Izakhiwo eziyingqayizivele zamabhuleki e-ceramic

Amabhuleki edisc ajwayelekile ahlanganisa insimbi eyinsimbi noma amadiski ensimbi namaphedi lapho isigcwalisi siqiniswa ngokushefa kwensimbi. Lapho i-asbestos iyisisekelo se-friction linings, kwakungekho mibuzo ekhethekile mayelana nokubunjwa, kodwa-ke kwavela ukuthi imicu ye-asbestos nothuli olukhishwe ngesikhathi sokubhuleka kunezindawo ezinamandla ze-carcinogenic. Ukusetshenziswa kwe-asbestos kwavinjelwa, futhi izinhlanganisela ezihlukahlukene zezinto eziphilayo zaqala ukusetshenziswa kumaphedi. Izakhiwo zabo zivele azanele ngaphansi kwezimo ezimbi kakhulu.

Kuyini i-ceramics futhi kungani kunjalo

I-Ceramics ingabhekwa noma yini engeyona into ephilayo noma yensimbi. Kube yizindawo zayo okuvele ukuthi yiyona edingekayo ukuze kushayisane amabhuleki ezimoto asebenza ngaphansi kwezimo ezinzima.

I-disc brake inezinzuzo ezinhle kakhulu kunezinye, kodwa isici sayo yindawo encane ye-pad. Futhi amandla amabhuleki aphezulu asho ukukhululwa ngokushesha kwesamba esikhulu samandla ashisayo. Njengoba wazi, amandla alingana namandla kanye nesikhathi akhishelwa ngaso. Futhi zombili zinquma ukusebenza kahle kwe-braking yemoto.

Ukukhululwa kwamandla abalulekile ngevolumu elinganiselwe ngesikhathi esifushane, okungukuthi, lapho ukushisa kungenaso isikhathi sokuhlakazeka endaweni ezungezile, ngokuhambisana ne-physics efanayo, kuholela ekwandeni kwezinga lokushisa. Futhi lapha izinto zendabuko okwenziwa kuzo ama-brake linings azikwazi ukubhekana nazo. Ukusetshenziswa kwamadiski ane-ventilated kungazinzisa umbuso oshisayo esikhathini eside, kodwa akulondolozi ekushiseni okweqile kwendawo endaweni yokuxhumana. I-pad material iyahwamuka ngokoqobo, futhi izingxenye eziwumphumela zakha indawo eshelelayo, i-coefficient yokushayisana yehla kakhulu, futhi amabhuleki ayahluleka.

I-Ceramics esekelwe ezintweni ezihlukahlukene ze-inorganic, ngokuvamile i-silicon carbide, ingamelana namazinga okushisa aphezulu kakhulu. Ngaphezu kwalokho, lapho zifudumala, zifaka kuphela imodi elungile, zinikeze i-coefficient ephezulu kakhulu yokungqubuzana.

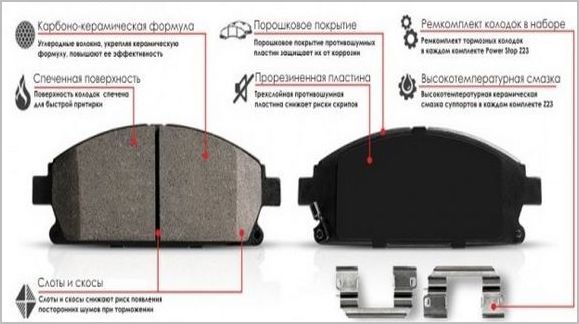

Ngaphandle kokuqiniswa, i-lining ngeke ikwazi ukuba namandla anele; ngenxa yalokhu, imicu ehlukahlukene yethulwa ekubunjweni. Ngokuvamile kuba shavings zethusi, carbon fiber isetshenziswa amabhuleki ezemidlalo. Izinto zokuqinisa zixubene ne-ceramics futhi zibhakwa ekushiseni okuphezulu.

Kuye ngohlobo lwesicelo, ukwakheka kwamaphedi kungase kuhluke. Lokhu kunqunywa inhloso yamabhuleki, umgwaqo, ezemidlalo noma amaphedi ohlobo oludlulele agqamile. Anamazinga okushisa okusebenza ahlukene kanye namandla okukhawulela. Kepha okujwayelekile kuzoba ukwanda kokusebenza kahle komsebenzi ezimeni ezinzima:

- ukuzinza kwe-coefficient ye-friction;

- ukunciphisa ukugqoka ama-disc;

- ukunciphisa umsindo wokusebenza nomthwalo wokudlidliza;

- ukumelana okuphezulu nokuphepha kwezinto emazingeni okushisa aphezulu okusebenza.

Ngokusetshenziswa kwe-ceramics, akwenziwanga kuphela ama-pads, kodwa nama-discs. Ngasikhathi sinye, ukugqoka okuphezulu akubonwa uma kwenzeka ukusetshenziswa okuxubile, amaphedi e-ceramic awaholeli ekusulweni okusheshayo kwensimbi namadiski ensimbi. Ama-rotor Ceramic (ama-discs) ahlukaniswa ngamandla aphezulu ngaphansi kwezimo zokulayisha ezishisayo, okwenza kube nokwenzeka ukungenzi kube mkhulu ngokungamukeleki, futhi futhi ungashiyi ukuguqulwa okusele ngesikhathi sokupholisa okungazelelwe. Futhi ngokufudumeza okunjalo, ngisho nokupholisa kwemvelo kuholela ekushintsheni okuphawulekayo kwezinga lokushisa ngesikhathi esilinganiselwe.

Ubuhle nobubi bamabhuleki e-ceramic

Sekuvele kushiwo mayelana nezinzuzo ze-ceramics, kunganezelwa ngezinto ezingacacile kangako:

- Izindlela ezinjalo zinesisindo esincane kanye nobukhulu obusebenza ngokulinganayo, okunciphisa inkomba ebalulekile ye-suspension dynamics njengesisindo esingaphumi;

- akukho ukukhululwa kwezinto eziyingozi endaweni ezungezile;

- ngokunyuka kwezinga lokushisa, ukusebenza kahle kwamabhuleki akunciphisi, kodwa kunalokho kuyanda, ngezinye izikhathi kudinga ukushisa kwangaphambili;

- izinto eziqinisayo azikho ngaphansi kokugqwala kwezinga lokushisa eliphezulu;

- izakhiwo ze-ceramics zibikezelwe kahle futhi zihlelwe lapho kukhethwa iresiphi, okwenza kube nokwenzeka ukukhiqiza izingxenye ezifanayo zezinhlelo zokusebenza ezihlukahlukene;

- inhlanganisela yezingxenye eziqukethe i-ferro nge-ceramic zingenzeka, akudingekile ukusebenzisa ama-disc afanayo kuma-ceramic pads;

- izingxenye ze-ceramic ziqinile kakhulu uma zisebenza ezimweni ezithambile.

Ayikwazanga ukwenza ngaphandle kwamaminithi, kodwa awekho amaningi awo ngokumelene nesizinda sezinzuzo:

- amabhuleki e-ceramic asabiza kakhulu;

- ikakhulukazi izingoma ezisebenzayo zidinga ukushisa kwangaphambili, njengoba i-coefficient of friction iyancipha ngokunciphisa izinga lokushisa;

- ngaphansi kwenhlanganisela ethile yezimo, bangakha i-creak okunzima ukuyikhipha.

Ngokusobala, izingxenye ze-ceramic brake azikho enye indlela ekushayeleni okunomoya kanye nezemidlalo. Kwezinye izimo, intengo yazo ephezulu yenza umuntu acabange ngokufaneleka kokusetshenziswa kwazo.