Ukushisela umzimba wemoto: ungakwenza kanjani ngokwakho

Okuqukethwe

Impilo yesevisi yemizimba yemoto yesimanje ayikwazi ukubizwa ngokuthi yinde. Ezimotweni zasekhaya, isikhathi esiphezulu seminyaka eyishumi. Izidumbu zezimoto zesimanje zakwamanye amazwe ziphila isikhathi eside - cishe iminyaka eyishumi nanhlanu. Ngemuva kwalesi sikhathi, umnikazi wemoto uzoqala ukubona izimpawu zokubhujiswa, okuzodingeka kwenziwe okuthile. Ngaphezu kwalokho, umzimba ungalimala ngesikhathi sengozi. Kungakhathaliseki ukuthi yisiphi isizathu, ikhambi lihlala lifana: thumba. Uma uqiniseka ngamakhono akho, ungazama ukwenza i-welding yomzimba wemoto ngezandla zakho.

Okuqukethwe

- 1 Izinhlobo nezici zemishini yokushisela

- 1.1 Welding Semiautomatic

- 1.2 Indlela yokupheka nge-inverter

- 1.3 Ngakho iyiphi indlela okufanele ukhethe?

- 2 Ukulungiswa nokuqinisekiswa kwemishini

- 2.1 Ukulungiselela i-semi-automatic welding yomzimba wemoto

- 2.2 Yini okufanele yenziwe ngaphambi kokuqala i-inverter

- 3 Izinyathelo Zokushisela

- 4 Inqubo ye-Semi-automatic car body welding

- 4.1 Amathuluzi we-DIY nezinto zokwakha

- 4.2 Ukulandelana kwemisebenzi ye-semi-automatic welding

- 4.3 Ukwelashwa komthungo we-Weld ngokumelene nokugqwala

Izinhlobo nezici zemishini yokushisela

Ukukhethwa kobuchwepheshe be-welding akuxhomekile kakhulu emshinini nasezintweni ezisetshenziswayo, kodwa endaweni yomonakalo. Ake sibhekisise.

Welding Semiautomatic

Iningi labanikazi bezimoto kanye nabasebenzi benkonzo yezimoto bakhetha ukusebenzisa imishini ye-semi-automatic. Isizathu esiyinhloko sokuthandwa kwabo kulula. Ngedivayisi ye-semi-automatic, ungakwazi ukupheka ngisho nomonakalo omncane otholakala ezindaweni ezingalungile kakhulu emzimbeni wemoto.

Ngobuchwepheshe, lobu buchwepheshe bucishe bufane ne-welding yendabuko: idivayisi ye-semi-automatic nayo idinga isiguquli samanje. Umehluko kuphela ezintweni ezisetshenziswayo. Lolu hlobo lwe-welding aludingi ama-electrode, kodwa ucingo olukhethekile oluboshwe ngethusi, ububanzi balo bungahluka kusuka ku-0.3 kuya ku-3 mm. Futhi umshini we-semi-automatic udinga isikhutha ukuze usebenze.

Ithusi ocingweni linikeza ukuthintana okuthembekile kagesi futhi lisebenza njenge-welding flux. Futhi i-carbon dioxide, ehlinzekwa ngokuqhubekayo ku-arc yokushisela, ayivumeli umoya-mpilo ovela emoyeni ukuba usabele lapho insimbi ishiselwa. I-semi-automatic inezinzuzo ezintathu ezibalulekile:

- isivinini sokuphakela ngocingo kudivayisi ye-semiautomatic singalungiswa;

- ama-semi-automatic seams ahlanzekile futhi amancane kakhulu;

- ungasebenzisa idivayisi ye-semiautomatic ngaphandle kwe-carbon dioxide, kodwa kulokhu kuzodingeka usebenzise ucingo olukhethekile lwe-welding, oluqukethe i-flux.

Kukhona futhi ukungalungi endleleni ye-semi-automatic:

- akulula kakhulu ukuthola ama-electrode angenhla ane-flux ethengiswayo, futhi abiza okungenani kabili njengokujwayelekile;

- uma usebenzisa i-carbon dioxide, akwanele ukuthola isilinda ngokwayo. Uzodinga futhi i-pressure reducer, okuzodinga ukulungiswa ngokunembile kakhulu, ngaphandle kwalokho ungakhohlwa ngama-seams aphezulu.

Indlela yokupheka nge-inverter

Ngamafuphi, i-inverter isengumshini ofanayo we-welding, kuphela imvamisa yamanje yokuguqulwa kuyo akuyona i-50 Hz, kodwa i-30-50 kHz. Ngenxa yokwanda kwemvamisa, i-inverter inezinzuzo ezimbalwa:

- ubukhulu bomshini wokushisela inverter buhlangene kakhulu;

- ama-inverters awazwani ne-voltage yamapayipi amakhulu aphansi;

- ama-inverters awanazo izinkinga ngokushiswa kwe-arc welding;

- ngisho ne-novice welder ingasebenzisa i-inverter.

Yebo, kukhona futhi nokubi:

- enqubweni yokushisela, kusetshenziswa ama-electrode awugqinsi anobubanzi obungu-3-5 mm, hhayi ucingo;

- ngesikhathi se-inverter welding, imiphetho yensimbi ehlanganisiwe ishisa kakhulu, engabangela ukuguqulwa kokushisa;

- umthungo uhlala ujiyile kunalapho ushisela ngomshini ozishintshayo.

Ngakho iyiphi indlela okufanele ukhethe?

Isincomo esijwayelekile silula: uma uhlela ukushisela ingxenye yomzimba osobala, futhi umnikazi wemoto akaphoqwa yimali futhi unokuhlangenwe nakho okuthile ngomshini wokushisela, khona-ke idivaysi ye-semiautomatic iyindlela engcono kakhulu. Futhi uma umonakalo ungabonakali ohlangothini (isibonelo, phansi kwalimala) futhi umnikazi womshini akazi kahle nge-welding, ngakho-ke kungcono ukupheka nge-inverter. Ngisho noma oqalayo enza iphutha, intengo yayo ngeke ibe phezulu.

Ukulungiswa nokuqinisekiswa kwemishini

Kungakhathaliseki ukuthi iyiphi indlela ye-welding ekhethiwe, inani lemisebenzi yokulungiselela kufanele yenziwe.

Ukulungiselela i-semi-automatic welding yomzimba wemoto

- ngaphambi kokuqala umsebenzi, umshicileli kufanele aqinisekise ukuthi umzila wokuqondisa kuthoshi lokushisela ufana nobubanzi bocingo olusetshenzisiwe;

- ububanzi bocingo kufanele bucatshangelwe lapho ukhetha ithiphu le-welding;

- umlomo wombhobho we-apparatus uhlolelwa ama-splashes ensimbi. Uma zikhona, kufanele zisuswe nge-sandpaper, ngaphandle kwalokho i-nozzle izohluleka ngokushesha.

Yini okufanele yenziwe ngaphambi kokuqala i-inverter

- ukuthembeka kwe-electrode fastenings kuhlolwa ngokucophelela;

- ubuqotho be-insulation kuzintambo, konke ukuxhuma kanye nesibambi sikagesi kuhlolwe;

- ukuthembeka kokuzibopha kwekhebula le-welding eliyinhloko liyahlolwa.

Izinyathelo Zokushisela

- wonke umsebenzi wokushisela wenziwa kuphela kuma-ovaroli omile enziwe ngezinto ezingashi, amagilavu kanye ne-mask yokuzivikela. Uma ukushisela kwenziwa ekamelweni elinesitezi sensimbi, kuphoqelekile ukusebenzisa i-rubberized mat noma izicathulo zenjoloba;

- umshini wokushisela, kungakhathaliseki uhlobo lwawo, kufanele uhlale uphansi;

- ku-inverter welding, ukunakwa okukhethekile kufanele kukhokhwe kukhwalithi yomnikazi we-electrode: abanikazi be-electrode abahle bangakwazi ukumelana neziqeshana ze-electrode ezingafika ku-7000 ngaphandle kokulimaza ukufakwa;

- kungakhathaliseki ukuthi hlobo luni lomshini wokushisela, ama-circuit breakers kufanele asetshenziswe njalo kuwo, aphule ngokuzimela umjikelezo kagesi lapho kwenzeka i-idling current;

- Igumbi okwenziwa kulo ukushisela kufanele libe nomoya omuhle. Lokhu kuzogwema ukunqwabelana kwamagesi akhishwe ngesikhathi senqubo yokushisela futhi kumelela ingozi ethile ohlelweni lokuphefumula lomuntu.

Inqubo ye-Semi-automatic car body welding

Okokuqala, ake sinqume ngemishini edingekayo.

Amathuluzi we-DIY nezinto zokwakha

- Umshini wokushisela oyi-Semi-automatic BlueWeld 4.135.

- I-Welding wire ene-copper coating, ububanzi obuyi-1 mm.

- I-sandpaper enkulu.

- Isinciphisi sokunciphisa ingcindezi.

- Isilinda se-carbon dioxide esinamandla angama-20 amalitha.

Ukulandelana kwemisebenzi ye-semi-automatic welding

- ngaphambi kwe-welding, indawo eyonakalisiwe ihlanzwa kukho konke ukungcola nge-sandpaper: ukugqwala, i-primer, upende, amafutha;

- izingxenye zensimbi ezishiselwe zicindezelwe ngokuqinile komunye nomunye (uma kunesidingo, kuvunyelwe ukusebenzisa ama-clamps ahlukahlukene, ama-bolts esikhashana noma izikulufo zokuzishaya);

- khona-ke kufanele ufunde ngokucophelela iphaneli yangaphambili yomshini wokushisela. Kukhona: i-switch, isilawuli samanje se-welding kanye nomlawuli wejubane lokuphakelayo ngocingo;

Indawo yamaswishi kuphaneli yangaphambili ye-BlueWeld welder

- manje i-reducer ixhunywe kusilinda se-carbon dioxide njengoba kuboniswe esithombeni;

Igiya lokunciphisa lixhunywe kusilinda se-carbon dioxide

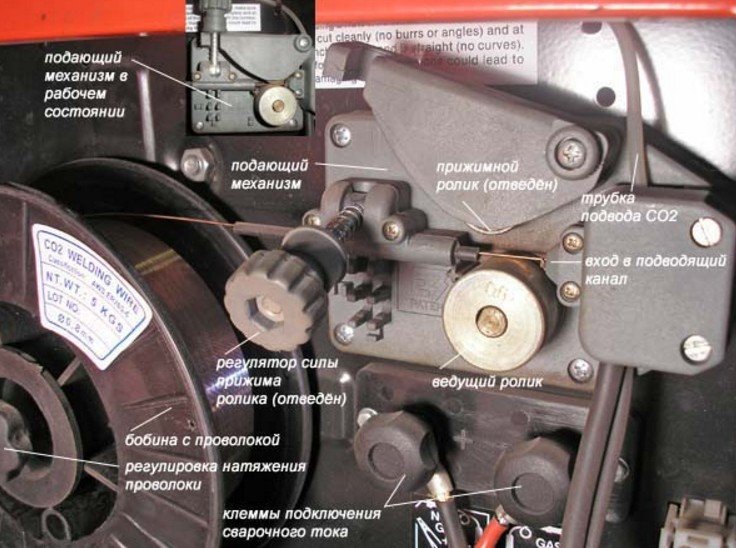

- i-bobbin ene-welding wire igxiliwe ku-apparatus, emva kwalokho ukuphela kocingo kufakwa ku-feeder;

Intambo yokushisela ifakwa esiphakelini

- i-nozzle ku-burner ikhishwe ngamapulangwe, ucingo lufakwe emgodini, emva kwalokho i-nozzle ibuyele emuva;

Ukukhipha umlomo wombhobho kuthoshi lokushisela

- Ngemva kokushaja idivayisi ngocingo, usebenzisa amaswishi ephaneli elingaphambili ledivayisi, i-polarity ye-welding current isethiwe: ukuhlanganisa kufanele kube kumnikazi we-electrode, kanye nokususa ku-burner (lokhu okubizwa ngokuthi i-polarity eqondile, ebekwe lapho isebenza ngocingo lwethusi Uma i-welding yenziwa ngocingo olujwayelekile ngaphandle kwe-copper coating , khona-ke i-polarity kufanele iguqulwe;

- umshini manje uxhumeke kunethiwekhi. Ithoshi elinesibambi se-electrode ilethwa endaweni elungiselelwe ngaphambilini ukuze ishiselwe. Ngemva kokucindezela inkinobho kumnikazi we-electrode, ucingo olushisayo luqala ukuphuma ku-nozzle, ngesikhathi esifanayo ukunikezwa kwe-carbon dioxide kuvula;

Inqubo yokushisela umzimba wemoto ngomshini we-semi-automatic

- uma i-weld inde, khona-ke i-welding yenziwa ngezigaba eziningana. Okokuqala, indawo okufanele ishiselwe "i-tacked" ngamaphuzu amaningana. Khona-ke ama-seams ama-2-3 amafushane ayenziwa eduze komugqa wokuxhuma. Kufanele ziqhelelane ngamasentimitha ayi-7-10. Lezi zithungo kufanele zivunyelwe ukuba zipholile imizuzu emi-5;

Ama-pre-seams amaningana amafushane

- futhi kuphela ngemva kwalokho izigaba ezisele ekugcineni zixhunyiwe.

Amaphethelo omzimba owonakele ashiselwe unomphela

Ukwelashwa komthungo we-Weld ngokumelene nokugqwala

Ekupheleni kwe-welding, umthungo kufanele uvikelwe, ngaphandle kwalokho uzowa ngokushesha. Izinketho ezilandelayo zingenzeka:

- uma umthungo ungabonakali futhi usendaweni efinyeleleka kalula, khona-ke umbozwa ngezendlalelo ezimbalwa ze-automotive seam sealant (ngisho nesabelomali inketho yengxenye eyodwa, njengoMzimba 999 noma i-Novol, izokwenza). Uma kunesidingo, i-sealant ifakwe nge-spatula futhi ipendwe;

- uma i-weld iwela emgodini wangaphakathi onzima ukufinyelela odinga ukucutshungulwa ngaphakathi, khona-ke kusetshenziswa izifutho zokulondolozwa kwe-pneumatic. Aqukethe i-compressor ye-pneumatic, ibhodlela lesifutho lokuthela isilondolozi (njenge-Movil isibonelo) kanye neshubhu lepulasitiki elide elingena emgodini olashiwe.

Ngakho, ungakwazi ukushisela umzimba owonakele ngokwakho. Ngisho noma umuntu oqalayo engenakho nhlobo isipiliyoni, akufanele uphatheke kabi: ungakwazi njalo ukuzijwayeza izingcezu zensimbi ezilahliwe kuqala. Futhi ukunakwa okukhethekile akufanele kukhokhwe kuphela emishinini yokuzivikela yomuntu siqu, kodwa futhi nemishini yokuphepha emlilweni. Isicishamlilo kufanele ngaso sonke isikhathi sibe seduzane kumshini wokushisela oqalayo.

Amazwana we-3

Syed

Lezi zithombe ezingcolile zihlangene ngani nemoto kanye nesihloko sesihloko?

Susa, unamahloni

Angaziwa

Yiziphi lezi ezinye izithombe, ngicela ungazisakazeli

Umama

Zinhle kakhulu futhi ziyaqabula