Indlela yokusetha kahle i-airbrush yokudweba imoto: imiyalelo yesinyathelo ngesinyathelo

Okuqukethwe

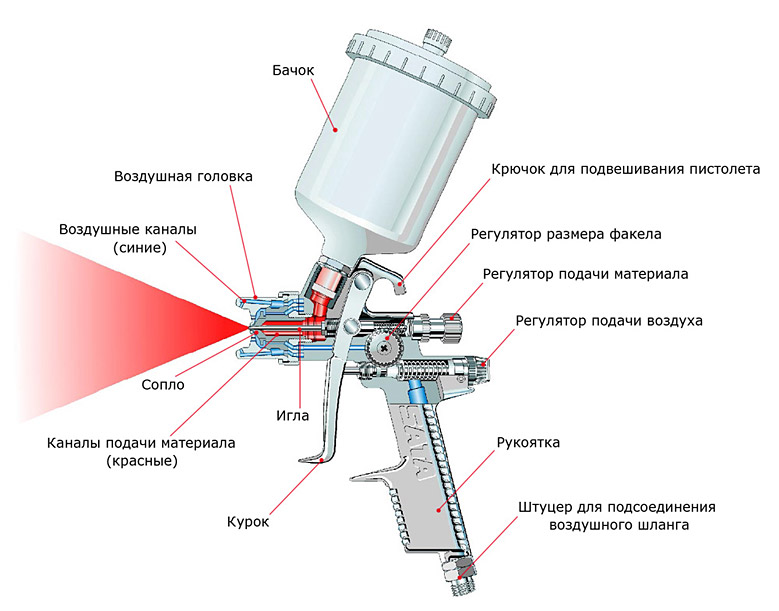

Idivayisi i-atomize ukwakheka koketshezi ngomoya ocindezelwe ngombhobho omncane. Ngaphezu kwalokho, amaconsi amancane engxube asatshalaliswa ngokulinganayo ebusweni. Ukusethwa kwesibhamu se-spray sokudweba imoto kungenziwa ngokusebenzisa izikulufo nezinkinobho kusibhamu se-spray.

Umshini uvikelekile ekugqwaleni nasezinhlayiyeni eziqhumayo ngokufafaza isisekelo se-koqweqwe lwawo loqweqwe lwawo kanye nokuvanisha. Ukusetha isibhamu se-spray sokudweba imoto kuzokuvumela ukuthi uthole isendlalelo esifanayo ngaphandle kwamaphutha. Kudivayisi, ukunikezwa kwengxube nomoya kulawulwa, futhi ingcindezi edingekayo ikhethiwe.

Umgomo wokusebenza kwesibhamu se-spray

Idivayisi i-atomize ukwakheka koketshezi ngomoya ocindezelwe ngombhobho omncane. Ngaphezu kwalokho, amaconsi amancane engxube asatshalaliswa ngokulinganayo ebusweni. Ukusethwa kwesibhamu se-spray sokudweba imoto kungenziwa ngokusebenzisa izikulufo nezinkinobho kusibhamu se-spray.

Izinzuzo zedivayisi ezenzakalelayo:

- umdwebo iyunifomu ebusweni imoto;

- ukungabi khona kwezinhlayiya zangaphandle kungqimba;

- okonga izinto;

- ukusebenza okukhulu.

Ngokusho kwesimiso sokusebenza, kunezinhlobo ezingu-3 zamadivayisi - i-pneumatic, kagesi kanye nebhukwana. Umthamo ophezulu, izibhamu ze-HVLP ezicindezelayo eziphansi zifaneleka kahle izicelo ze-acrylic ne-primer. Amadivayisi ohlobo lwe-LVLP aklanyelwe ukufafaza amavolumu amancane engxube ungqimba oluncane. Amadivayisi wesistimu ye-CONV anokukhiqiza okuphezulu kakhulu, kodwa ikhwalithi yokugqoka iphansi, ukulahlekelwa kwezinto ezibonakalayo kufinyelela ku-60-65%.

Indlela yokusetha isibhamu se-spray sokupenda imoto

Isendlalelo esifafazwe ngedivayisi ebusweni kufanele sifane, ngaphandle kwamaqhubu nama-smudges. Ngakho-ke, isibhamu sokufafaza esizenzakalelayo kufanele silungiswe ngaphambi kokuqala umsebenzi. Ungakwazi ukusetha isibhamu se-spray sokupenda imoto ngokulandela imiyalelo ngezandla zakho.

Futha ukulungiselelwa kwesibhamu

Izinyathelo eziyinhloko zokulungisa idivayisi:

- Ukulungiselela ngokusho kweresiphi, ukuhlunga nokugcwalisa ithangi ledivayisi ngenhlanganisela yokusebenza.

- Ukukhethwa kosayizi odingekayo, ukwakheka kanye nokuhlakazwa kwezinhlayiya zikapende ethoshi.

- Ukulungiswa komfutho womoya kusibhamu sesifutho ngegeji yokucindezela noma ngaphandle kwayo.

- Ukulungiswa kokugeleza kwengxube yokusebenza ekamelweni lokuxuba.

- Ukusetshenziswa kwesilingo sopende ebusweni kanye nesimo sokuqeda.

Ukulinganisa okwenziwe kahle kwedivayisi kuzohlinzeka ngekhwalithi ephezulu yekhwalithi yemoto nge-primer, i-varnish, isisekelo se-acrylic kanye ne-matrix-metallic ngokusetshenziswa okuphansi kwesisombululo sokusebenza.

Ukulungiswa Kosayizi Wethoshi

Imbobo yokuvula lapho ingxube isetshenziswa khona ingashintshwa ngenduku enyakazayo enekhanda eliyindilinga. Ngokuguqula isikulufu sokulungisa, imvume ye-nozzle kanye nosayizi wethoshi kulungiswa. Ngokugqagqana okuncane kwembobo, umfudlana ufafazwa ngekhoni ebanzi, ngokwakheka kwendawo yopende eyindilinga noma eyisiyingi ngaphezulu. Ngokunikezwa komoya okulinganiselwe, indiza yengxube incipha ibe iphuzu elilodwa. Isikulufu sokulungiswa kwefeni sitholakala kusibhamu sesibhamu.

Ukusetha umfutho womoya

Izinga le-automotive surface coating lincike kubukhulu bezinhlayiya zopende ezifuthwe. Ezincane zakha ungqimba oluncane lweyunifomu endaweni ngaphandle kwama-smudges kanye nokungahambi kahle. Ukuhlakazeka okufanele kokugeleza kwengxube kuqinisekiswa ukucindezela komoya okulungile.

Ukusebenzisa i-pressure gauge kanye nesilawuli

Isifutho sikapende esizenzakalelayo sisebenza kahle kakhulu ekucindezelweni komoya okulawulwayo. Ukuze ulungiselele, i-gauge yokucindezela kanye nesilawuli kufanele ixhunywe kusibhamu se-spray. Khipha izikulufu zokulungisa umoya nengxube. Vula isifutho bese usetha ingcindezi oyifunayo ohlelweni.

Igeji yengcindezi eyakhelwe ngaphakathi

Kungenzeka ukulungisa isibhamu se-spray sokupenda imoto, ifakwe idivayisi yokulinganisa imingcele yokugeleza, ngaphandle kokuxhuma amadivaysi angaphandle. Uma kulungiswa, ukuphuma komoya nopende kuvuleka ngokugcwele. Ukugeleza kukalwa kusetshenziswa igeji yokucindezela eyakhelwe ngaphakathi. Isikulufu sokulungisa sibeka umfutho womoya odingekayo ohlelweni.

Isilinganiso sokucindezela ngaphandle kwesilawuli

Amanye amamodeli aseShayina ezibhamu zokufuthwa akala kuphela amapharamitha wokugeleza, ngaphandle kokuthi kungenzeka ukulungiswa. Kuyadingeka ukuhlola ukufundwa komfutho womoya ngesibhamu esivulekile. Uma imingcele ineziphambeko, bese ulungisa i-gearbox ye-compressor yangaphandle.

I-manometer ayikho.

Amamodeli ashibhile awanazo izinsimbi zokulinganisa. Ngakho-ke, ukuze ulungise kahle isibhamu se-spray sokupenda imoto, kuyadingeka ukucabangela ukwehla kwengcindezi ku-hose kanye nesibhamu sesibhamu se-spray. Okulandelayo, ku-gearbox ye-compressor yangaphandle, ingcindezi edingekayo yokusebenza isethiwe, kucatshangelwa ukulahlekelwa ohlelweni.

Ukulungiselelwa kukayinki

Ngemuva kokubeka ingcindezi yokusebenza kanye nobukhulu kanye nokuma kwesibani, kuyadingeka ukulungisa ukugeleza kwengxube ekamelweni lokuxuba lesibhamu. Ukuze usethe kahle isibhamu sokufutha sezimoto zokupenda, isikulufu sokuphakelayo kufanele sikhishwe ngokujika oku-1-2 ukuze kusethwe ukugeleza okuncane. Bese wengeza ukugeleza kwengxube kuze kube yilapho ukusabalalisa okufanayo endaweni okumele kupende kutholakala. I-trigger yesibhamu se-spray ikuvumela ukuba ulungise ukugeleza ngesikhathi senqubo yokufafaza.

Ukulungisa upende

Ingxube elungiselelwe kahle yezingxenye inikeza ungqimba lwekhwalithi ephezulu yepende ebusweni. Ukusetha isibhamu se-spray sokudweba imoto ngepende ye-acrylic, sebenzisa i-viscometer ukuze unqume i-viscosity kanye ne-thinner.

Ivolumu edingekayo yezingxenye isethwe ngokusho kwetafula. Engeza ingxube ezingxenyeni ezincane, uvuselela ngenduku yezinto ezingathathi hlangothi. Ukuze usethe i-airbrush yokudweba imoto nge-metallic, sebenzisa izinkomishi zokulinganisa noma irula. I-solvent nayo isetshenziselwa ukunciphisa i-viscosity ibe yinani elidingekayo.

Futha ukuhlola isibhamu

Futha amapharamitha wokuhlola isibhamu:

- ithoshi imprint shape;

- ukusatshalaliswa kwengxube ebusweni;

- ikhwalithi yesendlalelo esisetshenzisiwe.

Ukuze usethe kahle isibhamu se-spray sokupenda imoto nge-metallic, lapho uhlola idivayisi, ukubunjwa kufanele kufafazwe ngokulinganayo ngaphandle kokushintsha izilungiselelo ezimisiwe. Kuyadingeka ukuhlola umphumela ngemuva kokusetha isendlalelo endaweni yokuhlola.

Uma, lapho usetha i-airbrush yokudweba imoto nge-acrylic, ingxube isetshenziswa ngokungalingani, futhi kuneziphambeko zokugqoka, khona-ke udinga ukuphinda izinyathelo futhi. Ngemuva kokulungiswa komoya kanye nokuxuba kwesibili, fafaza ukuhlolwa endaweni engaphansi.

Ukuhlolwa komumo wethoshi

Uma usetha kahle isibhamu se-spray sokupenda imoto, khona-ke isibhamu sisebenzisa ingxube ngesimo sendawo eyindilinga noma ye-oval symmetrical enemiphetho ebushelelezi. Lapho umlomo wombhobho uvalekile noma ukucindezela kweqile, isigxivizo sethoshi siyachezuka phakathi nendawo, izimpawu zendawo zivela endaweni ependiwe. Ukuhlolwa kokunemba kokuma kwendawo efafaziwe kwenziwa ekunikezeni okuphezulu kwengxube. Isibhamu siqondiswe ngokuqondile phezulu futhi sivulwe isekhondi elingu-1.

Hlola ukufana kokusatshalaliswa kwempahla kuthoshi

Ukuze uthole ungqimba olufanele lwepende ebusweni, ukusetshenziswa okufanayo kwamaconsi engxube kuyadingeka. Ngakho-ke, isibhamu se-spray kufanele senze inkungu enhle yezinhlayiya ezinobuningi obufanayo. Ukwenza ukuhlolwa kokufana kokusatshalaliswa kwezinto, ithoshi liqondiswe engeli endaweni eqondile. Bese beqala ukufafaza upende kuze kube yilapho kuvela ama-smudges, lapho ukugxila kwezinhlayiya zengxube kuthoshi kunqunywa.

Futha ukuhlolwa kwesibhamu

Futha ukuhlolwa kwekhwalithi

Ngemuva kokuhlola ukuphrinta kanye nobuningi bokubunjwa okusebenzayo, kuyadingeka ukulungisa umdwebo. Kudingeka ukufafaza ingxube ngesibhamu ebangeni elifanayo ukusuka entweni ngesivinini esingaguquki. Hlola ukuphrinta okuwumphumela ukuze uthole amaphutha.

Uma usetha kahle isibhamu sokupenda ukudweba imoto, ungqimba olusetshenzisiwe luzoba umfaniswano, ngaphandle kwe-shagreen kanye ne-smudges. Umehluko omncane kusayizi wezinhlayiyana zengxube kanye nokuncipha kogqinsi lwesendlalelo emaphethelweni ethoshi kuvunyelwe.

Ukungasebenzi kahle nokuqedwa kwazo

Ukuphambuka okuncane ekusebenzeni okujwayelekile kwesibhamu se-spray kungalungiswa. Ukulungiswa okuncane okuvamile kwenziwa ngesandla, ukuwohloka okungathí sina - ku-workshop.

Ukungasebenzi okuyinhloko kwesibhamu se-spray nezindlela zokubuyisela ukusebenza:

- Uma ingxube ingagelezi ethangini, khona-ke kuyadingeka ukuhlanza isihlungi noma ukufaka i-valve entsha.

- Lapho upende ufafaza ngokungalingani kusuka ku-nozzle, ithiphu le-nozzle eligugile kufanele lishintshwe.

- Amabhamuza omoya avamise ukungena ethangini eliyingxube lapho umlomo wokuphuma ugqokwe - ingxenye enesici kufanele ishintshwe.

- Ukuma okungalungile kwethoshi kungase kwenzeke ngenxa yokuvala isibhamu. Uzodinga ukuqaqa idivayisi futhi uyihlanze.

- Uma ukunikezwa kwengxube kuncishisiwe futhi iphampu ivuza, qinisa inadi lebhokisi lokugxusha kakhulu noma ushintshe i-cuff.

Isifundo esiyinhloko ukuthi ukuhlanzwa okuphelele nokugcinwa kwesibhamu sokufafaza kuzokwandisa impilo yesevisi, kuqinisekise ikhwalithi yokudweba ebusweni bemoto.

Buka le vidiyo ku-YouTube