Uyilungisa kanjani impompo yesiteringi samandla ngokwakho

Okuqukethwe

- ukuxilongwa kwezinga le-liquid kanye nokumpompa isikhiya somoya

- Izimpawu zokuhluleka kokuqondisa kwamandla kanye nezimbangela zazo ezingase zibe khona

- Ukunciphisa izinga loketshezi olusebenzayo:

- Imisindo engaphandle, ukushaya ikhwela ngenkathi uphendula isondo lokushayela injini isebenza:

- Uma ungenzi lutho noma ngesivinini esiphansi, amandla abalulekile ayadingeka ukuze uvule isondo lokuqondisa:

- Lapho ibhande lokushayela lisusiwe, ukudlala kwe-longitudinal noma okuphambanayo kwe-pump shaft kuzwakala:

- Ukudlidliza noma ukushaqeka lapho uphendula isondo lokushayela ngenkathi ushayela:

- Iphampu yokuqondisa amandla idinga ukunakwa okukhethekile

- Ukulungiselela ukulungisa iphampu

- Ukuhlukaniswa kwephampu, ukuxazulula izinkinga

- Ukuvuza ngenxa yamapayipi alimele, ama-seal noma ama-gaskets.

- ibhande lokushayela likhululekile noma ligugile;

- ama-bearings agugile noma i-pump shaft;

- ama-valve avaliwe;

- uketshezi oluyiqhwa.

- iphampu yokuqondisa amandla engalungile;

- uhlelo lwe-hydraulic oluvalekile;

- izinga eliphansi loketshezi.

- i-pump bearing idinga ukushintshwa.

- ibhande lokushayela likhululekile noma ligugile;

- iphampu yokuqondisa amandla engalungile;

- i-valve yokulawula engalungile;

- izinga eliphansi loketshezi;

- umoya ohlelweni.

- Imvamisa, ukuthwala kuyahluleka, ngakho qiniseka ukuthi ugcina okusha. Ngokuvamile inobubanzi obungaphandle obungu-35 mm futhi imakwe ngo-6202, nakuba ezinye izinketho zingenzeka.

- Ama-o-ring amabili erabha, i-oil seal, i-gasket namawasha amabili ethusi. Konke lokhu kungashintshwa ngekhithi yokulungisa iphampu yokuqondisa amandla, engatholakala esitolo sezimoto.

- Umoya omhlophe omncane noma i-WD-40.

- Indwangu yokuhlanza.

- Sandpaper kusuka ku-P1000 kuya ku-P2000. Kungathatha okuningi uma kunesidingo sokugaya.

- Isipetu esikhulu nesiqukathi sokumpompa uwoyela ethangini.

- ama-wrenches namakhanda we-12, 14, 16 no-24;

- i-circlip puller;

- isando;

- izikulufo;

- okugcwele ngokweqile;

- i-drill kagesi kanye ne-drill bit engu-12 mm noma ngaphezulu.

I-Power steering (GUR) iyingxenye yesiteringi futhi itholakala cishe kuzo zonke izimoto zesimanje. I-power steering ikuvumela ukuthi unciphise kakhulu umzamo womzimba odingekayo ukuze uvule isondo lokuqondisa, futhi uthuthukise ukuhamba nokusimama kwemoto emgwaqeni. Uma i-hydraulic system yehluleka, isiteringi siyagcinwa kodwa siyaqina.

Uhlelo lulonke luthembekile futhi aluvamile ukubangela izinkinga kubanikazi bezimoto. Kudingeka kuphela ukuqapha izinga lamafutha ku-tank yokugcina futhi, uma kwenzeka ukwehla okuphawulekayo, ukuhlonza ukuqina kwesistimu, thola futhi uqede ukuvuza, ikakhulukazi ezindaweni lapho amapayipi axhunywe khona ekufakweni.

Ukushintshwa okujwayelekile koketshezi olusebenzayo olungcolile nolukhathele kuzonweba kakhulu impilo ye-hydraulic booster. Lokhu kufanele kwenziwe okungenani kanye njalo eminyakeni emibili.

Kufanele futhi unake isimo sebhande le-pump drive. Kwenzeka ukuthi kuyadingeka ukuyilungisa noma ukuyiqinisa, futhi uma kwenzeka igqoke, ishintshe. Ukuze uqinise noma ususe ibhande, ngokuvamile udinga ukukhulula i-bolt yokulungisa futhi uhambise indlu yepompo ngendlela oyifunayo.

ukuxilongwa kwezinga le-liquid kanye nokumpompa isikhiya somoya

Izinga le-liquid lishintsha ngokushisa. Ukuyifudumeza ifike cishe ku-80 ° C, ngesivinini esingenzi lutho senjini evuthayo yangaphakathi, vula isondo lokushayela isethi yezikhathi ukusuka endaweni eyodwa ukuya kwenye. Lokhu kuzosiza futhi ukususa amaphakethe omoya ohlelweni lwe-hydraulic.

Ungalibambi isondo lokuqondisa lisesimweni esibi kakhulu imizuzwana engaphezu kwemihlanu, ukuze uketshezi lungabilisi futhi lulimaze iphampu noma ezinye izingxenye zokuqondisa amandla. bese umisa injini evuthayo yangaphakathi bese uhlola izinga loketshezi olusebenzayo.

Uma kusele umoya ohlelweni, izominyanisa lapho injini isebenza. Lokhu kuzobangela ukuthi izinga le-liquid lehle. Ngakho-ke, phinda uhlole izinga ethangini ngenjini esebenzayo ukuze uqiniseke ukuthi awukho umehluko.

Engeza uketshezi uma kudingeka.

Le nqubo elula ezimweni eziningi izoxazulula izinkinga ngesiteringi samandla. Uma kungenjalo, kuzodingeka ukuxilonga okwengeziwe.

Izimpawu zokuhluleka kokuqondisa kwamandla kanye nezimbangela zazo ezingase zibe khona

Ukunciphisa izinga loketshezi olusebenzayo:

Imisindo engaphandle, ukushaya ikhwela ngenkathi uphendula isondo lokushayela injini isebenza:

Uma ungenzi lutho noma ngesivinini esiphansi, amandla abalulekile ayadingeka ukuze uvule isondo lokuqondisa:

Lapho ibhande lokushayela lisusiwe, ukudlala kwe-longitudinal noma okuphambanayo kwe-pump shaft kuzwakala:

Ukudlidliza noma ukushaqeka lapho uphendula isondo lokushayela ngenkathi ushayela:

Ukudlidliza noma ukushaqeka kungase kubangelwe izizathu ezingahlobene nesiteringi sikagesi - ukulinganisa okungalungile kwesondo, ukumiswa noma ukwehluleka kwesiteringi. Ukuxilongwa okunembile kokuqondisa kwamandla kungenzeka kuphela endaweni ekhethekile ye-hydraulic stand.

Iphampu yokuqondisa amandla idinga ukunakwa okukhethekile

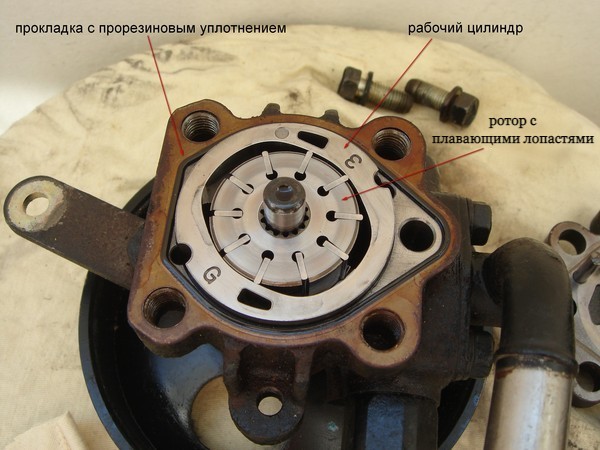

Isici esibucayi kakhulu nesisengozini yokuqondisa amandla yipompo, eqhutshwa injini yemoto futhi iphampa uketshezi olusebenzayo endaweni evaliwe. Ngokuvamile iyiphampu yohlobo lwe-vane, ehlukaniswa ngekhwalithi nokusebenza okuphezulu.

I-hydraulic pressure eyakhayo ingafinyelela ku-150 bar. I-rotor yepompo izungeziswa yidrayivu yebhande ukusuka ku-crankshaft. Ngesikhathi sokusebenza, iphampu ingaphansi kwemithwalo ebalulekile. Nguye ovame ukuba umthombo wezinkinga ekusebenzeni komshini wokuqondisa futhi udinga ukulungiswa noma ukushintshwa.

Ukwehluleka kwephampu kungabangelwa ukushisa ngokweqile, ukungcoliswa kwesistimu ye-hydraulic, inani elinganele loketshezi olusebenzayo noma ukungahambisani kwayo nezidingo.

Uma uqhubeka nokushayela ngephampu yesiteringi ye-hydraulic enephutha, lokhu kungagcina kuholele ekuhlulekeni kwezinye izingxenye zesiteringi samandla. Ngakho-ke, akufanelekile ukubambezeleka ukulungiswa noma ukushintshwa.

Ungathintana nesevisi yemoto, noma ungagcina imali ehloniphekile bese uzama ukulungisa iphampu ngokwakho. Ayidingi imishini eyinkimbinkimbi noma iziqu ezikhethekile. Kwanele ukuba nesifiso, isikhathi kanye nolwazi oluthile ekwenzeni umsebenzi wemishini, kanye nokunaka nokunemba.

Ukulungiselela ukulungisa iphampu

Ukuze uzihlukanise futhi ulungise iphampu yokuqondisa amandla, uzodinga amathuluzi athile, izingxenye ezisele kanye nezinto zokwakha.

Amathuluzi adingekayo:

Ukuze ugweme amaphutha ngesikhathi sokuhlanganisa kabusha, lungiselela indawo yokusebenza enamaphepha anezinombolo. kufanelekile ukuba nebhentshi lokusebenzela eline-vise.

Ukuhlukaniswa kwephampu, ukuxazulula izinkinga

Kungase kube khona umehluko ekuklanyweni kwepompo yemishini yemikhiqizo ehlukene, kodwa izinyathelo eziyisisekelo zokuqaqa nokulungisa ziyefana. Okokuqala udinga ukupompa uwoyela ohlelweni ngesirinji. bese unqamula amashubhu bese uxhuma izimbobo zokuphuma ngendwangu ukuze ukungcola kungangeni ngaphakathi.

Ukuze ususe iphampu, udinga ukukhulula ibhawudo elilivikela kubakaki, kanye nebhawodi lesistimu yokulungiswa kokuqina kwebhande ledrayivu. Ngaphambi kokudilizwa, iphampu esusiwe kufanele igezwe nge-solvent. Susa ikhava yangemuva.

Ukuze wenze lokhu, kuye ngomklamo, udinga ukukhulula ama-bolts angu-4 noma ususe indandatho yokugcina ngokuyishaya ngephini (ungasebenzisa isipikili) ngembobo eseceleni. ngokuqhubekayo, ngokushaya umzimba ngesando, sifinyelela ukuthi isiphethu ngaphakathi sikhama ikhava. Ukwenza kube lula ukususwa, ungafafaza uzungeze i-contour nge-lubricant ye-WD-40.

Sikhipha ngokucophelela okungaphakathi, sikhumbula indawo yezingxenye futhi sizibeka ngokulandelana. Sikhipha i-rotor ngamapuleti. Susa indandatho yerabha evalayo ngokuyicisha nge-screwdriver. Khipha isilinda esisebenzayo (stator).

Ohlangothini lwayo olungaphezulu kunamamaki (uhlamvu nenombolo) ukuze kufakwe kahle.

Ngezansi kunelinye ipuleti, isiphethu kanye nophawu lwamafutha.

Ngemva kokuhlakaza, sigeza zonke izingxenye ngomoya omhlophe futhi sihlole ngokucophelela.

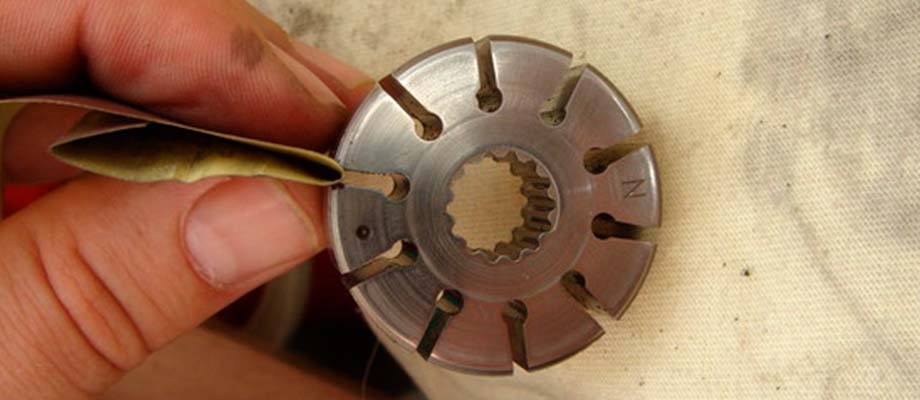

Sinaka isimo se-grooves yesigubhu se-rotor, imiphetho yabo kufanele ibe yindilinga, ibukhali futhi ingabi nama-burrs nezinye iziphambeko ezingase ziphazamise ukuhamba kwamahhala kwama-blades.

Uma kungenjalo, ukungahambi kahle kufanele kuqedwe ngefayela yenaliti kanye ne-sandpaper. Kufanele futhi usebenze ngokucophelela amapuleti ngokwawo (izindwani). Gwema ukushisekela ngokweqile futhi ungakusebenzisi ngokweqile.

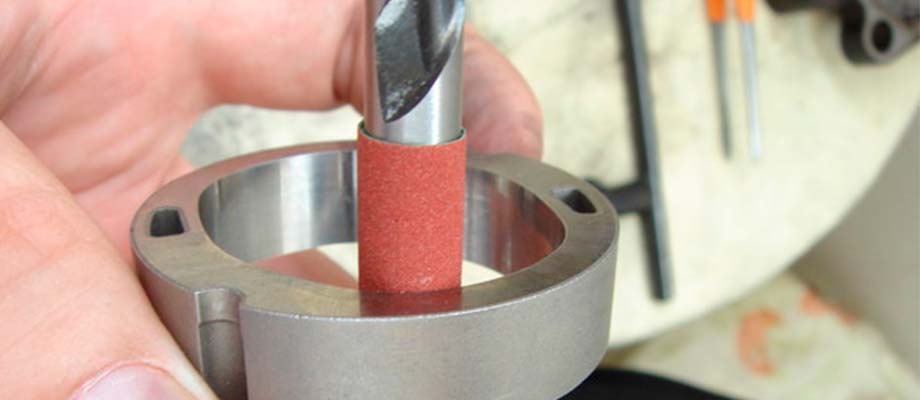

Ingaphakathi eliyi-elliptical surface yesilinda esisebenzayo kufanele libe bushelelezi. Ngokuvamile kuba ukukhubazeka kwe-ellipse okuyimbangela yokusebenza kabi kwepompo. Uma kukhona ama-grooves noma ama-gouges kusukela ekushayeni kwama-blades, kuzodingeka afakwe isihlabathi.

Inqubo yokugaya ngesandla yinde futhi inzima. Kungenziwa kube lula uma usebenzisa i-drill kagesi. Sigoqa i-sandpaper ku-drill enobubanzi obuyi-12 mm noma ngaphezulu bese siyibopha ku-drill chuck. Sigaya, sishintsha isikhumba njengoba siguga futhi kancane kancane sihamba sisuka kumaholoholo siye esicolekile.

Ukuze ufinyelele ku-bearing, kuzodingeka ukhiphe i-shaft ngokuyithinta ngesando.

Uma kufanele kushintshwe i-bearing, susa iringi ebambayo ngesidonsa. khona-ke udinga ukucindezela i-bearing off shaft bese ufaka entsha.

Endleleni, kufanelekile ukufaka esikhundleni se-oil seal, kanye nawo wonke ama-o-rings nama-washers.

Siqoqa yonke into ngokulandelana. Lapho ufaka amapuleti emigodini yesigubhu, qiniseka ukuthi uhlangothi lwawo oluyindilinga lubheke ngaphandle.

Ngemuva kokulungisa ipompo, kunconywa kakhulu ukuthi ubuyisele ngokuphelele uketshezi olusebenzayo.

Kungase kuthathe isikhathi ukugaya izindwani kanye ne-stator. Kulokhu, iphampu ingase iqhume kancane.