Ukuzijwayeza kwebhokisi Dsg 7

Okuqukethwe

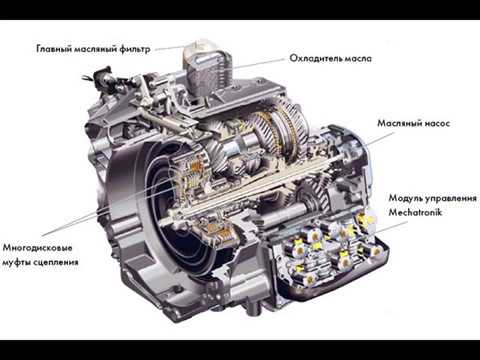

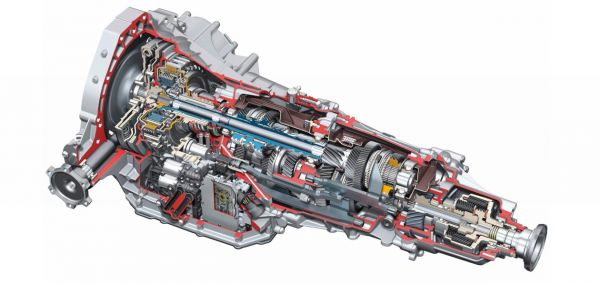

Ama-preselective transmissions akwaVolkswagen angu-7-speed DQ200 asebenzisa ama-clutch ohlobo olomile aguga ngokuhamba kwesikhathi. Ukuzijwayeza ngezikhathi ezithile kwe-DSG 7 kwenza kube nokwenzeka ukunxephezela izinguquko ekukhishweni kokusebenza phakathi kwama-discs kuma-clutch ashayisanayo. Ukulungiswa kwenziwa ngokuzenzakalelayo noma ngesandla ngokusekelwe emiphumeleni yokuxilongwa kwekhompiyutha, inani lokulungiswa okwenziwe lifakwa kumemori yomlawuli.

Kungani kudingeka ukuzivumelanisa nezimo

Uma ama-jerks noma ama-vibrations avela ngesikhathi sokusheshisa imoto efakwe i-othomathikhi yokudlulisela i-DQ200, kuyadingeka ukuhlola isimo se-clutch disc kanye nokushaywa kwezinsimbi ezilawula ama-clutch. Lapho uhlanganisa ukudluliselwa, umenzi ulungisa imingcele, kodwa njengoba ukugqoka kwanda, izikhala zizokwanda futhi isikhundla esihlobene sezakhi sizophazamiseka. Isilawuli senza ukuzivumelanisa nezimo ngemodi ezenzakalelayo, evumela ukunxeshezelwa kokuvunyelwa ngokweqile kumadrayivu, ukubuyisela ukusebenza okujwayelekile kweyunithi.

Ibhokisi lisebenzisa ama-clutches ohlobo oluvulekile, iyunithi ye-mechatronics ilungisa ukucindezelwa kwama-discs kuye ngokuqina kokusheshisa kanye nenani le-torque edlulisiwe. Ngesikhathi sokusheshisa okungazelelwe, induku yokulawula ifinyelela ebangeni eliphakeme kakhulu.

Umkhiqizi ubeka ububanzi be-rod stroke ohlelweni, kodwa ngokuguga ngokweqile kwama-linings, i-thrust ayinikezi ukucindezelwa kwama-disc friction, okuholela ekusheleleni kwe-clutch. Isenzakalo sokushelela kungenzeka futhi ngenxa yokuguquguquka noma ukushisa okweqile kwento yolwelwesi.

Ngaphezu kokuzenzakalela, ukuguqulwa kwe-manual kungenzeka, okwenziwa ngemva komsebenzi wokulungisa ohlobene nokushintshwa kwezingxenye ze-clutch noma uma uhlela kabusha iyunithi yokulawula. Inqubo iyadingeka uma usebenzisa u-gearbox owenziwe kabusha esikhundleni seyunithi yokuqala. Inqubo yokuzivumelanisa nezimo ihilela ukulungisa izikhala kuyunithi ye-clutch ne-mechatronics, ngemva kwalokho ukuhlolwa kwenziwa.

I-Transmission Diagnostics

Ukuze wenze ukuxilonga, uzodinga ikhebula le-VAG-COM noma ikhebula elifanayo le-VASYA-Diagnost elisebenza ngokusetshenziswa kwegama elifanayo. Isheke lenziwa njalo ngebanga elingu-15000 km, elikuvumela ukuthi uhlole isimo sokudluliselwa.

Ngemuva kokuxhuma ikhebula nokusebenzisa insiza yokuxilonga, udinga ukuya esigabeni 02, esikuvumela ukuthi uhlole inguqulo yesoftware. Ukuguqulwa kukhonjisiwe kunkambu Yengxenye (amadijithi angu-4 atholakala kwesokudla), ukuze kuqinisekiswe ukusebenza okuthembekile kokudluliselwa, kuyadingeka ukuvuselela inguqulo ye-firmware.

Khona-ke udinga ukuya kubhulokhi yokulinganisa (inkinobho Meas. Blocks - 08), okuvumela ukuthi uhlole ubukhulu obusele bezintambo zokungqubuzana kanye nokushaywa kwezinduku zokulawula. Ukuze unqume indawo ebekiwe, kuyadingeka ukubala umehluko phakathi kwamapharamitha I-Clutch adaptation AGK Ivaliwe futhi I-Clutch adaptation Isikhundla 3. Uma usebenzisa i-clutch entsha, inani lisebangeni lika-5-6,5 mm, uma ngemuva kokulungiswa isikhawu sincane. kuno-2 mm, ngakho-ke kuyadingeka ukuhlola ukufakwa okulungile.

Thatha izilinganiso zokunyakaza kwezinduku ekuhambeni ngokusheshisa okubushelelezi nokucijile. Amaqembu 091 kanye no-111 asetshenziselwa ukubonisa amapharamitha, okukuvumela ukuthi uhlole izici ze-clutch 1 kanye no-2, ngokulandelanayo. Ukugqokwa kokuhlanganisa akumele kudlule u-7 mm (Indawo Yangempela Yendawo I-Cluth). Inkinobho ye-Grapf ikuvumela ukuthi ubonise igrafu yokusebenza kwama-couplings. Ngemuva kokuhlola ingxenye yemishini yebhokisi, kuyadingeka ukuhlola umbuso wokushisa. Imiphumela ikhonjiswa emaqenjini angu-99 no-102 e-primary clutch disc kanye no-119 no-122 kuma-elementi e-clutch yesibili.

Izinga lokushisa eliphezulu lelayini liboniswa emaqenjini angu-98 no-118 (ikholomu kwesokudla). Amaqembu 56-58 akuvumela ukuthi ubuke inani lamaphutha ngesikhathi sokusebenza kwe-mechatronics, uma bekungekho zinkinga, khona-ke inombolo engu-65535 iboniswa emasimini. inkundla ehlukene ikhombisa ibanga le-gearbox.

Idizayini yebhokisi inquma kusengaphambili inani elandiwe lokuzijwayeza kwe-clutch yesibili. Isilinganiso senani lokuzijwayeza kwe-clutch yokuqala kuya kweyesibili akumele sidlule u-0,33. Uma ipharamitha ihluka phezulu, khona-ke lokhu kubonisa ukusebenza okungavamile kwebhokisi kanye nemizamo eqhubekayo ye-mechatronics yokuthola indawo efanele yamadiski nezinduku. Ngemva kokuthuthukiswa kwesofthiwe okwenziwa ekuqaleni kuka-2018, isilinganiso esingaba ngu-1 saba yizinga elijwayelekile (empeleni, i-clutch yenombolo elinganayo ijwayela kaningi kune-clutch yenombolo eyinqaba).

I-Adaptation DSG 7

Ukulungiswa okuphoqelekile kwebhokisi, izindlela ezi-2 zisetshenziswa:

- okujwayelekile, okubandakanya ukusetshenziswa kwekhompyutha;

- yenziwe lula, ayidingi ukusetshenziswa kwemishini eyengeziwe.

Indlela Ejwayelekile

Ngokuzijwayeza okujwayelekile, kusetshenziswa intambo exhunywe kubhulokhi yokuxilonga. Ibhokisi lifudumala lifike ku +30…+100°C, umsebenzisi angabheka inani lepharamitha ngohlelo lwe-VASYA-Diagnost esigabeni esithi "Izilinganiso".

Isikhethi siyiswa endaweni yokupaka, iyunithi yamandla ayivaliwe. Ngesikhathi senqubo yokulungisa, akuvunyelwe ukucindezela i-accelerator pedal, umshini ubanjwe ngokucindezela okuqhubekayo ku-pedal ye-brake.

Ukulandelana kwezenzo ngesikhathi sokujwayela:

- Ngemva kokuxhuma intambo, qalisa uhlelo lwe-VASYA-Diagnost bese uya esigabeni sezilungiselelo eziyisisekelo. Ukwengeza, kunconywa ukuhlola izinga lokushisa kwebhokisi ngokuya esigabeni 02 kanye neqembu lenani 011.

- Setha i-lever yokulawula endaweni yokupaka, ngaphezu kwalokho ukulungisa imoto nge-handbrake akudingeki.

- Misa injini, bese ubamba amasekhethi okuthuthukisa ukuthungela.

- Esigabeni 02 sohlelo, thola imenyu yezilungiselelo eziyisisekelo. Bese ukhetha ipharamitha 060, ekuvumela ukuthi ulungise amanani wokukhipha ku-clutch. Ukuqala inqubo, cindezela inkinobho yokuqala, amanani edijithali azoshintsha esikrinini. Lapho ulungisa, imisindo engaphandle noma ukuchofoza kungase kuzwakale kundlu yokudlulisela, okungelona uphawu lokungasebenzi kahle. Ubude benqubo yokulungisa bungaphakathi kwemizuzwana engu-25-30, isikhathi sincike esimweni samanodi kanye nenguqulo yesofthiwe.

- Ngemuva kokulinda ukuthi inhlanganisela yezinombolo 4-0-0 ivele esikrinini, udinga ukuqala injini. Phakathi kokuphela kwenqubo yokulinganisa kanye nokuqala kwenjini, akufanele kudlule imizuzwana eyi-10. Ngemva kokuqala kweyunithi yamandla, izinombolo ezisebhokisini lengxoxo zizoqala ukushintsha, imisindo engaphandle ingase izwakale kusukela endlini yokudlulisela. Umshayeli ulinde ukuphela kwenqubo yokujwayela, isibonisi kufanele sibonise izinombolo 254-0-0. Uma inhlanganisela ehlukile iboniswa esikrinini, bese kwenzeka iphutha ngesikhathi sokulinganisa, inqubo iphinda futhi.

- Ngemuva kokuthi ukuvumelanisa kuqedwe ngendlela efanele, kuyadingeka ukuphuma kumodi yokusetha eyisisekelo futhi uhlole amaphutha kuyunithi yokulawula iyunithi ye-DQ200. Amakhodi ephutha atholiwe ayasuswa, bese ukuthungela kuyacishwa. Ngemva kokuvala imishini yokuhlola, ukuhlolwa kokuhlolwa kwenziwa ngokuvumelana ne-algorithm ekhethekile.

Emishinini eyakhelwe kungxenyekazi ye-MQB eyimojuli, i-algorithm yokulungisa ihluke ngandlela thize ekulandelaneni okungenhla kwezenzo:

- Ngemuva kokufudumala iyunithi yamandla kanye nokudluliselwa, umshini uyama, injini iyacishwa futhi kusetshenziswe ibhuleki lesandla.

- Uma ukuvutha kuvuliwe, ikhompuyutha yokuhlola ixhunyiwe futhi isibali sokuzivumelanisa sisethwa kabusha kuzilungiselelo eziyisisekelo. Inqubo ithatha imizuzwana engama-30, ngemuva kokuvela kokuqinisekiswa kokubulawa okulungile, ukuthungela kuvaliwe imizuzwana emi-5. Amamephu wezinga lokushisa asulwa ngokohlelo olufanayo ngokuvutha nokucisha.

- Bese, ohlwini lwemisebenzi ohlelweni, kufanele ukhethe imodi yokufaka eyisisekelo. Ngemuva kokuvela kwesaziso sokuqala komsebenzi, udinga ukucindezela i-pedal ye-brake bese uqala injini. I-pedal ibanjwa kuyo yonke inqubo yokusetha, ethatha imizuzu engama-2-3. Ngesikhathi sokusebenza, ukuchofoza kanye nemisindo engaphandle kuzwakala ecaleni le-DQ200, ngemuva kokuthi inqubo isiqediwe, isaziso esihambisanayo siyavela esikrinini.

- Yenza ukuhlola kokudlulisela. Umkhiqizi uvimbela noma yikuphi ukukhohlisa phakathi nenqubo yokujwayela, ukuphazamisa inqubo kuholela ekusebenziseni imodi ephuthumayo ngokulahlekelwa ukuhamba. Ukubuyisela ukusebenza kweyunithi kungenzeka kuphela enkonzweni.

Indlela Eyenziwe Lula

Indlela eyenziwe lula ayidingi ukusetshenziswa kwentambo yesichibi, umshayeli usetha kabusha iyunithi yokulawula.

Ngaphambi kokuqala ukusetha kabusha, kuyadingeka ukufudumeza injini kanye ne-gearbox ekushiseni okujwayelekile (isibonelo, ngemuva kokushayela i-10-15 km). Vala iyunithi yamandla, bese uvula ukhiye ekhiyeni kuze kube yilapho ideshibhodi isebenza. Kweminye imishini, inqubo yokujwayela yenziwa lapho ukucisha kucishiwe. Indlela yenqubo incike kunguqulo ye-firmware kanye nosuku lokwenziwa komshini, kunconywa ukuthi uvumelane nezimo zombili izindlela.

Yehlisa ingilazi yomnyango, bese ucindezela kakhulu i-gas pedal. Imodi yokukhahlela phansi kufanele isebenze, okuholela ekuchofozeni okuzwakalayo esimweni sokudlulisela. I-pedal ibanjwe phansi imizuzwana engu-30-40 bese iyakhululwa. Isihluthulelo sisusiwe kukhiye wokuthungela, ngemuva kokushintsha isekethe futhi bese uqala injini, ungaqala ukunyakaza. Le nqubo ayizifanele zonke izimoto ezine-DQ200 transmission.

Hlola ukushayela ngemva kokujwayela

Ukuqedela inqubo yokujwayela ibhokisi, kwenziwa idrayivu yokuhlola yokulungisa, iyadingeka:

- Hlola uhlu lwamaphutha ohlelweni, amakhodi atholiwe ayasuswa. Khona-ke udinga ukunqamula izintambo zokuxilonga bese uvala injini.

- Qala injini, hambisa isikhethi endaweni eya phambili. Ukuhamba ngesivinini esincane imizuzwana engu-20, usebenzisa umsebenzi wokulawula i-cruise ukuze ugcine isivinini akuvumelekile.

- Misa imoto, faka igiya lokuhlehla, bese uqala ukushayela imizuzwana engu-20.

- Bhuleka bese uhambisa isikhethi sesivinini endaweni eya phambili. Shayela phambili ngebanga elidingekayo ukuze uhambise wonke amagiya. Akuvunyelwe ukusheshisa ngokucijile, izinyathelo kumele zishintshe kahle.

- Hambisa i-lever endaweni yokushintsha ngesandla, bese ushayela iminithi elingu-1 ngegiya elilinganayo (4 noma 6). Phinda inqubo, kodwa uhambe ngesivinini esingajwayelekile (5 noma 7). Phinda umjikelezo wokunyakaza ngesivinini esilinganayo futhi esiyinqaba, kuvunyelwe ukuhamba ngemodi ngayinye isikhathi esingaphezu komzuzu owodwa. Ijubane lenjini liphakathi kuka-1 no-2000 rpm, i-cruise control ayivumelekile.

Ngemuva kokujwayela kanye nokushayela kokuhlola, ama-jerks nama-twitches kufanele anyamalale. Uma inkinga iqhubeka, ngakho-ke kunconywa ukuthi ubuyekeze isofthiwe yeyunithi yokulawula injini. Kweminye imishini efakwe injini ye-BSE ene-displacement yamalitha angu-1,6, kunezinkinga lapho ushintsha kusukela ku-3rd kuya kweyesi-2 ngenxa yokungahambisani kokudluliselwa kanye nezinguqulo ze-firmware yenjini. Uma umnikazi engakwazi ukuxazulula inkinga, kunconywa ukuthi uxhumane nesevisi ukuze uthole ukuxilongwa okuphelele kokudluliswa kochwepheshe abanolwazi lokusebenza namayunithi e-DQ200.

Kufanele kwenziwe kangaki lokhu

Umnikazi wemoto wenza ukuzivumelanisa okuphoqelelwe lapho ukushaqeka noma ama-jerk kwenzeka lapho ushintsha, kodwa ngaphambi kokuqala inqubo, kunconywa ukwenza ukuxilongwa kokudluliselwa, okuzocacisa imbangela yokusebenza okungalungile kweyunithi.