Ukulungiswa kabusha kwephampu ye-GUR

Okuqukethwe

Ngizokutshela ukuthi ngiyilungise kanjani iphampu yesiteringi samandla. Kodwa okokuqala, isizinda esincane.

Isiteringi semoto ebandayo ehlobo nasebusika sisebenza ngaphandle kokukhononda. Kodwa lapho nje imoto ifudumala, ikakhulukazi ehlobo, isondo lokuqondisa lamashumi amabili liba lukhuni kakhulu, njengokungathi akukho GUR. Ebusika, le nkinga ayibonakali kangako, kodwa isekhona. Uma unyathela igesi, isondo lokuqondisa ngokushesha liphenduka kalula (nakuba lingaphelele, kodwa lilula). Ngesikhathi esifanayo, iphampu ayinqonqozi, ayikhali, ayigelezi, njll. ... (ungacabangi ngesitimela se-snotty) amafutha ahlanzekile futhi aphelele (ikakhulukazi, ngenxa yesimo se-snotty). isitimela sibuyekezwa njalo!), Ikhadini ligcotshiwe futhi alinamatheli!

Ngokuvamile, kunesibonakaliso esicacile sokuntuleka kokusebenza kwepompo yokuqondisa amandla ngamafutha ashisayo ngokungenzi lutho. Angizange ngihlupheke isikhathi eside, ekugcineni nganquma ukubhekana nale nkinga, ngachitha isikhathi esiningi, ngihlola i-intanethi, ngaqonda isimiso sepompo, ngathola incazelo efanayo futhi nganquma ukuxazulula inkinga yami " endala” iphampu.

Ukudiliza iphampu yokuqondisa amandla

Futhi ngakho-ke, okokuqala, sisusa iphampu, sidinga ukukhipha lonke uketshezi kuyo (indlela yokuyisusa futhi ikhiphe uketshezi, ngicabanga ukuthi noma ubani uzoyithola), futhi, esembozweni sangemuva sokuqondisa amandla. , udinga ukukhulula amabhawodi amane ngekhanda elingu-14.

Amabhawudi okuqiniswa kwekhava yangemuva yephampu ye-GUR

Ngemuva kokuthi siqale ukususa ngokucophelela ikhava, zama ukungonakali i-gasket (inophawu lwenjoloba yangaphakathi), endaweni yokuqondisa amandla sishiya ingxenye yangaphandle "ye-cylinder elliptical cylinder" (ngemuva kwalokhu i-cylinder nje). Asikho isidingo sokwesaba lapho isembozo sisuka kude nomzimba, kungase kubonakale sengathi siyahamba ngenxa yesenzo sentwasahlobo, lapho ukuhlanganisa kabusha kuzobonakala sengathi akuweli endaweni, vele uqhubeke ngokucophelela nangokunye. qinisa amabhawodi nge-diagonally, khona-ke konke kuzongena endaweni.

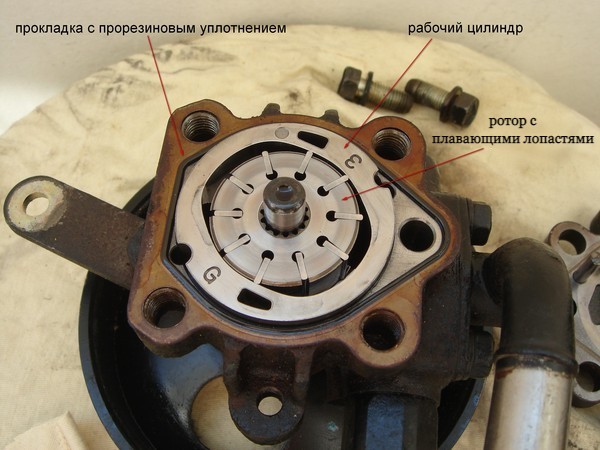

Ingxenye esebenzayo yekhava yangemuva yephampu yokuqondisa amandla

Ukuhlolwa nokunqunywa kwamaphutha

Hlola ngokucophelela okuqukethwe futhi ukhumbule (ungathatha isithombe) ukuthi kwakumi kuphi futhi kanjani (ukunakwa okwengeziwe kufanele kukhokhelwe isikhundla se-cylinder). Ungakwazi ukusonta i-pulley yokuqondisa amandla futhi uhlole ngokucophelela ngama-tweezers ukuthi ama-blades ahamba kanjani emiseleni ye-rotor.

Okuqukethwe kwephampu yokuqondisa amandla

Zonke izingxenye kufanele zikhishwe ngaphandle komzamo, njengoba zingenakho ukulungiswa, kodwa i-axis ephakathi ilungiswe ngokuqinile, ayikwazi ukususwa.

I-ekseli nama-blades wephampu yesiteringi yamandla

Sihlola i-rotor kusukela ohlangothini olungemuva, izingxenye (umzimba wokuqondisa amandla kanye nodonga lwekhava) oluthintayo, ukuthola amaphuzu noma ama-grooves, konke kungilungele.

Ukuhlolwa kwesimo se-rotor kusukela ohlangothini olungemuva

Manje sikhipha wonke umnotho wangaphakathi ku-rag "ehlanzekile" futhi siqala ukuyifunda ...

Ingaphakathi lephampu yokuqondisa amandla

Sihlola ngokucophelela i-rotor, wonke ama-grooves kuwo anemiphetho ebukhali kakhulu nxazonke. Olunye lwezinhlangothi zokugcina ze-groove ngayinye lunokulola okungaphakathi okuphinyiselwe, okuthi, lapho uhambisa i-blade ngaphakathi kwe-groove nge-slope engaguquki ukuya kulolu hlangothi, kuzoba nzima kakhulu ukunyakaza kwayo (lokhu kungase kube ingxenye yokuqala yokusebenza kabi kwamandla. ukuqondisa).

Ukuhlolwa kwesimo se-rotor kusukela ekugcineni

Izingxenye eziseceleni ze-rotor slots nazo "zicijile", ungazizwa uma uslayida umunwe wakho ngezindlela ezahlukene ekugcineni (i-circumference yangaphandle), kanye nezingxenye eziseceleni ze-rotor ngezindlela ezahlukene. Ngaphandle kwalokho, iphelele, awekho amaphutha noma amaphuzu.

Ukuhlolwa kwesimo sobuso obuhlangothini be-rotor yepompo yokuqondisa amandla

Okulandelayo, siqhubeka nokufunda ingaphakathi le-cylinder. Ezinhlangothini ezimbili ze-diagonal (izingxenye zokusebenza) kukhona ukungahambi kahle okujulile (ngendlela yama-dents transverse, njengokungathi kusukela ekushayeni kwama-blades ngamandla amakhulu). Ngokuvamile, ubuso bunamagagasi.

Amaphutha engxenyeni yokusebenza yesilinda sephampu yesiteringi samandla

Ukuqedwa kokukhubazeka empompini wokuqondisa amandla

Ukuqhekeka kuyatholakala, manje sesiqala ukukuqeda.

Sizodinga i-rag, umoya omhlophe, i-P1000 / P1500 / P2000 grit sandpaper, ifayela lenaliti elingunxantathu, i-drill bit engu-12mm (noma ngaphezulu) kanye ne-drill kagesi. Nge-rotor, yonke into ilula kakhulu, udinga isikhumba se-P1500 futhi siqala ukuhlanza yonke imiphetho ye-rotor grooves nayo (sihlanza abangaphandle nangaphandle ezinhlangothini zombili) ngazo zonke izindlela ezingenzeka. Sisebenza ngaphandle kokushiseka, umsebenzi oyinhloko ukususa ama-burrs abukhali kuphela.

Ukuhlanza ama-burrs nge-sandpaper emihle - indlela yokuqala

Ukuhlanza imiphetho ebukhali nge-sandpaper - indlela yesibili

Ukuhlanza imiphetho yemigqa ye-rotor yepompo - indlela yesithathu

Ngesikhathi esifanayo, ungakwazi ukupholisha kancane izinhlangothi zombili ze-rotor endaweni eyisicaba, kuhle ukusebenzisa i-sandpaper ye-P2000.

Ukupholishwa kwephampu yesiteringi samandla

khona-ke udinga ukuhlola umphumela womsebenzi wethu, siwuhlole ngokubuka nangokuthinta, yonke into ibushelelezi ngokuphelele futhi ayinamatheli.

Ukuhlola isimo samakhona ama-grooves ngemva kokupholisha

Ukuhlola isimo sengxenye yokugcina ngemva kokupholisha

Okokuqala, ungakwazi ukugaya ama-blades ezinhlangothini zombili (agaywe ngokunyakaza okuyisiyingi), kuyilapho kufanele acindezelwe ngobumnene esikhumbeni ngomunwe wakho.

Ukupholisha ama-rotor blades wephampu yokuqondisa amandla

Into enzima kakhulu izohambisana nobuso besilinda, mina ngokwami anginalutho olulula, angizange ngicabange ukuthi ungayenza kanjani i-grinder eyindilinga esikhumbeni, i-drill kanye ne-drill obukhulu (F12). Okokuqala, sithatha isikhumba se-P1000 kanye ne-drill enjalo, engagxilwa ku-drill.

Izinto zokupholisha isilinda sephampu yesiteringi samandla

khona-ke udinga ukuqinisa isikhumba ngokumelene nokujikeleza kwe-drill, ngokuphenduka okubili noma kathathu, akufanele kube khona izikhala.

Ithuluzi lokupholisha isilinda sephampu yesiteringi samandla

Ukubamba isakhiwo esisontekile ngokuqinile, udinga ukusifaka ku-drill (cindezela isikhumba futhi).

Idizayini yokupholisha isilinda sephampu yesiteringi samandla

Ngemuva kwalokho, ngezindlela ezilula kakhulu kuwe, qala ngokucophelela ukugaya isilinda, udinga ukugaya ngokulinganayo, ucindezele isilinda ngokuqinile bese usihambisa ngokuhlobene ne-axis yokujikeleza (ngejubane eliphezulu). Njengoba sidla isikhumba, siyasishintsha, ekugcineni sifinyelela isikhumba esincane kunazo zonke i-P2000.

Ukubuyisela ingaphakathi le-cylinder ngendlela yokuqala, faka futhi ulungise ingxenye ebusweni

Ukubuyisela ingaphakathi le-cylinder ngendlela yesibili, ukulungisa i-drill, skrola engxenyeni

Umphumela oyifunayo uyatholakala,

Ukuhlola ingaphezulu lephampu yesiteringi yamandla ngemva kokupholishwa

manje udinga ukusula ngokucophelela yonke into ngendwangu enomoya omhlophe. I-rotor ngokwayo enama-blades ingahlanzwa kuyo.

Izingxenye zephampu yesiteringi yamandla ashisayo ngemuva kokupholisha

Ngemuva kokuthi siqale umhlangano, konke kufakwa ngokulandelana okuphambene.

Ukufaka i-rotor ku-shaft

Ukufaka ama-blades ku-rotor

Ukufaka isilinda

Ngaphambi kokufaka isembozo, siphakamisa ukuqondisa kwamandla endaweni evundlile futhi siphendule ngokucophelela i-pulley yepompo, bheka, qiniseka ukuthi yonke into ijikeleza kahle, futhi ama-blades ahamba emigwaqweni njengoba kulindeleke. Bese uvala ngokucophelela isembozo bese uqinisa ama-bolts amane (asontekile nge-diagonally). Konke sekumi ngomumo!