokuqala lwe-carburetor lunikeza isiqalo esibandayo seyunithi yamandla. I-carburetor ine-damper ekhethekile, etholakala phezulu kwekamelo lokuxuba. Okwamanje i-damper ivala, i-vacuum ekamelweni iba nkulu, okuyinto edingekayo ngesikhathi sokuqala okubandayo. Nokho, ukunikezwa komoya akuvinjwanga ngokuphelele. Njengoba injini ifudumala, isici sokuvikela siyavuleka: umshayeli ulawula le mishini esuka endaweni yabagibeli ngentambo.

Uhlelo oluyize

Ukuze injini isebenze ngokuzinza ngokungenzi lutho (XX), isistimu engenzi lutho inikezwa ku-carburetor. Kumodi ye-XX, i-vacuum enkulu yenziwa ngaphansi kwama-dampers, ngenxa yalokho uphethiloli unikezwa ohlelweni lwe-XX kusuka emgodini ongaphansi kwezinga le-damper yokuqala yekamelo. Isibaseli sidlula kujethi engenzi lutho bese sixubana nomoya. Ngakho-ke, ingxube ye-fuel-air yenziwa, enikezwa ngeziteshi ezifanele kumasilinda enjini. Ngaphambi kokuba ingxube ingene ku-cylinder, ibuye ihlanjululwe ngomoya.

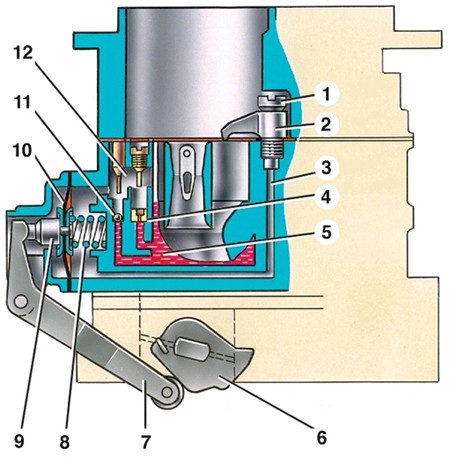

Ipompo ye-Accelerator

Iphampu ye-accelerator ingenye yezinhlelo ezibalulekile ze-carburetor, ehlinzeka ngengxube ye-fuel-air ngesikhathi kuvulwa i-damper. Iphampu isebenza ngokuzimela ngaphandle kokugeleza komoya okudlula kuma-diffuser. Uma kukhona ukusheshisa okubukhali, i-carburetor ayikwazi ukunikeza inani elidingekayo likaphethiloli kumasilinda. Ukuze kuqedwe lo mphumela, ipompo inikezwa esheshisa ukunikezwa kukaphethiloli kumasilinda enjini. Idizayini yepompo iqukethe izici ezilandelayo:

- isikulufu valve;

- isiteshi sikaphethiloli;

- i-bypass jet;

- igumbi lokuntanta;

- i-accelerator pump drive cam;

- i-drive lever;

- buyisela intwasahlobo;

- izinkomishi ze-diaphragm;

- i-diaphragm yepompo;

- i-valve yebhola yokungena;

- amakamelo kaphethiloli umhwamuko.

Isistimu yokudosa eyinhloko

Ukunikezwa kwevolumu eyinhloko kaphethiloli lapho injini isebenza kunoma iyiphi imodi, ngaphandle kwe-XX, inikezwa uhlelo oluyinhloko lokudosa. Lapho indawo yokuphehla amandla isebenza ngemithwalo emaphakathi, isistimu ihlinzeka ngenani elidingekayo lengxube ethambile ngokulingana okungaguquki. Lapho i-throttle valve ivuleka, kusetshenziswa umoya omncane kunophethiloli ophuma ku-atomizer. Lokhu kubangela ingxube ecebile. Ukuze ukubunjwa kungacetshiswa ngokweqile, kufanele kuhlanjululwe ngomoya, kuye ngokuthi isikhundla somshini wokushisa. Lesi sinxephezelo yilokho kanye okwenziwa yisistimu yomthamo omkhulu.

I-Econostat kanye ne-economizer

I-econostat kanye ne-economizer ku-carburetor kuyadingeka ukuze kuqinisekiswe ukugeleza kukaphethiloli ekamelweni lokuxuba, kanye nokuhlinzeka ngengxube ecebile ye-fuel-air ngesikhathi se-vacuum ephezulu, okungukuthi ekulayisheni injini ephezulu. I-economizer ingalawulwa kokubili ngomshini nangomoya. I-Econostat iyishubhu enezigaba ezahlukene kanye neziteshi ze-emulsion ezitholakala engxenyeni engenhla yegumbi lokuxuba. Kule ndawo, i-vacuum yenzeka lapho kugcwala kakhulu isikhungo samandla.

Yiziphi carburetors efakwe Vaz 2101

Abanikazi be-VAZ 2101 ngokuvamile bafuna ukwandisa amandla noma ukunciphisa ukusetshenziswa kwamafutha emoto yabo. Ukusheshisa, kanye nokusebenza kahle, kuncike ku-carburetor efakiwe kanye nokunemba kokulungiswa kwayo. Amamodeli amaningi we-Zhiguli asebenzisa idivayisi ye-DAAZ 2101 ekulungiseni okuhlukahlukene. Amadivayisi ahluke komunye nomunye ngobukhulu bejethi, kanye nokuba khona noma ukungabikho kwe-vacuum corrector. I-carburetor ye-VAZ 2101 yanoma yikuphi ukuguqulwa iklanyelwe ukusebenza kuphela ngezinjini ze-VAZ 2101 no-21011, lapho i-distributor ifakwe ngaphandle kwe-vacuum corrector. Uma wenza izinguquko ohlelweni lokuthungela injini, ungafaka ama-carburetor esimanje "penny". Cabanga ngamamodeli wamadivayisi afakwe "ku-classic".

I-DAAZ

I-Carburettor DAAZ 2101, 2103 kanye ne-2106 yimikhiqizo ye-Weber, ngakho-ke ibizwa ngokuthi i-DAAZ ne-Weber, okusho ukuthi idivayisi efanayo. Lawa mamodeli abonakala ngomklamo olula kanye nokusebenza okuhle kwe-overclocking. Kodwa kwakungeyona ngaphandle kwezinkinga: ukonakala okuyinhloko ukusetshenziswa kukaphethiloli okuphezulu, okusukela ku-10-14 amalitha nge-100 km ngayinye. Kuze kube manje, inkinga ebalulekile iphinde ibe nobunzima bokuthola idivayisi enjalo isesimweni esihle. Ukuze uhlanganise i-carburetor eyodwa evamile esebenzayo, uzodinga ukuthenga izingcezu ezimbalwa.

I-ozone

Ku-Zhiguli yemodeli yesihlanu neyesikhombisa, kwafakwa i-carburetor yesimanje, ebizwa ngokuthi i-Ozone. Indlela elungiswe kahle ikuvumela ukuthi unciphise ukusetshenziswa kukaphethiloli kumalitha ayi-7-10 ngebanga lika-100 km, futhi futhi kunikeze amandla okusheshisa okuhle. Ezicini ezingezinhle zale divayisi, kufanelekile ukugqamisa umklamo ngokwawo. Ngesikhathi sokusebenza okusebenzayo, izinkinga ziphakama ngekamelo lesibili, ngoba alivuli ngomshini, kodwa ngosizo lwe-valve ye-pneumatic.

Ngokusetshenziswa isikhathi eside, i-ozone carburetor iba ngcolile, okuholela ekwephuleni ukulungiswa. Ngenxa yalokho, igumbi lesibili livula ngokubambezeleka noma lihlala livaliwe ngokuphelele. Uma iyunithi ingasebenzi kahle, ukuphuma kwamandla ngenjini kuyalahleka, ukusheshisa kuba kubi, futhi isivinini esiphezulu siyancipha.

I-Solex

Okudume kakhulu "kwama-classic" yi-DAAZ 21053, okuwumkhiqizo we-Solex. Umkhiqizo unikezwe izinzuzo ezifana nokuguquguquka okuhle nokusebenza kahle kukaphethiloli. I-Solex ekwakhiweni kwayo ihluke ezinguqulweni zangaphambilini ze-DAAZ. Ifakwe uhlelo lokubuyisela uphethiloli ongena ethangini. Lesi sixazululo senza kwaba nokwenzeka ukuphambukisa uphethiloli oweqile ethangini likaphethiloli futhi wonge cishe u-400-800 g kaphethiloli ngebanga elingu-100 km.

Ezinye izinguquko zale carburetor zifakwe uhlelo lwe-XX olulungiswa nge-electrovalve, uhlelo lokuqala olubandayo oluzenzakalelayo. Izimoto ezithunyelwa ngaphandle zifakwe i-carburetors yalokhu kumiswa, futhi endaweni ye-CIS yangaphambili, i-Solex ene-XX solenoid valve yayisetshenziswa kakhulu. Nokho, lolu hlelo ngesikhathi sokusebenza lubonise ukushiyeka kwalo. Njengoba ku-carburetor enjalo iziteshi zikaphethiloli nomoya zincane, ngakho-ke, uma zingaseviswanga ngesikhathi, ziyavaleka ngokushesha, okuholela ezinkingeni zokungenzi lutho. Ngalesi carburetor, ukusetshenziswa kukaphethiloli ku-"classic" kungu-6-10 amalitha nge-100 km ngayinye. Mayelana nezici eziguqukayo, i-Solex ilahlekelwa kuphela ku-Weber.

Ama-carburetor asohlwini afakwe kuzo zonke izinjini zakudala ngaphandle kokulungiswa. Okuwukuphela kwento okufanele uyinake ukukhethwa kwedivayisi yokufuduka kwenjini. Uma umhlangano uklanyelwe ivolumu ehlukile, ama-jets akhethiwe futhi ashintshwe, umshini ulungiswa emotweni ethile.

Ukufakwa kwama-carburetor amabili

Abanye abanikazi be "classics" abanelisekile ngokusebenza kweyunithi yamandla ngesivinini esikhulu. Lokhu kuchazwa yiqiniso lokuthi ingxube kaphethiloli nomoya inikezwa amasilinda 2 no-3, futhi ukugxila kwayo kuncipha ngamasilinda 1 no-4. Ngamanye amazwi, umoya nophethiloli awafaki amasilinda njengoba kufanele. Kodwa-ke, kunesixazululo sale nkinga - lokhu ukufakwa kwama-carburetor amabili, okuzoqinisekisa ukutholakala okufanayo kwamafutha kanye nokwakhiwa kwengxube evuthayo yokugcwala okufanayo. Ukuthuthukiswa okunjalo kubonakala ekwandeni kwamandla kanye ne-torque ye-motor.

Inqubo yokwethula ama-carburetors amabili, ekuboneni kuqala, ingase ibonakale iyinkimbinkimbi, kodwa uma ubheka, ukuthuthukiswa okunjalo kungaphakathi kwamandla noma ubani onganelisekile ngokusebenza kwenjini. Izakhi eziyinhloko ezizodingeka kwinqubo enjalo ziyi-2 manifolds evela ku-Oka kanye ne-2 carburetors yemodeli efanayo. Ukuze ube nomthelela omkhulu ekufakeni ama-carburetors amabili, kufanele ucabange ngokufaka isihlungi somoya esengeziwe. Ifakwa ku-carburetor yesibili.

Ukufaka i-carburetors ku-VAZ 2101, i-manifold endala yokuthatha iyasuswa futhi izingxenye ezivela ku-Oka zilungiswa ukuze zibophe futhi zivumelane nekhanda le-block. Abashayeli bezimoto abanolwazi batusa ukudiliza ikhanda le-cylinder ukuze kube lula umsebenzi. Ukunakwa okukhethekile kukhokhwa eziteshini zabaqoqi: akufanele babe nezakhi eziqhamukayo, ngaphandle kwalokho, lapho imoto isebenza, kuzokwakhiwa ukumelana okukhulu nokugeleza okuzayo. Konke okuzophazamisa ukuhamba kwamahhala kwengxube ye-fuel-air ku-cylinder kufanele kususwe kusetshenziswa abasiki abakhethekile.

Ngemuva kokufaka ama-carburetors, izikulufu zekhwalithi nenani zikhishwa ngenani elifanayo lokuguquguquka. Ukuze uvule kanyekanye ama-dampers kumadivayisi amabili, uzodinga ukwenza ubakaki lapho kunikezwa khona i-thrust evela ku-pedal pedal. I-gas drive evela ku-carburetors yenziwa ngokusebenzisa izintambo, isibonelo, ezivela e-Tavria.

Izimpawu ze-carburetor engasebenzi kahle

I-VAZ 2101 carburetor iyithuluzi elidinga ukuhlanzwa nokulungiswa ngezikhathi ezithile, ngenxa yezimo zokusebenza kanye nophethiloli osetshenzisiwe. Uma kuphakama izinkinga ngomshini okukhulunywa ngawo, izimpawu zokungasebenzi kahle zizobonakala ekusebenzeni kweyunithi yamandla: ingase inyakaze, imise, ithole umfutho kabi, njll. Ukuba ngumnikazi wemoto enenjini ye-carburetor, kungaba usizo ukuqonda ama-nuances ayinhloko angenzeka nge-carburetor. Cabangela izimpawu zokungasebenzi kahle nezimbangela zazo.

Izitebele engenzi lutho

Inkinga evame kakhulu "kupeni" injini emile engenzi lutho. Izizathu okungenzeka kakhulu yilezi:

- ukuvala amajethi namashaneli angu-XX;

- ukwehluleka noma ukugoqa okungaphelele kwe-valve ye-solenoid;

- ukungasebenzi kahle kwebhulokhi ye-EPHH (i-economizer engasebenzi ephoqelelwe);

- ukulimala kwekhwalithi ye-screw seal.

Idivayisi ye-carburetor yakhelwe ngendlela yokuthi igumbi lokuqala lihlanganiswe nesistimu ye-XX. Ngakho-ke, ngokusebenza kwenjini okuyinkinga kumodi ye-idling, ukwehluleka kungabonwa kuphela, kodwa futhi nokuma okuphelele kwenjini ekuqaleni kokuhamba kwemoto. Inkinga ixazululwa kalula nje: izingxenye ezinesici ziyashintshwa noma iziteshi ziyashiswa futhi zihlanzwe, okuzodinga ukuhlakazwa ingxenye yomhlangano.

Ividiyo: ukutakula kokungenzi lutho usebenzisa i-Solex carburetor njengesibonelo

Ukuphahlazeka kokusheshisa

Kwesinye isikhathi lapho kusheshiswa imoto, kwenzeka lokho okubizwa ngamadiphu. Ukwehluleka kulapho, ngemva kokucindezela i-pedal yegesi, isikhungo samandla sisebenza ngesivinini esifanayo imizuzwana embalwa bese siqala ukuphenduka. Ukwehluleka kuhlukile futhi kungaholela hhayi ekuphenduleni kamuva kwenjini ekucindezeleni i-pedal yegesi, kodwa futhi nasekumeni kwayo okuphelele. Imbangela yalesi simo kungase kube ukuvinjelwa kwendiza enkulu yamafutha. Uma injini isebenza ngemithwalo ephansi noma ingenzi lutho, idla uphethiloli omncane. Uma ucindezela i-accelerator pedal, injini ishintshela kumodi yokulayisha ephezulu futhi ukusetshenziswa kukaphethiloli kukhuphuka kakhulu. Uma kwenzeka i-jet ye-fuel evaliwe, indawo yokugeleza ayinele, okuholela ekuhlulekeni ekusebenzeni kweyunithi yamandla. Inkinga iqedwa ngokuhlanza indiza.

I-Dips, kanye nama-jerks, ingahlotshaniswa nokulingana okuxekethile kwama-valve epompo ye-fuel noma izakhi zokuhlunga ezivaliwe, okungukuthi, nakho konke okungadala ukumelana lapho uphethiloli unikezwa. Ngaphezu kwalokho, ukuvuza komoya ohlelweni lwamandla kungenzeka. Uma izakhi zokuhlunga zingashintshwa kalula, isihlungi (i-mesh) se-carburetor singahlanzwa, khona-ke ipompo likaphethiloli kuzodingeka kusetshenzwe ngokungathí sina: ukuqaqa, ukuxazulula inkinga, ukufaka ikhithi yokulungisa, futhi mhlawumbe esikhundleni somhlangano.

Ugcwalisa amakhandlela

Enye yezinkinga ezingenzeka ngenjini ene-carbureted yilapho igcwala ama-spark plugs. Kulesi simo, amakhandlela amanzi kusuka kuphethiloli enkulu, kuyilapho ukubonakala kwenhlansi kungenakwenzeka. Ngenxa yalokho, ukuqala injini kuzoba yinkinga. Uma ngalesi sikhathi ukhulula amakhandlela ekhandlela kahle, ungaqiniseka ukuthi azoba manzi. Inkinga enjalo ezimweni eziningi ihlotshaniswa nokucebisa ingxube kaphethiloli ngesikhathi sokwethulwa.

Ukugcwalisa amakhandlela kungaba ngenxa yezizathu eziningi:

- i-carburetor starter ayisebenzi;

- i-valve yenaliti yehlulekile;

- iphampu iphampu yamafutha;

- ukuvinjwa kwamajethi omoya.

Ake sicabangele isizathu ngasinye ngokuningiliziwe. Ezimweni eziningi, inkinga yamakhandlela agcwele i-VAZ 2101 kanye nezinye "zakudala" ikhona ngesikhathi sokuqala okubandayo. Okokuqala, ukuvunyelwa kokuqala kufanele kusethwe kahle ku-carburetor, okungukuthi, ibanga phakathi kwama-dampers nezindonga zekamelo. Ngaphezu kwalokho, i-diaphragm yesiqalisi kufanele iphelele, futhi indlu yaso ivalwe. Uma kungenjalo, i-air damper ye-carburetor, lapho iqala iyunithi yamandla kuya kubanda, ngeke ikwazi ukuvula kancane nge-angle oyifunayo, okuyincazelo yokusebenza kwedivayisi yokuqala. Ngenxa yalokho, ingxube evuthayo izobe igxilile ngenkani ngokunikezwa komoya, futhi ukungabikho kwegebe elincane kuzofaka isandla ekwakhiweni kwengxube ecebile, okuzoholela emphumeleni "wamakhandlela amanzi".

Ngokuqondene ne-valve yenaliti, ingase imane ivuze, okuholela ekudluleleni kukaphethiloli oweqile egunjini lokuntanta. Lesi simo sizophinde siholele ekwakhekeni kwengxube ethuthukisiwe ngesikhathi sokuqala iyunithi yamandla. Uma kwenzeka ukungasebenzi kahle nge-valve yenaliti, amakhandlela angagcwaliswa kokubili kubanda nokushisayo. Kulokhu, kungcono ukufaka esikhundleni ingxenye.

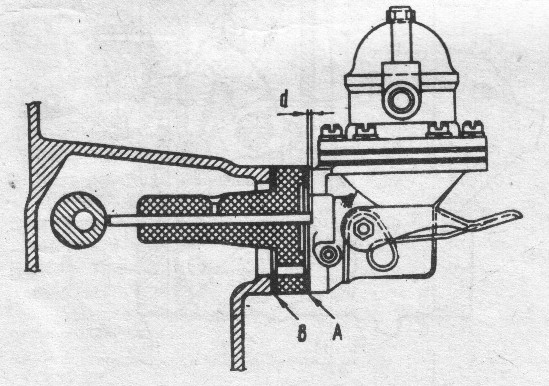

Amakhandlela nawo angagcwaliswa ngenxa yokulungiswa okungalungile kwe-fuel fuel drive, ngenxa yalokho ipompo iphampu uphethiloli. Kulesi simo, i-valve yohlobo lwenaliti yenziwa ingcindezi eningi kaphethiloli, okuholela ekuchichimeni kukaphethiloli kanye nokwanda kwezinga layo ekamelweni lokuntanta. Ngenxa yalokho, ingxube kaphethiloli iba inothe kakhulu. Ukuze induku iphumele kusayizi oyifunayo, kuyadingeka ukufaka i-crankshaft endaweni lapho idrayivu izophuma kancane. Bese ukala usayizi d, okufanele ube ngu-0,8-1,3 mm. Ungakwazi ukufeza ipharamitha oyifunayo ngokufaka ama-gaskets obukhulu obuhlukene ngaphansi kwepompo likaphethiloli (A no-B).

Amajethi omoya ekamelo eliyinhloko le-metering anesibopho sokuhlinzeka umoya engxubeni kaphethiloli: adala ingxenye edingekayo kaphethiloli nomoya, okudingekayo ekuqaleni kwenjini evamile. Uma amajethi evalekile, ukunikezwa komoya kumiswa kancane noma kumiswe ngokuphelele. Ngenxa yalokho, ingxube yamafutha iba ecebile kakhulu, okuholela ekukhukhuleni kwamakhandlela. Inkinga ixazululwa ngokuhlanza amajethi.

Iphunga likaphethiloli ekhabetheni

Ngezinye izikhathi abanikazi be-VAZ 2101 babhekene nenkinga yokuba khona kwephunga likaphethiloli ekamelweni. Isimo akusona esimnandi kakhulu futhi sidinga ukusesha okusheshayo kwembangela nokuqedwa kwayo. Phela, ama-fuel vapors awagcini nje ngokulimaza impilo, kodwa ngokuvamile ayingozi. Esinye sezizathu zephunga kungase kube ithangi legesi ngokwalo, okungukuthi, i-microcrack ingavela ethangini. Kulokhu, uzodinga ukuthola ukuvuza futhi uvale imbobo.

Ngaphandle kwethangi likaphethiloli, ulayini wephethiloli ngokwawo ungavuza, ikakhulukazi uma kukhulunywa nge "penny", ngoba imoto ikude nentsha. Amapayipi kaphethiloli namapayipi kudingeka ahlolwe. Ngaphezu kwalokho, ukunakwa kufanele kukhokhwe kupompo likaphethiloli: uma i-membrane yonakalisiwe, umshini ungavuza, futhi iphunga lingangena ku-cabin. Njengoba ukunikezwa kukaphethiloli yi-carburetor kwenziwa ngomshini, ngokuhamba kwesikhathi idivayisi kufanele ilungiswe. Uma le nqubo yenziwa ngokungalungile, i-carburetor ingase ichithe uphethiloli, okuzoholela ephunga lesici ekamelweni.

Ukulungisa i-carburetor VAZ 2101

Ngemuva kokuqinisekisa ukuthi i-carburetor "ye-penny" idinga ukulungiswa, okokuqala udinga ukulungiselela amathuluzi adingekayo nezinto zokwakha:

- izipanela;

- amagwababa;

- isethi yama-screwdrivers (isiphambano, flat);

- amagilavu okuzivikela;

- isisombululo;

- ama-toothpicks;

- umoya ocindezelwe ikani noma iphampe;

- ikhithi yokulungisa.

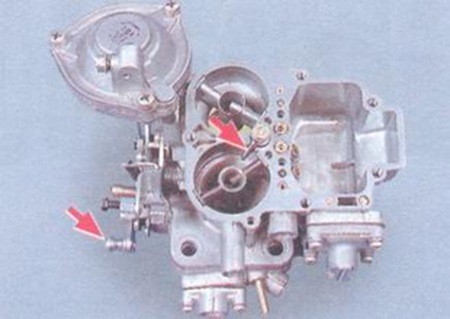

Ngemva kokulungiselela, ungaqhubeka nomsebenzi wokulungisa. Inqubo ayidingi umzamo omkhulu njengokunemba nokunemba. Ukusetha umhlangano kuhilela ukuhlanza i-carburetor, lapho i-valve ephezulu, i-float kanye ne-vacuum ikhishwa.. Ngaphakathi, yonke into ihlanzwa ngokungcola, ikakhulukazi uma ukugcinwa kwe-carburetor kwenziwa kuyaqabukela. Sebenzisa i-spray can noma i-compressor ukuze usule ama-clogs. Esinye isinyathelo esiyisibopho ngaphambi kokuqala ukulungiswa ukuhlola uhlelo lokuthungela. Ukuze wenze lokhu, hlola igebe phakathi koxhumana nabo be-distributor, ubuqotho bezintambo ze-high-voltage, amakhoyili. Ngemuva kwalokho, kusele ukufudumala injini ekushiseni okusebenzayo kuka + 90 ° C, ukuyicisha bese usetha imoto kubhuleki lokupaka.

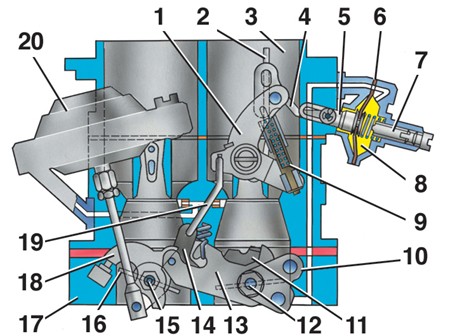

Ukulungiswa kwe-valve mpintsha

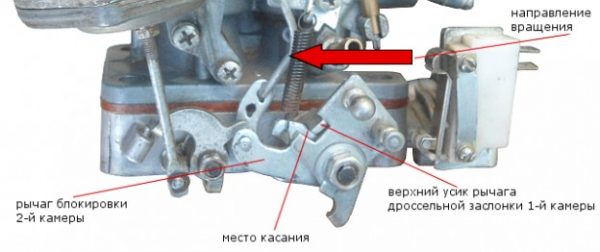

Ukusetha i-carburetor kuqala ngokubeka indawo efanele ye-throttle, lapho sikhipha khona i-carburetor enjini futhi senze lezi zinyathelo ezilandelayo:

- Vula i-lever control ye-damper ngokuphambene newashi ize ivuleke ngokugcwele.

Ukushuna kwe-carburetor kuqala ngokulungiswa kwe-throttle ngokuyizungezisa ngokuphambene newashi ize ime.

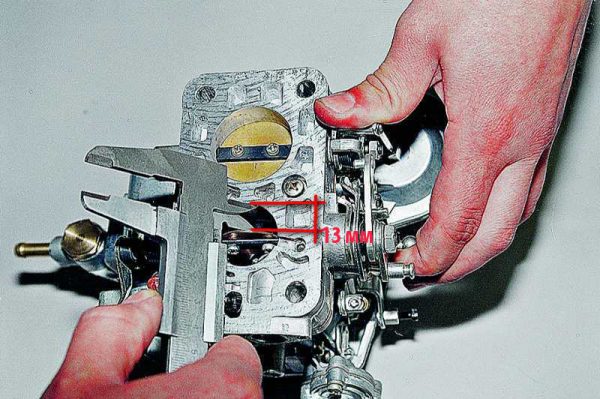

Ukushuna kwe-carburetor kuqala ngokulungiswa kwe-throttle ngokuyizungezisa ngokuphambene newashi ize ime. - Silinganisela ekamelweni lokuqala. Inkomba kufanele ibe ngu-12,5-13,5 mm. Ukuze uthole ezinye izinkomba, izimpondo zokudonsa zigobile.

Lapho uhlola igebe phakathi kwe-valve ye-throttle kanye nodonga lwegumbi eliyinhloko, inkomba kufanele ibe ngu-12,5-13,5 mm.

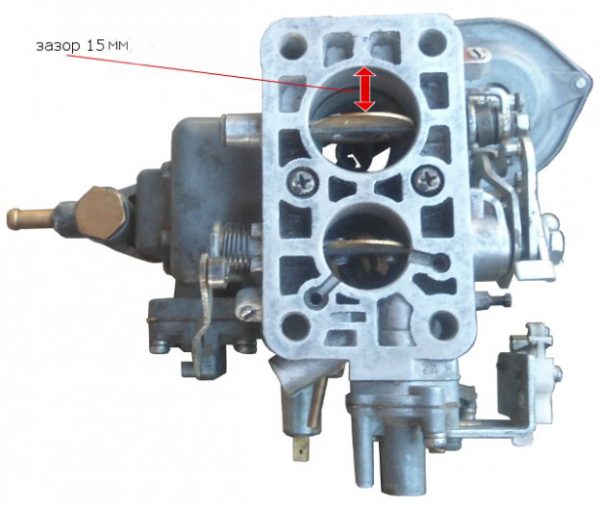

Lapho uhlola igebe phakathi kwe-valve ye-throttle kanye nodonga lwegumbi eliyinhloko, inkomba kufanele ibe ngu-12,5-13,5 mm. - Nquma inani lokuvula le-damper yegumbi lesibili. Ipharamitha ye-14,5-15,5 mm ibhekwa njengejwayelekile. Ukuze silungise, sisonta induku ye-pneumatic drive.

Igebe phakathi kwe-throttle nodonga lwegumbi lesibili kufanele libe ngu-14,5-15,5 mm.

Igebe phakathi kwe-throttle nodonga lwegumbi lesibili kufanele libe ngu-14,5-15,5 mm.

Qalisa ukulungiswa

Esigabeni esilandelayo, idivayisi yokuqala ye-VAZ 2101 carburetor ingaphansi kokulungiswa. Ukuze wenze lokhu, yenza lezi zinyathelo ezilandelayo:

- Sivula i-valve ye-throttle yegumbi lesibili, okuzoholela ekuvaleni kwayo.

- Sihlola ukuthi unqenqema lwe-thrust lever lulingana kahle ne-axis ye-throttle valve yegumbi eliyinhloko, nokuthi i-trigger rod itholakala ekugcineni kwayo. Uma ukulungiswa kuyadingeka, induku igobile.

Uma kunesidingo sokulungiswa okunjalo, kufanele kwenziwe ngokucophelela, ngoba kunamathuba amaningi okulimala ekugxilweni.

Ividiyo: indlela yokulungisa i-carburetor starter

Buka le vidiyo ku-YouTube

Ukulungiswa kwephampu ye-Accelerator

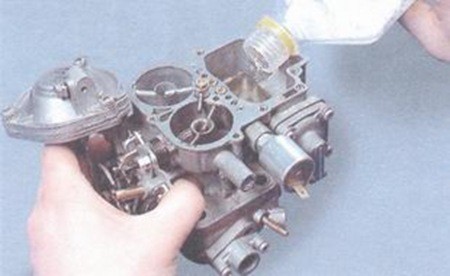

Ukuze uhlole ukusebenza kahle kwepompo ye-accelerator ye-VAZ 2101, kubalulekile ukuhlola ukusebenza kwayo. Ukuze wenze lokhu, udinga isitsha esincane, isibonelo, ibhodlela lepulasitiki elisikiwe. Bese senza lezi zinyathelo ezilandelayo:

- Sidiliza ingxenye engenhla ye-carburetor futhi isigamu sigcwalise igumbi le-float ngophethiloli.

Ukuze ulungise iphampu ye-accelerator, uzodinga ukugcwalisa igumbi le-float ngophethiloli

Ukuze ulungise iphampu ye-accelerator, uzodinga ukugcwalisa igumbi le-float ngophethiloli - Sifaka isitsha ngaphansi kwe-carburetor, sinyakaze i-throttle lever izikhathi ezingu-10 kuze kube yilapho ime.

Sihlola ukusebenza kwepompo ye-accelerator ngokuhambisa i-throttle lever counterclockwise

Sihlola ukusebenza kwepompo ye-accelerator ngokuhambisa i-throttle lever counterclockwise - Ngemva kokuqoqa uketshezi olugelezayo ku-sprayer, silinganisa ivolumu yalo ngesirinji noma ibhika. Inkomba evamile ingu-5,25–8,75 cm³ emivimbo engu-10 yomswakama.

Enkambweni yokuxilongwa, udinga ukunaka ukuma kanye nesiqondiso sejethi likaphethiloli kusuka ku-nozzle yepompo: kufanele ibe ncamashi, iqhubeke, futhi iwe ngokucacile phakathi kodonga lwe-diffuser kanye ne-damper evulekile. Uma kungenjalo, hlanza imbobo yokuvuleka ngokufutha ngomoya ocindezelwe. Uma kungenakwenzeka ukulungisa ikhwalithi nesiqondiso se-jet, i-accelerator pump sprayer kufanele ishintshwe.

Uma iphampu ye-accelerator ihlanganiswe kahle, ukunikezwa kukaphethiloli okujwayelekile kuqinisekiswa izici nobukhulu besilinganiso sepompo. Kusukela embonini, i-screw inikezwa ku-carburetor evumela ukuthi ushintshe ukunikezwa kukaphethiloli ngepompo: banganciphisa kuphela ukunikezwa kukaphethiloli, cishe okungadingeki. Ngakho-ke, futhi isikulufu akufanele sithintwe.

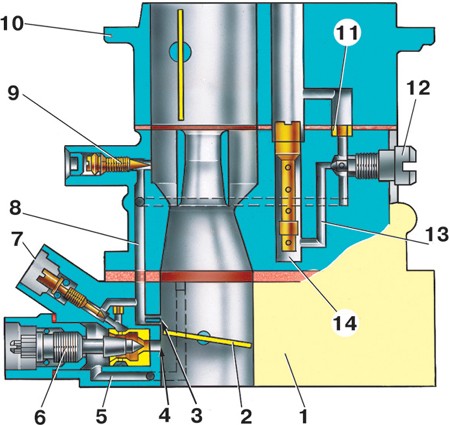

Ukulungiswa kwegumbi lokuntanta

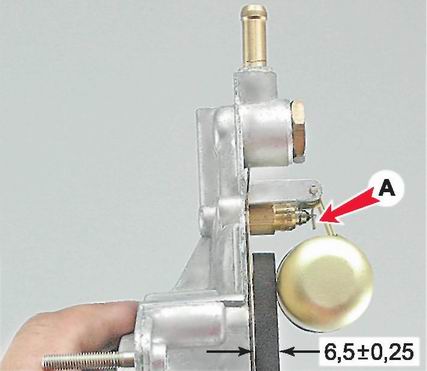

Isidingo sokulungisa izinga likaphethiloli ekamelweni lokuntanta livela lapho kushintsha izakhi zalo eziyinhloko: i-float noma i-valve. Lezi zingxenye ziqinisekisa ukunikezwa kwamafutha kanye nokugcinwa kwawo ezingeni elithile, okudingekayo ekusebenzeni okujwayelekile kwe-carburetor. Ngaphezu kwalokho, ukulungiswa kuyadingeka lapho kulungiswa i-carburetor. Ukuze uqonde ukuthi ukulungiswa kwalezi zakhi kuyadingeka yini, kuzodingeka wenze isheke. Ukuze wenze lokhu, thatha ikhadibhodi eliwugqinsi bese usika imicu emibili engu-6,5 mm no-14 mm ububanzi, ezosebenza njengesifanekiso. Bese senza lezi zinyathelo ezilandelayo:

- Ngemva kokudiliza ikhava ephezulu ku-carburetor, siyibeka ngokuqondile ukuze ulimi oluntantayo luncike ebholeni le-valve, kodwa ngesikhathi esifanayo, intwasahlobo ayicindezeli.

- Usebenzisa isifanekiso esincane, hlola ibanga phakathi kwesici sekhava ephezulu kanye nentanta. Inkomba kufanele ibe ngu-6,5 mm. Uma ipharamitha ingahambisani, sigoba ulimi A, okuyi-fastening ye-valve yenaliti.

Ukuze uhlole izinga eliphezulu likaphethiloli ekamelweni lokuntanta, phakathi kwe-float kanye ne-gasket yengxenye engenhla ye-carburetor, sincika ithempulethi engu-6,5 mm ububanzi.

Ukuze uhlole izinga eliphezulu likaphethiloli ekamelweni lokuntanta, phakathi kwe-float kanye ne-gasket yengxenye engenhla ye-carburetor, sincika ithempulethi engu-6,5 mm ububanzi. - Ukuthi i-valve yenaliti ivuleka kangakanani kuncike ekushayeni kwe-float. Sihoxisa i-float ngangokunokwenzeka futhi, usebenzisa ithempulethi yesibili, hlola igebe phakathi kwe-gasket ne-float. Inkomba kufanele ibe phakathi kuka-14 mm.

Sihoxisa i-float ngangokunokwenzeka futhi sisebenzisa ithempulethi ukuhlola ibanga phakathi kwe-gasket ne-float. Inkomba kufanele ibe ngu-14 mm

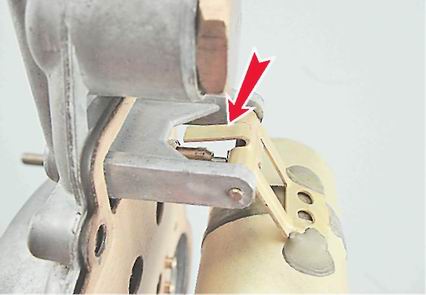

Sihoxisa i-float ngangokunokwenzeka futhi sisebenzisa ithempulethi ukuhlola ibanga phakathi kwe-gasket ne-float. Inkomba kufanele ibe ngu-14 mm - Uma kunesidingo sokulungiswa, sigoba isitobhi esikubakaki we-float.

Uma kunesidingo sokulungisa izinga likaphethiloli, sigoba isitobhi esikubakaki we-float

Uma kunesidingo sokulungisa izinga likaphethiloli, sigoba isitobhi esikubakaki we-float

Uma iflothi ilungiswa kahle, ukushaywa kwayo kufanele kube ngu-8 mm.

Ukulungiswa kwejubane lokungenzi lutho

Isinyathelo sokugcina sokulungisa i-carburetor ukusetha isivinini sokungenzi lutho senjini. Inqubo imi kanje:

- Enjinini eshisiwe ngaphambili, sigoqa ngokuphelele izikulufu zekhwalithi nobuningi.

- Siqaqa isikulufu sobuningi ngokujika oku-3, isikulufu sekhwalithi ngamajika angu-5.

- Siqala injini futhi sifinyelele inani le-screw ukuze injini isebenze ku-800 rpm. imiz.

- Vula kancane isikulufu sesibili sokulungisa, uthole ukwehla kwesivinini.

- Siqaqa isikulufu sekhwalithi ngokujika okuyingxenye futhi sisishiye kule ndawo.

Ividiyo: Ukulungiswa kwe-Weber carburetor

Buka le vidiyo ku-YouTube

Ukuhlanza nokushintsha amajethi

Ukuze "ipeni" yakho ingabangeli izinkinga mayelana nokusebenza kwenjini, ukugcinwa ngezikhathi ezithile kwesistimu yamandla futhi ikakhulukazi i-carburetor iyadingeka. Njalo ngamakhilomitha ayizinkulungwane ezingu-10, kunconywa ukuthi ushaye kuzo zonke izindiza ze-carburetor ezinomoya ocindezelwe, kuyilapho akudingekile ukususa umhlangano ku-motor. Isihlungi se-mesh esitholakala endaweni yokungena ku-carburetor naso sidinga ukuhlanzwa. Njalo ngamakhilomitha ayizinkulungwane ezingu-20, zonke izingxenye zomshini zidinga ukushaywa. Ukuze wenze lokhu, ungasebenzisa i-benzene noma uphethiloli. Uma kukhona ukungcola lokhu ketshezi olungakwazi ukukususa, khona-ke kusetshenziswa i-solvent.

Lapho uhlanza amajethi "akudala", ungasebenzisi izinto zensimbi (intambo, izinaliti, njll.). Ngalezi zinhloso, induku yokhuni noma yepulasitiki ifanelekile. Ungasebenzisa futhi i-rag engashiyi lint. Ngemuva kokuthi wonke ama-jets ahlanjululwe futhi ahlanjululwe, ahlola ukuthi lezi zingxenye zilinganiselwe imodeli ethile ye-carburetor. Izimbobo zingahlolwa ngenaliti yokuthunga enobubanzi obufanele. Uma amajethi eshintshwa, bese kusetshenziswa izingxenye ezinemingcele efanayo. Amajethi amakwe ngezinombolo ezithile ezikhombisa ukuphuma kwezimbobo zazo.

Ukumaka ngakunye kwejethi kunomphumela wako.

Ithebula: izincwadi zokumaka kanye nokuphumayo kwamajethi e-Solex ne-Ozone carburetor

| Ukumaka i-Jet | Umkhawulokudonsa |

| 45 | 35 |

| 50 | 44 |

| 55 | 53 |

| 60 | 63 |

| 65 | 73 |

| 70 | 84 |

| 75 | 96 |

| 80 | 110 |

| 85 | 126 |

| 90 | 143 |

| 95 | 161 |

| 100 | 180 |

| 105 | 202 |

| 110 | 225 |

| 115 | 245 |

| 120 | 267 |

| 125 | 290 |

| 130 | 315 |

| 135 | 340 |

| 140 | 365 |

| 145 | 390 |

| 150 | 417 |

| 155 | 444 |

| 160 | 472 |

| 165 | 500 |

| 170 | 530 |

| 175 | 562 |

| 180 | 594 |

| 185 | 627 |

| 190 | 660 |

| 195 | 695 |

| 200 | 730 |

Umthamo wezimbobo uvezwa ngo-cm³/min.

Ithebula: ukumakwa kwejethi ye-carburetor ye-VAZ 2101

| Ukuqokwa kwe-Carburetor | Indiza yamafutha yesistimu eyinhloko | Ijethi yomoya yesistimu eyinhloko | Ijethi yamafutha engasebenzi | Indiza yomoya engenzi lutho | I-Accelerator pump jet | |||||

| 1 igumbi | 2 igumbi | 1 igumbi | 2 igumbi | 1 igumbi | 2 igumbi | 1 igumbi | 2 igumbi | uphethiloli | dlula | |

| 2101-1107010 | 135 | 135 | 170 | 190 | 45 | 60 | 180 | 70 | 40 | 40 |

| 2101-1107010-02 | 130 | 130 | 150 | 190 | 50 | 45 | 170 | 170 | 50 | 40 |

| 2101-1107010-03; 2101-1107010-30 | 130 | 130 | 150 | 200 | 45 | 60 | 170 | 70 | 40 | 40 |

| 2103-1107010 | 135 | 140 | 170 | 190 | 50 | 80 | 170 | 70 | 40 | 40 |

| 2103-1107010-01; 2106-1107010 | 130 | 140 | 150 | 150 | 45 | 60 | 170 | 70 | 40 | 40 |

| 2105-1107010-10 | 109 | 162 | 170 | 170 | 50 | 60 | 170 | 70 | 40 | 40 |

| 2105-110711010; 2105-1107010; 2105-1107010-20 | 107 | 162 | 170 | 170 | 50 | 60 | 170 | 70 | 40 | 40 |

| 21053 | 100 | 115 | 150 | 135 | 35-45 | 50 | 140 | 150 | 45 | 40 |

| 2107-1107010; 2107-1107010-20 | 112 | 150 | 150 | 150 | 50 | 60 | 170 | 70 | 40 | 40 |

| 2107-1107010-10 | 125 | 150 | 190 | 150 | 50 | 60 | 170 | 70 | 40 | 40 |

| 2108-1107010 | 97,5 | 97,5 | 165 | 125 | I-42 ± 3 | 50 | 170 | 120 | 30/40 | - |

Naphezu kweqiniso lokuthi izimoto carburetor izinjini akhiqizwa namuhla, kukhona impela eziningi izimoto amandla amayunithi, kuhlanganise phakathi umndeni Zhiguli. Ngokulungiswa okufanele futhi okufika ngesikhathi kwe-carburetor, iyunithi izosebenza isikhathi eside ngaphandle kwezikhalazo. Uma kuphakama izinkinga, kungcono ukungalibali ukulungisa, ngoba ukusebenza kahle kwenjini kuphazamiseka, okuholela ekwandeni kokusetshenziswa kukaphethiloli kanye nokuwohloka kwamandla.