Ukuqokwa, ukulungiswa, ukulungiswa kanye esikhundleni valve Vaz 2101 ngezandla zakho

Okuqukethwe

I-VAZ 2101 iyimodeli yokuqala eyenziwe yiVolga Automobile Plant ekuqaleni kuka-1970. I-Fiat 124, esungulwe kahle eYurophu, yathathwa njengesisekelo sokuthuthukiswa kwayo, i-VAZ 2101 yokuqala ifakwe injini ye-carburetor engu-1.2 no-1.3 litre, umshini we-valve owawudinga ukulungiswa ngezikhathi ezithile.

Inhloso nokuhlelwa kwe-valve mechanism VAZ 2101

Ukusebenza kwenjini yomlilo yangaphakathi akunakwenzeka ngaphandle kwendlela yokusabalalisa igesi (isikhathi), okuqinisekisa ukugcwaliswa okufika ngesikhathi kwamasilinda ngengxube ye-fuel-air futhi kususe imikhiqizo yayo evuthayo. Ukuze wenze lokhu, i-cylinder ngayinye inama-valve amabili, eyokuqala eyokuthatha ingxube, kanti eyesibili ngeyokukhipha amagesi. Ama-valve alawulwa ngamakhamera we-camshaft.

I-camshaft iqhutshwa yi-crankshaft ngokusebenzisa iketango noma i-belt drive. Ngakho-ke, ohlelweni lwe-piston, ukungena nokuphuma kwamagesi okusatshalaliswa isikhathi kuqinisekiswa ngokuhambisana nokulandelana kwezigaba zokusabalalisa igesi. Amathiphu ayindilinga amakhamera e-camshaft acindezela izingalo ze-rocker (ama-lever, ama-rocker), wona, ashukumisa umshini we-valve. I-valve ngayinye ilawulwa yikhamera yayo, ivula futhi ivale ngokuhambisana nesikhathi se-valve. Ama-valve avalwa ngokusebenzisa iziphethu.

I-valve iqukethe induku (isiqu, intamo) kanye nekepisi elinendawo eyisicaba (ipuleti, ikhanda) elivala igumbi elivuthayo. Induku ihamba emkhonweni oqondisa ukunyakaza kwayo. Lonke ibhande lesikhathi ligcotshwe ngamafutha enjini. Ukuvimbela amafutha ukuthi angangeni emakamelweni omlilo, ama-caps e-oil scraper anikezwa.

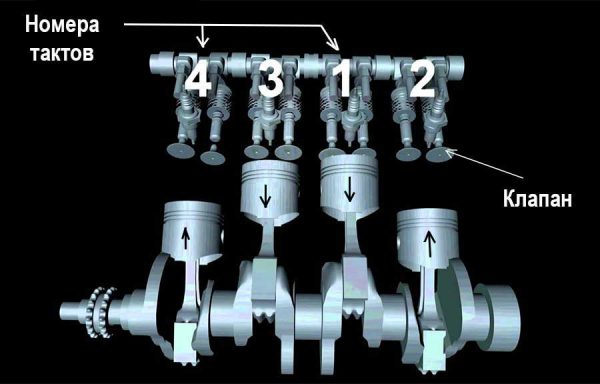

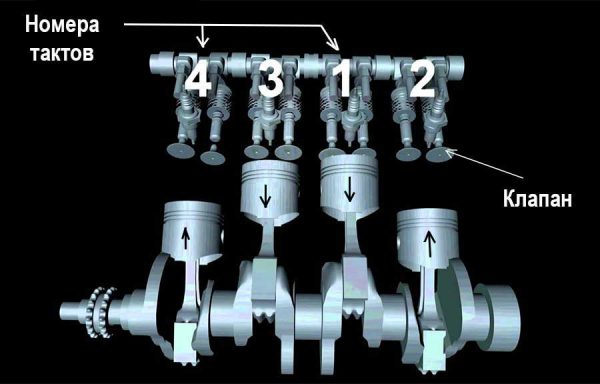

Isikhathi se-valve ngayinye kufanele sihambisane ngokuqinile nokuma kwamapiston kumasilinda. Ngakho-ke, i-crankshaft ne-camshaft zixhunywe ngokuqinile nge-drive, futhi shaft yokuqala ijikeleza ngokuphindwe kabili ngokusheshisa okwesibili. Umjikelezo ogcwele wokusebenza wenjini unezigaba ezine (imivimbo):

- Inlet. Ihamba phansi kusilinda, ipiston idala ivacuum ngaphezu kwayo. Ngesikhathi esifanayo, i-valve yokungenisa ivula futhi ingxube ye-fuel-air (FA) ingena ekamelweni elivuthayo ngokucindezela okuphansi. Lapho i-piston ifika esikhungweni esiphansi esifile (BDC), i-valve yokungena iqala ukuvala. Phakathi nalesi sifo, i-crankshaft ijikeleza ngo-180 °.

- Ukucindezelwa. Lapho ifinyelela ku-BDC, i-piston ishintsha indlela yokuhamba. Iyakhuphuka, icindezela ukuhlangana kukaphethiloli futhi idale umfutho omkhulu kusilinda (8.5-11 atm kuphethiloli kanye no-15-16 atm ezinjinini zikadizili). Ama-valve okungena nawokuphuma avaliwe. Ngenxa yalokho, i-piston ifinyelela esikhungweni esiphezulu esifile (TDC). Ngemijikelezo emibili, i-crankshaft yenza inguquko eyodwa, okungukuthi, yaphenduka i-360 °.

- Ukunyakaza okusebenzayo. Kusukela ku-spark, umhlangano wamafutha uvutha, futhi ngaphansi kwengcindezi yegesi ephumela, i-piston iqondiswe ku-BDC. Phakathi nalesi sigaba, ama-valve nawo avaliwe. Kusukela ekuqaleni komjikelezo wokusebenza, i-crankshaft izungeza i-540 °.

- Khulula. Ngemva kokudlula i-BDC, i-piston iqala ukunyuka phezulu, icindezela imikhiqizo evuthayo yegesi yemihlangano yamafutha. Lokhu kuvula i-valve yokukhipha, futhi ngaphansi kwengcindezi yamagesi e-piston asuswa ekamelweni elivuthayo. Ngemijikelezo emine, i-crankshaft yenza ama-revolutions amabili (waphenduka ama-720 °).

Isilinganiso segiya phakathi kwe-crankshaft necamshaft singu-2:1. Ngakho-ke, phakathi nomjikelezo wokusebenza, i-camshaft yenza inguquko eyodwa ephelele.

Isikhathi sezinjini zesimanje siyahluka kule mingcele elandelayo:

- indawo engenhla noma ephansi ye-shaft yokusabalalisa igesi;

- inani lama-camshafts - eyodwa (SOHC) noma amabili (DOHC) shafts;

- inani lama-valve ku-cylinder eyodwa (kusuka ku-2 kuya ku-5);

- uhlobo lokushayela kusuka ku-crankshaft kuya ku-camshaft (ibhande lamazinyo, iketanga noma igiya).

Injini yokuqala ye-carburetor yemodeli ye-VAZ, eyakhiwe kusukela ngo-1970 kuya ku-1980, inamasilinda amane anenani eliphelele lama-1.2 amalitha, amandla angama-60 amalitha. Nge. futhi iyiyunithi yamandla ye-four-stroke yakudala. Isitimela samavalvu saso sinamavalvu ayisishiyagalombili (amabili kusilinda ngasinye). Ukuzithoba nokuthembeka emsebenzini kumvumela ukuthi asebenzise uphethiloli we-AI-76.

Ividiyo: ukusebenza kwendlela yokusabalalisa igesi

Indlela yokusabalalisa igesi i-VAZ 2101

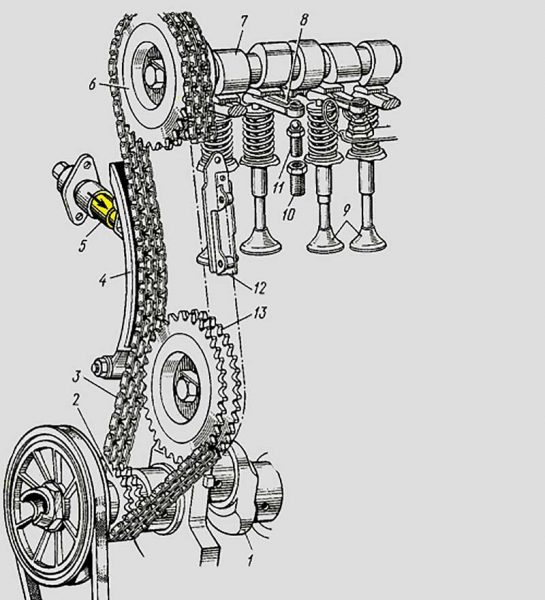

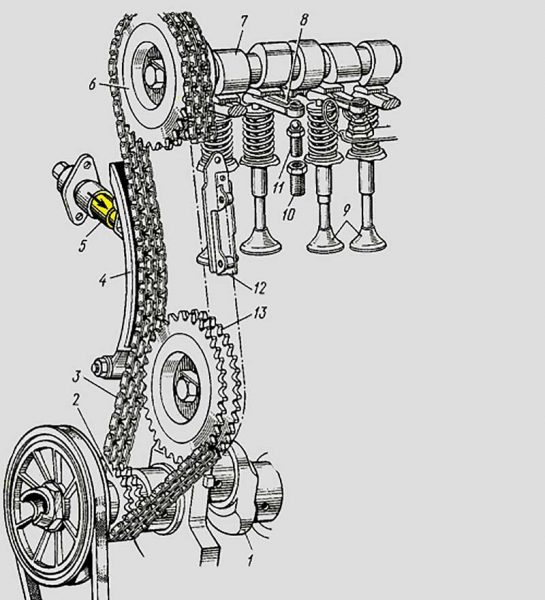

Umshini wokusabalalisa igesi we-VAZ 2101 uqhutshwa yi-crankshaft, futhi i-camshaft inesibopho sokusebenza kwama-valve.

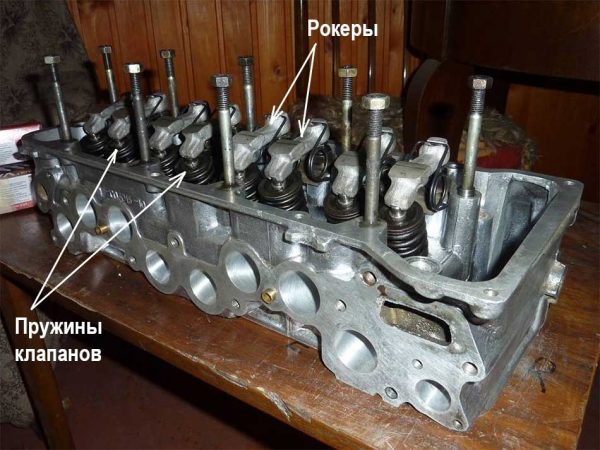

I-torque esuka ku-crankshaft yenjini (1) nge-drive sprocket (2), iketango (3) kanye ne-sprocket eqhutshwayo (6) idluliselwa ku-camshaft (7) etholakala ku-cylinder head (cylinder head). Amalobe e-camshaft asebenza ngezikhathi ezithile ezingalweni ze-actuator noma ama-rocker (8) ukuze ahambise ama-valve (9). Ukucaciswa okushisayo kwama-valve kusethwa ngamabhawodi alungisayo (11) atholakala ezihlahleni (10). Ukusebenza okuthembekile kwe-chain drive kuqinisekiswa yi-bushing (4) kanye neyunithi yokulungisa (5), i-tensioner, kanye ne-damper (12).

Imijikelezo yokusebenza kumasilinda enjini ye-VAZ 2101 inokulandelana okuthile.

Ukungasebenzi okuyinhloko kwesikhathi se-VAZ 2101

Ngokwezibalo, konke ukungasebenzi kahle kwenjini yesihlanu kwenzeka emshinini wokusabalalisa igesi. Ngezinye izikhathi ukungasebenzi kahle okuhlukile kunezimpawu ezifanayo, ngakho-ke isikhathi esiningi sichithwa ekuxilongweni nasekulungiseni. Izimbangela ezilandelayo ezivame kakhulu zokwehluleka kwesikhathi ziyahlukaniswa.

- Setha igebe elishisayo ngokungalungile phakathi kwama-rocker (ama-lever, izingalo ze-rocker) namakhamera e-camshaft. Lokhu kubangela ukuvuleka noma ukuvala okungaphelele kwama-valve. Ngesikhathi sokusebenza, umshini we-valve uyashisa, insimbi iyakhula, futhi iziqu ze-valve ziba zinde. Uma igebe ezishisayo isethwe ngokungalungile, injini kuyoba nzima ukuqala futhi uzoqala ukuphelelwa amandla, kuyoba pops kusukela muffler futhi knock endaweni motor. Lokhu kungasebenzi kuqedwa ngokulungisa imvume noma ukubuyisela ama-valve kanye ne-camshaft uma zigqokile.

- Izigxivizo ze-valve ezigugile, iziqu ze-valve noma izihlahla eziqondisayo. Umphumela walokhu kuzoba ukwanda kokusetshenziswa kukawoyela wenjini kanye nokuvela kwentuthu ephuma epayipini le-exhaust ngesikhathi sokungenzi lutho noma ukuphefumula. Ukungasebenzi kahle kuqedwa ngokufaka ama-caps, ama-valve nokulungisa ikhanda le-cylinder.

- Ukuhluleka kwe-camshaft drive ngenxa yeketanga elixegayo noma eliphukile, ukuphuka kwe-tensioner noma i-chain damper, ukugqokwa kwama-sprockets. Ngenxa yalokho, isikhathi se-valve sizophulwa, ama-valve azoqina, futhi injini izomisa. Kuzodinga ukulungiswa okukhulu ngokushintshwa kwazo zonke izingxenye ezihlulekile.

Amavalvu angagotshwa ngenxa yokushelela noma ukuphuka kweketango lesikhathi

Amavalvu angagotshwa ngenxa yokushelela noma ukuphuka kweketango lesikhathi - Iziphethu zamavalvu eziphukile noma ezigugile. Ama-valve ngeke avale ngokuphelele futhi azoqala ukungqongqoza, isikhathi se-valve sizophazamiseka. Kulokhu, iziphethu kufanele zishintshwe.

- Ukuvalwa okungaphelele kwama-valve ngenxa yokushiswa kwama-chamfers asebenzayo amapuleti e-valve, ukwakheka kwamadiphozithi avela kumadiphozithi kawoyela wekhwalithi ephansi kanye nophethiloli. Imiphumela izofana naleyo echazwe esigabeni 1 - ukulungiswa nokushintshwa kwama-valve kuyodingeka.

- Ukugqoka ama-bearings namakhamera we-camshaft. Ngenxa yalokho, isikhathi se-valve sizophulwa, amandla kanye nokuphendula kwe-throttle yenjini kuzokwehla, ukungqongqoza kuzovela ngesikhathi, futhi ngeke kube nzima ukulungisa ukuvunyelwa okushisayo kwama-valve. Inkinga ixazululwa ngokushintsha izinto ezigugile.

Ngemva kokuqeda noma yikuphi ukungasebenzi kahle kwenjini ye-VAZ 2101, kuzodingeka ulungise igebe phakathi kwama-rockers namakhamera we-camshaft.

Ividiyo: umphumela wokususwa kwe-valve ekusebenzeni kwesikhathi

Buka le vidiyo ku-YouTube

Ukudilizwa nokulungiswa kwekhanda le-cylinder Vaz 2101

Ukushintsha izindlela ze-valve kanye ne-bushings yokuqondisa, kuzodingeka ukuthi uhlakaze ikhanda le-cylinder. Lokhu kusebenza kudla isikhathi futhi kubuhlungu, kudinga amakhono athile okukhiya. Ukuze wenze lokhu, uzodinga amathuluzi alandelayo:

- isethi yama-wrenches (idinga ukuba khona kwamakhanda ku-8, 10, 13, 17, 19);

- slotted kanye Phillips screwdrivers;

- abadayisi;

- ama-mandrels wokucindezela nokucindezela amahlahla omhlahlandlela;

- ithuluzi A.60311/R lokukhipha ama-valve springs (raskuharivatel);

- umdonsa kanye ne-mandrel yezimpawu zamafutha;

- ukusonta kwe-torque.

Ngaphambi kokuqala ukudilizwa kwekhanda le-cylinder, kuyadingeka:

- Khipha i-antifreeze ohlelweni lokupholisa injini.

- Susa isihlungi somoya kanye ne-carburetor, njengoba unqamule ngaphambilini wonke amapayipi namapayipi.

- Nqamula izintambo, khulula ama-spark plug kanye nenzwa yokushisa evimbela ukuqhwa.

- Ngemva kokukhulula amantongomane okubopha ngesikrufu esingu-10, susa isembozo se-valve kanye ne-gasket endala.

Uzodinga isikrufu esingu-10mm ukuze ususe ikhava yevalvu.

Uzodinga isikrufu esingu-10mm ukuze ususe ikhava yevalvu. - Qondanisa izimpawu zokuqondanisa ze-crankshaft ne-camshaft. Kulokhu, ama-pistons amasilinda okuqala nesine azothuthela endaweni ephakeme kakhulu.

Ngaphambi kokukhipha ikhanda le-cylinder, kubalulekile ukuhlanganisa amamaki wokuqondanisa we-crankshaft ne-camshaft (ngakwesokunxele - i-camshaft sprocket, ngakwesokudla - i-pulley ye-crankshaft)

Ngaphambi kokukhipha ikhanda le-cylinder, kubalulekile ukuhlanganisa amamaki wokuqondanisa we-crankshaft ne-camshaft (ngakwesokunxele - i-camshaft sprocket, ngakwesokudla - i-pulley ye-crankshaft) - Khulula i-tensioner chain, susa i-thrust washer kanye ne-camshaft sprocket. Awukwazi ukususa iketanga ku-sprocket, udinga ukubopha ngocingo.

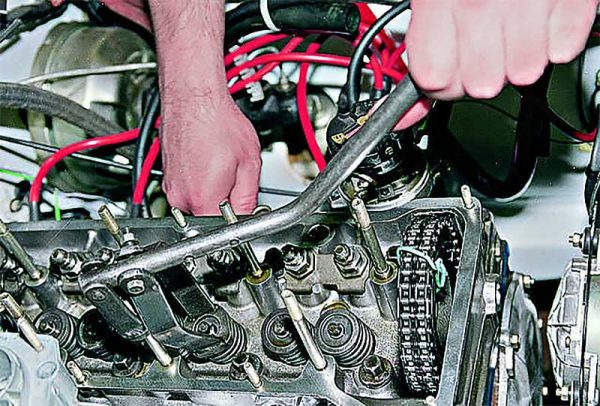

- Susa i-camshaft kanye nezindlu ezithwalayo.

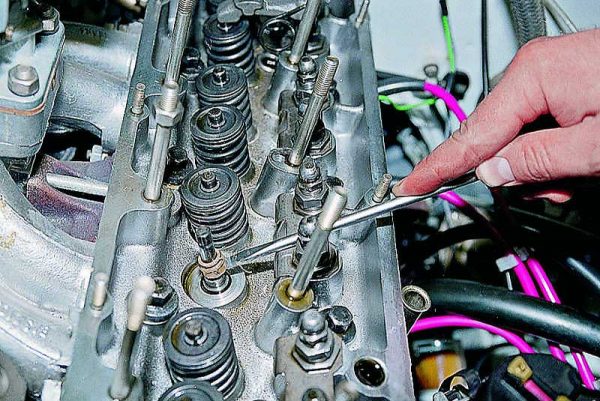

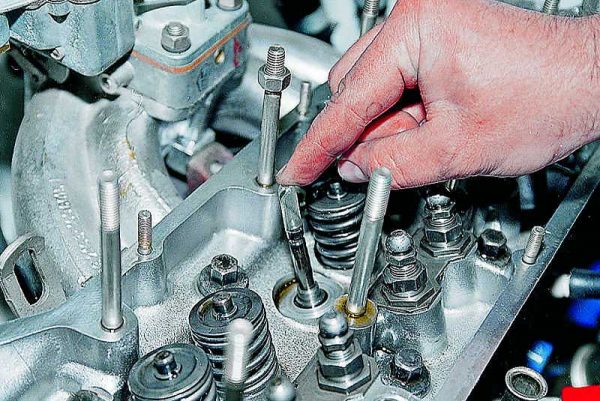

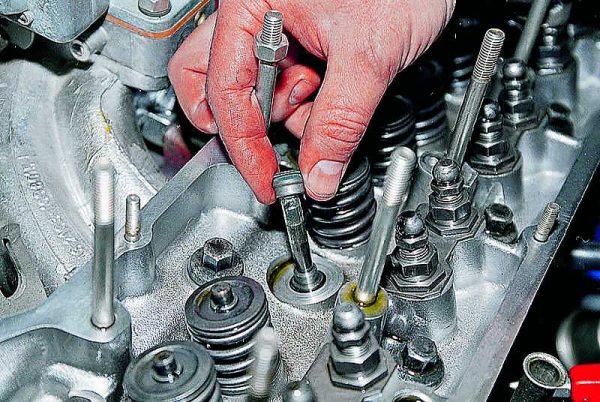

- Susa ama-bolts wokulungisa, susa emithonjeni bese ususa wonke ama-rocker.

Ukushintsha ama-valve springs nama-valve stem seal

Ukusekela ama-bearings, i-camshaft, iziphethu kanye nezimpawu ze-valve stem zingashintshwa ngaphandle kokukhipha ikhanda le-cylinder. Ukuze wenze lokhu, uzodinga ithuluzi lokukhipha (ukumisa) iziphethu ze-valve. Okokuqala, izakhi ezibonisiwe zishintshwa kuma-valve amasilinda okuqala nesine, ase-TDC. Khona-ke i-crankshaft ijikeleziswa ngesiqalisi esigwegwile ngo-180о, futhi ukusebenza kuyaphindwa kuma-valve amasilinda wesibili nowesithathu. Zonke izenzo zenziwa ngokulandelana okuchazwe ngokuqinile.

- Ibha yensimbi ethambile enobubanzi obungaba ngu-8 mm ifakwa embotsheni yekhandlela phakathi kwepiston nevalvu. Ungasebenzisa i-tin solder, ithusi, ithusi, ithusi, ezimweni ezimbi kakhulu - i-screwdriver ye-Phillips.

Ibha yensimbi ethambile noma i-screwdriver ye-Phillips ifakwa embotsheni yepulaki yenhlansi phakathi kwepiston nevalvu.

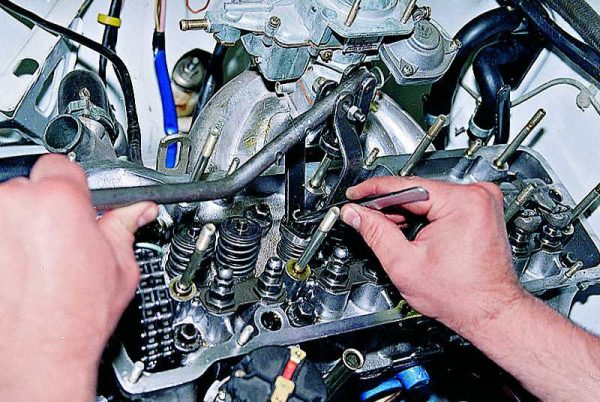

Ibha yensimbi ethambile noma i-screwdriver ye-Phillips ifakwa embotsheni yepulaki yenhlansi phakathi kwepiston nevalvu. - Inadi liboshwe phezu kwe-camshaft ephethe isigxobo sendlu. Ngaphansi kwayo, ukubanjwa kwedivayisi yokukhipha ama-crackers (idivayisi A.60311 / R) kuyaqalwa, okukhiya isiphethu nepuleti layo.

I-nati ku-stud isebenza njengesisekelo, idala i-lever ye-cracker

I-nati ku-stud isebenza njengesisekelo, idala i-lever ye-cracker - Intwasahlobo icindezelwa nge-cracker, futhi ama-crackers okukhiya asuswa ngama-tweezers noma induku yamagnetized.

Esikhundleni sama-tweezers, kungcono ukusebenzisa induku yamagnetic ukukhipha ama-crackers - kulokhu, ngeke alahleke.

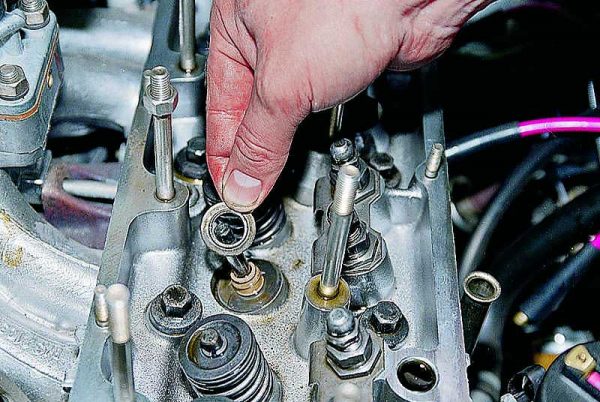

Esikhundleni sama-tweezers, kungcono ukusebenzisa induku yamagnetic ukukhipha ama-crackers - kulokhu, ngeke alahleke. - Ipuleti liyasuswa, bese kuba nemithombo yangaphandle nengaphakathi.

Iziphethu zicindezelwa phezulu ngepuleti elihlanganiswe nama-crackers amabili

Iziphethu zicindezelwa phezulu ngepuleti elihlanganiswe nama-crackers amabili - Amawasha asekelayo aphezulu naphansi atholakala ngaphansi kweziphethu ayasuswa.

Ukuze ususe uphawu lwamafutha, udinga ukususa ama-washers okusekela

Ukuze ususe uphawu lwamafutha, udinga ukususa ama-washers okusekela - Nge-screwdriver ene-slot, vala ngokucophelela bese ususa i-oil scraper cap.

Gcoba i-cap nge-screwdriver ngokucophelela ukuze ungalimazi umkhawulo womkhono we-valve

Gcoba i-cap nge-screwdriver ngokucophelela ukuze ungalimazi umkhawulo womkhono we-valve - Umkhono wepulasitiki ovikelayo ufakwa esiqwini se-valve (esihlinzekwe ngamakepisi amasha).

Umkhono uvikela i-oil scraper cap ekulimaleni ngesikhathi sokufakwa kwayo.

Umkhono uvikela i-oil scraper cap ekulimaleni ngesikhathi sokufakwa kwayo. - Isigqoko sokususa uwoyela sifakwa esihlahleni bese siyiswa endukwini.

Unqenqema olusebenzayo lwekepisi kufanele lugcotshwe ngamafutha omshini ngaphambi kokufakwa.

Unqenqema olusebenzayo lwekepisi kufanele lugcotshwe ngamafutha omshini ngaphambi kokufakwa. - Umkhono wepulasitiki ukhishwa ngama-tweezers, bese ikepisi licindezelwa kumkhono wevalvu.

Ukuze ungalimazi i-cap, i-mandrel ekhethekile isetshenziswa uma uyicindezela

Ukuze ungalimazi i-cap, i-mandrel ekhethekile isetshenziswa uma uyicindezela

Uma kungekho omunye umsebenzi wokulungisa odingekayo, umhlangano wesikhathi wenziwa ngokulandelana okuphambene. Ngemva kwalokho, kuyadingeka ukulungisa imvume yokushisa yama-valve.

Ukushintsha ama-valve nokuwaxhapha, ukufaka ama-bushings amasha omhlahlandlela

Uma amakhanda e-valve eshile, noma ukumbozwa kokungcola emafutheni kanye nophethiloli kuye kwakheke phezu kwawo, ukuvimbela ukulingana okunethezeka ezihlalweni, ama-valve kufanele ashintshwe. Lokhu kuzodinga ukudilizwa kwekhanda le-cylinder, okungukuthi, kuzodingeka ukuthi ugcwalise wonke amaphuzu we-algorithm engenhla ngaphambi kokufaka izimpawu ezintsha ze-valve stem ezintanyeni ze-valve. Ama-caps kanye neziphethu ngokwazo zingafakwa ekhanda le-cylinder elisusiwe ngemva kokufaka esikhundleni nokufaka ama-valve. Umsebenzi wenziwa ngokulandelana okulandelayo.

- Amapayipi anqanyuliwe ku-carburetor, ipayipi lokungena kanye nepayipi lokuphuma lejazi lokupholisa lekhanda lesilinda.

- I-starter guard kanye ne-exhaust pipe ye-mufflers inqanyuliwe ku-multifold exhaust.

- Nqamula inzwa yomfutho kawoyela.

- Amabhawodi avikela ikhanda le-cylinder ku-cylinder block ayadatshulwa, bese ejikiswa nge-crank ne-ratchet. Ikhanda lesilinda liyasuswa.

- Uma izindlela ze-valve zingakahlakazwa, ziyasuswa ngokuhambisana nemiyalelo engenhla (bheka "Ukushintsha ama-valve springs nama-valve stem seal").

Ukushintsha ama-valve nama-bushings, udinga ukuqaqa izindlela ze-valve

Ukushintsha ama-valve nama-bushings, udinga ukuqaqa izindlela ze-valve - Ikhanda le-cylinder liyaphendulwa ukuze uhlangothi oluseduze ne-cylinder block lube phezulu. Ama-valve amadala ayakhishwa kubaqondisi bawo.

Ama-valve amadala kufanele akhishwe kumhlahlandlela wawo.

Ama-valve amadala kufanele akhishwe kumhlahlandlela wawo. - Ama-valve amasha ashuthelwa kumhlahlandlela futhi ahlolwe ukuthi ayadlala yini. Uma kudingekile ukufaka esikhundleni se-bushings yomhlahlandlela, amathuluzi akhethekile asetshenziswa.

Mandrel for knock out (phezulu) kanye ngokucindezela (phansi) guide bushings

Mandrel for knock out (phezulu) kanye ngokucindezela (phansi) guide bushings - Ikhanda lesilinda liyashisa - ungakwazi esitofini sikagesi. Ukuze ama-bushings alingane kangcono ezisekelweni, kufanele agcotshwe ngamafutha enjini.

Ukufaka ama-bushings amasha kuzodinga isando ne-mandrel namafutha enjini

Ukufaka ama-bushings amasha kuzodinga isando ne-mandrel namafutha enjini - Ama-valve amasha axhashazwa ezihlalweni zekhanda le-cylinder kusetshenziswa unamathisele okhethekile wokugoqa kanye ne-drill. Ngesikhathi sokujikeleza, ama-valve discs kumele acindezelwe ngezikhathi ezithile ngokumelene nezihlalo ngesibambo sesando sokhuni. I-valve ngayinye ihlikihlwa imizuzu embalwa, bese i-paste ikhishwa ebusweni bayo.

I-Lapping iqedwa lapho ingaphezulu lesihlalo kanye ne-valve endaweni oxhumene nayo iba matte

I-Lapping iqedwa lapho ingaphezulu lesihlalo kanye ne-valve endaweni oxhumene nayo iba matte - Ukufakwa kwezinqubo ze-valve kanye nokuhlanganiswa kwekhanda le-cylinder kwenziwa ngokulandelana okuphambene. Ngaphambi kwalokhu, indawo engaphezulu yekhanda ne-cylinder block ihlanzwa ngokucophelela, igcotshwe ngamafutha e-graphite, futhi i-gasket entsha ifakwa kuma-cylinder block studs.

Lapho ufaka ikhanda le-cylinder ku-cylinder block, i-gasket kufanele ishintshwe ibe entsha.

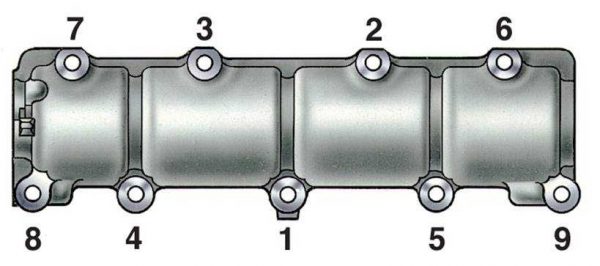

Lapho ufaka ikhanda le-cylinder ku-cylinder block, i-gasket kufanele ishintshwe ibe entsha. - Lapho ufaka ikhanda ku-cylinder block, ama-bolts aqiniswa nge-torque wrench ngokulandelana okuqinile nangamandla athile. Okokuqala, amandla angu-33.3–41.16 Nm asetshenziswa kuwo wonke amabhawodi. (3.4–4.2 kgf-m.), Bese ziqiniswa ngamandla angu-95.94–118.38 Nm. (9.79–12.08 kgf-m.).

Uma ungalandeli umyalelo wokuqinisa ama-bolts, ungalimaza i-gasket kanye nobuso bekhanda le-cylinder.

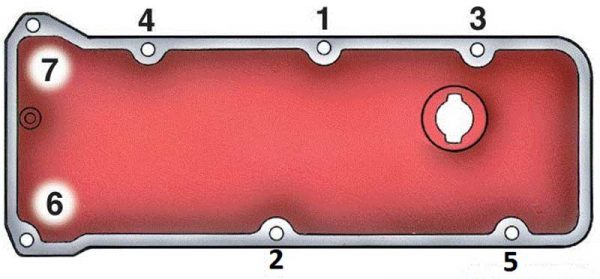

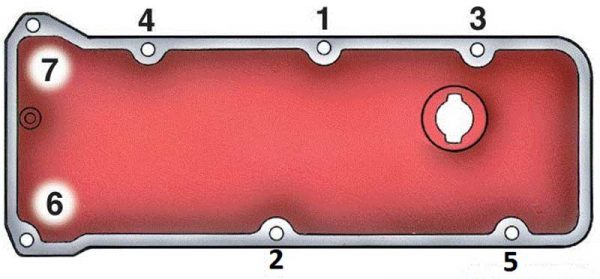

Uma ungalandeli umyalelo wokuqinisa ama-bolts, ungalimaza i-gasket kanye nobuso bekhanda le-cylinder. - Lapho ufaka i-camshaft ethwele izindlu, amantongomane ezigxotsheni nawo aqiniswa ngokulandelana okuthile.

Uma ungalandeli i-oda lokuqinisa amantongomane ezindlu ezithwele i-camshaft, ungakwazi ukugoqa i-camshaft ngokwayo.

Uma ungalandeli i-oda lokuqinisa amantongomane ezindlu ezithwele i-camshaft, ungakwazi ukugoqa i-camshaft ngokwayo. - Ngemuva kokufaka ikhanda le-cylinder kanye nezindlu ze-camshaft, ukuvunyelwa okushisayo kwama-valve kulungiswa.

Ividiyo: ukulungiswa kwekhanda lesilinda i-VAZ 2101-07

Buka le vidiyo ku-YouTube

Ukulungiswa kwe-valve ye-thermal clearance

Isici sokuklama sezinjini zamamodeli we-VAZ asendulo ukuthi ngesikhathi sokusebenza, igebe phakathi kwekhamera ye-camshaft kanye ne-valve rocker-pusher iyashintsha. Kunconywa ukulungisa lesi sikhala njalo ngamakhilomitha ayizinkulungwane ezingu-15. Ukuze usebenze, uzodinga ama-wrenches angu-10, 13 no-17 kanye ne-probe engu-0.15 mm ubukhulu. Ukuhlinza kulula, futhi ngisho nomshayeli ongenalwazi angawenza. Zonke izenzo zenziwa enjinini ebandayo ngendlela elandelayo:

- Ngokwemiyalelo engenhla, ikhava ye-valve isusiwe (isigatshana sesi-4 sesigaba esithi "Ukudilizwa nokulungiswa kwekhanda le-cylinder ye-VAZ 2101"), bese kuba ikhava yokusabalalisa umlilo. I-dipstick yamafutha iyasuswa.

- Izimpawu ze-crankshaft ne-camshaft zihlangene (isigatshana sesi-5 sesigaba esithi "Ukudilizwa nokulungiswa kwekhanda le-cylinder Vaz 2101"). I-piston yesilinda sesine isethwe endaweni ye-TDC, kuyilapho ama-valve womabili evaliwe.

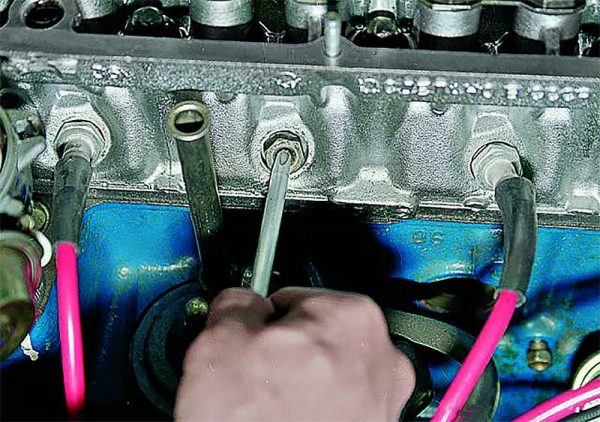

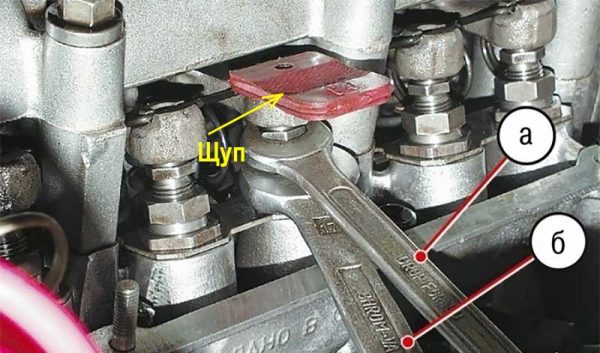

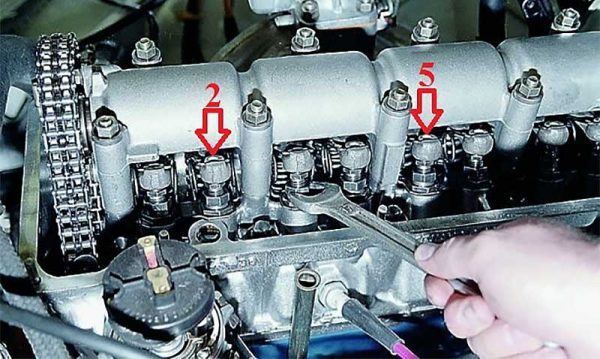

- I-probe ifakwa phakathi kwe-rocker nekhamera ye-camshaft yamavalvu angu-8 no-6, okufanele ingene esikhaleni ngobunzima obuncane futhi inganyakazi ngokukhululeka. I-lock nut ithukululwa ngokhiye ongu-17, futhi igebe libekwe ngokhiye ongu-13. Ngemuva kwalokho, i-bolt yokulungisa iboshwe nge-locknut.

Lapho ulungisa igebe ngokhiye we-17, i-lock nut iyakhululwa, futhi igebe ngokwalo lisethwe ngokhiye we-13.

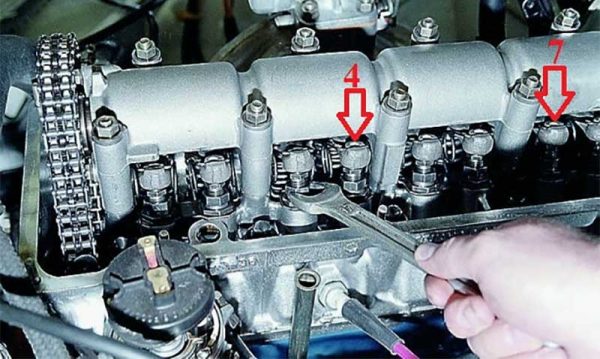

Lapho ulungisa igebe ngokhiye we-17, i-lock nut iyakhululwa, futhi igebe ngokwalo lisethwe ngokhiye we-13. - I-crankshaft izungeziswa ngesiqalisi esigwegwile ngokwewashi ngo-180 °. Ama-valve 7 no-4 alungiswa ngendlela efanayo.

Ngemuva kokuguqula i-crankshaft engu-180 °, ama-valve 7 no-4 ayalungiswa

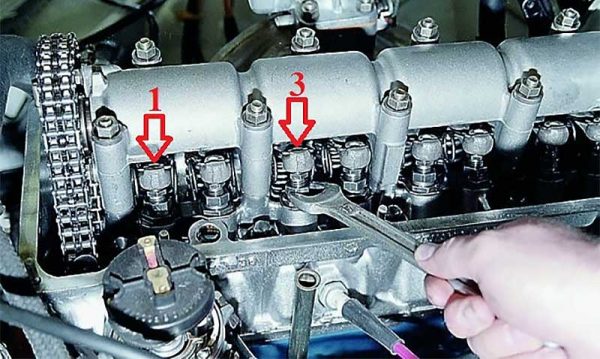

Ngemuva kokuguqula i-crankshaft engu-180 °, ama-valve 7 no-4 ayalungiswa - I-crankshaft izungeziswe ngo-180° ngokwewashi futhi futhi amavalvu 1 no-3 ayalungiswa.

Uma igeji yokuzizwa ingangeni esikhaleni esiphakathi kwekhamera ne-rocker, khulula ilokhithi kanye nebhawodi yokulungisa.

Uma igeji yokuzizwa ingangeni esikhaleni esiphakathi kwekhamera ne-rocker, khulula ilokhithi kanye nebhawodi yokulungisa. - I-crankshaft izungeziswe ngo-180 ° ngokwewashi futhi futhi amavalvu 2 no-5 ayalungiswa.

Ngemuva kokulungisa ukucaciswa kwe-valve, qala injini futhi uhlole ukusebenza kwayo.

Ngemuva kokulungisa ukucaciswa kwe-valve, qala injini futhi uhlole ukusebenza kwayo. - Zonke izingxenye, kuhlanganise nesembozo se-valve, zifakwe endaweni.

Ividiyo: ukulungisa imvume ye-valve VAZ 2101

Buka le vidiyo ku-YouTube

Isivalo se-valve

Isembozo se-valve sivala futhi sivale isikhathi, sivimbele amafutha e-camshaft, ama-valve nezinye izingxenye ukuthi zingavuzi. Ngaphezu kwalokho, amafutha enjini entsha athululelwa entanyeni yayo lapho eshintsha. Ngakho-ke, i-gasket yokuvala ifakwe phakathi kwesembozo se-valve nekhanda le-cylinder, elishintshwa njalo lapho ama-valve elungiswa noma elungiswa.

Ngaphambi kokuyishintsha, sula ngokucophelela izindawo zekhanda le-cylinder kanye nekhava ezinsalela zamafutha enjini. Khona-ke i-gasket ifakwa kuma-cylinder head studs futhi icindezelwe ikhava. Kuyadingeka ukuthi i-gasket ingene ncamashi emifuleni yekhava. Ngemuva kwalokho, ngokulandelana okuchazwe ngokuqinile, amantongomane okubopha aqiniswa.

Ividiyo: ukuqedwa kokuvuza kwamafutha ngaphansi kwesembozo se-valve i-VAZ 2101-07

Buka le vidiyo ku-YouTube

Ukushintsha nokulungisa ama-valve ku-VAZ 2101 kuwumsebenzi odla isikhathi futhi kudinga amakhono athile. Kodwa-ke, ukuba nesethi yamathuluzi adingekayo atholakalayo futhi agcwalise ngokuqhubekayo izidingo zemiyalelo yochwepheshe, kungenzeka ukwenza kube ngokoqobo ngisho nakumshayeli ongenalwazi.