I-Asynchronous motor - isimiso sokusebenza nezici zokulawula

Okuqukethwe

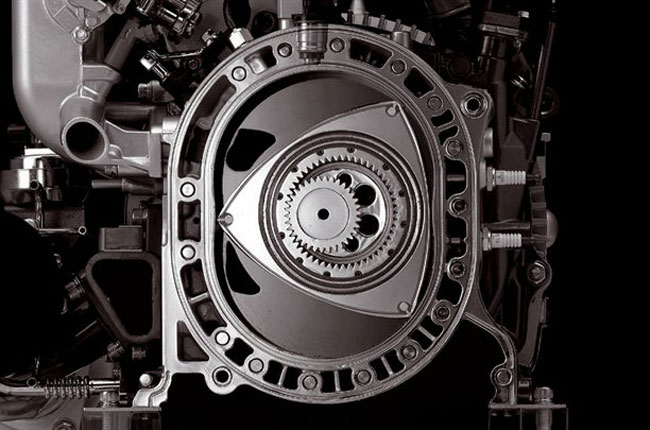

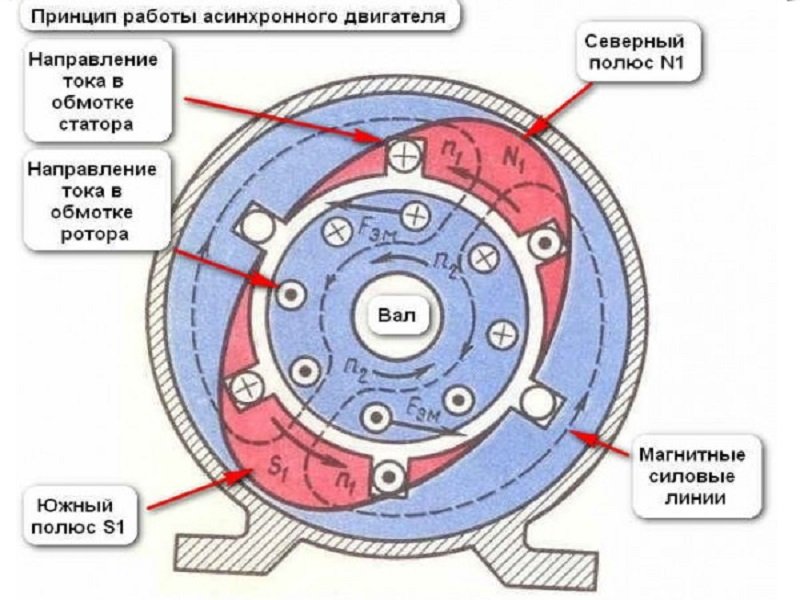

Phakathi kwawo wonke ama-motor kagesi, i-asynchronous motor kufanele iqashelwe ngokukhethekile, isimiso sokusebenza esisekelwe ekusebenzelaneni kwezindawo kazibuthe ze-stator ne-electric current ebangelwa yilo mkhakha ku-rotor winding. Inkambu kazibuthe ezungezayo ikhiqizwa umsinga wamanje oshintshanayo onezigaba ezintathu odlula endaweni yokuma ye-stator, ehlanganisa amaqembu amathathu amakhoyili.

I-induction motor - isimiso sokusebenza kanye nokusetshenziswa

Umgomo wokusebenza kwe-asynchronous motor usekelwe emandleni okudlulisa amandla kagesi emsebenzini wemishini kunoma yimuphi umshini wezobuchwepheshe. Lapho uwela ukuvala okuvaliwe kwe-rotor, insimu yamagnetic ifaka ugesi kuwo. Ngenxa yalokho, insimu yamagnetic ejikelezayo ye-stator ixhumana nemisinga ye-rotor futhi ibangela ukuvela komzuzu ojikelezayo we-electromagnetic, obeka i-rotor ekuhambeni.

Ngaphezu kwalokho, isici somshini we-induction motor sisekelwe ekusebenzeni kwayo ezinguqulweni ezimbili. Ingasebenza njengejeneretha noma i-motor kagesi. Ngenxa yalezi zimfanelo, isetshenziswa kaningi njengomthombo kagesi ohambahambayo, kanye nakumadivaysi amaningi nemishini yezobuchwepheshe.

Uma kucatshangelwa idivayisi ye-asynchronous motor, kufanele kuqashelwe izakhi zayo zokuqala, ezihlanganisa i-capacitor yokuqala kanye nokuvunguza kokuqala ngokumelana okukhulayo. Zihlukaniswa ngezindleko zazo eziphansi kanye nokulula, azidingi izici ezengeziwe zokushintsha isigaba. Njengokubi, kufanele kuqashelwe ukuklama okubuthakathaka kokuvuthwa kokuqala, okuvame ukuhluleka.

Idivayisi ye-induction motor kanye nemithetho yokugcinwa

Isifunda sokuqala se-asynchronous motor singathuthukiswa ngokuxhuma ochungechungeni nge-capacitor winding yokuqala. Ngemva kokunqamula i-capacitor, zonke izici zenjini zigcinwa ngokugcwele. Imvamisa, umjikelezo oshintshayo we-asynchronous motor unomoya osebenzayo, ohlukaniswe izigaba ezimbili ezixhunywe ochungechungeni. Kulokhu, ukushintsha kwendawo yezimbazo kusebangeni ukusuka ku-105 kuya ku-120 degrees. Ama-motor anezigxobo ezivikelwe asetshenziselwa ukushisisa abalandeli.

Buka le vidiyo ku-YouTube

Idivayisi ye-asynchronous motor enezigaba ezintathu idinga ukuhlolwa kwansuku zonke, ukuhlanza kwangaphandle kanye nomsebenzi wokulungisa. Kabili ngenyanga noma ngaphezulu, injini kufanele ivuthelwe ngaphakathi ngomoya ocindezelekile. Ukunakwa okukhethekile kufanele kukhokhwe ekufakeni i-lubrication, okumele ifanele uhlobo oluthile lwemoto. Ukushintshwa okuphelele kwe-lubricant kwenziwa kabili ngonyaka, ngokugudluzwa kanyekanye kwama-bearings ngophethiloli.

Umgomo wokusebenza kwe-asynchronous motor - ukuxilonga nokulungiswa kwayo

Ukuze ulawule i-asynchronous motor ye-asynchronous yesigaba ezintathu ngokushelelayo futhi isikhathi eside, kuyadingeka ukuqapha umsindo wama-bearings ngesikhathi sokusebenza. Imisindo yokushaya ikhwelo, ukuklabalasa noma ukunwaya kufanele kugwenywe, okubonisa ukuntuleka kokugcoba, kanye nama-thuds, okubonisa ukuthi iziqeshana, amabhola, izihlukanisi zingase zonakaliswe.

Uma kwenzeka umsindo ongavamile noma ukushisa ngokweqile, ama-bearings kufanele ahlakazwe futhi ahlolwe.. Igrisi endala iyasuswa, emva kwalokho zonke izingxenye zishaywa ngophethiloli. Ngaphambi kokufaka ama-bearings amasha ku-shaft, kufanele ashiswe ngaphambili ngamafutha ekushiseni okufunayo. Igrisi entsha kufanele igcwalise umthamo wokusebenza wokuthwala cishe ingxenye eyodwa kwezintathu, isatshalaliswe ngokulinganayo kuwo wonke umjikelezo.

Buka le vidiyo ku-YouTube

Isimo sama-slip rings wukuhlola ngokuhlelekile indawo yawo. Uma zithinteka ukugqwala, ingaphezulu lihlanzwa nge-sandpaper elithambile futhi lisulwa ngophalafini. Ezimweni ezikhethekile, anesithukuthezi futhi aphucuziwe. Ngakho-ke, ngokunakekelwa okujwayelekile kwenjini, izokwazi ukusebenzisa isikhathi sayo sewaranti futhi isebenze isikhathi eside.