Indlela ye-valve yenjini, idivayisi yayo kanye nesimiso sokusebenza

Okuqukethwe

I-valve mechanism iyisicuphi sesikhathi esiqondile, esiqinisekisa ukutholakala ngesikhathi kwengxube yamafutha omoya kumasilinda enjini kanye nokukhishwa okulandelayo kwamagesi okukhipha umoya. Izakhi eziyinhloko zesistimu ziyi-valve, okumele, phakathi kwezinye izinto, iqinisekise ukuqina kwekamelo elivuthayo. Bangaphansi kwemithwalo esindayo, ngakho umsebenzi wabo ungaphansi kwezidingo ezikhethekile.

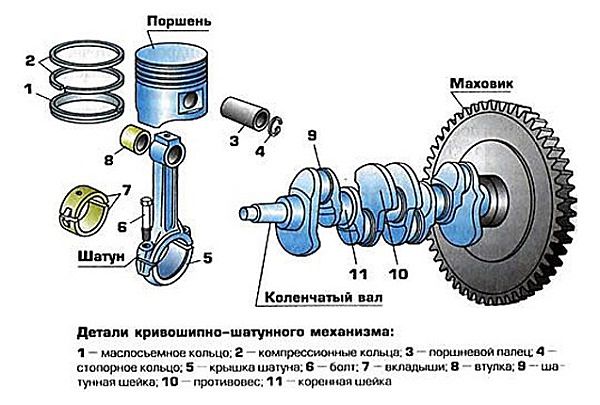

Izakhi eziyinhloko ze-valve mechanism

Injini idinga okungenani ama-valve amabili isilinda, i-intake kanye ne-exhaust, ukuze isebenze kahle. I-valve ngokwayo iqukethe isiqu nekhanda ngendlela yepuleti. Isihlalo yilapho ikhanda le-valve lihlangana khona nekhanda le-cylinder. Ama-valve okudonsa anobubanzi bekhanda obukhulu kunama-valve okukhipha umoya. Lokhu kuqinisekisa ukugcwaliswa okungcono kwegumbi elivuthayo ngengxube yamafutha omoya.

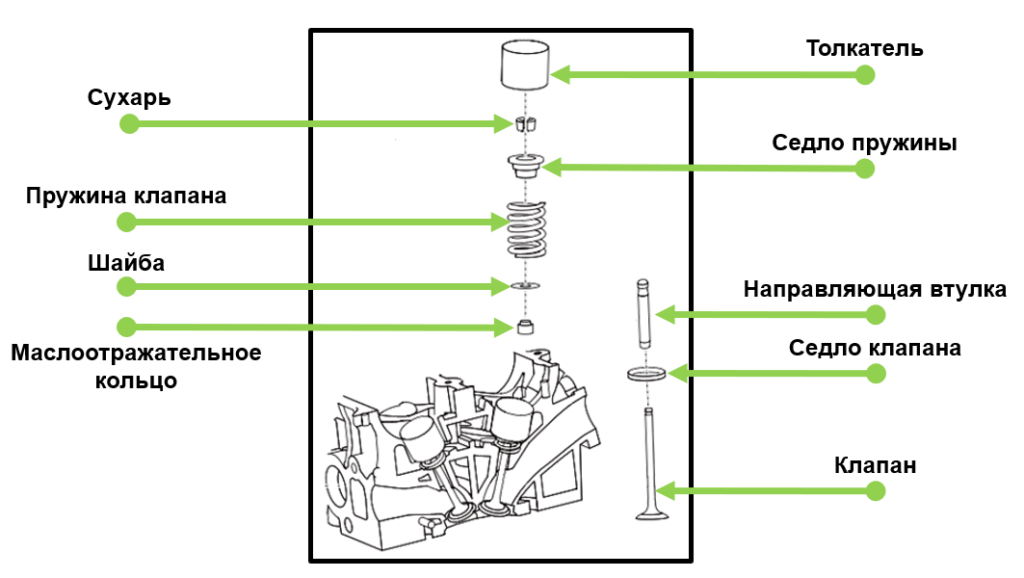

Izinto eziyinhloko zemeshini:

- ama-valve okungena kanye nokukhipha - eklanyelwe ukufaka ingxube ye-air-fuel kanye nokukhipha amagesi avela ekamelweni elivuthayo;

- ama-bushings aqondisayo - qinisekisa isiqondiso esiqondile sokuhamba kwama-valve;

- intwasahlobo - ibuyisela i-valve endaweni yayo yokuqala;

- isihlalo se-valve - indawo yokuxhumana kwepuleti enekhanda le-cylinder;

- ama-crackers - asebenza njengesisekelo sentwasahlobo futhi alungise sonke isakhiwo);

- ama-valve stem seal noma izindandatho ze-slinger zamafutha - kuvimbela uwoyela ukuthi ungangeni kusilinda;

- i-pusher - idlulisela ingcindezi kusuka kukhamera ye-camshaft.

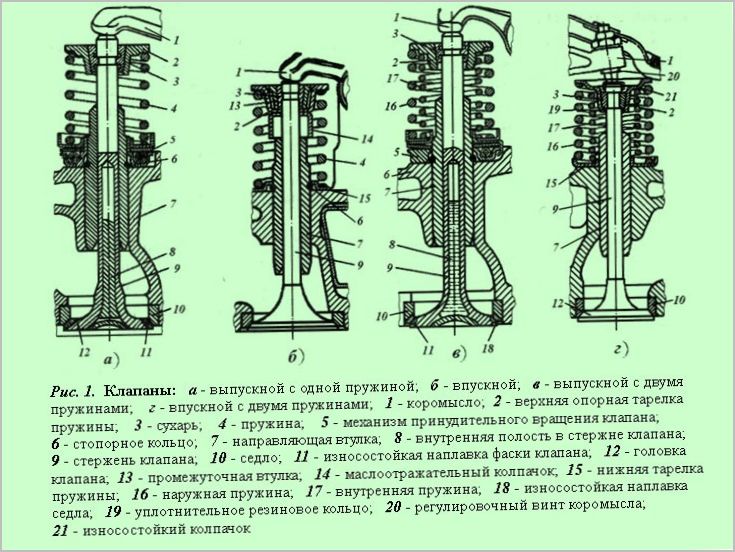

Amakhamera aku-camshaft acindezela ama-valve, alayishwe entwasahlobo ukuze abuyele endaweni yawo yasekuqaleni. Intwasahlobo ihlanganiswe nenduku enama-crackers kanye nepuleti yasentwasahlobo. Ukudambisa ukudlidliza okuzwakalayo, hhayi okukodwa, kodwa iziphethu ezimbili ezinamajika aguquguqukayo zingafakwa entweni.

Umkhono womhlahlandlela uyisiqephu esiyicylindrical. Inciphisa ukungqubuzana futhi iqinisekise ukusebenza kahle nokulungile kwenduku. Ngesikhathi sokusebenza, lezi zingxenye nazo zingaphansi kokucindezeleka nokushisa. Ngakho-ke, ama-alloys angagugi futhi angashisi asetshenziselwa ukwenziwa kwawo. Ama-valve e-exhaust kanye nama-valve wokungenisa ahluka kancane ngenxa yokuhluka komthwalo.

Indlela i-valve mechanism esebenza ngayo

Ama-valve ahlala evezwe emazingeni okushisa aphezulu kanye nezingcindezi. Lokhu kudinga ukunakwa okukhethekile kumklamo kanye nezinto zalezi zingxenye. Lokhu kuyiqiniso ikakhulukazi ngeqembu le-exhaust, njengoba amagesi ashisayo aphuma kuwo. Ipuleti levalvu yokukhipha umoya ezinjinini zikaphethiloli lingashisisa kufikela ku-800˚C - 900˚C, futhi ezinjinini zikadizili 500˚C - 700C. Umthwalo epuleti le-valve yokungena ungaphansi izikhathi eziningana, kodwa ufinyelela ku-300˚С, nawo omningi kakhulu.

Ngakho-ke, ama-alloys ensimbi angavimbeli ukushisa anezithasiselo ze-alloying asetshenziswa ekukhiqizeni kwawo. Ngaphezu kwalokho, ama-valve e-exhaust ngokuvamile anesiqu esingenalutho esigcwele i-sodium. Lokhu kuyadingeka ukuze kube ne-thermoregulation engcono kanye nokupholisa kwepuleti. Isodium engaphakathi kwenduku iyancibilika, igeleze, futhi ithatha okunye ukushisa epuletini ikudlulisele endukwini. Ngale ndlela, ukushisa kwengxenye kungagwenywa.

Ngesikhathi sokusebenza, amadiphozi ekhabhoni angase akheke phezu kwesihlalo. Ukuvimbela lokhu ukuthi kungenzeki, imiklamo isetshenziselwa ukuzungezisa i-valve. Isihlalo siyindandatho yensimbi enamandla amakhulu ecindezelwa ngqo ekhanda le-cylinder ukuze kuthinteke kakhudlwana.

Ngaphezu kwalokho, ukuze kusebenze kahle umshini, kuyadingeka ukubheka igebe elilawulwayo lokushisa. Amazinga okushisa aphezulu abangela ukuba izingxenye zande, okungabangela ukuthi i-valve ingasebenzi kahle. Igebe phakathi kwamakhamera we-camshaft kanye nama-pushers lilungiswa ngokukhetha ama-washers ensimbi akhethekile obukhulu obuthile noma ama-pusher ngokwawo (izibuko). Uma injini isebenzisa iziphakamisi ezinama-hydraulic, igebe liyalungiswa ngokuzenzakalelayo.

Igebe elikhulu kakhulu lokuvula livimbela i-valve ukuthi ingavuleki ngokugcwele, ngakho-ke amasilinda azogcwalisa ingxube entsha ngokungasebenzi kahle. Igebe elincane (noma ukungabi khona kwalo) ngeke livumele ama-valve ukuba avale ngokuphelele, okuzoholela ekushisweni kwe-valve nokuncipha kokucindezela injini.

Ukuhlukaniswa ngenani lamavalvu

Inguqulo yakudala yenjini enemivimbo emine idinga ama-valve amabili kuphela isilinda ukuze isebenze. Kodwa izinjini zesimanje zibhekana nezidingo eziningi ngokwanda kwamandla, ukusetshenziswa kukaphethiloli nokuhlonipha imvelo, ngakho lokhu akusanele kubo. Njengoba ama-valve amaningi, kuzoba ngcono kakhulu ukugcwalisa isilinda ngokushaja okusha. Ngezikhathi ezahlukahlukene, lezi zinhlelo ezilandelayo zahlolwa ezinjinini:

- i-valve emithathu (i-inlet - 2, i-outlet - 1);

- i-valve emine (i-inlet - 2, i-exhaust - 2);

- i-valve emihlanu (i-inlet - 3, i-exhaust - 2).

Ukugcwaliswa okungcono nokuhlanza amasilinda kufinyelelwa ngama-valve amaningi nge-cylinder ngayinye. Kodwa lokhu kwenza ukuklama kwenjini kube nzima.

Namuhla, izinjini ezithandwa kakhulu ezinama-valve angu-4 nge-cylinder ngayinye. Eyokuqala yalezi zinjini yavela ngo-1912 ku-Peugeot Gran Prix. Ngaleso sikhathi, lesi sixazululo asizange sisetshenziswe kabanzi, kodwa kusukela ngo-1970 izimoto ezikhiqizwa ngobuningi ezinama-valve amaningi zaqala ukukhiqizwa ngenkuthalo.

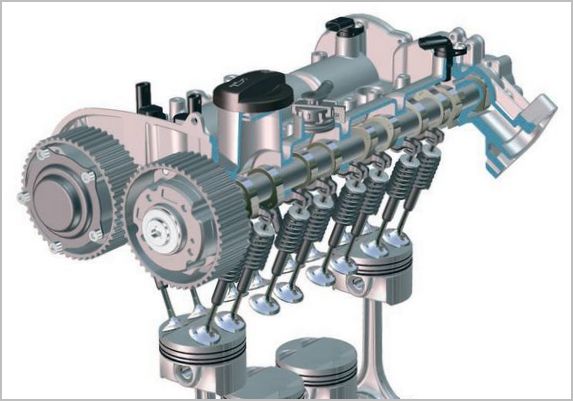

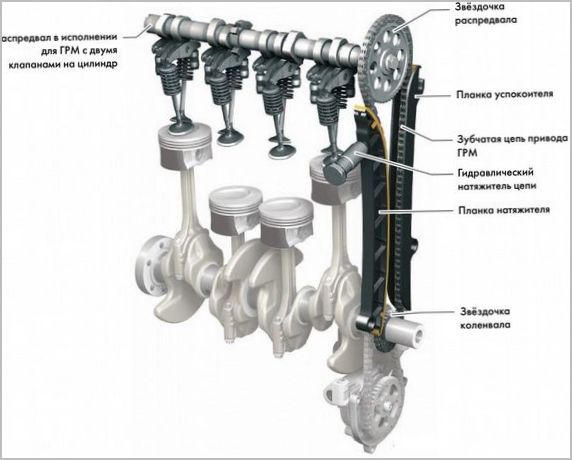

Idizayini yeDrayivu

I-camshaft kanye ne-timing drive inesibopho sokusebenza okulungile nokufika ngesikhathi komshini we-valve. Idizayini nenani lama-camshaft ohlobo ngalunye lwenjini akhethwa ngawodwana. Ingxenye ingumgodi lapho amakhamera omumo othile atholakala khona. Uma bephenduka, bacindezela ama-pushrods, ama-hydraulic lifter noma izingalo ze-rocker bese bevula ama-valve. Uhlobo lwesekethe luncike enjinini ethile.

I-camshaft itholakala ngqo ekhanda le-cylinder. Ukushayela kuyo kuvela ku-crankshaft. Kungaba iketango, ibhande noma igiya. Okuthembeke kakhulu iketango, kodwa kudinga amadivaysi asizayo. Isibonelo, i-chain vibration damper (damper) kanye ne-tensioner. Isivinini sokujikeleza kwe-camshaft siyingxenye yesivinini sokujikeleza kwe-crankshaft. Lokhu kuqinisekisa umsebenzi wabo ohlangene.

Inani lama-camshaft lincike enanini lama-valve. Kunezikimu ezimbili eziyinhloko:

- I-SOHC - nge-shaft eyodwa;

- I-DOHC - izingcezu ezimbili.

Ama-valve amabili kuphela anele i-camshaft eyodwa. Iyazungeza futhi ivula ngokushintshana amavalvu okungenisa nawokukhipha. Izinjini ezivame kakhulu ezine-valve zinama-camshaft amabili. Enye iqinisekisa ukusebenza kwama-valve okungenisa, kanti enye iqinisekisa ama-valve okukhipha umoya. Izinjini zohlobo lwe-V zifakwe ama-camshaft amane. Amabili ohlangothini ngalunye.

Amakhamera e-camshaft awasunduzi isiqu se-valve ngokuqondile. Kunezinhlobo ezimbalwa "zabaxhumanisi":

- ama-roller levers (ingalo ye-rocker);

- ama-pusher mechanical (izibuko);

- ama-hydraulic pushers.

Ama-roller lever ayindlela ethandwayo. Okubizwa ngokuthi izingalo ze-rocker zishwibeka kuma-axle e-plug-in futhi zifaka ingcindezi ku-hydraulic pusher. Ukuze unciphise ukungqubuzana, i-roller inikezwa ku-lever eyenza ukuthintana okuqondile nekhamera.

Kwesinye isikimu, kusetshenziswa ama-hydraulic pushers (i-gap compensators), atholakala ngqo entweni. Izinxephezelo zeHydraulic zilungisa ngokuzenzakalelayo igebe elishisayo futhi zinikeze ukusebenza okushelelayo nokuthule komshini. Le ngxenye encane iqukethe isilinda esinepiston nesiphethu, amaphaseji kawoyela kanye nevalve yokuhlola. I-hydraulic pusher inikwa amandla ngamafutha aphuma ohlelweni lokuthambisa injini.

Amapusha omshini (izibuko) ayizihlahla ezivaliwe ohlangothini olulodwa. Zifakwe endlini yekhanda le-cylinder futhi zidlulisela ngokuqondile amandla esiqwini se-valve. Ububi bayo obukhulu yisidingo sokulungisa izikhala ngezikhathi ezithile kanye nokungqongqoza lapho usebenza ngenjini ebandayo.

Umsindo emsebenzini

Ukungasebenzi kahle kwe-valve wukushaya injini ebandayo noma eshisayo. Ukushaya injini ebandayo kuyanyamalala ngemva kokukhuphuka kwezinga lokushisa. Lapho zishisa futhi zanda, igebe elishisayo liyavaleka. Ngaphezu kwalokho, i-viscosity yamafutha, engagelezi ngevolumu efanele ku-hydraulic lifters, ingaba imbangela. Ukungcoliswa kwemigudu kawoyela yesinxephezelo nakho kungaba yimbangela yokuthepha kwesici.

Amavalvu angakwazi ukungqongqoza enjinini eshisayo ngenxa yomfutho ophansi kawoyela ohlelweni lokuthambisa, isihlungi sikawoyela esingcolile, noma imvume engalungile yokushisa. Kuyadingeka futhi ukucabangela ukugqokwa kwemvelo kwezingxenye. Amaphutha angase abe kumshini we-valve ngokwawo (ukugqokwa kwentwasahlobo, umkhono oqondisayo, ompompi bamanzi, njll.).

Ukulungiswa kokusula

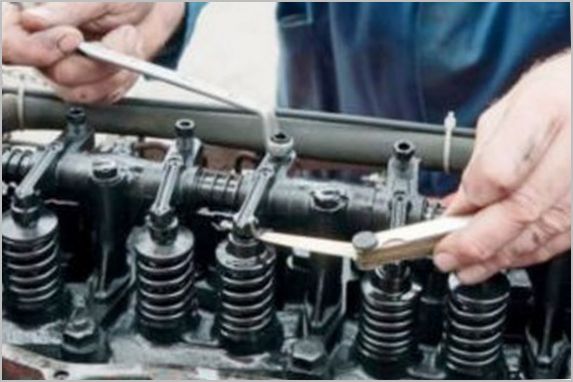

Ukulungiswa kwenziwa kuphela enjinini ebandayo. Igebe lamanje elishisayo linqunywa ama-probes ensimbi ayisicaba ahlukahlukene. Ukushintsha igebe ezingalweni ze-rocker kukhona isikulufa esikhethekile sokulungisa esiphendukayo. Kumasistimu anepusher noma amashimu, ukulungiswa kwenziwa ngokukhetha izingxenye zobukhulu obudingekayo.

Cabangela inqubo yesinyathelo ngesinyathelo yokulungisa ama-valve ezinjini ezinama-pusher (izibuko) noma ama-washer:

- Susa ikhava ye-valve yenjini.

- Vula i-crankshaft ukuze i-piston yesilinda sokuqala sibe phezulu endaweni efile. Uma kunzima ukwenza lokhu ngamamaki, ungakhulula ipulaki yenhlansi bese ufaka isikrudrayiva emthonjeni. Ukuya phezulu kwayo phezulu kuzoba indawo efile.

- Usebenzisa isethi yamageji okuzizwa, kala ukuphuma kwevalvu ngaphansi kwamakhamera angacindezeli ompompi. I-probe kufanele ibe ne-tight, kodwa hhayi ukudlala mahhala kakhulu. Rekhoda inombolo ye-valve kanye nevelu yokususa.

- Zungezisa i-crankshaft i-revolution eyodwa (360°) ukuze ulethe ipiston yesilinda yesi-4 ku-TDC. Kala imvume ngaphansi kwawo wonke ama-valve. Bhala phansi idatha.

- Hlola ukuthi yimaphi ama-valve angabekezelelani. Uma kukhona, khetha ama-pusher of the ukushuba oyifunayo, susa ama-camshafts bese ufaka izibuko ezintsha. Lokhu kuqeda inqubo.

Kunconywa ukuhlola izikhala njalo ngamakhilomitha ayizinkulungwane ezingu-50-80. Amanani ajwayelekile okuvunyelwa angatholakala encwadini yokulungisa izimoto.

Sicela uqaphele ukuthi ukucaciswa kwe-valve yokudonsa kanye ne-exhaust ngezinye izikhathi kungase kuhluke.

Indlela yokusabalalisa igesi elungiswe kahle futhi eshuniwe izoqinisekisa ukusebenza kahle nokufana kwenjini yangaphakathi evuthayo. Lokhu kuzoba nomthelela omuhle ezinsizeni zenjini kanye nokunethezeka komshayeli.