Ukungasebenzi kahle kwekhanda le-cylinder Vaz 2106: ukuthi ungayibona kanjani futhi uyilungise

Okuqukethwe

Ukungasebenzi kahle kwekhanda le-cylinder ye-VAZ "eziyisithupha" zenzeka njalo. Kodwa-ke, lapho zivela, akufanelekile ukulibazisa ukulungiswa. Ngokuya ngesimo sokuphuka, kungadingeki nje kuphela ukugcwalisa njalo uwoyela noma okokupholisa, kodwa nokuncipha nempilo yenjini.

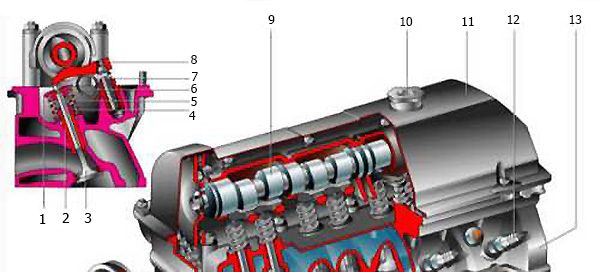

Incazelo yekhanda le-cylinder Vaz 2106

Ikhanda lesilinda (ikhanda le-cylinder) liyingxenye ebalulekile yanoma iyiphi iyunithi yamandla omlilo wangaphakathi. Ngalo mshini, ukunikezwa kwengxube evuthayo kumasilinda kanye nokukhishwa kwamagesi okukhipha kuwo kulawulwa. I-node inokungasebenzi kahle kwemvelo, ukutholwa nokuqedwa okufanele kugxilwe kukho ngokuningiliziwe.

Inhloso nomgomo wokusebenza

Inhloso eyinhloko yekhanda le-cylinder ukuqinisekisa ukuqina kwe-cylinder block, okungukuthi, ukudala isithiyo esanele sokuphunyuka kwamagesi ngaphandle. Ngaphezu kwalokho, inhloko ye-block ixazulula uhla lonke lwemisebenzi eqinisekisa ukusebenza kwenjini:

- amafomu avaliwe amakamelo omlilo;

- uhlanganyela emsebenzini we-State Russian Museum;

- ibandakanyeka ohlelweni lokuthambisa kanye nokupholisa lwenjini. Kulokhu, kunemigudu ehambisanayo ekhanda;

- ubamba iqhaza ekusebenzeni kwesistimu yokuthungela, njengoba ama-spark plugs atholakala ekhanda le-cylinder.

Kuzo zonke lezi zinhlelo, inhloko ye-block iyisici somzimba esiqinisekisa ukuqina nobuqotho bomklamo weyunithi yamandla. Uma kwenzeka ukungasebenzi kahle ngekhanda le-cylinder, ukusebenza okuvamile kwenjini kuyaphazamiseka. Kuye ngesimo sokuphuka, kungase kube nezinkinga kokubili kwesistimu yokuthungela, ukuthambisa, nesistimu yokupholisa, edinga ukulungiswa ngokushesha.

Umgomo wokusebenza kwekhanda le-cylinder wehliselwa kulezi zinyathelo ezilandelayo:

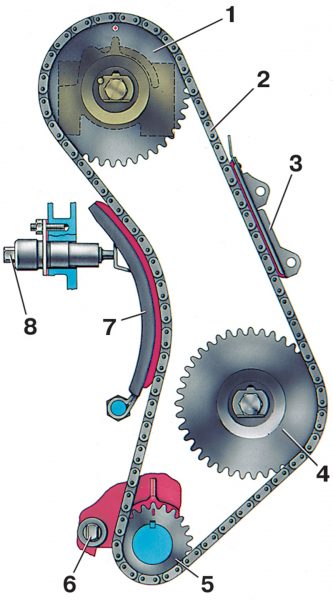

- I-camshaft iqhutshwa ku-crankshaft yenjini ngokusebenzisa i-timing chain kanye ne-sprocket.

- Amakhamera e-camshaft asebenza kuma-rocker ngesikhathi esifanele, avule futhi avale ama-valve ekhanda le-cylinder ngesikhathi esifanele, agcwalise amasilinda ngengxube yokusebenza ngokusebenzisa i-manifold yokuthatha futhi akhiphe amagesi okukhipha umoya ngokusebenzisa i-exhaust.

- Ukusebenza kwama-valve kwenzeka ngokulandelana okuthile, kuye ngokuthi indawo ye-piston (i-inlet, ukucindezela, ukushaya, ukukhipha).

- Umsebenzi ohlanganisiwe we-chain drive uhlinzekwa yi-tensioner kanye ne-damper.

Ngabe iqukethe ini

Inhloko yesilinda ye "six" iyi-valve engu-8 futhi iqukethe izingxenye ezilandelayo zesakhiwo:

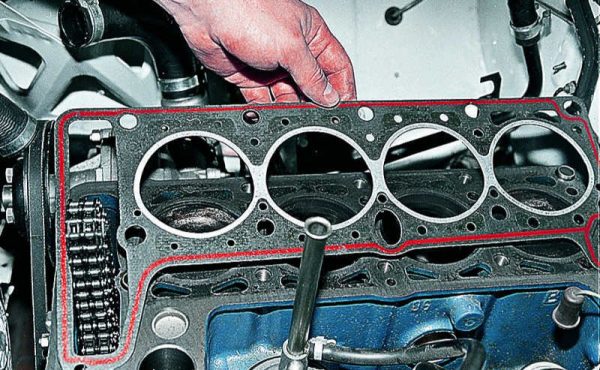

- ikhanda gasket;

- indlela yokwenza isikhathi;

- izindlu zekhanda le-cylinder;

- i-chain drive;

- igumbi lomlilo;

- idivayisi ye-tension;

- izimbobo zamakhandlela;

- izindiza zokufaka ama-intake kanye ne-exhaust manifolds.

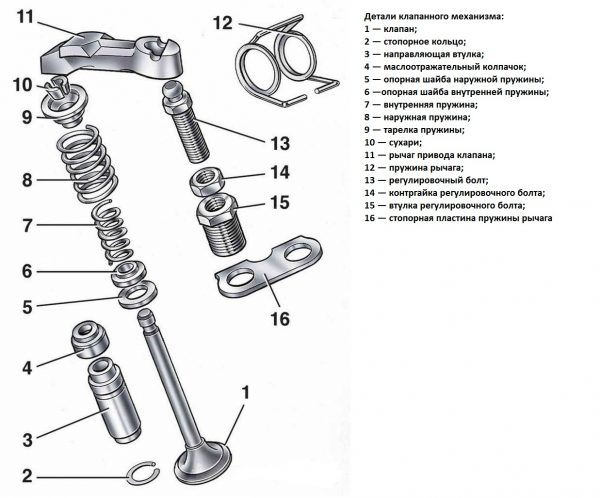

I-node okukhulunywa ngayo ijwayelekile kumasilinda amane. Izihlalo ze-cast iron nama-valve bushings zifakwa emzimbeni. Imiphetho yezihlalo yenziwa ngomshini ngemva kokufakwa emzimbeni ukuze kuqinisekiswe ukulingana okuphelele kwamavalvu. Izimbobo ezihlahleni nazo zenziwe ngomshini ngemuva kokucindezelwa ekhanda le-cylinder. Lokhu kuyadingeka ukuze ububanzi bemigodi maqondana nezindiza zokusebenza zezihlalo bunembile. Ama-bushings anemigodi ye-helical yokuthambisa i-valve stem. Ama-valve ama-valve atholakala phezulu kwezihlahla, ezenziwe ngerabha ekhethekile kanye nendandatho yensimbi. Ama-cuffs alingana ngokuqinile esiqwini se-valve futhi avimbele okokugcoba ukuthi kungangeni ekamelweni elivuthayo ngokusebenzisa izikhala phakathi kodonga olubhishi kanye nesiqu se-valve. I-valve ngayinye ifakwe iziphethu zekhoyili ezimbili, ezisekelwa ama-washer akhethekile. Phezulu kwemithombo kukhona ipuleti eliphethe ama-crackers amabili esiqwini se-valve, esinomumo we-cone encishisiwe.

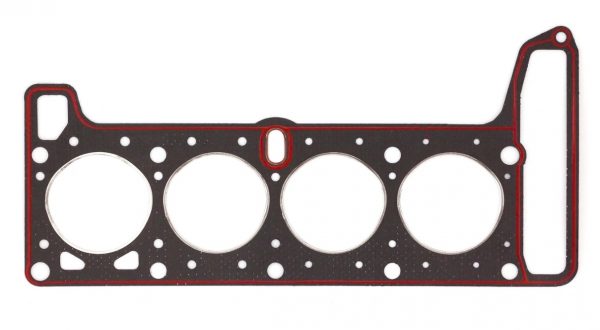

I-cylinder head gasket

I-gasket yekhanda iqinisekisa ukuthi ikhanda le-cylinder lilingana kahle ne-cylinder block. Izinto zokwakha uphawu ziqiniswa i-asbestos, ekwazi ukumelana nokushisa okuphezulu okwenzeka ngesikhathi sokusebenza kweyunithi yamandla. Ngaphezu kwalokho, i-asbestos eqinisiwe imelana nokucindezela okukhulu ngaphansi kwemithwalo yenjini ehlukene.

Indlela yesikhathi

Idivayisi yokusabalalisa igesi iqukethe indlela ye-valve kanye ne-chain drive. Owokuqala wabo unesibopho sokusebenza kwama-valve futhi aqukethe izakhi zokungena kanye ne-outlet, iziphethu, ama-levers, izimpawu, ama-bushings kanye ne-camshaft. Umklamo wesibili uhlanganisa iketango elinemigqa emibili, inkanyezi, i-damper, idivayisi ye-tension nesicathulo.

izindlu ze-cylinder head

Inhloko ye-block yenziwe ngama-alloys e-aluminium futhi igxilwe ku-cylinder block ngokusebenzisa i-gasket isebenzisa ama-bolts ayishumi, aqiniswe ngendlela ethile nangamandla anikeziwe. Ohlangothini lwesobunxele lwekhanda le-cylinder, kwenziwa imithombo yamakhandlela lapho ama-spark plugs e-screw. Ngakwesokunene, izindlu zineziteshi nezindiza, lapho ama-manifolds wezinhlelo zokungenisa kanye ne-exhaust zihlangana ngophawu. Kusukela phezulu, ikhanda livalwe ngesembozo se-valve, esivimbela amafutha ukuba aphume emotweni. I-tensioner kanye nedrayivu ye-timing mechanism kufakwe ngaphambili.

Ukungasebenzi kahle lapho ukususwa nokufakwa kwekhanda le-cylinder liyadingeka

Kukhona ukungasebenzi kahle, ngenxa yokuthi inhloko yesilinda ye-VAZ "eyisithupha" kufanele ikhishwe emotweni ukuze ihlolwe noma ilungiswe. Ake sigxile kuzo ngokuningiliziwe.

I-gasket ishile

Izimpawu ezilandelayo zibonisa ukuthi i-cylinder head gasket yehlulekile (yayishisa noma yayibhoboza):

- ukubonakala kwama-smudges noma ukuqhuma kwegesi lapho kuhlangana khona ibhulokhi yenjini nekhanda. Ngalesi sigameko, umsindo ophuma ngaphandle uyavela ekusebenzeni kwesikhungo sikagesi. Uma igobolondo langaphandle le-seal liphuka, iminonjana yamafutha noma epholile (epholile) ingase ivele;

- ukwakheka kwe-emulsion emafutheni enjini. Lokhu kwenzeka lapho isipholile singena kuwoyela nge-gasket noma uma uqhekeko kwakheka ku-BC;

Ukwakhiwa kwe-emulsion kubonisa ukungena kokupholisa emafutheni

Ukwakhiwa kwe-emulsion kubonisa ukungena kokupholisa emafutheni - intuthu emhlophe evela ohlelweni lwe-exhaust. I-exhaust emhlophe ivela lapho isipholile singena endaweni evuthayo yenjini. Esimweni esinjalo, izinga le-liquid ku-tank yokwandisa liyancipha kancane kancane. Ukulungiswa okungalungile kungaholela esando samanzi. isando samanzi - ukungasebenzi okubangelwa ukwanda okubukhali kwengcindezi endaweni engaphansi kwepiston;

Uma i-gasket yonakalisiwe futhi isipholile singena kumasilinda, kuzophuma intuthu emhlophe ewugqinsi epayipini lokukhipha umoya.

Uma i-gasket yonakalisiwe futhi isipholile singena kumasilinda, kuzophuma intuthu emhlophe ewugqinsi epayipini lokukhipha umoya. - okokugcoba kanye / noma amagesi akhipha amandla angena ohlelweni lokupholisa injini. Ungakwazi ukubona ukungena kwe-lubricant ku-coolent ngokuba khona kwamabala kawoyela ebusweni boketshezi ethangini lokunweba. Ngaphezu kwalokho, lapho ukuqina kwe-gasket kuphukile, ama-bubbles angase avele ethangini, okubonisa ukungena kwamagesi okukhipha igesi ohlelweni lokupholisa.

Ukubonakala kwamabhamuza omoya ethangini lokunweba kubonisa ukungena kwamagesi okukhipha umoya ohlelweni lokupholisa.

Ukubonakala kwamabhamuza omoya ethangini lokunweba kubonisa ukungena kwamagesi okukhipha umoya ohlelweni lokupholisa.

Ividiyo: ukulimala kwe-cylinder head gasket

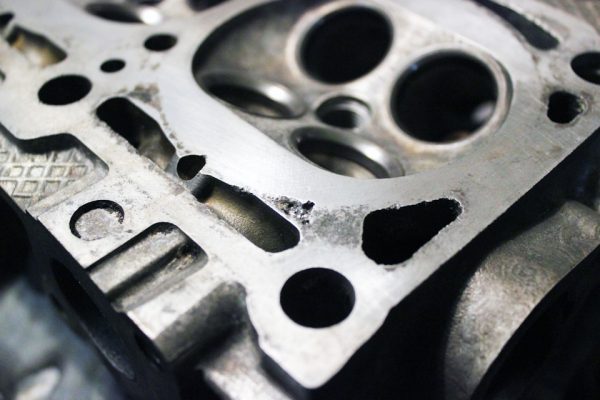

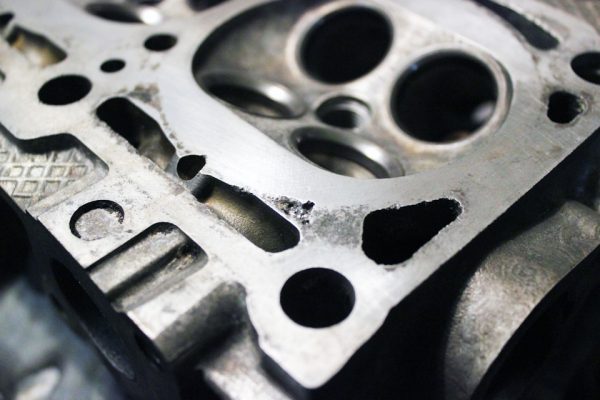

Ukulimala kwendiza yokukhwelana kwekhanda lesilinda

Izizathu ezilandelayo zingaholela ekwakhekeni kweziphambeko endaweni yokuhlangana kwekhanda le-block:

- ukusebenza isikhathi eside kweyunithi yamandla;

- ukushisa kwemoto;

- ukupholisa izinga eliphansi.

Amaphutha alolu hlobo aqedwa ngokucubungula indiza, ngokudilizwa kwekhanda okokuqala.

Imifantu ekhanda lebhulokhi

Izizathu eziyinhloko eziholela ekubukeni kwemifantu ekhanda le-cylinder ukushisa kwe-motor, kanye nokuqiniswa okungalungile kwamabholithi afaka phakathi nokufakwa. Kuye ngesimo somonakalo, ikhanda lingalungiswa ngokusebenzisa i-argon welding. Uma kuneziphambeko ezimbi kakhulu, ikhanda le-cylinder kuzodingeka lishintshwe.

Ukugqoka kwe-Bushing Guide

Ngebanga lenjini eliphezulu noma ukusetshenziswa kwamafutha enjini esezingeni eliphansi, iziqondiso zamavalvu ziyaguga, okuholela ekuvuzeni phakathi kwesihlalo sevalvu nediski yevalvu. Isibonakaliso esiyinhloko sokungasebenzi kahle okunjalo ukwanda kokusetshenziswa kwamafutha, kanye nokubonakala kwentuthu eluhlaza okwesibhakabhaka embhobho wokukhipha. Inkinga ilungiswa ngokushintsha ama-bushings omhlahlandlela.

Ukugqokwa kwesihlalo se-valve

Izihlalo ze-valve zingagqoka ngenxa yezizathu eziningana:

- ukusetshenziswa kwamafutha ekhwalithi ephansi;

- mileage yenjini ephezulu;

- ukulungiselelwa okungalungile kokuthungela.

Ukungasebenzi kahle kuxazululwa ngokuhlela noma ngokushintsha izihlalo. Ngaphezu kwalokho, isistimu yokushisa kufanele ihlolwe.

Ipulaki ye-spark ephukile

Akuvamile, kodwa kwenzeka ukuthi ngenxa yokuqina ngokweqile kwekhandlela, ingxenye inqamuka entanjeni emgodini wekhandlela. Ukuze ususe izinsalela zesici sekhandlela lekhanda le-cylinder, kuyadingeka ukuthi uqaqe futhi ukhulule ingxenye enentambo ngamathuluzi athuthukisiwe.

Ukungasebenzi kahle kwe-CPG

Uma kwenzeka ukungasebenzi kahle kweqembu le-cylinder-piston lenjini, ikhanda lebhulokhi kufanele lisuswe. Ukuhlukaniswa okuvame kakhulu kwe-CPG kufaka:

- ukwanda kokugqoka kwamasilinda, izindandatho namapiston;

- ukulimala kwepiston;

- ukubekwa izindandatho.

Ngokuguga ngokweqile kwamasilinda, injini ihlakazwa ngokuphelele ukuze ithathe indawo yeqembu le-piston, kanye nokubhoboza umgodi ongaphakathi wamasilinda emshinini. Ngokuqondene nomonakalo wamapiston ngokwawo, ayasha, nakuba engavamile. Konke lokhu kuholela esidingweni sokuqaqa ikhanda le-cylinder bese ushintsha izingxenye ezinephutha. Lapho amasongo elele, ukusebenza okuvamile kwesilinda kanye nenjini iyonke kuba yinto engenakwenzeka.

I-Ring Stuck - Izindandatho zibhajwe emigodini ye-piston ngenxa yokunqwabelana kwemikhiqizo evuthayo kuzo. Ngenxa yalokho, ukucindezelwa namandla kuyancishiswa, ukusetshenziswa kwamafutha kuyanda futhi ukugqoka kwama-cylinder okungalingani kwenzeka.

Ukulungiswa kwekhanda lesilinda

Uma kunezinkinga ngekhanda le-cylinder ye-Zhiguli yemodeli yesithupha efuna umhlangano ususwe emotweni, khona-ke umsebenzi wokulungisa ungenziwa egaraji ngokulungiselela amathuluzi afanele kanye nezingxenye.

Esusa ikhanda

Ukuze ususe ikhanda lesilinda, uzodinga ithuluzi elilandelayo:

- idolo elinokwelulwa;

- iqoqo lokhiye;

- izibambo ze-ratchet;

- amakhanda ku-13 no-19.

Ukulandelana kwezenzo zokudiliza i-node imi kanje:

- Khipha isipholile ohlelweni lokupholisa.

- Sisusa isihlungi somoya ngezindlu, i-carburetor, isembozo se-valve, sinqamule ama-nifolds wokungenisa nokukhipha, sihambisa okokugcina eceleni kanye "nebhulukwe".

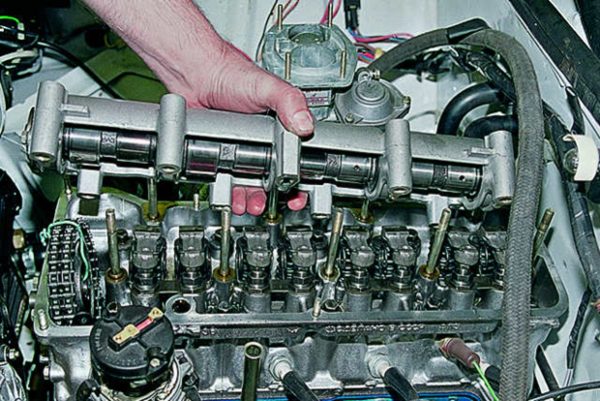

- Sikhulula intaba futhi sisuse i-sprocket ku-camshaft, bese i-camshaft ngokwayo isuka ekhanda le-cylinder.

Sikhulula izinsimbi futhi sisuse i-camshaft ekhanda le-block

Sikhulula izinsimbi futhi sisuse i-camshaft ekhanda le-block - Sikhulula i-clamp bese siqinisa ipayipi lokuhlinzeka ngokupholisa ku-heater.

Sikhulula i-clamp bese siqinisa ipayipi lokuhlinzeka ngokupholisa esitofini

Sikhulula i-clamp bese siqinisa ipayipi lokuhlinzeka ngokupholisa esitofini - Ngokufanayo, susa amapayipi aya ku-thermostat nakurediyetha.

Sisusa amapayipi ukuya kurediyetha kanye thermostat

Sisusa amapayipi ukuya kurediyetha kanye thermostat - Susa itheminali kunzwa yezinga lokushisa.

Susa itheminali kunzwa yezinga lokushisa

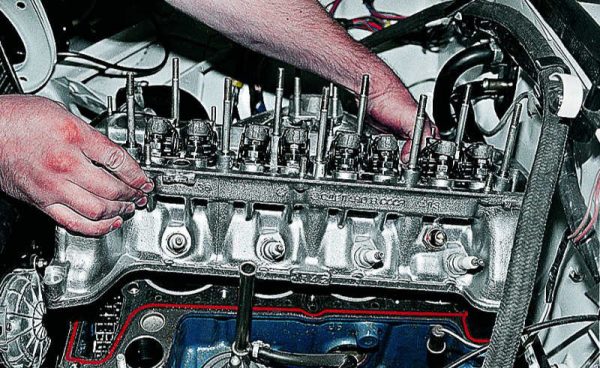

Susa itheminali kunzwa yezinga lokushisa - Ngekhanda le-13 kanye ne-19 eline-knob nesandiso, siqaqa amabhawodi avikela ikhanda lesilinda kubhulokhi.

Sivala ukuqiniswa kwekhanda lebhulokhi nge-wrench enekhanda

Sivala ukuqiniswa kwekhanda lebhulokhi nge-wrench enekhanda - Phakamisa umshini bese uwususa kumotho.

Ukukhulula izinsimbi, susa ikhanda le-cylinder ku-cylinder block

Ukukhulula izinsimbi, susa ikhanda le-cylinder ku-cylinder block

Ukuhlakazwa kwekhanda lebhulokhi

Kudingeka ukuhlakazwa kwekhanda lesilinda eliphelele ukuze kulungiswe njengokushintshwa kwamavalvu, iziqondiso zamavalvu noma izihlalo zamavalvu.

Uma izimpawu ze-valve zingasebenzi, ngakho-ke asikho isidingo sokususa ikhanda le-cylinder - izindebe zomlomo zingashintshwa ngokukhipha kuphela i-camshaft nokomisa ama-valve.

Kwamathuluzi ozowadinga:

- ukhiye ka-17 no-21;

- i-cracker;

- i-oil seal remover;

- ama-tweezers;

- ibha ye-tin solder d = 8 mm;

- isando;

- izidladla zekhala ezinde noma isibambo kazibuthe.

Sihlukanisa i-node ngale ndlela:

- Sidiliza ama-rocker kanye nemithombo yokukhiya.

Susa ama-rocker nama-springs ekhanda le-cylinder

Susa ama-rocker nama-springs ekhanda le-cylinder - Nge-cracker, sicindezela iziphethu ze-valve yokuqala futhi sikhiphe ama-crackers nge-pliers yekhala elide.

Cindezela imithombo nge-dryer bese ususa ama-crackers

Cindezela imithombo nge-dryer bese ususa ama-crackers - Susa ipuleti le-valve neziphethu.

Sidiliza ipuleti futhi siphuma ku-valve

Sidiliza ipuleti futhi siphuma ku-valve - Nge-puller siqinisa i-cap ye-oil scraper.

I-oil scraper cap ikhishwa esiqwini se-valve kusetshenziswa i-screwdriver noma i-puller

I-oil scraper cap ikhishwa esiqwini se-valve kusetshenziswa i-screwdriver noma i-puller - Susa i-valve esihlahleni somhlahlandlela.

I-valve ikhishwa kumkhono womhlahlandlela

I-valve ikhishwa kumkhono womhlahlandlela - Senza inqubo efanayo nawo wonke ama-valve.

- Khulula futhi ukhiphe isikulufu sokulungisa.

Khulula futhi ukhiphe isikulufu sokulungisa

Khulula futhi ukhiphe isikulufu sokulungisa - Sikhulula ama-bushings wezikulufa zokulungisa ngokhiye ongu-21.

Ukusebenzisa i-wrench engu-21, khulula ama-bushings wezikulufu zokulungisa

Ukusebenzisa i-wrench engu-21, khulula ama-bushings wezikulufu zokulungisa - Hlukanisa ipuleti lokukhiya.

Khipha isikulufu, susa ipuleti lokukhiya

Khipha isikulufu, susa ipuleti lokukhiya - Ngemva kokuqeda inqubo yokulungisa, sihlanganisa ikhanda le-cylinder ngokulandelana okuphambene.

Amaphayiphu wokushaya

Lapho ushintsha ama-valve noma izihlalo, izakhi kufanele zihlanganiswe ndawonye ukuze kuqinisekiswe ukuqina. Ngomsebenzi uzodinga:

- unama wedayimane;

- i-drill kagesi enejubane eliguquguqukayo.

Sigaya ama-valve ngendlela elandelayo:

- Faka i-lapping paste ku-valve plate.

I-abrasive paste isetshenziswa endaweni ewelayo

I-abrasive paste isetshenziswa endaweni ewelayo - Sifaka i-valve emkhonweni womhlahlandlela bese sibopha isiqu ku-chuck ye-drill kagesi.

- Sivula i-drill ngesivinini esiphansi, cindezela i-valve esihlalweni bese uyijikelezisa kuqala ngendlela eyodwa, bese kwenye indawo.

I-valve enesiqu esiboshelwe ku-drill chuck ixhunywe ngesivinini esiphansi

I-valve enesiqu esiboshelwe ku-drill chuck ixhunywe ngesivinini esiphansi - Sigaya ingxenye kuze kube uphawu lwe-matte luvela esihlalweni kanye ne-chamfer ye-disc valve.

Ngemuva kokushaya, indawo yokusebenza ye-valve nesihlalo kufanele ibe buthuntu

Ngemuva kokushaya, indawo yokusebenza ye-valve nesihlalo kufanele ibe buthuntu - Sigeza ama-valve nama-saddles nge-parafini, sibeke endaweni, sishintshe izimpawu.

Ukushintshwa kwesihlalo

Ukuze ushintshe isihlalo, kuzodingeka sihlakazwe kusukela ekhanda le-cylinder. Njengoba kungekho mishini ekhethekile yalezi zinhloso ezimweni zegaraji, ukushisela noma amathuluzi athuthukisiwe asetshenziselwa ukulungiswa. Ukudiliza isihlalo, i-valve endala ishiselwe kuso, ngemva kwalokho ikhishwe ngesando. Ingxenye entsha ifakiwe ngokulandelana okulandelayo:

- Sishisa ikhanda le-cylinder ku-100 ° C, bese sipholisa ama-saddles efrijini izinsuku ezimbili.

- Ngomhlahlandlela ofanelekayo, sishayela izingxenye ezindlini zekhanda.

Isihlalo esisha sifakwe i-adaptha efanelekile

Isihlalo esisha sifakwe i-adaptha efanelekile - Ngemva kokupholisa ikhanda le-cylinder, nciphisa izihlalo.

- Ama-Chamfers asikwa ngabasiki ngama-engeli ahlukene.

Ukusika i-chamfer esihlalweni se-valve, ama-cutters anama-engeli ahlukene asetshenziswa.

Ukusika i-chamfer esihlalweni se-valve, ama-cutters anama-engeli ahlukene asetshenziswa.

Ividiyo: ukushintshwa kwesihlalo se-valve yekhanda lesilinda

Esusa bushings

Iziqondiso zamavalvu zithathelwa indawo yisethi yamathuluzi alandelayo:

- isando;

- mandrel for knocking out futhi ucindezela bushings;

- i-reamer 8.025 mm;

- isikrufu sokuphela esivulekile.

Inqubo yokushintsha i-bushing iqukethe izinyathelo ezilandelayo:

- Sikhipha isihlahla esidala ngesando ne-adaptha efanelekile.

Izihlahla ezindala zicindezelwa nge-mandrel nesando

Izihlahla ezindala zicindezelwa nge-mandrel nesando - Ngaphambi kokufaka izingxenye ezintsha, zibeke esiqandisini amahora angu-24, bese ushisa inhloko ye-block emanzini ekushiseni kuka-+60˚С. Sishaya umkhono ngesando kuze kube yilapho ume, ngemva kokubeka isitobha.

I-bushing entsha ifakwe esihlalweni futhi icindezelwe ngesando ne-mandrel.

I-bushing entsha ifakwe esihlalweni futhi icindezelwe ngesando ne-mandrel. - Usebenzisa i-reamer, yenza izimbobo ngokuvumelana nobubanzi besiqu se-valve.

Ngemuva kokufaka ama-bushings omhlahlandlela ekhanda, kuyadingeka ukuwafaka usebenzisa i-reamer

Ngemuva kokufaka ama-bushings omhlahlandlela ekhanda, kuyadingeka ukuwafaka usebenzisa i-reamer

Ividiyo: ukushintsha iziqondiso ze-valve

Buka le vidiyo ku-YouTube

Ukufakwa kwekhanda lesilinda

Lapho ukulungiswa kwekhanda lebhulokhi kuqediwe noma i-gasket ishintshwa, umshini kufanele ubuyiselwe. Ikhanda lesilinda lifakwa kusetshenziswa amathuluzi alandelayo:

- amakhanda 13, 17, 19;

- idolo elinokwelulwa;

- ukusonta kwe-torque.

Inqubo yokufaka imi kanje:

- Sisula ubuso bekhanda le-cylinder bese sivimba nge-rag ehlanzekile.

- Sibeka i-gasket entsha ku-cylinder block.

I-cylinder head gasket entsha ifakwe ngokuhlehlayo.

I-cylinder head gasket entsha ifakwe ngokuhlehlayo. - Senza ukuqondanisa kwe-seal kanye nenhloko yebhulokhi usebenzisa ama-bushings amabili.

Kunezihlahla ezimbili ku-cylinder block yokubeka phakathi i-gasket nekhanda le-cylinder.

Kunezihlahla ezimbili ku-cylinder block yokubeka phakathi i-gasket nekhanda le-cylinder. - Siqinisa ama-bolts No. 1-10 nge-torque wrench enamandla angu-33,3-41,16 N.m, bese ekugcineni siyiqinisa ngomzuzwana we-95,9-118,3 N.m. Okokugcina, sigoqa ibhawudi No. 11 eduze komsabalalisi ngamandla angu-30,6–39 N.m.

- Siqinisa amabhawodi ngokulandelana okuthile, njengoba kuboniswe esithombeni.

Ikhanda le-cylinder liqiniswa ngokulandelana okuthile

Ikhanda le-cylinder liqiniswa ngokulandelana okuthile - Ukuhlanganiswa okwengeziwe kwekhanda le-cylinder kwenziwa ngokulandelana kokuhlehlisa.

Ividiyo: ukuqinisa ikhanda lesilinda ku-"classic"

Buka le vidiyo ku-YouTube

Ukwenqatshwa kwamabhawodi ekhanda lesilinda

Kunconywa ukuthi ushintshe amabhawodi abambe ikhanda lebhulokhi ngokudilizwa ngakunye komhlangano. Kodwa-ke, lokhu kwenziwa kuyaqabukela futhi kunqunyelwe ekuhloleni okuvamile kochungechunge. Uma ihlelekile, amabhawodi aphinde asetshenziswe. Kufanele kukhunjulwe ukuthi ibhawudi elisha linosayizi we-12 * 120 mm. Uma ubude buhluke kakhulu noma izixhumi zinzima ukuzifaka kubhulokhi yesilinda lapho uzama ukukulufinya, lokhu kungase kubonise ukwelula kanye nesidingo sokushintsha ibhawudi. Lapho uqinisa ikhanda le-cylinder nge-bolt eseluliwe ngamabomu, kukhona ithuba lokuphuka kwayo.

Uma, ngesikhathi sokufakwa kwekhanda le-block block, i-bolt eseluliwe ayiphuli, ngakho-ke lokhu akusona isiqinisekiso sokuthi izohlinzeka ngamandla adingekayo okuqinisa ngesikhathi sokusebenza kwemoto. Ngemva kwesikhathi esithile, ukuqiniswa kwekhanda le-cylinder kungase kukhululeke, okuzoholela ekuqhekekeni kwe-gasket.

Uma kukhona ukungasebenzi kahle kwekhanda le-cylinder ye-VAZ 2106, ngenxa yalokho ukusebenza okujwayelekile kweyunithi yamandla kuphazamiseka, ungakwazi ukulungisa inkinga ngokwakho ngaphandle kokuvakashela isevisi yemoto. Ukuze wenze lokhu, udinga ukulungiselela ithuluzi elifanele, ufunde futhi ulandele imiyalelo yesinyathelo ngesinyathelo.