Iyini isilinganiso sokucindezela senjini evuthayo yangaphakathi

Esinye sezici ezibalulekile zokuklama zenjini evuthayo yangaphakathi ye-piston isilinganiso sokucindezela. Le parameter ithinta amandla enjini yomlilo yangaphakathi, ukusebenza kahle kwayo, kanye nokusetshenziswa kukaphethiloli. Phakathi naleso sikhathi, bambalwa abantu abanombono weqiniso walokho okushiwo ngezinga lokucindezelwa. Abantu abaningi bacabanga ukuthi lokhu kungumqondo ofanayo wokucindezelwa. Nakuba lokhu kwakamuva kuhlobene nezinga lokucindezelwa, nokho, lezi yizinto ezihluke ngokuphelele.

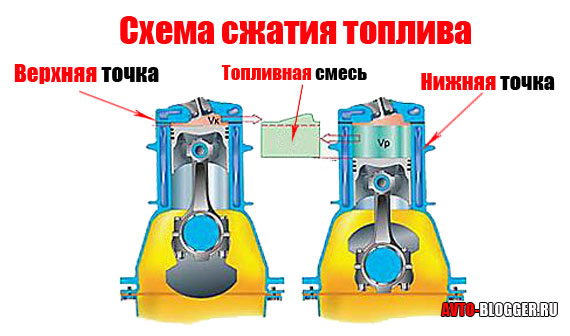

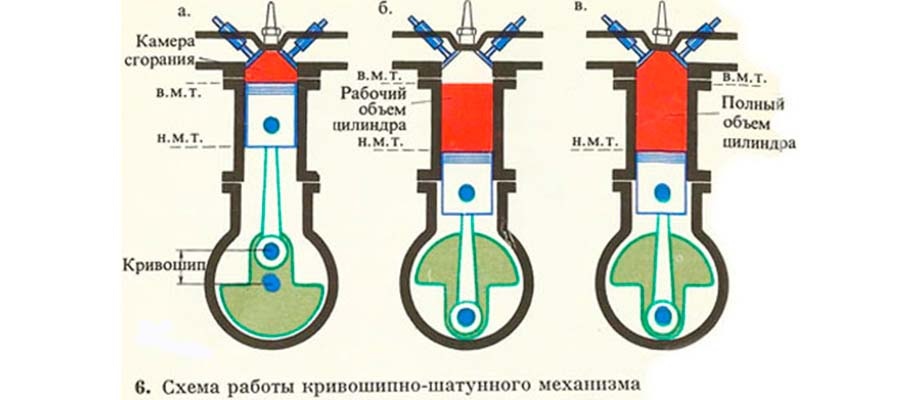

Ukuze uqonde amagama, udinga ukuqonda ukuthi isilinda seyunithi yamandla sihlelwa kanjani, futhi uqonde isimiso sokusebenza kwenjini yangaphakathi yomlilo. Ingxube evuthayo ijovwa kumasilinda, bese icindezelwa yipiston esuka esikhungweni esiphansi esifile (BDC) iye endaweni ephezulu efile (TDC). Ingxube ecindezelwe ngesikhathi esithile eduze ne-TDC iyavutha futhi iphele. Igesi ekhulayo yenza umsebenzi wemishini, iphusha i-piston kwelinye icala - ku-BDC. Ixhunywe ku-piston, induku yokuxhuma isebenza ku-crankshaft, ibangele ukuthi ijikeleze.

Isikhala esiboshwe izindonga zangaphakathi zesilinda ukusuka ku-BDC kuya ku-TDC umthamo wokusebenza we-cylinder. Ifomula yezibalo yokususwa kwesilinda esisodwa imi kanje:

Vₐ = πr²s

lapho u-r eyirediyasi yengxenye engaphakathi yesilinda;

s ibanga ukusuka ku-TDC ukuya ku-BDC (ubude be-piston stroke).

Uma i-piston ifika ku-TDC, sisekhona isikhala ngaphezu kwayo. Leli yigumbi lomlilo. Ukuma kwengxenye engenhla yesilinda kuyinkimbinkimbi futhi kuncike kumklamo othize. Ngakho-ke, akunakwenzeka ukuveza ivolumu Vₑ yegumbi lomlilo nganoma iyiphi ifomula eyodwa.

Ngokusobala, isamba sevolumu yesilinda Vₒ silingana nesamba sevolumu yokusebenza kanye nevolumu yegumbi lomlilo:

Vₒ = Vₐ+Vₑ

Futhi isilinganiso sokucindezela isilinganiso sevolumu ephelele yesilinda kuya kuvolumu yegumbi lomlilo:

ε = (Vₐ+Vₑ)/Vₑ

Leli nani alinamkhawulo, futhi empeleni libonisa ushintsho oluhlobene nokucindezela kusukela ngesikhathi ingxube ijovwa kusilinda kuze kube yisikhathi sokuthungela.

Kungabonakala kufomula ukuthi kungenzeka ukwandisa isilinganiso sokucindezela noma ngokukhulisa umthamo wokusebenza we-cylinder, noma ngokunciphisa umthamo wekamelo lomlilo.

Ezinjini ezihlukahlukene zangaphakathi ezivuthayo, le pharamitha ingase ihluke futhi inqunywe uhlobo lweyunithi nezici zomklamo wayo. Isilinganiso sokucindezelwa kwezinjini zesimanje zikaphethiloli zangaphakathi zisebangeni elisuka ku-8 kuye ku-12, kwezinye izimo lingafinyelela ku-13 ... 14. Ngezinjini ze-diesel, iphakeme futhi ifinyelela ku-14 ... 18, lokhu kungenxa yezici zenqubo yokuthungela ingxube yedizili.

Futhi mayelana nokucindezelwa, lokhu ukucindezela okukhulu okwenzeka kusilinda njengoba ipiston isuka ku-BDC iye ku-TDC. Iyunithi ye-SI yamazwe ngamazwe yokucindezela i-pascal (Pa/Pa). Amayunithi okulinganisa afana nebha (ibha) nomoya (at / at) nawo asetshenziswa kabanzi. Isilinganiso seyunithi sithi:

1 at = 0,98 ibha;

1 ibha = 100 Pa

Ngaphezu kwezinga lokucindezela, ukwakheka kwengxube evuthayo kanye nesimo sobuchwepheshe senjini evuthayo yangaphakathi, ikakhulukazi izinga lokugqoka izingxenye zeqembu le-cylinder-piston, lithinta ukucindezela.

Ngokunyuka kwesilinganiso sokucindezela, ingcindezi yamagesi ku-piston iyanda, okusho ukuthi, ekugcineni, amandla ayanda kanye nokusebenza kahle kwenjini yomlilo yangaphakathi kwanda. Ukushiswa okuphelele okwengeziwe kwengxube kuholela ekusebenzeni okuthuthukisiwe kwemvelo futhi kunomthelela ekusebenziseni uphethiloli ukonga.

Kodwa-ke, amathuba okwandisa isilinganiso sokucindezela anqunyelwe ingozi yokuqhunyiswa. Kule nqubo, ingxube ye-air-fuel ayishisi, kodwa iyaqhuma. Umsebenzi owusizo awenziwa, kodwa ama-piston, amasilinda kanye nezingxenye ze-crank mechanism kuba nomthelela omkhulu, okuholela ekugugeni kwawo ngokushesha. Ukushisa okuphezulu ngesikhathi sokuqhunyiswa kungabangela ukushiswa kwama-valve kanye nendawo yokusebenza yama-pistons. Ngokwezinga elithile, uphethiloli onezinga eliphezulu le-octane usiza ukubhekana nokuqhunyiswa.

Enjinini ye-diesel, i-detonation nayo ingenzeka, kodwa lapho kubangelwa ukulungiswa okungalungile komjovo, umsizi endaweni engaphakathi yamasilinda, nezinye izizathu ezingahlobene nokwenyuka kwesilinganiso sokucindezela.

Kungenzeka ukuphoqa iyunithi ekhona ngokukhulisa umthamo wokusebenza wamasilinda noma isilinganiso sokucindezela. Kodwa lapha kubalulekile ukuthi ungayidluli futhi ubale ngokucophelela yonke into ngaphambi kokugijimela empini. Amaphutha angaholela ekungalinganisweni okunjalo ekusebenzeni kweyunithi nokuqhunyiswa okungaze kusize uphethiloli we-octane ephezulu noma ukulungiswa kwesikhathi sokubasa okuzosiza.

Alikho iphuzu ekuphoqeni injini ekuqaleni enezinga eliphezulu lokucindezela. Izindleko zomzamo kanye nemali zizoba zikhulu kakhulu, futhi ukwanda kwamandla kungenzeka kube okungasho lutho.

Umgomo oyifunayo ungafinyelelwa ngezindlela ezimbili - ngokubhokisa amasilinda, okuzokwenza umthamo wokusebenza wenjini yangaphakathi yomlilo ube mkhulu, noma ngokugaya indawo ephansi (ikhanda le-cylinder).

Isilinda kuyisicefe

Isikhathi esihle salokhu yilapho kufanele ubhoboze amasilinda noma kunjalo.

Ngaphambi kokwenza lo msebenzi, udinga ukukhetha ama-piston namaringi osayizi omusha. Cishe ngeke kube nzima ukuthola izingxenye zokulungisa izilinganiso zale injini evuthayo yangaphakathi, kodwa lokhu ngeke kunikeze ukwanda okuphawulekayo komthamo wokusebenza namandla enjini, njengoba umehluko ngosayizi mncane kakhulu. Kungcono ukubheka ama-piston ama-diameter amakhulu namaringi amanye amayunithi.

Akufanele uzame ukubhoboza amasilinda ngokwakho, ngoba lokhu akudingi ikhono kuphela, kodwa futhi nemishini ekhethekile.

Ukuqedelwa kwekhanda lesilinda

Ukugaya indawo engezansi yekhanda le-cylinder kuzonciphisa ubude besilinda. Igumbi lomlilo, elitholakala ngokwengxenye noma ngokuphelele ekhanda, lizoba lifushane, okusho ukuthi isilinganiso sokucindezela sizokhula.

Mayelana nezibalo ezilinganiselwe, kungacatshangwa ukuthi ukususa ungqimba lwekota yemilimitha kuzonyusa isilinganiso sokucindezela cishe ingxenye eyodwa kweshumi. Isilungiselelo esihle sizonikeza umphumela ofanayo. Ungakwazi futhi ukuhlanganisa eyodwa nomunye.

Ungakhohlwa ukuthi ukuphothulwa kwekhanda kudinga ukubala okunembile. Lokhu kuzogwema isilinganiso sokucindezela ngokweqile nokuqhunyiswa okungalawuleki.

Ukuphoqa injini evuthayo yangaphakathi ngale ndlela kugcwele enye inkinga engaba khona - ukufinyeza isilinda kwandisa ingozi yokuthi ama-piston ahlangane nama-valve.

Phakathi kwezinye izinto, kuyodingeka futhi ukulungisa kabusha isikhathi se-valve.

Isilinganiso sevolumu yekamelo lomlilo

Ukuze ubale isilinganiso sokucindezela, udinga ukwazi umthamo wegumbi lomlilo. Ukuma kwangaphakathi okuyinkimbinkimbi kwenza kungenzeki ukubala umthamo wayo ngokwezibalo. Kodwa kunendlela elula yokuyilinganisa. Ukuze wenze lokhu, ipiston kufanele ibekwe phezulu endaweni efile bese usebenzisa isirinji enevolumu elinganiselwa ku-20 cm³, uthele uwoyela noma olunye uketshezi olufanelekile ngembobo ye-spark plug kuze kugcwale ngokuphelele. Bala ukuthi mangaki amakhyubhu owathelile. Lokhu kuzoba umthamo wegumbi lomlilo.

Ivolumu yokusebenza yesilinda esisodwa inqunywa ngokuhlukanisa ivolumu yenjini evuthayo yangaphakathi ngenani lamasilinda. Ngokwazi kokubili amanani, ungakwazi ukubala isilinganiso sokucindezela usebenzisa ifomula engenhla.

Ukuhlinzwa okunjalo kungase kudingeke, isibonelo, ukushintshela kuphethiloli oshibhile. Noma udinga ukuhlehla uma injini ingaphumelelanga. Khona-ke, ukuze babuyele ezindaweni zabo zasekuqaleni, i-cylinder head gasket eqinile noma ikhanda elisha liyadingeka. Njengenketho, sebenzisa ama-spacers amabili ajwayelekile, lapho kungafakwa khona ukufakwa kwe-aluminium. Ngenxa yalokho, igumbi lomlilo lizokhula, futhi isilinganiso sokucindezela sizokwehla.

Enye indlela ukususa ungqimba lwensimbi endaweni yokusebenza yamapiston. Kodwa indlela enjalo izoba yinkinga uma indawo yokusebenza (phansi) ine-convex noma i-concave shape. Ukuma okuyinkimbinkimbi komqhele we-piston kuvame ukwenziwa ukuze kuthuthukiswe inqubo yokuvutha kwengxube.

Kuma-ICE amadala e-carburetor, ukuphoqa akubangeli izinkinga. Kodwa ukulawulwa nge-elekthronikhi kwezinjini zesimanje ezivuthayo zangaphakathi emva kwenqubo enjalo kungase kube iphutha ekulungiseni isikhathi sokuthungela, bese ukuqhunyiswa kungase kwenzeke uma kusetshenziswa uphethiloli we-octane ephansi.