Kungani abashayeli bokuphakamisa u-hydraulic bengqongqoza

Okuqukethwe

Abashayeli abaningi, lapho beqala injini ebandayo, bezwa isici esithi "clatter" kuyo. Ukuze unqume ukuthi kungani ama-hydraulic lifters engqongqoza, udinga ukuzijwayeza ukwakheka kwawo kanye nesimiso sokusebenza kwawo.

Okuqukethwe

- 1 Hydrocompensator: kuyini

- 1.1 Idivayisi

- 1.2 Ukuthi isebenza kanjani

- 1.2.1 Isigaba 1

- 1.2.2 Isigaba 2

- 1.2.3 Isigaba 3

- 1.2.4 Isigaba 4

- 2 Zizwakala kanjani iziphakamisi ezinama-hydraulic?

- 3 Kungani abashayeli bokuphakamisa u-hydraulic bengqongqoza

- 3.1 Emakhazeni

- 3.2 Kuyashisa

- 3.2.1 Ividiyo: idivayisi, isimiso sokusebenza, izimbangela zokungqongqoza

- 3.3 Ukungqongqoza kwamafindo amasha

- 4 Ungasibona kanjani isiphakamisi se-hydraulic esinephutha

- 4.1 Ividiyo: ungathola kanjani ukuthi iyiphi i-hydrik engqongqozayo

- 5 Yini ukungqongqoza okuyingozi

- 6 Indlela ukususa knock

- 6.1 Ividiyo: ukuqaqa, ukulungisa, ukuhlolwa

Hydrocompensator: kuyini

Izingxenye kanye nezingxenye zenjini egijimayo, ukushisa, ukwanda ngosayizi. Lokhu kuphinda kusebenze endleleni yokusabalalisa igesi (GRM).

Ukuze ugweme ukuphuka nokunciphisa ukusebenza kahle kwe-valve drive mechanism, izikhala ezishisayo zihlinzekwa ngokwesakhiwo phakathi kwezingxenye zayo ngazinye. Ngenqubo yokufudumala injini, izingxenye zikhula ngosayizi. Izikhala ziyanyamalala, injini isebenza kahle. Kodwa-ke, ngokuhamba kwesikhathi, izingxenye ziyaguga, futhi igebe le-thermal nalo liyashintsha.

I-hydraulic compensator (i-hydraulic pusher, "hydric") iyisisetshenziswa esibamba igebe elakhiwe phakathi kwamakhamera e-camshaft nama-valve rockers, izinduku, ama-valve, naphezu kwezinga lokushisa enjini nezinga lawo lokugqoka.

Afakwe kuzo zonke izinhlobo zesikhathi ezinjinini ezine-camshaft ephezulu nephansi.

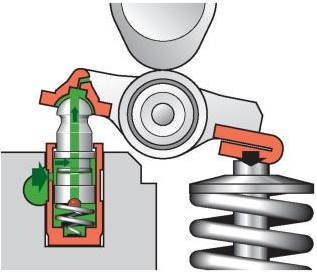

Izindawo zokuphakamisa i-hydraulic

Ezinhlotsheni ezahlukahlukene zesikhathi, izinhlobo ezi-4 eziyinhloko zezinxephezelo zenziwe:

- I-pusher ye-hydraulic;

- I-roller hydraulic pusher;

- Ukwesekwa kwe-Hydro;

- Ukusekelwa kwe-hydraulic kwezingalo ze-rocker nama-levers.

Izinhlobo zama-hydraulic lifters

Idivayisi

Nakuba zonke izinhlobo zeziphakamisi ze-hydraulic zihluka ngomklamo, isenzo esiyinhloko kanye nomgomo wedivayisi kuyafana.

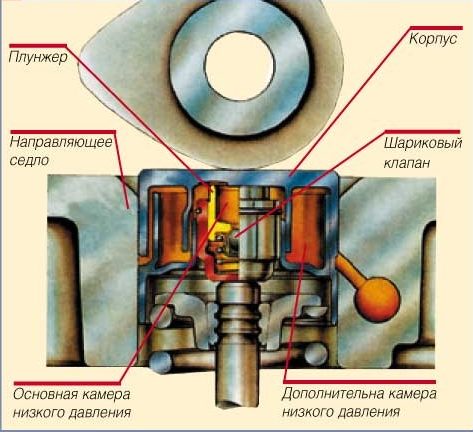

Umhlangano omkhulu we-hydraulic pusher yipheya eligudlukayo le-plunger elinevalvu yebhola etholakala ngaphakathi. Konke lokhu kubekwe ecaleni. Igebe lama-microns angama-5-7 anikezwe phakathi kwendawo ye-plunger nepiston egudlukayo liqinisekisa ukuqina kwawo.

Umzimba wesinxephezelo uhamba ngokukhululeka eduze kwesihlalo somhlahlandlela esisekhanda lesilinda (BC).

Idizayini ye-labyrinth hydraulic pusher

Ibalulekile! Kuzinxephezelo ezimiswe ngokuqinile ezingalweni ze-rocker, i-plunger enengxenye esebenzayo ephumele ngaphandle komzimba isebenza njengento eqondisayo.

Phansi kwe-plunger kunembobo yoketshezi olusebenzayo, evinjwe ivalve yokuhlola enebhola. Isiphethu sokubuya esiqinile sitholakala emzimbeni wepiston futhi sizama ukuyisunduza isuke ku-plunger.

Isithako esisebenzayo esiwuketshezi uwoyela wenjini, ongena ku-hydraulic pusher ngembobo yendlu esuka kumzila kawoyela we-BC.

Ukuthi isebenza kanjani

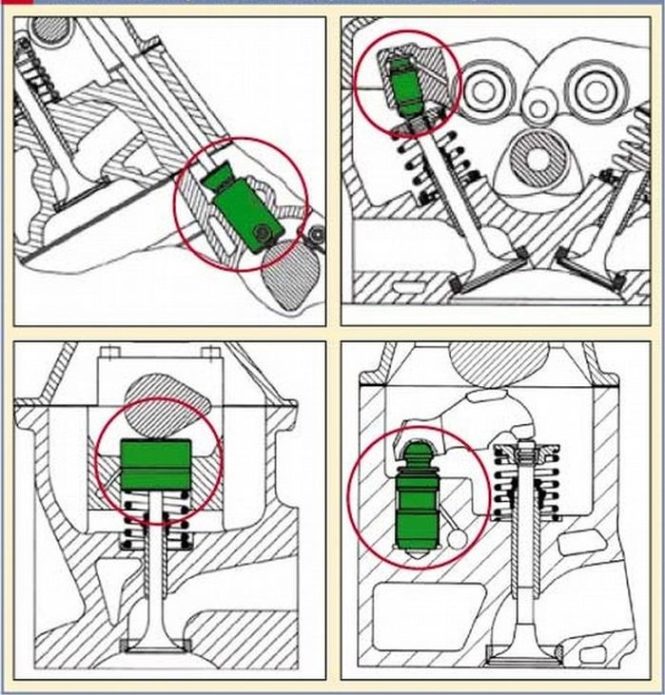

Kusetshenziswa isibonelo se-hydraulic pusher, ukusebenza okuyisisekelo kwawo wonke ama-hydraulic lifters kuyaboniswa.

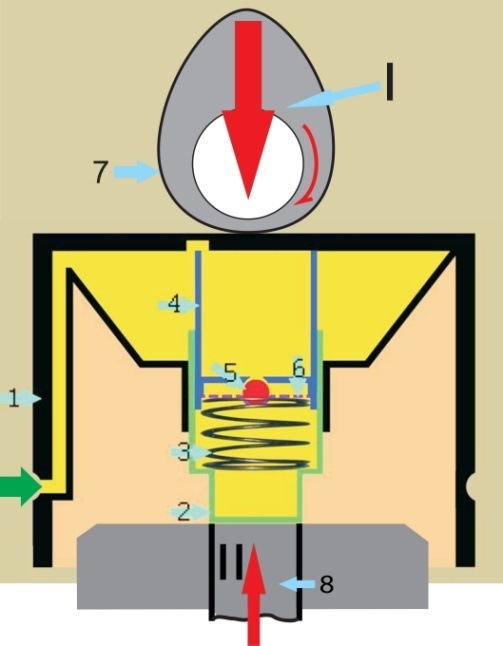

1. Umzimba. 2. Piston. 3. Buyela entwasahlobo. 4. Plunger. 5. I-valve yokuhlola ibhola. 6. Isigcini se-valve. 7. Ikhamera ye-camshaft. 8. I-valve spring.

Amandla (imicibisholo ebomvu I kanye no-II) avela ku-camshaft cam 7 kanye ne-valve spring 8 aphoqa i-tappet ye-hydraulic ukuthi ihlale ihamba ngendlela ebuyelanayo.

Isigaba 1

Lapho i-hydraulic pusher itholakala endaweni ephakeme kakhulu, imbobo emzimbeni 1 isezingeni elifanayo nesiteshi samafutha se-BC. Amafutha (umbala ophuzi) angena ngokukhululekile endlini (igumbi lokucindezela eliphansi elengeziwe). Ngaphezu kwalokho, ngokusebenzisa umzila we-bypass otholakala phansi kwendlu, uwoyela ugeleza ungene emgodini we-plunger 4 (igumbi elinomfutho ophansi). Khona-ke, nge-valve evulekile 5, amafutha angena emgodini we-piston 2 (igumbi lokucindezela okuphezulu).

I-piston ihamba ngokukhululeka emikhombandlela eyakhiwe i-plunger 4 kanye ne-bulkhead yezindlu 1. Ukucindezela kwentwasahlobo 3 kuqeda igebe phakathi kwe-hydraulic pusher piston 2 kanye nevalve yesikhathi engu-8.

Isigaba 2

Ngokushesha nje lapho i-cam 7 ye-camshaft iqala ukufaka ingcindezi endlini engu-1, iyasuswa. Uketshezi olusebenzayo alusanikezwa ekamelweni elengeziwe lomfutho ophansi. I-valve spring 8 inamandla kakhulu kune-return spring 3 ye-hydraulic pusher, ngakho-ke igcina i-valve isendaweni. I-Piston 2, naphezu kokumelana kwentwasahlobo yokubuya, iqala ukuhamba ngaphakathi kwendlu 1, iphusha amafutha emgodini we-plunger.

Umfutho wamafutha ku-piston 2 ukhuphuka ngenxa yomthamo omncane wegumbi lokucindezela okuphezulu, ekugcineni uvale i-valve yokuhlola 5. I-hydraulic compensator, njengomzimba owodwa oqinile, iqala ukudlulisa amandla kusuka ku-camshaft cam 7 kuya ku-valve yesikhathi 8. . I-valve iyanyakaza, isiphethu sayo sicindezelekile.

Isigaba 3

I-Cam 7 ye-camshaft, isidlule indawo ephakeme kakhulu, kancane kancane inciphisa amandla ku-hydraulic pusher housing. I-valve spring 8, iqondisa, iyibuyisela endaweni ephakeme kakhulu. Ivalvu iphusha isinxephezelo se-hydraulic ngepiston sibheke ekamereni. I-return spring 3 iqala ukuqondisa. Ukucindezela ku-piston 2 kwehla. Amafutha, ayenesikhathi sokugeleza emgodini we-plunger 4 ekuqaleni kwesigaba sesibili, manje acindezela ibhola le-valve engu-5, ekugcineni alivule.

Isigaba 4

I-Cam 7 ye-camshaft iyayeka ukucindezela isinxephezelo se-hydraulic. I-valve spring 8 inwetshwe ngokugcwele. Intwasahlobo ebuyayo yesi-3 ye-hydraulic pusher ayicaciswanga. I-valve yokuhlola 5 ivuliwe. Ukucindezela kwamafutha kuwo wonke amagumbi kuyafana. Izimbobo emzimbeni 1 we-hydraulic pusher, ebuyele endaweni yayo yasekuqaleni endaweni ephakeme kakhulu, iphinde ihambisane neziteshi zikawoyela ze-BC. Ukushintsha uwoyela ngokwengxenye kuyaqhubeka.

Intwasahlobo ebuyayo ngaphakathi kwe-hydraulic izama ukuqondisa, isusa igebe phakathi kwekhamera ne-hydraulic pusher, ngisho nokuguga okungenakugwemeka kwezingxenye zesikhathi.

Ibalulekile! Ubukhulu bezakhi ze-hydraulic pusher buyashintsha lapho kushisa, kodwa kunxeshezelwa idivayisi ngokwayo.

Zizwakala kanjani iziphakamisi ezinama-hydraulic?

Uma usuyiqalile injini, ngezinye izikhathi ungezwa ngokushesha ukungqongqoza kwensimbi okuzwakalayo, i-clatter. Ingikhumbuza imisindo yokushayisana kwezingxenye zensimbi ezincane eziphonswa ngamandla endaweni yensimbi. Ukuvula i-hood, ungathola ukuthi imisindo iphuma ngaphansi kwesembozo se-valve. Imvamisa yokungqongqoza iyashintsha kuye ngesivinini senjini.

Izinga lomsindo elivela kubanxephezeli alixhomekile emthwalweni wenjini. Lokhu kungahlolwa ngokuvula bonke abasebenzisi bamandla (i-heater fan, i-air conditioner, i-high beam).

Ibalulekile! Imvamisa ukungqongqoza kwesinxephezelo se-hydraulic esinephutha kudidaniswa nomsindo wevalvu. Ezakamuva zinomsindo. Ukungqongqoza kwesinxephezelo kucace kakhulu futhi kunomsindo.

Uma umsindo ungazange uvele ngokushesha ngemva kokuqala injini, ihlala njalo lapho ijubane layo lishintsha futhi lishintsha kuye ngomthwalo weyunithi, umthombo wokungqongqoza uhlukile.

Kungani abashayeli bokuphakamisa u-hydraulic bengqongqoza

Isici se-metallic knock esivelayo, okokuqala, sikhomba ukuvela kwegebe ngesikhathi, lapho ukusekelwa kwe-hydraulic engakwazi ukunxephezela khona.

Ngokuya ngezinga lokushisa lemoto, ukungasebenzi kahle okungenzeka kanye nezinkinga ezibangele ukungqongqoza kwama-hydraulic lifters zihlukaniswa.

Emakhazeni

Izimbangela ezijwayelekile ze-hydro bearing clatter enjinini esanda kuqaliswa kungaba:

- Ukungcola okungena ngaphakathi kwesinxephezelo. Ngenxa yalesi sizathu, kokubili i-plunger pair kanye nebhola le-valve yokuhlola kungajam. Kuzo zombili izimo, i-hydraulic pusher ngeke yenze umsebenzi wayo.

- Amafutha angcolile. Ngokuhamba kwesikhathi, imikhiqizo yokungqubuzana yezingxenye nensile inqwabelana emafutheni. Konke lokhu kungavala imigudu kawoyela ehlinzeka “ngamahydrics” ngoketshezi olusebenzayo. Ngemva kokufudumala kwenjini, uketshezi lwamafutha luyanda, futhi imigudu kancane kancane iyagudluzwa.

- Ukuwohloka kwamayunithi we-hydraulic pusher. Isisetshenziswa esisebenzayo se-compensator singama-50-70 ayizinkulungwane km. Ngalesi sikhathi, umonakalo ungase wenzeke ezindaweni zokusebenza eziphula ukuqina kwazo. Ngenxa yalokho, akukho ukucindezela kwamafutha okudingekayo emgodini we-piston we-compensator.

- Amafutha e-viscous kakhulu. Kulesi simo, kuze kube yilapho injini ifudumala ngokuphelele, amafutha awangeni ngokugcwele kuma-pushers we-hydraulic, angakwazi ukwenza umsebenzi wawo.

- Isihlungi sikawoyela esivalekile. Kulesi simo, uwoyela we-viscous obandayo kumthamo odingekayo awukwazi ukudlula isihlungi bese ungena ekhanda lenjini. Ngezinye izikhathi inkinga iyanyamalala ngemva kokufudumala kwenjini.

- Ukupheka iziteshi zamafutha. Kungenzeka kokubili ku-cylinder block kanye naku-compensator. Kulesi simo, kunconywa ukuthi ungasebenzisi izithasiselo zokuhlanza. Ukuhlanza ngomshini kuphela ngemva kokuhlakazeka kuzosiza.

Kuyashisa

Izizathu zokushayeka kwama-hydraulic lifter enjinini ebandayo nazo zibalulekile kuyunithi efudunyeziwe ifike ezingeni lokushisa lokusebenza. Kodwa kunezinkinga ezivela kuphela lapho kushisa:

- Amafutha alahlekelwe izinga lawo. Ngemva 5-7 ayizinkulungwane km, uwoyela ithuthukisa insiza yokusebenza. I-viscosity yayo iyancipha. Ama-hydraulic pushers awashayi emakhazeni. Uma injini ishisa, ukungqongqoza kuzwakala, okubangelwa ukungabi khona kwamafutha ku-hydraulics ngenxa yokucindezela okuphansi ohlelweni lokuthambisa.

- Iphampu kawoyela enesici. Ayikhiqizi ingcindezi yokusebenza. Amafutha awafinyeleli kuma-hydraulic lifters.

- Izinga likawoyela eliphansi kakhulu noma eliphakeme kakhulu. Zombili lezi zimo zigcwele ukukhihliza amagwebu komkhiqizo oshisayo kanye nokushaywa umoya kwama-hydraulic pushers. Umoya ongene ku-compensator ngesikhathi sokucindezelwa awukwenzi ukucindezela okudingekayo, ukungqongqoza kubonakala.

Ividiyo: idivayisi, isimiso sokusebenza, izimbangela zokungqongqoza

Ukungqongqoza kwamafindo amasha

Ngemuva kokufakwa, i-pusher entsha ye-hydraulic iqala ukungqongqoza i-100-150 km. Lokhu kungenxa yezingxenye zokugaya, emva kwalokho ukungqongqoza kuyanyamalala.

Uma, ngesikhathi sokufakwa, isinxephezelo singatshalwanga ngokugcwele emthonjeni, isiteshi samafutha sekhanda le-block ngeke sihambisane nomgodi wezindlu ze-hydraulic. Amafutha ngeke ageleze ku-compensator, okuzongqongqoza ngokushesha.

Ngezinye izikhathi lapho ufaka i-pusher, ukungcola kungena ngaphakathi komthombo, kuvale umgudu wamafutha. Kulokhu, isinxephezelo sikhishwa, isiteshi sihlanzwa ngomshini.

Ungasibona kanjani isiphakamisi se-hydraulic esinephutha

Ukuze kutholwe okuzimele kwesinxephezelo se-hydraulic esinesici, iphonendoscope enethiphu yensimbi isetshenziswa ngokushintshana kukhava yevalvu ezindaweni "ze-hydrics". Kuzwakala ukungqongqoza okuqinile endaweni yabaphusha abanephutha.

Uma ingekho i-phonendoscope, umhloli angenziwa ngezindlela ezithuthukisiwe. I-resonator (ubhiya noma ithini lethini elijulile) lixhunywe ekugcineni kwentonga yensimbi. Ngemva kokucindezela indlebe ku-resonator, induku enesiphelo sayo samahhala isetshenziselwa isembozo se-valve. Ukulandelana kokusesha kufana nokusebenza kwefonindoscope.

Umshayeli onolwazi angathola isinxephezelo se-hydraulic esinephutha ngokwaso

Ezimweni ezimbi kakhulu, ungasebenzisa induku evamile yokhuni.

Uma ikhava ye-valve isusiwe, bazama ukusunduza isinxephezelo se-hydraulic ngasinye nge-screwdriver. I-pusher ehlehliswa kalula inephutha.

Ividiyo: ungathola kanjani ukuthi iyiphi i-hydrik engqongqozayo

Buka le vidiyo ku-YouTube

Ibalulekile! Ensizakalweni yemoto, iziphakamisi ezingasebenzi ze-hydraulic zinqunywa kusetshenziswa ukuxilongwa kwe-acoustic.

Yini ukungqongqoza okuyingozi

Ukungqongqoza kwama-hydraulic pushers kukhombisa inkinga ethinta izinga lesikhathi. Imvamisa inkinga iba ohlelweni lokuthambisa, olugcwele ukuguga okukhulayo kwazo zonke izingxenye zenjini nezindlela.

Ukusebenza kwemoto ene-knocking hydraulic pushers kunikeza:

- Ukwanda petrol;

- Ukuncipha kokuguquguquka kokusheshisa;

- Ukulahlekelwa amandla afinyelela ku-30%;

- Ukushisa okungenzeka kwe-motor.

Indlela ukususa knock

Isinxephezelo esidonsa amanzi ngaso sonke isikhathi esidinga ukushintshwa kufakwe esisha. Lapho kuvela ukungqongqoza kwesici, okokuqala, udinga ukushintsha uwoyela ngesihlungi samafutha. Ngezinye izikhathi le nqubo yanele, umsindo uyanyamalala.

Ungasebenzisa ama-flushes akhethekile wesistimu yokugcoba. Ngosizo lwentuthuko yesimanje yemikhiqizo ehamba phambili, kungenzeka ukugeza hhayi kuphela ukungcola, kodwa futhi namashaneli amafutha aphekiwe.

Iziteshi zikawoyela kumele zigezwe ngezikhathi ezithile ngoketshezi olukhethekile.

Okusebenza kahle kakhulu ukuhlanzwa ngomshini kweziphakamisi ezinama-hydraulic. Ama-hydraulics ayasuswa, ahlakazwe, ahlanzwe futhi awashwe.

Ividiyo: ukuqaqa, ukulungisa, ukuhlolwa

Ibalulekile! Uma umonakalo womshini utholakala, isinxephezelo kufanele sishintshwe.

Ukungqongqoza kwama-hydraulic lifters okuvele kuyizimpawu kumnikazi wemoto ngezinkinga ezivele ohlelweni lokuthambisa noma lwezikhathi. Ukuxilongwa ngesikhathi kanye nokuqedwa kwezimbangela zokungqongqoza kungenziwa ngokuzimela ngaphandle kokuxhumana nochwepheshe.