Ukulungiswa kwenduku yokuxhuma nekhithi yepiston

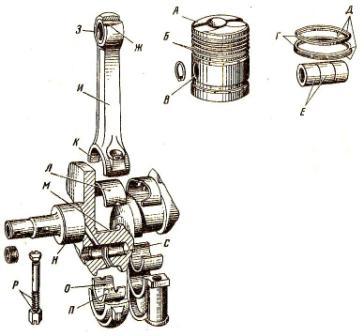

Amaphutha amakhulu ezingxenyeni zenduku yokuxhuma kanye nekhithi yepiston kuboniswe kuMfanekiso 64.

Ilayisi. 64. Ukukhubazeka okungenzeka ezingxenyeni zenduku yokuxhuma kanye nekhithi ye-piston.

A) - idiphozi ye-soot, i-coke, itiyela;

B) - ukugqoka kwe-groove;

B) - ukugqoka izimbobo zeminwe ku-piston;

D) - ukugqoka kwendawo yangaphandle yamasongo;

D) - ukugqoka amasongo ukuphakama;

E) - ukugqoka kweminwe ngaphandle;

D) - ukugqoka komkhono wangaphandle wenduku yokuxhuma;

H) - ukugqoka kwe-bushing ngaphakathi kwenduku yokuxhuma;

I) - Ukugoba nokudwengula kwenduku yokuxhuma;

K) - ukugqoka kwangaphakathi kwekhanda eliphansi lenduku yokuxhuma;

L) - gqoka ohlangothini lwangaphandle lwe-lining;

M) - ukugqokwa kwejenali yenduku yokuxhuma;

H) - Ukugqokwa okuyinhloko kwentamo;

O) - ukugqokwa kohlangothi lwangaphakathi lwe-lining;

P) - Ukucekelwa phansi kokufakwa kwezinti;

P) - Ukuqhekeka nokubhujiswa kwemicu yezintambo zokuxhuma;

C) - Ukubekwa kwemikhiqizo yokugqokwa.

Iphinikhodi ye-piston ibuyiselwa ukunwetshwa okubandayo (ukuguqulwa kwepulasitiki) okulandelwa ukwelashwa kokushisa, ukunwetshwa kwe-hydrothermal ngokwelashwa kokushisa ngesikhathi esisodwa, izindlela ze-electroplating (i-chromium plating, insimbi eqinile). Ngemuva kokubuyiselwa, izikhonkwane ze-piston zicutshungulwa emishinini yokugaya engenawo isikhungo futhi iphucuziwe ibe usayizi ojwayelekile, kuyilapho ukuqina kwendawo kufinyelela ku-Ra = 0,16-0,32 microns.

Ngokusatshalaliswa kwe-hydrothermal, i-HDTV ishisa umunwe ku-inductor ezingeni lokushisa elingu-790-830 degrees Celsius, bese ipholisa ngamanzi agelezayo, idlule emgodini wayo wangaphakathi. Kulokhu, umunwe uqina, ubude bawo nobubanzi bangaphandle bukhuphuka kusuka ku-0,08 kuya ku-0,27 mm. Iminwe emide igaywe emaphethelweni, bese kuthi ama-chamfer akhishwe ngaphandle nangaphakathi.

Izihlahla zekhanda eliphezulu lenduku yokuxhuma. Zibuyiselwa ngezindlela ezilandelayo: i-thermal diffusion zinc plating ngokucubungula okulandelayo; ama-deposit ku-rod yokuxhuma; ukucindezela okulandelwa ukwakheka kwendawo yangaphandle ye-tape yensimbi nge-electrocontact welding (ubukhulu be-tape kusuka ezinsimbi eziphansi ze-carbon yi-0,4-0,6 mm).

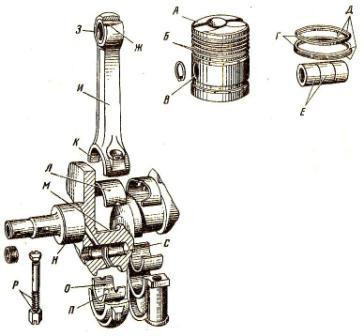

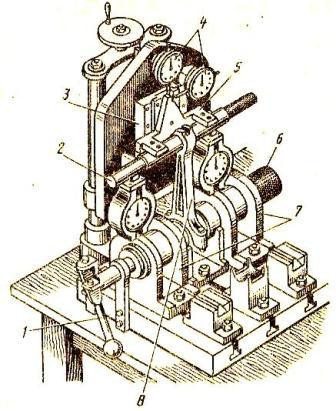

Induku yokuxhuma. Lapho ubuso obungaphansi kwesihlahla bugugile, induku yokuxhuma idonswa komunye wosayizi wokulungisa ngesikhawu esingu-0,5 mm, i-chamfering ekugcineni 1,5 mm x 45 degrees. Ukuze uthole isidina, kusetshenziswa umshini wokumba idayimane we-URB-VP, ukulungisa induku yokuxhuma [Umfanekiso wamashumi ayisithupha nanhlanu].

Ilayisi. 65. Ukubopha induku yokuxhuma emshinini ngokubhoboza i-bushing yekhanda eliphezulu.

1) - Ukulungisa;

2) - Amaprism ezokuthutha;

3) - Isondo lokuqondisa lokunyakaza kwemoto;

4) - isikulufa sokukhiya senqola;

5) - Ukusekela;

6) - Inqaba;

7) - Ukusekela;

- Induku yokuxhuma.

Lo mshini ungabhoboza izimbobo ezinobubanzi obungu-28-100 mm ngesivinini esingu-600-975 min-1 kanye nesiphakeli esingu-0,04 mm/rev.

Ibanga eliphakathi kwezimbazo zamakhanda angaphezulu naphansi lifinyelelwa ngokubeka isifanekiso phakathi kwezitobhi zobakaki (5) nekalishi eligudlukayo. Ukufaneleka kokufakwa kwembobo yenduku yokuxhuma endizeni eqondile ihlolwe nge-cutter futhi ilungiswe ngebakaki (7).

Izindawo zangaphakathi ezigugile zamakhanda aphansi nangaphezulu ezinduku zokuxhuma ezitolo zokulungisa ziyandiswa ngokufakwa kwe-electroplating, ukubhoboza nokugaya noma ukupholisha osayizi abajwayelekile.

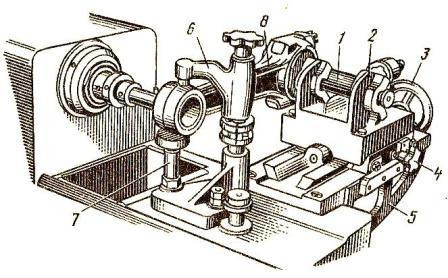

Ukuze unqume ukuchezuka kusuka ku-parallelism (ukugoba) ezindizeni eziqondile nezivundlile (i-torsion) zezimbazo zekhanda elingaphezulu elihlobene nekhanda eliphansi ezinjini ze-carburetor, umhlangano wenduku yokuxhuma nesembozo ihlolwe kudivayisi ekhethekile [ENG. 66], futhi kubo bonke abanye, shayela ku-70-8735-1025.

Ilayisi. 66. Ithuluzi lokulungisa kabusha izinduku zokuxhuma zezinjini zezimoto.

1) - isibambo sokususa i-roller;

2) - i-mandrel encane;

3) - iziqondiso ezishelelayo;

4) - inkomba;

5) - i-rocker;

6) - i-mandrel enkulu;

7) - Ishalofu;

- Induku yokuxhuma.

Ukuchezuka ku-parallelism (ukugoba) kwezimbazo zamakhanda ezinduku ezinkulu zokuxhuma kuvunyelwe ezinjinini zikadizili:

D-50 - 0,18mm;

D-240 - 0,05mm;

SMD-17, SMD-18 - 0,15mm;

SMD-60, A-01, A-41 - 0,07mm;

YaMZ-238NB, YaMZ-240B - 0,08mm.

Ukunyakaza okuvunyelwe:

D-50 - 0,3mm;

I-D-240 ne-YaMZ-240NB - 0,08mm;

SMD-17, SMD-18 - 0,25mm;

SMD-60 - 0,07mm;

A-01, A-41 - 0,11 mm;

I-YaMZ-238NB - 0,1mm.

Ezinjinini zezimoto, ukuchezuka ku-parallelism of shafts kuzo zonke izindiza akuvunyelwe ngaphezu kuka-0,05 mm ubude obuyi-100 mm. Ukuze kuqedwe lesi sici, kuvunyelwe ukuhlela izinduku zokuxhuma kuphela ngemva kokushisa induku yabo nge-high-frequency current noma i-gas burner flame ekushiseni kwama-450-600 degrees Celsius, okungukuthi, ngokulungiswa kokushisa.

Ama-Pistons Ukubuyiselwa kwama-pistons ezinjini zikadizili ze-SMD kungenzeka ngokuvela kwe-plasma-arc. Ukuze wenze lokhu, i-piston ihlanzwa ngosawoti oncibilikisiwe ekushiseni kwama-375-400 degrees Celsius imizuzu engu-10, igezwe, iphathwe nge-10% ye-nitric acid futhi iphinde igezwe ngamanzi ashisayo ukuze isuse i-varnish ne-carbon deposits emigodini. Ku-piston, i-groove engenhla nekhanda ziphonswa ngocingo lwe-SVAMG futhi kwenziwa ngomshini.

Ukupakisha, ukuhlanganisa. Amasethi ezintambo zokuxhuma ezinama-caps, ama-bots namantongomane akhethwa ngesisindo ngokusho kwethebula 39.

Ithebula 39

| Enza injini | Umehluko wesisindo, g | ||

| izinduku zokuxhuma | amavolovolo | ukuxhuma izinduku nge umhlangano we-piston | |

| A-01M, A-41 | 17 | amashumi amabili | 40 |

| YaMZ-240B, YaMZ-238NB | 17 | 10 | amashumi amathathu |

| SMD-14, SMD-62 nabanye | 10 | 7 | 22 |

| D-240, D-50 | amashumi amabili | 10 | amashumi amathathu |

| I-D-37M | 10 | 10 | 25 |

| I-GAZ-53, ZIL-130 | 8 | 5 | neshumi nesithupha |

Kwezinye zazo, ubukhulu buboniswa endaweni engaphandle yekhanda eliphansi, kukhava ngokuhambisana nomgodi webhowudi yenduku yokuxhuma. Uma kudingekile ukulinganisa ubukhulu, kuyadingeka ukufaka insimbi yenduku yokuxhuma emgqeni wokuhlukaniswa kwezimpawu ekujuleni kwe-1 mm.

Umehluko ngobuningi bezingxenye emhlanganweni wenjini ngesikhathi sokusebenza kwawo kuholela ekuveleni kwamandla e-inertia angalingani, okubangela ukudlidliza futhi kusheshise inqubo yokugqoka yezingxenye.

Ngesisindo esifanayo senduku yokuxhuma, ukusatshalaliswa kwezinto ngobude kufanele kube kangangokuthi izixuku zamakhanda aphansi nangaphezulu kusethi yenduku yokuxhuma zilingana (umehluko akufanele udlule ± 3 amagremu).

Ama-piston abuye akhethwe ngobukhulu nesisindo. Ubukhulu be-piston buboniswa phansi. Ama-piston anemikhono aqedwa ngokwegebe eliphakathi kwepiston (eceleni kwesiketi) nomkhono, aqoka amaqembu ngezinhlamvu zezinhlamvu zesiRashiya (B, C, M, njll.), ezisuswa phansi kwepiston futhi ehlombe lomkhono.

Izikhonkwane ze-piston zikhethwa ngokuhambisana nobukhulu beqembu lezimbobo emakhanda e-piston futhi zimakwe ngopende noma izinombolo 0,1, 0,2, njll.

Ama-Bushs ngokusho kobubanzi bangaphandle akhethiwe ngokusho kobubanzi bekhanda elingaphezulu lenduku yokuxhuma, futhi ngokusho kobubanzi bangaphakathi - ngokusho kobubanzi bephini, kucatshangelwa isabelo somshini.

Amalayini kufanele afane nobubanzi bejenali ye-crankshaft.

Izindandatho ze-Piston zikhethwa ngokuhambisana nobukhulu bama-liners kanye nokuvunyelwa ku-piston groove, okuvunyelwe indandatho yokuqala yezinjini zedizili ze-YaMZ, A-41 ne-SMD-60 izinhlobo ezingu-0,35 mm (okunye - 0,27 mm). Ezingxenyeni zokucindezela zesibili nezesithathu, igebe liyi-0,30 mm no-0,20 mm, ngokulandelana.

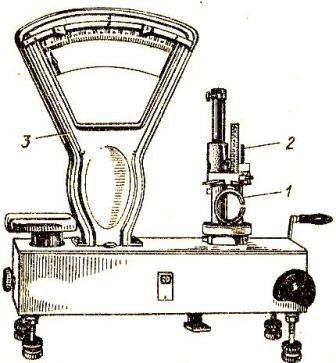

Ukunwebeka kwamasongo kuhlolwa ngokuwabeka ndawonye endaweni enezingqimba endaweni yesikhulumi sesilinganiso esikhethekile se-MIP-10-1 [Fig. 67]. Iringi ilayishwe nge-hinge clearance evamile. Amandla aboniswa ekudayeleni kwesikali kufanele ahlangabezane nezidingo zobuchwepheshe.

Ilayisi. 67. Ukuhlola ukunwebeka kwamasongo e-piston kudivayisi.

1) - Indandatho;

2) - Idivayisi;

3) - Iphawundi.

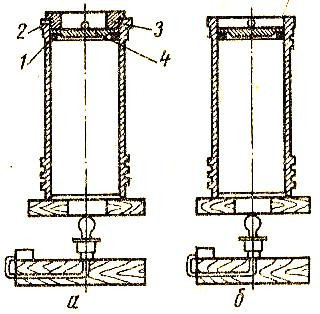

Ukuze uhlole igebe ku-gasket, izindandatho ze-piston zifakwe ku-cylinder ngokuqinile endizeni ehambisana ne-axis futhi ihlolwe nge-feeler gauge. Ikhwalithi yokulingana kwamasongo odongeni lwesilinda ekukhanyeni nayo iyahlolwa [Fig. 68].

Ilayisi. 68. Ukuhlola ukuphuma kwamasongo episton.

a) - Ukufakwa kweringi,

b) - hlola;

1) - Indandatho;

I-2) - I-Sleeve (isilinda sokusekela);

3) - Indandatho yomhlahlandlela;

4) - Isiyalezo.

Igebe ekuhlanganiseni izindandatho ezintsha izinjini diesel kufanele kube 0,6 ± 0,15 mm, kuvunyelwe ngaphandle ukulungiswa - kufika ku-2 mm; amasongo enjini entsha ye-carburetor - 0,3-0,7 mm.

Ukudlala kwe-radial (backlash) phakathi kweringi nesilinda ezinjinini zikadizili akumele kudlule ku-0,02 mm ezindaweni ezingaphezu kwezimbili kuma-arcs angama-30 degrees futhi kungasondeli kuno-30 mm ukusuka kulokhi. Ukuze uthole izindandatho ze-torsion kanye ne-conical, igebe alivunyelwe ngaphezu kuka-0,02 mm, emasongweni e-oil scraper - 0,03 mm noma yikuphi, kodwa hhayi eduze kuka-5 mm ukusuka kukhiye. Ukudlala emasongweni ezinjini ze-carburetor akuvunyelwe.

Baphinde bahlole ukuphakama kwendandatho kanye nokuhlanekezelwa kwezindawo zokugcina, okungafanele kudlule u-0,05 mm ukuze kube nobubanzi obufika ku-120 mm no-0,07 mm ngamasongo obubanzi obukhulu.

ukuhlanganisa nokulawula. Ukuhlanganiswa kwenduku yokuxhuma kanye nekhithi ye-piston kuqala ngokucindezela ama-bushings ekhanda elingaphezulu lenduku yokuxhuma ngokulingana kokuphazamiseka kwe-0,03-0,12 mm yezinjini ze-diesel zezinhlobo ezahlukene, 0,14 mm ezinjini ze-carburetor. Induku yokuxhuma ifakwe emshinini wokumba idayimane we-URB-VP ngendlela efanayo njengoba kukhonjisiwe kuMfanekiso 65, bese kuthi i-bushing ibhojwe ngokuvunyelwa:

igoqe 0,04-0,06mm,

ngokujika ngo-0,08-0,15 mm noma ukulungisa kabusha ngo-0,05-0,08 mm uma kuqhathaniswa nobubanzi obujwayelekile bephinikhodi.

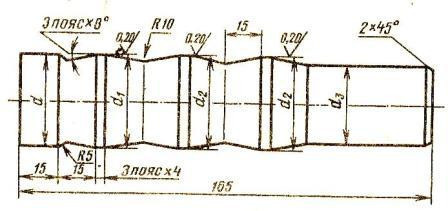

I-bushings igoqeka ngokugoqa i-pulse emshinini wokumba oqondile, enesithukuthezi ngaphansi komshini wokunyathelisa oqhutshwa ngomshini ngokuphakelayo kwe-mandrel okuqhubekayo [Fig. 69], igcotshwe ngamafutha edizili.

Ilayisi. 69. Dorn of the bushing of the upper head of the connecting rod.

d = D - 0,3;

d1 = D(-0,02/-0,03);

d2 = D(-0,09/-0,07);

d3 = D – 3;

D = iphinikhodi ye-piston ububanzi begama.

Khona-ke ukuphambuka kusuka ekufaniseni kwama-ax emigodini ye-bushing kanye nekhanda eliphansi lenduku yokuxhuma lilawulwa ngokuvumelana nezidingo zobuchwepheshe. Kulesi simo, ukuhlela induku yokuxhuma akuvunyelwe. Okulandelayo, inhloko engezansi yenduku yokuxhuma ihlanganiswe nezihlahla, isembozo nama-bolts. Ama-bolts kufanele angene emigodini ngokushaywa okukhanyayo kusuka esando se-200-gram.

Iziteshi zikawoyela wenduku yokuxhuma ziyagezwa futhi zihlanzwe ngomoya. Ama-pistons kufanele ashiswe kukhabhinethi kagesi ye-OKS-7543 noma endaweni yokugeza yamanzi kawoyela endaweni yokushisa engu-80-90 degrees Celsius, bese ixhunywe ku-rod yokuxhuma ngephinikhodi ye-piston ku-vice.

Umhlangano ohlangene ufakwe epuleti yokulawula ukuze i-piston ithinte noma yiliphi iphuzu ebusweni bepuleti. Ngegebe elimise okwe-wedge elingaphezu kuka-0,1 mm ubude obungu-100 mm (kukalwa nge-probe), ikhithi iyahlakazwa, izingxenye zihlolwe, isici sibonakala futhi siqedwe.

Iphinikhodi ye-piston kubaphathi be-piston ihlanganiswe nezingidi zasentwasahlobo. Ngaphambi kokufaka izindandatho, hlola i-taper yendawo yabo yangaphandle ku-control plate usebenzisa isikwele.

Izindandatho zifakwe ku-piston ezinobubanzi obuncane obuphezulu (ukucindezela, ukusika phansi) okuyisishiyagalombili *