Izici zamafutha enjini

Okuqukethwe

Izici zamafutha enjini bonisa ukuthi uwoyela uziphatha kanjani ekushiseni okuhlukile nezimo zokulayisha, futhi ngaleyo ndlela usize umnikazi wemoto ukuthi akhethe kahle uketshezi lokugcoba lwenjini evuthayo yangaphakathi. Ngakho-ke, lapho ukhetha, kuyasiza ukunaka hhayi kuphela ukumaka (okungukuthi, i-viscosity nokubekezelelana kwabakhiqizi bezimoto), kodwa futhi nezici zobuchwepheshe zamafutha emoto, njenge-kinematic and viscosity ashukumisayo, inombolo yesisekelo, okuqukethwe komlotha we-sulfate. , ukuguquguquka nokunye. Kubanikazi abaningi bezimoto lezi zinkomba azisho lutho. A Eqinisweni, bafihla ikhwalithi yamafutha, ukuziphatha kwawo ngaphansi komthwalo kanye neminye imininingwane yokusebenza.

Ngakho-ke, uzofunda ngokuningiliziwe ngamapharamitha alandelayo:

- i-kinematic viscosity;

- I-viscosity enamandla;

- Inkomba ye-viscosity;

- ukuntengantenga;

- umthamo wokupheka;

- okuqukethwe komlotha we-sulfate;

- inombolo ye-alkaline;

- Ukuminyana;

- Iphuzu elikhanyayo;

- uthele iphuzu;

- Izithasiselo;

- Isikhathi sempilo.

Izici eziyinhloko zamafutha emoto

Manje ake sidlulele kumapharamitha angokwenyama namakhemikhali abonisa wonke amafutha enjini.

I-Viscosity iyindawo eyinhloko, ngenxa yokuthi ikhono lokusebenzisa umkhiqizo ezinhlotsheni ezihlukahlukene zezinjini zomlilo zangaphakathi zinqunywa. Ingavezwa ngamayunithi e-kinematic, ashukumisayo, anemibandela kanye ne-viscosity ethize. Izinga le-ductility le-motor material linqunywa izinkomba ezimbili - i-viscosity kinematic kanye ne-dynamic. Le mingcele, kanye nokuqukethwe komlotha we-sulfate, inombolo yesisekelo kanye ne-viscosity index, yizinkomba eziyinhloko zekhwalithi yamafutha emoto.

I-viscosity ye-Kinematic

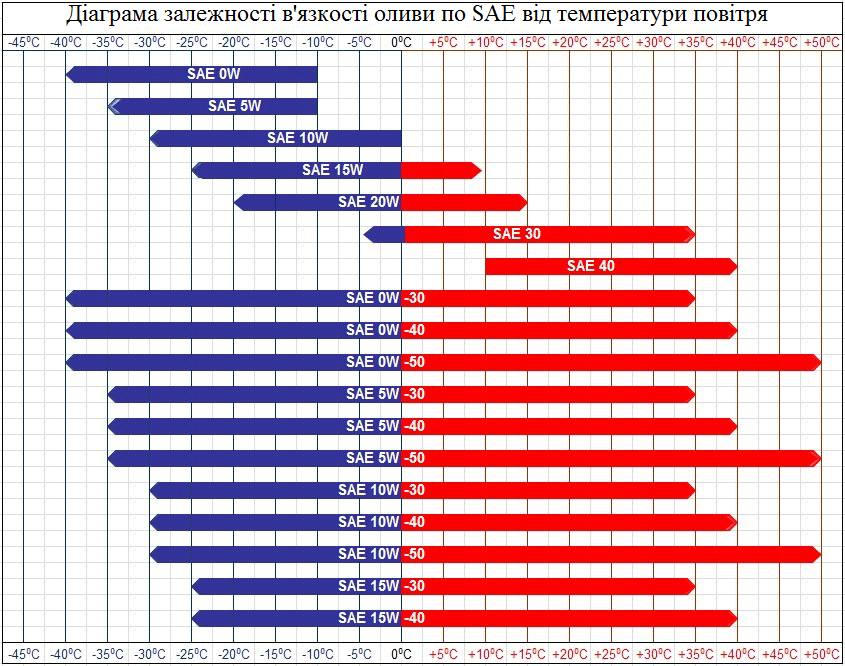

Igrafu yokuncika kwe-viscosity ekushiseni kwamafutha enjini

I-kinematic viscosity (ukushisa okuphezulu) iyipharamitha eyisisekelo yokusebenza yazo zonke izinhlobo zamafutha. Kuyisilinganiso se-viscosity eguquguqukayo kuya kubuningi boketshezi ezingeni lokushisa elifanayo. I-kinematic viscosity ayithinti isimo samafutha, inquma izici zedatha yokushisa. le nkomba ibonisa ukungqubuzana kwangaphakathi kokwakheka noma ukumelana kwayo nokugeleza kwayo. Ichaza uketshezi lwamafutha emazingeni okushisa okusebenza angu-+100°C no-+40°C. Amayunithi okulinganisa - mm² / s (centiStokes, cSt).

Ngamagama alula, le nkomba ibonisa i-viscosity yamafutha kusukela ekushiseni futhi ikuvumela ukuba ulinganise ukuthi izokhula ngokushesha kangakanani lapho izinga lokushisa lehla. Ngemva kwakho konke kancane amafutha ashintsha i-viscosity yawo ngokushintsha kwezinga lokushisa, izinga likawoyela likhuphuka.

I-viscosity enamandla

I-viscosity eguquguqukayo yamafutha (absolute) ibonisa amandla okumelana noketshezi olunamafutha okwenzeka ngesikhathi sokuhamba kwezingqimba ezimbili zamafutha, ngo-1 cm ukusuka komunye nomunye, ezihamba ngesivinini esingu-1 cm / s. I-Dynamic viscosity iwumkhiqizo we-kinematic viscosity yamafutha kanye nokuminyana kwawo. Amayunithi aleli nani amasekhondi e-Pascal.

Kalula nje, kukhombisa umphumela wokushisa okuphansi ekuqineni kokuqala kwenjini evuthayo yangaphakathi. Futhi lapho i-viscosity eguquguqukayo kanye ne-kinematic iphansi emazingeni okushisa aphansi, kuzoba lula ngesistimu yokugcoba ukupompa uwoyela esimweni sezulu esibandayo, kanye nesiqalisi sokuvula i-ICE flywheel ngesikhathi sokuqala okubandayo. Inkomba ye-viscosity yamafutha enjini nayo ibaluleke kakhulu.

Inkomba ye-viscosity

Izinga lokuncipha kwe-kinematic viscosity ngokukhuphuka kwezinga lokushisa libonakala ngokuthi inkomba ye-viscosity amafutha. Inkomba ye-viscosity ihlola ukufaneleka kwamafutha ngezimo zokusebenza ezinikeziwe. ukuze unqume inkomba ye-viscosity, qhathanisa i-viscosity yamafutha emazingeni okushisa ahlukene. Uma iphezulu, i-viscosity encane incike ekushiseni, ngakho-ke ikhwalithi yayo ingcono. Kafushane nje, Inkomba ye-viscosity ibonisa "i-degree of thinning" yamafutha.. Leli inani elingenasici, i.e. ayilinganiswa kunoma yimaphi amayunithi - iyinombolo nje.

Inkomba ephansi injini yamafutha viscosity kulapho amafutha aba mancane khona, i.e. ubukhulu befilimu yamafutha buba buncane kakhulu (ngenxa yokuthi kukhona ukugqoka okwenyuka). Inkomba ephezulu i-viscosity yamafutha enjini, amafutha amancane amancane, i.e. ubukhulu befilimu kawoyela obudingekayo ukuze kuvikelwe izindawo zokuhlikihla kunikezwa.

Amafutha anenkomba ephezulu aqinisekisa ukusebenza kwenjini evuthayo yangaphakathi ebangeni lokushisa elibanzi (indawo). Ngenxa yalokho, ukuqalisa okulula kwenjini yomlilo yangaphakathi emazingeni okushisa aphansi kanye nogqinsi olwanele lwefilimu kawoyela (ngakho-ke ukuvikelwa kwenjini yomlilo yangaphakathi ekugugeni) emazingeni okushisa aphezulu kunikezwa.

Amafutha amaminerali asezingeni eliphakeme ngokuvamile anenkomba ye-viscosity ye-120-140, i-semi-synthetic 130-150, i-synthetic 140-170. Leli nani lincike ekusetshenzisweni ekwakhiweni kwama-hydrocarbon kanye nokujula kokwelashwa kwamafrakshini.

Ibhalansi iyadingeka lapha, futhi lapho ukhetha, kufanelekile ukucabangela izidingo zomkhiqizi wezimoto kanye nesimo seyunithi yamandla. Nokho, lapho inkomba ye-viscosity iphakeme, izinga lokushisa elingasetshenziswa uwoyela liyanda.

Ukuhwamuka

Ukuhwamuka (okubizwa nangokuthi i-volatility noma imfucuza) kubonakalisa inani lesisindo soketshezi oluthambisayo olwahwamuka phakathi nehora elilodwa ekushiseni kwalo okungu-+245,2 ° C kanye nengcindezi yokusebenza engu-20 mm. rt. Art. (± 0,2). Ihambisana nezinga le-ACEA. Kukalwa njengephesenti lesamba sengqikithi, [%]. Kwenziwa kusetshenziswa umshini okhethekile we-Noack ngokuya nge-ASTM D5800; Idatha ye-DIN 51581.

Than i-viscosity ephezulu yamafutha, the ine-volatility ephansi ngokukaNoak. Amanani athile okuguquguquka ancike ohlotsheni lukawoyela wesisekelo, i.e. asethwe umkhiqizi. Kukholelwa ukuthi ukuguquguquka okuhle kusezingeni elifinyelela ku-14%, nakuba amafutha atholakala nokudayiswa, ukuguquguquka okufinyelela ku-20%. Ngamafutha okwenziwa, leli nani ngokuvamile alidluli u-8%.

Ngokuvamile, kungashiwo ukuthi i-Noack volatility value ephansi, iyancipha ukutubeka kwamafutha. Ngisho nomehluko omncane - 2,5 ... amayunithi angu-3,5 - angathinta ukusetshenziswa kwamafutha. Umkhiqizo we-viscous owengeziwe ushisa kancane. Lokhu kuyiqiniso ikakhulukazi ngamafutha amaminerali.

I-Carbonization

Ngamazwi alula, umqondo wokupheka yikhono lamafutha okwenza ama-resin kanye nama-deposits kuvolumu yawo, okuyinto, njengoba wazi, ukungcola okuyingozi oketshezini lokugcoba. Umthamo wokupheka uncike ngqo ezingeni lokuhlanzwa kwawo. Lokhu kuphinde kuthinteke ukuthi yikuphi uwoyela oyisisekelo owasetshenziswa ekuqaleni ukudala umkhiqizo oqediwe, kanye nobuchwepheshe bokukhiqiza.

Inkomba efanele yamafutha anezinga eliphezulu le-viscosity yinani 0,7%. Uma amafutha ane-viscosity ephansi, inani elihambisanayo lingase libe ku-0,1 ... 0,15%.

Umlotha oshubile

Okuqukethwe komlotha we-sulfate kawoyela wenjini (umlotha we-sulphate) kuyinkomba yokuba khona kwezithasiselo emafutheni, okuhlanganisa izinhlanganisela zensimbi eziphilayo. Ngesikhathi sokusebenza kwe-lubricant, zonke izithasiselo nezithasiselo zikhiqizwa - ziyashisa, zenze umlotha (i-slag ne-soot) ehlala kuma-pistons, ama-valve, amasongo.

Okuqukethwe komlotha one-sulphate kawoyela kunciphisa ikhono lamafutha lokuqoqa izinhlanganisela zomlotha. Leli nani libonisa ukuthi ungakanani usawoti wezinto ezingaphili (umlotha) osala ngemva kokushiswa (ukuhwamuka) kwamafutha. Kungase kube ama-sulfates kuphela ("besabisa" abanikazi bezimoto, izimoto ezinezinjini ze-aluminium "ezisabayo" ze-sulfuric acid). Okuqukethwe komlotha kukalwa njengephesenti yenani lesisindo sokwakheka, [% mass].

Ngokuvamile, ama-ash deposits avala izihlungi ze-diesel particulate kanye nama-catalysts kaphethiloli. Nokho, lokhu kuyiqiniso uma kukhona ukusetshenziswa okuphawulekayo kwamafutha e-ICE. Kumele kuqashelwe ukuthi ukuba khona kwe-sulfuric acid emafutheni kubaluleke kakhulu kunokuqukethwe komlotha we-sulfate.

Ekwakhiweni kwamafutha omlotha ogcwele, inani lezithasiselo ezifanele lingase lidlule kancane ku-1% (kufika ku-1,1%), emafutheni omlotha ophakathi - 0,6 ... 0,9%, emafutheni omlotha ophansi - hhayi ngaphezu kuka-0,5% . ngokulandelana, eliphansi leli nani, lingcono.

Amafutha anomlotha ophansi, lawo abizwa nge-Low SAPS (abhalwe ngokwe-ACEA C1, C2, C3 kanye ne-C4). Ziyindlela engcono kakhulu yezimoto zesimanje. Ivamise ukusetshenziswa ezimotweni ezinohlelo lokukhipha igesi ephumayo kanye nezimoto ezihamba ngegesi yemvelo (ene-LPG). Umlotha obalulekile ezinjinini zikaphethiloli ngu-1,5%, ezinjinini zikadizili ungu-1,8%, kanti ezinjinini zikadizili ezinamandla angu-2%. Kodwa kufanele kuqashelwe ukuthi amafutha omlotha aphansi awahlali e-sulfure ephansi, ngoba okuqukethwe komlotha ophansi kutholakala ngenombolo yesisekelo esiphansi.

Izithasiselo zomlotha ezigcwele, nazo ziyi-Full SAPA (enokumaka ACEA A1 / B1, A3 / B3, A3 / B4, A5 / B5). Kuthinta kabi izihlungi ze-DPF, kanye nama-catalyst akhona ezigaba ezintathu. Amafutha anjalo awanconywa ukuthi asetshenziswe ezinjinini ezifakwe i-Euro 4, Euro 5 kanye ne-Euro 6 izinhlelo zemvelo.

Okuqukethwe komlotha we-sulfate okuphezulu kungenxa yokuba khona kwezithasiselo zokuhlanza eziqukethe izinsimbi ekubunjweni kwamafutha enjini. Izingxenye ezinjalo ziyadingeka ukuze kuvinjwe amadiphozithi ekhabhoni kanye nokwakheka kwevarnish kumapiston kanye nokunikeza uwoyela amandla okunciphisa ama-asidi, abonakala ngobuningi ngenombolo yesisekelo.

Inombolo yesisekelo

Leli nani libonisa ukuthi uwoyela unganciphisa isikhathi esingakanani ama-asidi ayingozi kuwo, abangele ukugqwala okubolayo kwezingxenye zenjini evuthayo futhi athuthukise ukwakheka kwamadiphozithi ekhabhoni ahlukahlukene. I-Potassium hydroxide (KOH) isetshenziselwa ukunciphisa. Ngokulandelana inombolo yesisekelo ikalwa ngo-mg KOH ngegremu lamafutha, [mg KOH/g]. Ngokomzimba, lokhu kusho ukuthi inani le-hydroxide liyalingana ngokusebenza nephakheji elengeziwe. Ngakho-ke, uma imibhalo ibonisa ukuthi inombolo yesisekelo esiphelele (TBN - Ingqikithi Yenombolo Yesisekelo), isibonelo, i-7,5, lokhu kusho ukuthi inani le-KOH lingu-7,5 mg igremu ngayinye yamafutha.

Uma isibalo sesisekelo siphezulu, uwoyela uzokwazi ukunqanda isenzo sama-asidi isikhathi eside.kwakheka ngesikhathi se-oxidation yamafutha kanye nokushiswa kukaphethiloli. Okusho ukuthi, kuzokwazi ukuyisebenzisa isikhathi eside (nakuba amanye amapharamitha nawo anomthelela kule nkomba). Izakhiwo zokuhlanza eziphansi zimbi emafutheni, ngoba kulokhu kuzokwakhiwa idiphozi engenakucimeka ezingxenyeni.

Ngesikhathi sokusebenza kwamafutha enjini evuthayo yangaphakathi, inombolo ye-alkaline iyancipha ngokungenakugwenywa, futhi izithasiselo ezingathathi hlangothi ziyasetshenziswa. Ukwehliswa okunjalo kunemingcele eyamukelekayo, ngaphezu kwalokho amafutha angeke akwazi ukuvikela ngokumelene nokugqwala ngama-acidic compounds. Ngokuqondene nenani eliphelele lenombolo yesisekelo, ngaphambili kwakukholelwa ukuthi kuma-ICE kaphethiloli kuzoba cishe u-8 ... 9, kanye nezinjini zikadizili - 11 ... 14. Kodwa-ke, ukwakheka kwamafutha esimanjemanje kuvame ukuba nezinombolo eziphansi, kuze kufike ku-7 ngisho no-6,1 mg KOH/g. Sicela uqaphele ukuthi kuma-ICE anamuhla ungasebenzisi amafutha anenombolo yesisekelo engu-14 noma ngaphezulu.

Inombolo yesisekelo esiphansi emafutheni esimanje yenziwa ngokuzenzela ukuze ivumelane nezidingo zamanje zemvelo (EURO-4 kanye ne-EURO-5). Ngakho-ke, lapho la mafutha eshiswa enjini yomlilo yangaphakathi, kwakheka inani elincane lesulfure, elinomthelela omuhle kwikhwalithi yamagesi okukhipha amandla. Kodwa-ke, uwoyela onenombolo yesisekelo esiphansi ngokuvamile awuzivikeli izingxenye zenjini ukuthi zingagugi ngokwanele.

Lokhu kusho ukuthi i-SC eningi akudingekile ngaso sonke isikhathi ukuthi ibe inombolo enkulu noma encane.

Ubuningi

Ukuminyana kusho ukuminyana kanye ne-viscosity yamafutha enjini. Kunqunywa ekushiseni kwe-ambient +20°C. Ikalwa ngo-kg/m³ (akuvamile ku-g/cm³). Ibonisa isilinganiso sesisindo esiphelele somkhiqizo kumthamo wayo futhi incike ngokuqondile ku-viscosity yamafutha kanye nesici sokucindezela. Kunqunywa amafutha ayisisekelo kanye nezithako eziyisisekelo, futhi futhi kuthinta kakhulu i-viscosity eguquguqukayo.

Uma ukuhwamuka kwamafutha kuphezulu, ukuminyana kuzokwanda. Ngakolunye uhlangothi, uma uwoyela unomthamo ophansi, futhi ngesikhathi esifanayo i-flash point (okungukuthi, inani eliphansi lokuguquguquka), khona-ke kungahlulelwa ukuthi uwoyela wenziwa kuwoyela wesisekelo sekhwalithi ephezulu.

Ukuphakama komthamo, kubi nakakhulu amafutha edlula kuzo zonke iziteshi kanye nezikhala zenjini yangaphakathi evuthayo, futhi ngenxa yalokhu, ukujikeleza kwe-crankshaft kuba nzima nakakhulu. Lokhu kuholela ekwenyukeni kokugqoka, ukufakwa kwediphozithi, idiphozithi ye-carbon kanye nokwanda kokusetshenziswa kukaphethiloli. Kodwa ukuminyana okuphansi kwe-lubricant nakho kubi - ngenxa yalo, ifilimu yokuzivikela emincane futhi engazinzile, ukushiswa kwayo ngokushesha. Uma injini evuthayo yangaphakathi ivame ukusebenza ngokungenzi lutho noma kwimodi yokumisa, kungcono ukusebenzisa uketshezi lokuthambisa olungaminyene kakhulu. Futhi ngokuhamba isikhathi eside ngesivinini esikhulu - kuminyene kakhulu.

Ngakho-ke, bonke abakhiqizi bakawoyela banamathela ebangeni lokuminyana lamafutha akhiqizwa yibo ebangeni lika-0,830 .... 0,88 kg / m³, lapho kuphela ububanzi obudlulele bubhekwa njengekhwalithi ephezulu kakhulu. Kodwa ukuminyana kusuka ku-0,83 kuya ku-0,845 kg / m³ kuwuphawu lwama-esters nama-PAO emafutheni. Futhi uma ukuminyana kungu-0,855 ... 0,88 kg / m³, lokhu kusho ukuthi izithasiselo eziningi kakhulu zengeziwe.

I-Flash point

Leli izinga lokushisa eliphansi kakhulu lapho umhwamuko kawoyela wenjini eshisayo, ngaphansi kwezimo ezithile, wenza ingxube nomoya, oqhuma lapho ilangabi lenyuka (ukubala kokuqala). Esikhathini se-flash point, amafutha nawo awabasi. Iphuzu elikhanyayo linqunywa ukushisa amafutha enjini enkomishini evuliwe noma evaliwe.

Lokhu kuyinkomba yokuba khona kwama-fractions aphansi abilayo emafutheni, okunquma ikhono lokwakheka ukwenza amadiphozi e-carbon futhi ashise lapho ethintana nezingxenye zenjini eshisayo. Ikhwalithi namafutha amahle kufanele abe nephuzu elikhanyayo ngangokunokwenzeka. Amafutha enjini yesimanje ane-flash point edlula +200°C, ngokuvamile +210…230°C nangaphezulu.

Thela iphuzu

Inani lokushisa ku-Celsius, lapho uwoyela ulahlekelwa izakhiwo zawo ezingokomzimba, isici soketshezi, okungukuthi, liyaqina, liba linganyakazi. Ipharamitha ebalulekile yabashayeli abahlala ezindaweni ezisenyakatho, nakwabanye abanikazi bezimoto abavame ukuqala injini yomlilo yangaphakathi "ebandayo".

Nakuba Eqinisweni, ngezinhloso ezingokoqobo, inani lephoyinti lokuthulula alisetshenziswa. Ukubonisa ukusebenza kwamafutha eqhweni, kunomunye umqondo - izinga lokushisa elincane lokupompa, okungukuthi, izinga lokushisa elincane lapho iphampu yamafutha ikwazi ukupompa amafutha ohlelweni. Futhi izoba phezulu kancane kunephuzu lokuthela. Ngakho-ke, emibhalweni kufanelekile ukunaka izinga lokushisa elincane lokupompa.

Ngokuqondene nendawo yokuthela, kufanele ibe ngu-5 ... 10 degrees ngaphansi kwezinga lokushisa eliphansi kakhulu lapho injini yomlilo yangaphakathi isebenza khona. Kungaba -50 ° C ... -40 ° C nokunye, kuye ngokuthi i-viscosity ethile yamafutha.

Izithasiselo

Ngaphezu kwalezi zici eziyisisekelo zamafutha emoto, ungathola futhi imiphumela eyengeziwe yokuhlolwa kwelabhorethri ngenani le-zinc, i-phosphorus, i-boron, i-calcium, i-magnesium, i-molybdenum nezinye izakhi zamakhemikhali. Zonke lezi zithasiselo zithuthukisa ukusebenza kwamafutha. Zivikela ekutholeni amaphuzu nasekugugekeni kwenjini evuthayo yangaphakathi, futhi ziphinde zinwebe ukusebenza kukawoyela ngokwawo, ziwuvimbele ukuthi ungafaki i-oxidizing noma ubambe kangcono amabhondi e-intermolecular.

Isibabule - sinezici zokucindezela okwedlulele. I-Phosphorus, i-chlorine, i-zinc nesibabule - izakhiwo zokulwa nokugqoka (qinisa ifilimu yamafutha). I-Boron, i-molybdenum - ukunciphisa ukungqubuzana (isiguquli esengeziwe somphumela omkhulu wokunciphisa ukuguga, ukufaka amaphuzu kanye nokungqubuzana).

Kodwa ngaphandle kokuthuthukiswa, nazo zinezakhiwo eziphambene. okungukuthi, ahlala ngendlela ye-soot enjinini yangaphakathi evuthayo noma afake i-catalyst, lapho enqwabelana khona. Ngokwesibonelo, izinjini diesel nge DPF, SCR kanye converters isitoreji isibabule isitha, futhi oxidation converters isitha phosphorus. Kodwa izithasiselo zokuhlanza (izihlanzi) i-Ca ne-Mg zakha umlotha ngesikhathi sokusha.

Izakhiwo zokuvikela zezithasiselo zincike ezindleleni zokukhiqiza kanye nekhwalithi yezinto ezingavuthiwe, ngakho-ke ubuningi bazo abuhlali bubonisa ukuvikelwa okungcono kakhulu nekhwalithi. Ngakho-ke, i-automaker ngayinye inemikhawulo yayo yokusebenzisa injini ethile.

Ukusebenza komsebenzi

Ezimotweni eziningi, uwoyela uyashintsha kuye ngokuthi ingakanani ibanga lemoto. Kodwa-ke, kwamanye ama-brand of lubricating fluids kuma-canister, usuku lwawo lokuphelelwa yisikhathi luboniswa ngokuqondile. Lokhu kungenxa yokusabela kwamakhemikhali okwenzeka emafutheni ngesikhathi sokusebenza kwawo. Ivamise ukuvezwa njengenani lezinyanga zokusebenza okuqhubekayo (12, 24 kanye Nokuphila Okude) noma inani lamakhilomitha.

Amathebula epharamitha yamafutha enjini

Ukuze uthole ulwazi oluphelele, sethula amathebula ambalwa anikeza ulwazi ngokuncika kwamanye amapharamitha kawoyela wenjini kwamanye noma ezintweni zangaphandle. Ake siqale ngeqembu lamafutha ayisisekelo ngokuhambisana nezinga le-API (API - American Petroleum Institute). Ngakho-ke, amafutha ahlukaniswe ngezinkomba ezintathu - inkomba ye-viscosity, okuqukethwe kwesibabule kanye nengxenye enkulu ye-naphthenoparaffin hydrocarbons.

| Ukuhlukaniswa kwe-API | I | II | III | IV | V |

|---|---|---|---|---|---|

| Okuqukethwe kwama-hydrocarbon agcwele,% | > 90 | > 90 | I-PJSC | Ama-Ethers | |

| Okuqukethwe kwesibabule, % | > 0,03 | ||||

| Inkomba ye-viscosity | 80… 120 | 80… 120 | > 120 |

Njengamanje, inani elikhulu lezithasiselo zamafutha zisemakethe, okuthi ngandlela-thile ziguqule izici zayo. Isibonelo, izithasiselo ezinciphisa inani lamagesi okukhipha amandla futhi zandise i-viscosity, izithasiselo zokulwa nokukhuhlana ezihlanza noma ezinweba impilo yesevisi. Ukuze uqonde ukuhlukahluka kwazo, kufanelekile ukuqoqa ulwazi ngazo etafuleni.

| Iqembu lempahla | Izinhlobo ezingeziwe | Ukuqokwa |

|---|---|---|

| Ingxenye yokuvikela indawo | Izihlanzi (izihlanzi) | Ivikela izingxenye zezingxenye ekwakhekeni kwamadiphozithi kuzo |

| Abahlakaza | Vimbela ukufakwa kwemikhiqizo egugile yenjini evuthayo yangaphakathi kanye nokonakaliswa kukawoyela (kunciphisa ukwakheka kodaka) | |

| I-Anti-wear kanye nokucindezela okukhulu | Yehlisa ukungqubuzana nokuguga, gwema ukubamba kanye nokuklolodela | |

| I-anti-corrosion | Vimbela ukugqwala kwezingxenye zenjini | |

| Guqula izakhiwo zamafutha | I-Depressor | Yehlisa indawo yokuqandisa. |

| Izilungisi ze-viscosity | Nweba uhla lokushisa kwesicelo, ukwandisa inkomba viscosity | |

| Ukuvikelwa kwamafutha | I-anti-foam | Vimbela ukwakheka kwegwebu |

| Ama-Antioxidants | Vimbela i-oxidation kawoyela |

Ukushintsha amanye amapharamitha kawoyela wenjini abalwe esigabeni sangaphambilini kuthinta ngokuqondile ukusebenza nesimo senjini evuthayo yangaphakathi yemoto. Lokhu kungavezwa kuthebula.

| Inkomba | Okuthrendayo | Isizathu | Ipharamitha ebalulekile | Yini ethintayo |

|---|---|---|---|---|

| Ukungabi nabulungisa | liyakhula | Imikhiqizo ye-oxidation | 1,5 izikhathi ukwanda | Iqala Izakhiwo |

| Thela iphuzu | liyakhula | Amanzi kanye nemikhiqizo ye-oxidation | No | Iqala Izakhiwo |

| Inombolo yesisekelo | Yehla | Isenzo sokuhlanza | Yehlisa izikhathi ezi-2 | Ukugqwala nokuphila okuncishisiwe kwezingxenye |

| Okuqukethwe komlotha | liyakhula | Izithako ze-alkaline | No | Ukubonakala kwamadiphozithi, ukuguga kwezingxenye |

| Ukungcola kwemishini | liyakhula | Imikhiqizo yokugqoka imishini | No | Ukubonakala kwamadiphozithi, ukuguga kwezingxenye |

Imithetho yokukhetha uwoyela

Njengoba kushiwo ngenhla, ukukhethwa kwamafutha enjini eyodwa noma enye akufanele kusekelwe kuphela ekufundweni kwe-viscosity nokubekezelelana kwabakhiqizi bezimoto. Ngaphezu kwalokho, kukhona nemingcele emithathu eyisibopho okufanele icatshangelwe:

- izakhiwo zokuthambisa;

- izimo zokusebenza zamafutha (imodi yokusebenza ye-ICE);

- izici zesakhiwo senjini yomlilo yangaphakathi.

Iphuzu lokuqala lincike kakhulu ekutheni yiluphi uhlobo lwamafutha okwenziwa, oluyi-semi-synthetic noma amaminerali ngokuphelele. Kuyafiseleka ukuthi uketshezi oluthambisayo lube nalezi zimpawu zokusebenza ezilandelayo:

- Okokuhlanza okuphezulu okuhlakazekayo-zinza kanye nezindawo ezincibilikisayo maqondana nezinto ezingancibiliki kuwoyela. Izici ezishiwo zikuvumela ukuthi uhlanze ngokushesha futhi kalula ingaphezulu lezingxenye zokusebenza zenjini yangaphakathi evuthayo kusuka ekungcoleni okuhlukahlukene. Ngaphezu kwalokho, ngenxa yabo, kulula ukuhlanza izingxenye ezingcolile ngesikhathi sokudilizwa.

- Ikhono lokunciphisa imiphumela yama-asidi, ngaleyo ndlela kuvinjwe ukuguga ngokweqile kwezingxenye zenjini evuthayo futhi kwandise insiza yayo yonke.

- Izakhiwo ezishisayo ezishisayo kanye ne-thermal-oxidative. Ziyadingeka ukuze kuphole ngempumelelo izindandatho namapiston.

- Ukungaguquguquki okuphansi, kanye nokusetshenziswa kawoyela okuphansi kokumosha.

- Ukungabi khona kwekhono lokwenza igwebu kunoma yisiphi isimo, ngisho nokubanda, ngisho nalapho kushisa.

- Ukuhambisana ngokugcwele nezinto okwenziwa kuzo izigxivizo (imvamisa irabha engamelana nowoyela) esetshenziswa ohlelweni lwe-gas neutralization, kanye nakwamanye amasistimu wezinjini zomlilo zangaphakathi.

- Ukugcotshwa kwekhwalithi ephezulu kwezingxenye zenjini evuthayo yangaphakathi kunoma yiziphi izimo ezibucayi (ngesikhathi sesithwathwa noma ukushisa ngokweqile).

- Ikhono lokupompa ngezakhi zesistimu yokugcoba ngaphandle kwezinkinga. Lokhu akuhlinzeki nje ngokuvikeleka okunokwethenjelwa kwezakhi zenjini yomlilo yangaphakathi, kodwa futhi kusiza ukuqala injini yomlilo yangaphakathi esimweni sezulu esibandayo.

- Ukungangeni ekuphenduleni kwamakhemikhali ngezinto zensimbi nezenjoloba zenjini evuthayo yangaphakathi phakathi nesikhathi sayo eside sokungasebenzi ngaphandle komsebenzi.

Izinkomba ezisohlwini zekhwalithi yamafutha enjini zivame ukugxeka, futhi uma amanani abo engaphansi kwesimiso, khona-ke lokhu kugcwele ukugcotshwa okwanele kwezingxenye ezithile zenjini evuthayo yangaphakathi, ukuguga kwazo ngokweqile, ukushisa ngokweqile, futhi lokhu. ngokuvamile kuholela ekwehleni kwensiza yazo zombili izingxenye ngazinye kanye nenjini evuthayo yangaphakathi iyonke .

noma yimuphi umshayeli kufanele aqaphe ngezikhathi ezithile izinga lamafutha enjini ku-crankcase, kanye nesimo sawo, ngoba ukusebenza okuvamile kwenjini yomlilo yangaphakathi kuncike ngqo kulokhu. Ngokuqondene nokukhetha, kufanele kwenziwe, kuncike, okokuqala, kuzincomo zomkhiqizi wenjini. Yebo, ulwazi olungenhla mayelana nezakhiwo zomzimba kanye nemingcele yamafutha ngokuqinisekile izokusiza wenze ukukhetha okufanele.