Inzwa yesikhundla se-Crankshaft

Okuqukethwe

Inzwa ye-crankshaft inikeza ukulawula kusuka ku-ECU yenjini yesikhundla sengxenye yemishini ebhekele ukusebenza kwesistimu yomjovo kaphethiloli. Uma i-DPKV ihluleka, itholakala ngosizo lwabahloli abakhethekile abasebenza ngesimiso se-ohmmeter. Uma kwenzeka ukuthi ukumelana kwamanje kungaphansi kwenani elijwayelekile, isilawuli sizodinga ukushintshwa.

Yini enesibopho futhi isebenza kanjani inzwa ye-crankshaft?

Inzwa yokuma kwe-crankshaft inquma ngqo ukuthi uphethiloli kufanele uthunyelwe nini kumasilinda enjini evuthayo yangaphakathi (ICE). Emiklamo ehlukene, i-DPKV inesibopho sokulawula ukulungiswa kokufana kokunikezwa kukaphethiloli ngama-injection.

Imisebenzi yenzwa ye-crankshaft ukubhalisa nokudlulisa idatha elandelayo kukhompyutha:

- linganisa indawo ye-crankshaft;

- umzuzu lapho ama-pistons edlula i-BDC ne-TDC kumasilinda okuqala nawokugcina.

Inzwa ye-PKV ilungisa izinkomba ezilandelayo:

- inani lamafutha angenayo;

- isikhathi sokunikezwa kukaphethiloli;

- i-camshaft angle;

- isikhathi sokushisa;

- umzuzu nesikhathi sokusebenza kwe-valve ye-adsorption.

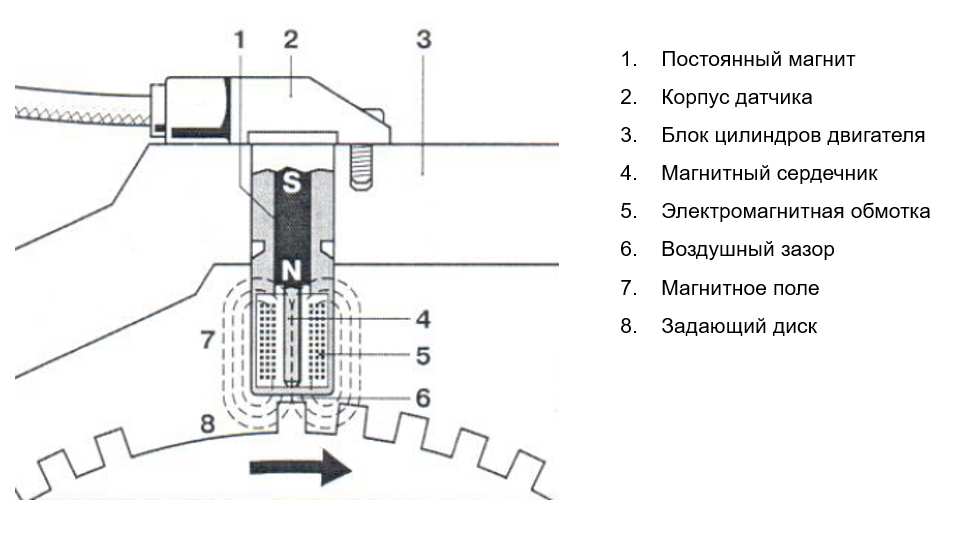

Umgomo wokusebenza kwenzwa yesikhathi:

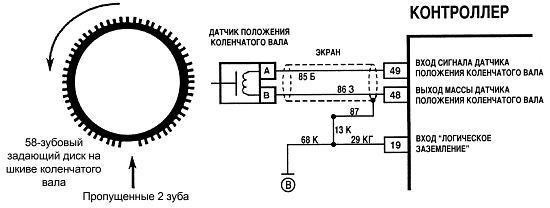

- I-crankshaft ifakwe idiski enamazinyo (ukuqala kanye ne-zeroing). Lapho umhlangano ujikeleza, inkambu kazibuthe iqondiswe emazinyweni avela kunzwa ye-PKV, isebenze kuwo. Izinguquko zirekhodwa ngendlela yama-pulses futhi ulwazi ludluliselwa kukhompyutha: indawo ye-crankshaft iyalinganiswa futhi lapho ama-pistons edlula izikhungo ezifile eziphezulu naphansi (i-TDC ne-BDC) zirekhodwa.

- Uma i-sprocket idlula inzwa yesivinini se-crankshaft, ishintsha uhlobo lokufunda okuthuthukisiwe. Ngenxa yalesi sizathu, i-ECU izama ukubuyisela ukusebenza okuvamile kwe-crankshaft.

- Ngokusekelwe kuma-pulses atholiwe, ikhompuyutha esebhodini ithumela isignali kumasistimu emoto adingekayo.

Idivayisi ye-DPKV

Idizayini yenzwa ye-Crankshaft:

- i-aluminium noma i-plastic case ye-cylindrical shape enesici esibucayi, lapho kuthunyelwa khona isignali kukhompyutha;

- ikhebula lokuxhumana (i-magnetic circuit);

- idrayivu yunithi;

- uphawu;

- ukugoqa;

- ubakaki wokukhweza injini.

Ithebula: izinhlobo zezinzwa

| Имя | Incazelo |

| Inzwa kazibuthe

| Inzwa iqukethe uzibuthe unomphela kanye ne-central winding, futhi lolu hlobo lwesilawuli aludingi ukunikezwa kwamandla okuhlukile. Idivayisi kagesi eguquguqukayo ayilawuli kuphela indawo ye-crankshaft, kodwa futhi nesivinini. Isebenza nge-voltage eyenzeka lapho izinyo lensimbi (ithegi) lidlula endaweni kazibuthe. Lokhu kukhiqiza ukushaya kwesignali okuya ku-ECU. |

| Inzwa Optical

| Inzwa yokubona iqukethe isamukeli ne-LED. Isebenzisana nediski yewashi, ivimba ukugeleza kokubona okudlula phakathi komamukeli ne-LED. I-transmitter ithola ukuphazamiseka kokukhanya. Lapho i-LED idlula endaweni enamazinyo agugile, umamukeli usabela ku-pulse futhi enze ukuvumelanisa ne-ECU. |

| Inzwa yeHholo

| Idizayini yenzwa ihlanganisa:

Kusenzwa ye-crankshaft ye-Hall effect, iyageleza yamanje njengoba isondela endaweni yamagnetic eshintshayo. Umjikelezo wenkundla yamandla uyavuleka lapho udlula ezindaweni ezinamazinyo agugile futhi isignali idluliselwa kuyunithi yokulawula injini ye-elekthronikhi. Isebenza emthonjeni wamandla ozimele. |

Itholakala kuphi inzwa?

Indawo yenzwa yokuma kwe-crankshaft: eduze kwediski phakathi kwe-alternator pulley ne-flywheel. Ukuze uxhumeke mahhala kunethiwekhi esebhodini, kunikezwa ikhebula elingu-50-70 cm ubude, lapho kukhona izixhumi zokhiye. Kukhona ama-spacers phezu kwesihlalo sokusetha igebe 1-1,5mm.

Izimpawu nezimbangela zokungasebenzi kahle

Izimpawu ze-DPKV ephukile:

- injini ayiqali noma ime ngokuzenzakalelayo ngemva kwesikhashana;

- azikho izinhlansi;

- Ukuqhunyiswa kwe-ICE kwenzeka ngezikhathi ezithile ngaphansi kwemithwalo enamandla;

- isivinini sokungenzi lutho esingazinzile;

- amandla enjini namandla emoto ayancishiswa;

- lapho ushintsha izindlela, ushintsho oluzenzakalelayo enanini lokuguquguquka kwenzeka;

- hlola ukukhanya kwenjini kudeshibhodi.

Izimpawu zikhomba izizathu ezilandelayo zokuthi kungani inzwa ye-PCV ingaba nephutha:

- isifunda esifushane phakathi kokujika okujikajikayo, ukuhlanekezela okungenzeka kwesiginali mayelana nokuma kwepiston ku-BDC naku-TDC;

- ikhebula elixhuma i-DPKV ku-ECU lonakele - ikhompyutha esebhodini ayitholi isaziso esifanele;

- ukukhubazeka kwamazinyo (ama-scuffs, ama-chips, ukuqhekeka), injini ingase ingaqali;

- ukungena kwezinto zangaphandle phakathi kwe-pulley enamazinyo kanye nekhawunta noma umonakalo ngenkathi usebenza endaweni yenjini ngokuvamile kubangela ukungasebenzi kahle kwe-DPKV.

Izinkinga ngokuqala injini

Izinhlobonhlobo zokungasebenzi kahle kwenzwa ye-crankshaft ethinta ukusebenza kwenjini yomlilo yangaphakathi:

- Injini ayiqali. Lapho ukhiye wokuthungela uphendulwa, isiqalisi siphendulela injini bese iphampu yamafutha ikhala. Isizathu siwukuthi injini ECU, ngaphandle kokuthola isignali kusukela crankshaft isikhundla inzwa, ayikwazi kahle ukukhipha umyalo: lapho amasilinda ukuqala futhi kuphi ukuvula umlomo wombhobho.

- Injini ishisa ifike ezingeni elithile lokushisa futhi igcine izitebele noma ayiqalisi esithwathwaneni esinamandla. Kunesizathu esisodwa kuphela - i-microcrack ekungeneni kwenzwa ye-PKV.

Ukusebenza okungazinzile kwenjini ngezindlela ezahlukahlukene

Lokhu kwenzeka uma i-DPKV ingcolisiwe, ikakhulukazi uma ama-chips ensimbi noma amafutha engena kuyo. Ngisho nomthelela omncane ku-microcircuit yamagnetic yenzwa yesikhathi ishintsha ukusebenza kwayo, ngoba i-counter ibucayi kakhulu.

Ukuba khona kwe-detonation ye-motor ngomthwalo okhulayo

Isizathu esivame kakhulu ukwehluleka kwemitha, kanye ne-microcrack ekujikeni, egoba ngesikhathi sokudlidliza, noma ukuqhuma endlini, lapho umswakama ungena khona.

Izimpawu zokushayeka kwenjini:

- ukwephulwa kokushelela kwenqubo yokushiswa kwengxube ye-fuel-air kumasilinda enjini yomlilo yangaphakathi;

- ukweqa ku-receiver noma i-exhaust system;

- ukwehluleka;

- ukuncipha okucacile kwamandla enjini.

Amandla enjini ancishisiwe

Amandla enjini ayehla lapho ingxube ye-fuel-air inganikezwa ngesikhathi. Isizathu sokungasebenzi kahle yi-delamination ye-shock absorber kanye nokufuduka kwenkanyezi enamazinyo ngokuhlobene ne-pulley. Amandla enjini nawo ayancishiswa ngenxa yokulimala kokujikajika noma izindlu zemitha yendawo ye-crankshaft.

Ungahlola kanjani inzwa ye-crankshaft ngokwakho?

Ungakwazi ngokuzimela ukuphenya impilo ye-DPKV usebenzisa:

- ohmmeter;

- i-oscillograph;

- eziyinkimbinkimbi, usebenzisa multimeter, megohmmeter, inethiwekhi transformer.

Kubalulekile ukwazi

Ngaphambi kokufaka umshini wokulinganisa, kuyanconywa futhi ukwenza ukuxilonga okuphelele kwekhompyutha yenjini yomlilo yangaphakathi. Khona-ke ukuhlolwa kwangaphandle kwenziwa, kuqedwe ukungcola noma ukulimala komshini. Futhi kuphela ngemva kwalokho baqala ukuxilonga ngemishini ekhethekile.

Ukuhlola nge-ohmmeter

Ngaphambi kokuqhubeka nokuxilongwa, vala injini bese ususa inzwa yesikhathi.

Imiyalo yesinyathelo ngesinyathelo sokufunda i-DPKV nge-ohmmeter ekhaya:

- Faka i-ohmmeter ukukala ukumelana.

- Nquma izinga lokumelana ne-throttle (thinta ama-tester probes kumatheminali bese uwakhalisa).

- Inani elamukelekayo lisuka ku-500 kuye ku-700 ohms.

Ukusebenzisa i-oscilloscope

Inzwa yokuma kwe-crankshaft ihlolwa ngenjini esebenzayo.

I-algorithm yezenzo usebenzisa i-oscilloscope:

- Xhuma isihloli kusibali sikhathi.

- Qalisa uhlelo kukhompuyutha esebhodini eqapha ukufundwa okuvela kusisetshenziswa sikagesi.

- Dlula into yensimbi phambi kwenzwa ye-crankshaft izikhathi ezimbalwa.

- I-multimeter ILUNGILE uma i-oscilloscope iphendula ukunyakaza. Uma zingekho amasiginali esikrinini se-PC, kutuswa ukuba uxilongwe ngokuphelele.

Isheke eliphelele

Ukuze ukwenze, kufanele ube:

- i-megohmmeter;

- inethiwekhi transformer;

- imitha yokungenisa;

- i-voltmeter (mhlawumbe yedijithali).

I-algorithm yezenzo:

- Ngaphambi kokuqala ukuskena okugcwele, inzwa kufanele ikhishwe enjinini, igezwe kahle, yomiswe, bese ilinganiswa. Kwenziwa kuphela ekamelweni lokushisa, ukuze izinkomba zinembile kakhulu.

- Okokuqala, inductance yenzwa (coil inductive) iyalinganiswa. Ibanga elisebenzayo lezilinganiso zezinombolo kufanele libe phakathi kuka-200 no-400 MHz. Uma inani lihluke kakhulu kunani elishiwo, kungenzeka ukuthi inzwa inephutha.

- Okulandelayo, udinga ukukala ukumelana ne-insulation phakathi kwamatheminali ekhoyili. Kulokhu, i-megohmmeter isetshenziswa, ibeka i-voltage yokuphuma ku-500 V. Kungcono ukwenza inqubo yokulinganisa izikhathi ezingu-2-3 ukuze uthole idatha enembe kakhudlwana. Inani elilinganisiwe lokumelana nokufakwa kufanele okungenani libe ngu-0,5 MΩ. Uma kungenjalo, ukwehluleka kwe-insulation kukhoyili kunganqunywa (kuhlanganise nokwenzeka kwesekethe emfushane phakathi kokujika). Lokhu kubonisa ukwehluleka kwedivayisi.

- Khona-ke, usebenzisa i-transformer yenethiwekhi, idiski yesikhathi i-demagnetized.

Ukudubula inkinga

Kunengqondo ukulungisa inzwa yezinkinga ezifana nalezi:

- ukungena ku-PKV inzwa yokungcola;

- ukuba khona kwamanzi kusixhumi senzwa;

- ukuphuka kwe-sheath yokuzivikela yezintambo noma amahhanisi enzwa;

- ukushintsha kwe-polarity yezintambo zesignali;

- akukho ukuxhumana nehhanisi;

- izintambo ezimfushane zesignali emhlabathini wezinzwa;

- kuncishiswe noma kukhushulwe imvume yokukhuphuka kwenzwa kanye nediski yokuvumelanisa.

Ithebula: sebenza ngeziphambeko ezincane

| Okuzenzakalelayo | Kusho |

|---|---|

| Ukungena ngaphakathi kwenzwa ye-PKV nokungcola |

|

| Ukuba khona kwamanzi kusixhumi senzwa |

|

| Isihlangu sekhebula lenzwa ephukile noma amahhanisi |

|

| Hlehlisa i-polarity yezintambo zesignali |

|

| Inzwa ayixhunyiwe kumahhanisi |

|

| Izintambo zesignali yenzwa zifinyelelwe phansi |

|

| Ukunciphisa noma ukukhulisa imvume yokukhuphuka kwenzwa kanye nediski yokuvumelanisa |

|

Ungashintsha kanjani inzwa yendawo ye-crankshaft?

Ama-nuances abalulekile okufanele abhekwe lapho ushintsha i-DPKV:

- Ngaphambi kokuhlakazwa, kuyadingeka ukusebenzisa amamaki abonisa isikhundla sebhawodi esihlobene nenzwa, i-DPKV uqobo, kanye nokumaka izintambo nokuxhumana kukagesi.

- Lapho ukhipha futhi ufaka inzwa entsha ye-PKV, kunconywa ukuthi uqiniseke ukuthi idiski yesikhathi isesimweni esihle.

- Shintsha imitha ngehhanisi ne-firmware.

Ukuze ungene esikhundleni senzwa ye-PKV, uzodinga:

- idivayisi yokulinganisa entsha;

- umhloli ozenzakalelayo;

- i-cavernometer;

- isikliphu 10.

I-algorithm yesenzo

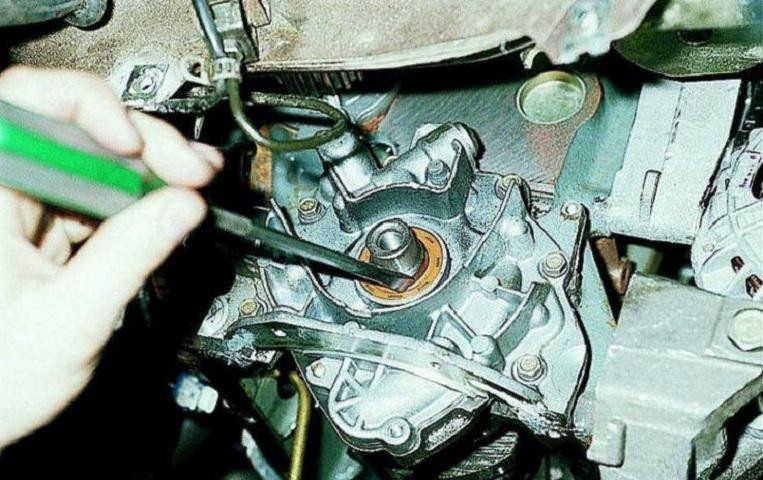

Ukuze ushintshe inzwa yendawo ye-crankshaft ngezandla zakho, udinga:

- Cisha ukuthungela.

- Nciphisa idivayisi ye-elekthronikhi amandla ngokunqamula ibhulokhi yetheminali kusilawuli.

- Ngesikrufu, khumula isikulufu esilungisa inzwa, susa i-DPKV engalungile.

- Sebenzisa iragi ukuze uhlanze indawo okufikela kuyo amadiphozithi anamafutha kanye nokungcola.

- Faka igeji yokucindezela entsha usebenzisa izibophelelo ezindala.

- Yenza izilinganiso zokulawula zegebe phakathi kwamazinyo e-alternator drive pulley kanye ne-sensor core usebenzisa i-vernier caliper. Isikhala kufanele sihambisane namanani alandelayo: 1,0 + 0,41 mm. Uma igebe lincane (likhulu) kunenani elishiwo ngesikhathi sokulinganisa kokulawula, indawo yenzwa kufanele ilungiswe.

- Hlola ukumelana kwenzwa yendawo ye-crankshaft usebenzisa ukuzihlola. Ngenzwa esebenzayo, kufanele ibe kububanzi obusuka ku-550 kuye ku-750 ohms.

- Setha kabusha ikhompuyutha yohambo ukuze uvale isignali Yenjini Yokuhlola.

- Xhuma inzwa yokuma kwe-crankshaft kumapayipi amakhulu (isixhumi sifakwe lokhu).

- Hlola ukusebenza kwento esebenza ngogesi ngezindlela ezihlukene: lapho uphumule futhi ungaphansi komthwalo oguquguqukayo.