Indlela yokuhlanza nokupakisha kabusha ama-wheel bearings

Okuqukethwe

Isondo elithwele kufanele lihlanzwe futhi livalwe kabusha uma kukhona ukuguga okungajwayelekile kwamasondo, ukugaya amathayi noma ukudlidliza kwesondo lokuqondisa.

Kusukela ekusungulweni kwemoto yesimanje, ama-wheel bearing aye asetshenziswa ngezinga elithile ukuze avumele amathayi namasondo ukuba ajikeleze ngokukhululeka njengoba imoto iya phambili noma ihlehla. Nakuba ukwakhiwa, umklamo, nezinto ezisetshenziswa namuhla kuhluke kakhulu kokwaseminyakeni edlule, umqondo oyisisekelo wesidingo sokugcotshwa okufanele ukuze kusebenze ngempumelelo usasekhona.

Amasondo amasondo enzelwe impilo ende yesevisi; nokho, ngokuhamba kwesikhathi alahlekelwa ukuthambisa kwawo ngenxa yokushisa okudlulele noma imfucumfucu okuthi ngandlela thize ingene phakathi nendawo yehabhu lamasondo lapho itholakala khona. Uma zingahlanzwa futhi zingapakishwa kabusha, ziyaguga futhi zidinga ukushintshwa. Uma ziphuka ngokuphelele, kuzodala ukuthi inhlanganisela yamasondo namasondo iwe emotweni ngenkathi ushayela, okuyisimo esiyingozi kakhulu.

Ngaphambi kuka-1997, izimoto eziningi ezithengiswa e-United States zazinesondo elingaphakathi nangaphandle, okwakuvame ukuseviswa njalo ngamakhilomitha angu-30,000. "Isondlo samahhala" amabheringi esondo elilodwa, aklanyelwe ukunweba impilo yamabheringi amasondo ngaphandle kwesidingo sokunakekelwa, agcine ephume phambili.

Nakuba izimoto eziningi emgwaqeni zinalolu hlobo olusha lwamasondo, izimoto ezindala zisadinga ukunakekelwa, okuhlanganisa ukuhlanza nokugcwalisa kabusha isondo lamasondo ngamafutha amasha. Abakhiqizi abaningi bezimoto bayavuma ukuthi ukupakishwa kabusha nokuhlanza amasondo kufanele kwenziwe njalo ngemva kwamakhilomitha angu-30,000 XNUMX noma njalo ngemva kweminyaka emibili. Isizathu salokhu ukuthi ngokuhamba kwesikhathi amafutha alahlekelwa ukuthambisa kwawo okuningi ngenxa yokuguga nokushisa. Kuphinde kuvame kakhulu ukuthi ukungcola nemfucumfucu kungene endaweni enesondo, ngenxa yothuli lwamabhuleki noma okunye ukungcola eduze kwehabhu lamasondo.

Sizobhekisela emiyalweni evamile yokuhlanza nokupakisha kabusha amasondo amasondo angagqokile. Ezigabeni ezingezansi, sizochaza izimpawu zebherethi yamasondo egugile. Uma ubona noma yiziphi zalezi zimpawu, kuwumqondo omuhle ukushintsha ama-bearings kunokuthi uhlanze amadala. Kuphinde kunconywe ukuthi uthenge imanuwali yesevisi yemoto yakho ukuze uthole izinyathelo eziqondile zokuthola nokushintsha le ngxenye emotweni yakho njengoba ingase ihluke phakathi kwezimoto ngazinye.

Ingxenye 1 kokungu-3: Ukuhlonza Izimpawu Zokungcola noma Ukugqokwa Kwamasondo Amasondo

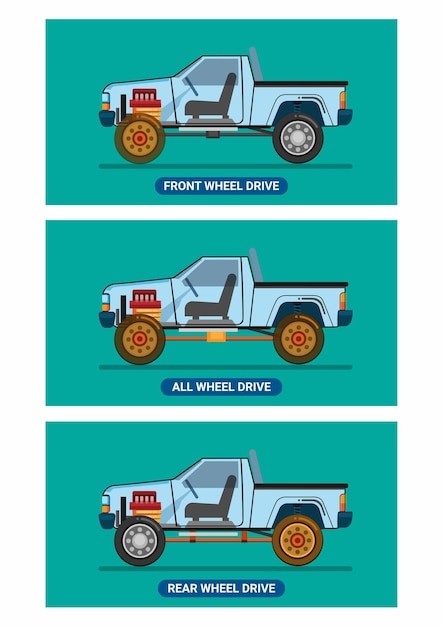

Lapho isondo elithwalayo ligcwaliswa kahle ngamafutha, lijikeleza ngokukhululekile futhi alikhiqizi ukushisa okweqile. Amasondo amasondo afakwa ngaphakathi kwehabhu lamasondo, elinamathisela isondo nesondo emotweni. Ingxenye engaphakathi ye-wheel bearing ixhunywe ku-drive shaft (ku-front-wheel drive, i-back-wheel drive kanye nezimoto ezidonsa ngamasondo amane) noma ijikeleze ngokukhululekile kwi-ekseli engashayeli. Uma isondo elithwalayo lihluleka, ngokuvamile kungenxa yokulahlekelwa ukuthambisa ngaphakathi kwendlu yokuthwala isondo.

Uma isondo elithwalayo lilimele, libonisa izimpawu ezimbalwa eziyisixwayiso noma izimpawu ezixwayisa umnikazi wemoto ukuthi ashintshe amabhodi amasondo kunokumane awahlanze futhi awapakishe kabusha. Ukugqokwa Kwesondo Okungavamile: Uma isondo elithwalayo lixega noma ligugile, libangela isondo nesondo ukuthi kungahambi kahle kuhabhu. Ezimweni eziningi, lokhu kubangela ukuguga ngokweqile emaphethelweni angaphakathi noma angaphandle esondo. Kunezinkinga eziningana zemishini ezingase zibe nezimpawu ezifanayo, okuhlanganisa amathayi agcwale kakhulu noma aphansi kakhulu, amajoyinti e-CV agugile, ama-shock absorber noma ama-struts awonakele, nokungalingani kokumiswa.

If you’re in the process of removing, cleaning and repacking the wheel bearings and you find excessive tire wear, consider replacing the wheel bearings as preventative maintenance. Grinding or roaring noise coming from the tire area: This symptom is commonly caused due to excess heat that has built up inside the wheel bearing and a loss of lubricity. The grinding sound is metal to metal contact. In most cases, you’ll hear the sound from one side of the vehicle as it’s very rare that the wheel bearings on both side wear out at the same time. If you notice this symptom, do not clean and repack the wheel bearings; replace both of them on the same axle.

Ukudlidliza kwesondo lokuqondisa: Uma ama-wheel bearing alimele, isondo nesondo kuxega kakhulu kuhabhu. Lokhu kudala umphumela wokubhampa, okwenza isiteringi sinyakaze njengoba imoto igijima. Ngokungafani nezinkinga zokulinganisa amathayi ezivame ukubonakala ngesivinini esiphezulu, ukudlidliza kwesondo lokuqondisa ngenxa yebheringi eligugile kubonakala ngesivinini esiphansi futhi kancane kancane kuyanda njengoba imoto igijima.

Kujwayeleke kakhulu ukuthi imoto ibe nenkinga yokushayela amasondo kanye ne-acceleration uma ama-bearings amasondo kuma-axle okushayela elimele. Kunoma yikuphi, lapho izimpawu ezingenhla zivela, kunconywa ukuthi ushintshe ama-wheel bearings, njengoba ukumane ukuhlanza nokuyivala kabusha ngeke kuxazulule inkinga.

Ingxenye 2 koku-3: Ukuthenga Ama-Bearings Amasondo Ekhwalithi

Nakuba izinsimbi eziningi zokuzilibazisa zivame ukubheka amanani angcono kakhulu ezingxenyeni ezishintshwayo, ama-wheel bearings awazona izinto ofuna ukuzifaka ezingxenyeni ezithile noma ikhwalithi yomkhiqizo. I-wheel bearing inesibopho sokusekela isisindo semoto, kanye nokunika amandla nokuqondisa imoto ngendlela efanele. Ama-bearings amasondo ashintshwayo kufanele enziwe ngezinto ezisezingeni eliphezulu kanye nabakhiqizi abathembekile. Ezimweni eziningi, inketho engcono kakhulu ukuthenga amasondo amasondo e-OEM. Kodwa-ke, kunabakhiqizi abambalwa bemakethe yangemuva abenze izingxenye zemakethe zangemuva ezihlukile ezidlula okulinganayo kwe-OEM.

Noma nini lapho uhlela ukuhlanza nokupakisha kabusha ama-wheel bearings akho, cabanga ukwenza lezi zinyathelo ezilandelayo kuqala ukuze wonge isikhathi, umzamo, kanye nemali ngokuhamba kwesikhathi.

Isinyathelo 1: Bheka izimpawu ezikhombisa isidingo sokushintsha ama-wheel bearings.. Isondo elithwalayo kufanele libe ngokuhleleka kokusebenza, lihlanzeke, lingabi nemfucumfucu, izigxivizo kufanele zibe ziphelele futhi zisebenze ngendlela efanele.

Khumbula umthetho wegolide wama-wheel bearings: uma ungabaza, shintsha.

Isinyathelo sesi-2: Xhumana nomnyango wezingxenye zomkhiqizi wezimoto.. Uma kukhulunywa ngamasondo amasondo, ezimweni eziningi inketho ye-OEM ingcono.

Kunabakhiqizi abambalwa be-aftermarket abenza imikhiqizo elinganayo, kodwa i-OEM ihlala ingcono kakhulu kuma-wheel bearings.

Isinyathelo sesi-3: Qiniseka ukuthi izingxenye ezishintshayo zifana ncamashi nonyaka, ukwakheka, kanye nemodeli.. Ngokuphambene nalokho okushiwo isitolo sakho sezingxenye zezimoto sasendaweni, akuwona wonke amasondo amasondo aphuma kumkhiqizi ofanayo afanayo.

Kubaluleke kakhulu ukwenza isiqiniseko sokuthi uthola ingxenye enconyiwe yokufaka esikhundleni sonyaka, ukwakheka, imodeli futhi ezimweni eziningi nciphisa izinga lemoto oyilungisayo. Futhi, lapho uthenga ama-bearings ashintshayo, qiniseka ukuthi usebenzisa amafutha okufaka uphawu anconyiwe. Ngokuvamile ungathola lolu lwazi encwadini yomnikazi wemoto yakho.

Ngokuhamba kwesikhathi, ama-wheel bearings aba nemithwalo emikhulu. Nakuba zilinganiselwe ukuthi zihlale ngaphezu kwamamayela angu-100,000, uma zingahlanzwa njalo futhi zipakishwe kabusha, zingaguga ngaphambi kwesikhathi. Ngisho noma zilungiswa njalo futhi zilungiswa, ziyaguga ngokuhamba kwesikhathi. Omunye umthetho wesithupha uwukushintsha njalo ama-wheel bearing njalo ngamamayela ayi-100,000 njengengxenye yokulungiswa okuhleliwe.

Ingxenye yesi-3 koku-3: Ukuhlanza nokushintsha ama-wheel bearing

Umsebenzi wokuhlanza nokupakisha kabusha amabheringi amasondo kuwumsebenzi omakhenikha abaningi abayizimfundamakhwela abangathandi ukuwenza ngesizathu esisodwa esilula: kuwumsebenzi ongcolile. Ukuze ukhiphe amabheringi amasondo, uwahlanze futhi uphinde uwagcwalise ngamafutha, udinga ukwenza isiqiniseko sokuthi imoto iphakanyisiwe nokuthi unendawo eyanele yokusebenza ngaphansi naseduze kwayo yonke ihabhu lamasondo. Kuhlale kunconywa ukuthi uhlanze futhi upakishe amabheringi amasondo e-asili efanayo ngosuku olufanayo noma phakathi nesevisi efanayo.

Ukuze wenze le sevisi, udinga ukuqoqa izinto ezilandelayo:

Izinto ezidingekayo

- Ithini lokuhlanza amabhuleki

- Indwangu yesitolo ehlanzekile

- i-screwdriver esicaba

- isixhumi

- UJack umile

- Ispanner

- Udladla — adjustable kanye inaliti-nose

- Izikhonkwane ze-cotter ezishintshayo

- Ukushintshwa kwezimpawu zamafutha zangaphakathi zamasondo amasondo

- Ukushintsha ama-wheel bearings

- Izibuko zokuphepha

- Amagilavu okuvikela e-latex

- Isondo eliphethe amafutha

- Amasokisi wesondo

Iqoqo lokhiye namakhanda

UkuvimbelaIMP: Kuhlala kungcono kakhulu ukuthenga futhi ubuyekeze imanuwali yesevisi yemoto ukuze wenze okuthile, unyaka, kanye nemodeli ukuze uqedele le nqubo. Uma usubuyekeze imiyalelo eqondile, qhubeka kuphela uma uqinisekile ukuthi uzowuqeda lo msebenzi. Uma ungaqiniseki ngokuhlanza nokuvala kabusha amasondo akho, xhumana nenye yemishini yethu yasendaweni eqinisekisiwe ye-ASE ukuze ikwenzele le sevisi.

Izinyathelo zokususa, ukuhlanza kanye nokupakisha kabusha amabheringi amasondo kulula kakhulu kumakhenika onolwazi. Ezimweni eziningi, ungenza isondo ngalinye lithwale emahoreni amabili kuya kwamathathu. Njengoba kuphawuliwe ngenhla, kubaluleke kakhulu kuwe ukuthi usebenzise izinhlangothi zombili ze-ekseli efanayo ngesikhathi sesevisi efanayo (noma ngaphambi kokuphinda ungene emotweni). Izinyathelo ezingezansi ZIJWAYELEKILE ngokwemvelo, ngakho hlala ubheka imanuwali yesevisi ukuze uthole izinyathelo eziqondile nezinqubo.

Isinyathelo 1: Nqamula izintambo zebhethri. Izimoto eziningi zinezinzwa ezixhunywe emasondweni (ABS ne-speedometer) ezisebenza ngebhethri.

Kuhlale kunconywa ukuthi unqamule izintambo zebhethri ngaphambi kokukhipha noma yiziphi izingxenye eziwugesi ngokwemvelo. Susa amatheminali amahle kanye namatheminali ngaphambi kokuphakamisa imoto.

Isinyathelo sesi-2: Phakamisa imoto endaweni eyi-hydraulic lift noma ojeke.. Uma unokufinyelela ku-hydraulic lift, isebenzise.

Lo msebenzi kulula kakhulu ukuwenza ngenkathi umile. Kodwa-ke, uma ungenayo i-hydraulic lift, ungakwazi ukusevisa ama-wheel bearings ngokujeqa imoto. Qiniseka ukuthi usebenzisa ama-chock amasondo kwamanye amasondo angavuswanga, futhi njalo uphakamisa imoto ngepheya lojeke ku-ekseli efanayo.

Isinyathelo sesi-3: Susa isondo kuhabhu. Uma imoto isiphakanyisiwe, qala ngakolunye uhlangothi futhi uyiqedele ngaphambi kokudlulela kolunye.

Isinyathelo sokuqala lapha ukususa isondo kuhabhu. Sebenzisa isikrufu somthelela kanye nesokhethi noma isikrufu se-torx ukuze ususe amantongomane esondweni. Uma lokho sekwenziwe, susa isondo ulibeke eceleni futhi uqhele endaweni yakho yokusebenza okwamanje.

Isinyathelo sesi-4: Susa i-brake caliper kuhabhu.. Ukuze ususe ihabhu eliphakathi futhi uhlanze ama-wheel bearings, kuzodingeka ususe i-brake caliper.

Njengoba imoto ngayinye ihlukile, inqubo nayo ihlukile. Landela izinyathelo zemanuwali yakho yesevisi yokususa i-brake caliper. UNGAWASUSI imigqa yamabhuleki phakathi nalesi sinyathelo.

Isinyathelo sesi-5: Susa isivalo sehabhu lamasondo angaphandle.. Ngemuva kokukhipha ama-brake caliper nama-brake pads, isondo elithwala isondo kufanele lisuswe.

Ngaphambi kokukhipha le ngxenye, hlola uphawu lwangaphandle kukhava ngomonakalo. Uma isigxivizo sephukile, lokhu kubonisa ukuthi isondo elithwalayo lilimele ngaphakathi. Isondo elingaphakathi elinesigxivizo libaluleke kakhulu, kodwa uma le khava yangaphandle ilimele, kufanele ishintshwe. Kufanele uqhubeke nokuthenga ama-bearing amasha bese ushintsha womabili amasondo e-ekseli efanayo. Usebenzisa iphinifa elilungisekayo, bamba izinhlangothi zesivalo bese unyakazisa kancane uye phambili kuze kunqamuke uphawu oluphakathi nendawo. Ngemuva kokuvula uphawu, susa isembozo bese ubeka eceleni.

- Imisebenzi: Umakhenikha onekhono ngokuvamile ulandela inqubo emsiza ukuba agcine zonke izingxenye zisendaweni elawulwayo. Ithiphu okufanele uyiqaphele ukwenza i-shop rag pad lapho ubeka khona izingcezu njengoba zisuswa futhi ngokulandelana kwazo. Lokhu akusizi nje ukunciphisa izingxenye ezilahlekile, kodwa futhi kusiza ukukukhumbuza ngohlelo lokufaka.

Isinyathelo sesi-6: Susa iphinikhodi ephakathi. Ngemva kokukhipha isivalo sokuthwala isondo, ihabhu lehabhu lesondo eliphakathi nendawo kanye nephinikhodi ye-cotter kuzobonakala.

Njengoba kuboniswe esithombeni esingenhla, uzodinga ukususa le phinikhodi ye-cotter ngaphambi kokukhipha ihabhu lesondo ku-spindle. Ukuze ususe iphinikhodi ye-cotter, sebenzisa iphini lekhala lenaliti ukugoba iphinikhodi liqonde, bese ubamba enye iphetho yephinikhodi ye-cotter ngamaphini bese udonsela phezulu ukuze uyisuse.

Beka eceleni iphinikhodi ye-cotter, kodwa hlala uyishintshe ufake entsha noma nini lapho uhlanza futhi upakisha kabusha amabheringi amasondo.

Isinyathelo sesi-7: Khipha inadi yehabhu emaphakathi.. Ukuze ukhulule inadi eliphakathi nendawo, uzodinga isokhethi elifanelekile kanye ne-ratchet.

Khulula inadi ngesokhethi kanye ne-ratchet futhi ukhulule inadi ngokuphotha ngesandla. Beka inati ku-rag efanayo nepulaki emaphakathi ukuze uqiniseke ukuthi azilahleki noma azilahleki. Uma nati selikhishiwe, uzodinga ukususa ihabhu ku-spindle.

Kukhona futhi i-nati ne-outer bear evela ku-spindle njengoba ususa ihabhu. I-internal bear izohlala injalo ngaphakathi kwehabhu njengoba uyisusa. Donsa ihabhu ku-spindle uma usususe inati, bese ubeka iwasha nesondo langaphandle elithwele indwangu efanayo nenathi nesembozo.

Isinyathelo sesi-8: Susa uphawu lwangaphakathi kanye nesondo elithwalayo. Abanye omakhenikha bakholelwa kuqhinga elidala elithi «beka inadi ku-spindle bese ususa ukuthwala isondo langaphakathi”, kodwa leyo akuyona indlela enhle yokwenza lokhu.

Kunalokho, sebenzisa i-screwdriver ye-flathead ukuze uhlole ngokucophelela uphawu lwangaphakathi ngaphakathi kwehabhu lamasondo. Uma uphawu lususiwe, sebenzisa i-punch ukuze ukhiphe i-internal bear ngaphandle kwehabhu. Njengezinye izingcezu ozisusile, zibeke ku-rag efanayo lapho lesi sinyathelo sesiphelile.

Isinyathelo sesi-9: Hlanza amabheringi namasondo okuphotha. Indlela engcono kakhulu yokuhlanza amabheringi amasondo kanye ne-axle spindle ukususa wonke amafutha amadala ngeragi noma amathawula ephepha alahlwayo. Lokhu kuzothatha isikhashana futhi kungase kube ukumoshakala, ngakho qiniseka ukuthi usebenzisa amagilavu erabha e-latex ukuvikela izandla zakho kumakhemikhali.

Uma wonke amafutha engeziwe esekhishiwe, uzodinga ukufafaza inani elikhulu le-brake cleaner ngaphakathi kwamabheringi amasondo ukuze ususe noma iyiphi imfucumfucu eyeqile kumabheringi "amasondo" angaphakathi. Qiniseka ukuthi uqedela lesi sinyathelo kukho kokubili okungaphakathi nangaphandle. Amabheringi amasondo angaphakathi nangaphandle, ihabhu lamasondo angaphakathi kanye nesondo lokuphotha kumele nakho kuhlanzwe ngale ndlela.

Isinyathelo se-10: Gcwalisa ama-bearings, i-spindle kanye nehabhu eliphakathi ngamafutha.. Akuwona wonke amagrisi afanayo, ngakho-ke kufanele uhlale ubheka ukuthi igrisi oyisebenzisayo ihambisana namasondo amasondo. I-Tier 1 Moly EP grease ifaneleka kakhulu kulolu hlelo lokusebenza. Ngokuyisisekelo, ufuna ukufaka ugrisi omusha kuwo wonke amakhona ebhodi lesondo elisuka kuzo zonke izinhlangothi. Le nqubo ingaba yimbi kakhulu futhi, ngandlela thize, ingasebenzi kahle.

Ukuze uqedele lesi sinyathelo, kukhona amaqhinga ambalwa. Ukupakisha amabheringi amasondo, faka i-bearing ehlanzekile ngaphakathi kwesikhwama sepulasitiki sokukhiya iziphu kanye nenani elikhululekile lamafutha amasha aphethe isondo. Lokhu kukuvumela ukuthi usebenzise amafutha esondweni ngalinye elincane kanye nokuthwala ngaphandle kokudala isiphithiphithi esiningi ngaphandle kwendawo yokusebenza. Yenza lokhu kuwo womabili ama-bearings amasondo angaphakathi nangaphandle Isinyathelo 11: Gcoba ugrisi omusha ku-spindle yamasondo..

Qinisekisa ukuthi unongqimba lwamafutha olubonakalayo kuyo yonke i-spindle, kusukela ngaphambili kuya ku-backing plate.

Isinyathelo 12: Gcoba amafutha amasha ngaphakathi kwehabhu lamasondo.. Qinisekisa ukuthi imiphetho yangaphandle ivalwe ngokuphelele ngaphambi kokufaka i-bearing yangaphakathi futhi ufake i-bearing seal gasket entsha.

Isinyathelo 13: Faka i-internal bearing kanye nophawu lwangaphakathi. Lokhu kufanele kube lula njengoba indawo isihlanziwe.

Uma ucindezela uphawu lwangaphakathi endaweni, luchofoza endaweni.

Uma usuyifakile i-arearing yangaphakathi, ufuna ukufaka inani elifanelekile lamafutha ngaphakathi kwalezi zingxenye, njengoba kukhonjisiwe esithombeni esingenhla. Faka uphawu lwangaphakathi ngemuva kokuthi yonke indawo igcwaliswe ngokuphelele ngamafutha amasha.

Isinyathelo 14: Faka ihabhu, i-outer bear, iwasha namantongomane.. Le nqubo iwukuhlanekezela kokususa, ngakho-ke izinyathelo ezijwayelekile zimi kanje.

Shelelezisa ibheyili yangaphandle ngaphakathi kwehabhu emaphakathi bese ufaka iwasha noma isibambi ukuze uqondanise ibheyili yangaphandle ngqo kuhabhu. Beka inadi eliphakathi ku-spindle bese uqinisa kuze kube yilapho imbobo emaphakathi ihambisana nembobo yokuphotha. Iphinikhodi entsha ifakwe lapha. Faka iphinikhodi ye-cotter bese ugoba phansi phezulu ukuze usekele i-spindle.

Isinyathelo 15 Spina i-rotor nehabhu ukuze uhlole umsindo nokushelela.. Uma upakishe kahle futhi ufake ama-bearings ahlanzekile, kufanele ukwazi ukuzungeza i-rotor ngokukhululekile ngaphandle kokuzwa umsindo.

Kufanele kube bushelelezi futhi mahhala.

Isinyathelo 16: Faka ama-brake caliper nama-pads.

Isinyathelo sesi-17: Faka isondo nesondo.

Isinyathelo 18: Qedela olunye uhlangothi lwemoto.

Isinyathelo sesi-19: Yehlisa imoto.

Isinyathelo 20: Torque womabili amasondo ukuya kuthoshi enconyiwe ngumkhiqizi..

Isinyathelo 21: Faka kabusha izintambo zebhethri..

Isinyathelo 22: Hlola ukulungiswa. Thatha imoto uyoyihlola isikhashana futhi uqiniseke ukuthi imoto ijikela kwesokunxele nakwesokudla kalula.

Kufanele ulalele ngokucophelela noma yiziphi izimpawu zokugaya noma zokuchofoza njengoba lokhu kungase kubonise ukuthi ama-bearings awafakwanga ngqo kuhabhu. Uma ubona lokhu, buyela ekhaya futhi uhlole zonke izinyathelo ezingenhla.

Uma uyifundile le miyalo, funda imanuwali yesevisi, bese unquma ukuthi ungcono ukushiyela le sevisi kuchwepheshe, xhumana nomunye womakhenikha oqinisekisiwe we-AvtoTachki ASE wasendaweni ukuze akuhlanzele futhi akupakishele kabusha amabheringi amasondo.