Ukwakhiwa nokusebenza kwephampu yamanzi (ipompo) enjinini yemoto

Okuqukethwe

Ukushintshaniswa kokushisa enjinini kwenziwa ngokudluliswa kwamandla ukusuka emthonjeni endaweni yesilinda emoyeni oshaywa nge-radiator yokupholisa. Iphampu ye-centrifugal vane, evame ukubizwa ngokuthi ipompo, inesibopho sokuhambisa into epholile kusistimu yohlobo loketshezi. Ngokuvamile nge-inertia, amanzi, nakuba amanzi ahlanzekile ezimotweni engakaze asetshenziswe isikhathi eside.

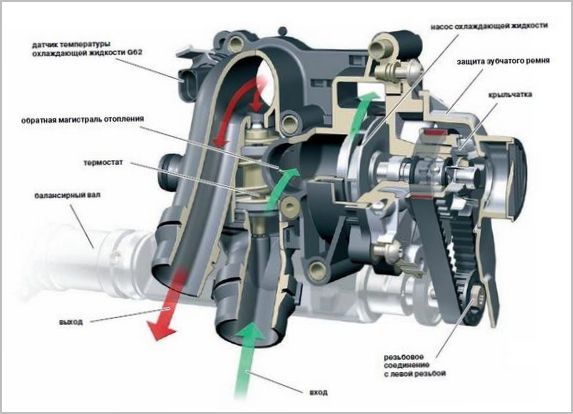

Izingxenye zephampu

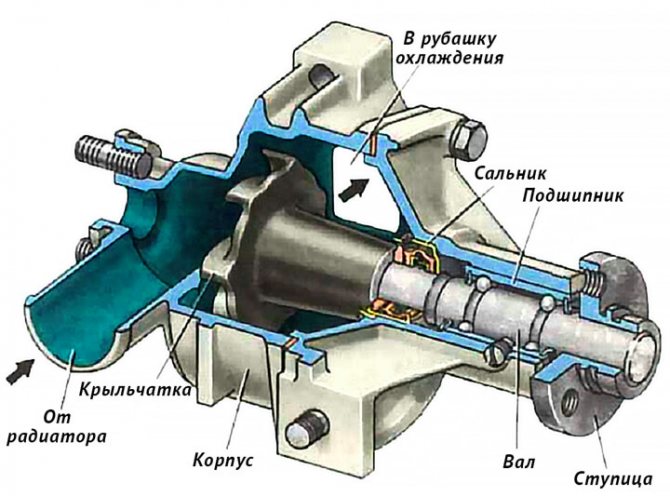

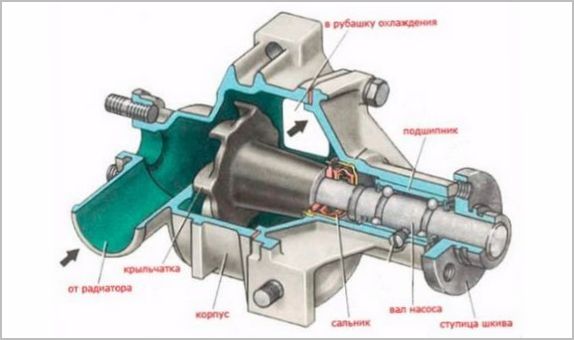

Iphampu ye-antifreeze circulation circulation yenziwa ngokwethiyori kunokuba ingathobeki, umsebenzi wayo ususelwa oketshezini oluphonswa amandla angama-centrifugal emaphethelweni ama-blades, lapho lujova khona amajakhethi okupholisa. Ukuqamba kuhlanganisa:

- i-shaft, ekugcineni lapho kukhona umjovo we-injection eyenziwe ngensimbi noma epulasitiki, kanti ngakolunye - i-pulley yokushayela ye-V-belt noma enye i-transmission;

- izindlu ezine-flange zokufakwa enjini kanye nokuhlalisa izingxenye zangaphakathi;

- ukuthwala lapho i-shaft ijikeleza khona;

- uphawu lwamafutha oluvimbela ukuvuza kwe-antifreeze kanye nokungena kwayo ekuthwaleni;

- i-cavity emzimbeni, engeyona ingxenye ehlukile, kodwa inikeza izakhiwo ezidingekayo ze-hydrodynamic.

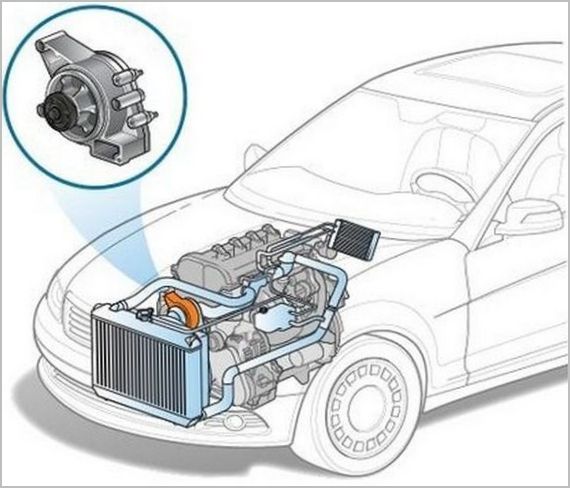

Ipompo ngokuvamile itholakala enjinini kusukela engxenyeni lapho uhlelo lwe-accessory drive lutholakala khona kusetshenziswa amabhande noma amaketanga.

I-physics yephampu yamanzi

Ukwenza i-ejenti yokushisa ye-liquid ihambe embuthanweni, kuyadingeka ukudala umehluko wengcindezi phakathi kokungena nokuphuma kwepompo. Uma ukucindezela okunjalo kutholakala, khona-ke i-antifreeze izosuka endaweni lapho ingcindezi iphakeme, ngokusebenzisa yonke injini iye endaweni yokungena yepompo ene-vacuum ehlobene.

Ukuhamba kobuningi bamanzi kuzodinga izindleko zamandla. Ukungqubuzana koketshezi lwe-antifreeze ezindongeni zazo zonke iziteshi namapayipi kuzovimbela ukujikeleza, lapho umthamo wesistimu umkhulu, izinga lokugeleza liphezulu. Ukudlulisa amandla abalulekile, kanye nokuthembeka okuphezulu, idrayivu yemishini evela ku-crankshaft drive pulley cishe isetshenziswa njalo. Kukhona amaphampu ane-motor kagesi, kodwa ukusetshenziswa kwawo kunqunyelwe ezinjini ezinomnotho kakhulu, lapho into eyinhloko yizindleko eziphansi zikaphethiloli, futhi izindleko zemishini azibhekwa. Noma ezinjinini ezinamaphampu engeziwe, isibonelo, ezinama-preheaters noma ama-heaters amabili.

Ayikho indlela eyodwa yokushayela iphampu ukusuka kuliphi ibhande. Izinjini eziningi zisebenzisa ibhande lesikhathi elinamazinyo, kodwa abanye abaklami banomuzwa wokuthi kwakungafaneleki ukuhlanganisa ukwethembeka kwesikhathi ohlelweni lokupholisa, futhi iphampu iqhutshwa lapho isuka ebhandeni elishintshashintshayo langaphandle noma elinye lamanye angeziwe. Ifana ne-compressor ye-A/C noma iphampu yesiteringi yamandla.

Lapho i-shaft ene-impeller ijikeleza, i-antifreeze ehlinzekwa engxenyeni yayo ephakathi iqala ukulandela iphrofayili yama-blades, ngenkathi ibhekana namandla e-centrifugal. Ngenxa yalokho, idala ukucindezela okweqile epayipini lokuphuma, futhi isikhungo sigcwaliswa ngezingxenye ezintsha ezivela kubhulokhi noma kurediyetha, kuye ngokuthi ukuma kwamanje kwamavalvu e-thermostat.

Ukungasebenzi kahle kanye nemiphumela yako injini

Ukwehluleka kwamaphampu kungahlukaniswa njengokuphoqelekile noma okuyinhlekelele. Angeke kube khona abanye lapha, ukubaluleka kokupholisa kuphezulu kakhulu.

Ngokuguga kwemvelo noma amaphutha okukhiqiza epompo, i-bearing, ibhokisi lokugxusha noma i-impeller ingase iqale ukuwa. Uma esimweni sokugcina lokhu mhlawumbe kuwumphumela wesici sefekthri noma ukonga ubugebengu ngekhwalithi yezinto zokwakha, khona-ke ibhokisi elithwalayo nelokugxusha lizoguga nakanjani, okuwukuphela kombuzo isikhathi. I-bearing ehlulekayo ngokuvamile imemezela izinkinga zayo ngokuhum noma ngokugoqoza, ngezinye izikhathi ngekhwelo eliphakeme.

Imvamisa, izinkinga zepompo ziqala ngokubonakala kokudlala kuma-bearings. Naphezu kokulula okubonakalayo komklamo, zilayishwa lapha ngokuphawulekayo. Lokhu kungenxa yezinto ezilandelayo:

- Amafutha ku-bearing afakwa kanye efekthri futhi awakho ngaphansi kokuvuselelwa ngesikhathi sokusebenza.

- kungakhathaliseki ukuthi yiziphi izimpawu zomgodi wangaphakathi we-bearing, lapho izakhi zayo ezigoqayo, amabhola noma ama-rollers zikhona, i-oksijeni yasemkhathini ingena lapho, okuyinto ekushiseni okuphezulu komhlangano kubangela ukuguga okusheshayo kwe-lubricant;

- ukuthwala kubhekana nomthwalo ophindwe kabili, ngokwengxenye ngenxa yesidingo sokudlulisa amandla abalulekile nge-shaft ku-impeller ezungeza endaweni eyi-liquid ngesivinini esikhulu, futhi ikakhulukazi ngenxa yamandla aphezulu okudonsa kanzima kwebhande lokushayela, okuthi, ngaphezu kwalokho, livame ukuqina ngokweqile ngesikhathi sokulungiswa uma i-automatic tensioner inganikezwanga;

- kuyaqabukela, kusetshenziswe ibhande elihlukile ukuzungezisa iphampu, imvamisa amayunithi asizayo amaningana anamandla anama-rotor amakhulu kanye nokumelana okuguquguqukayo kokujikeleza kulenga kudrayivu evamile, lawa angaba ijeneretha, ama-camshaft, iphampu yokuqondisa amandla ngisho ne-air conditioning. i-compressor;

- kukhona imiklamo lapho i-fan enkulu yokupholisa okuphoqelekile ye-radiator ifakwe ku-pulley yepompo, nakuba okwamanje cishe wonke umuntu ushiye isisombululo esinjalo;

- Umhwamuko we-antifreeze ungangena ku-bearing ngokusebenzisa ibhokisi lokugxusha elivuzayo.

Ngisho noma ukuthwala kwekhwalithi ephezulu kungaphumeleli, khona-ke ukudlala kungase kwakheke kuwo ngenxa yokugqoka. Kwamanye ama-node kuphephile ngokwanele, kodwa hhayi esimweni sepompo. I-shaft yayo ivalwe ngophawu lwamafutha lomklamo oyinkimbinkimbi, ocindezelwa ukucindezela okukhulu okuvela ngaphakathi ohlelweni. Ngeke ikwazi ukusebenza ngaphansi kwezimo zokudlidliza kwe-high-frequency ngenxa ye-bearing play isikhathi eside. I-antifreeze eshisayo ingena kuyo yehla ngokudonsa izoqala ukungena ku-bearing, igeze i-lubricant noma ibangele ukuwohloka kwayo, futhi yonke into izophela nge-avalanche yokuguga.

Ingozi yalesi simo ukuthi iphampu ivame ukushayelwa ibhande lesikhathi, okuncike kulo ukuphepha kwenjini iyonke. Ibhande aliklanyelwe ukusebenza ngaphansi kwezimo lapho lithelwa khona nge-antifreeze eshisayo, lizoguga ngokushesha futhi liphule. Ezinjinini eziningi, lokhu ngeke kuholele ekumisweni kuphela, kodwa ekwephulweni kwezigaba zokuvula i-valve enjinini esaqhubeka ezungezayo, okuzophela ngomhlangano wamapuleti e-valve anezingqimba zepiston. Iziqu ze-valve zizogoba, kuzodingeka uhlukanise injini futhi ushintshe izingxenye.

Kulokhu, kuhlale kunconywa ukufaka esikhundleni sepompo ngokuvimbela ekufakweni ngakunye okuhleliwe kwekhithi yesikhathi esisha, imvamisa ekhonjiswe ngokucacile emiyalweni. Ngisho noma iphampu ibukeka kahle impela. Ukuthembeka kubaluleke kakhulu, ngaphandle kwalokho, akudingeki ukuthi uchithe imali ekuhlakazweni okungahleliwe kwengaphambili lenjini.

Kukhona okuhlukile kuyo yonke imithetho. Endabeni yokushintshwa kwephampu, lokhu kungenxa yokusetshenziswa kwemikhiqizo okusobala ukuthi inomthombo omude ukwedlula ngisho nemishini yasefekthri. Kodwa futhi zibiza kakhulu. Ongakukhetha, ukushintshwa okuvamile noma insiza emangalisayo - wonke umuntu angazinqumela yena. Yize noma imaphi amaphampu amahle kakhulu angabulawa ngokungazi ukuthi i-antifreeze yekhwalithi ephansi, ukushintshwa kwayo kungakafiki isikhathi, noma ukwephulwa komshini webhande lokushayela ibhande noma ubuchwepheshe.