I-axle yangemuva i-MAZ

Okuqukethwe

Ukulungiswa kwe-axle yangemuva ye-MAZ kuhlanganisa ukufaka esikhundleni sezingxenye ezigugile noma ezilimele. Idizayini ye-axle yangemuva ivumela ukulungiswa okuningi ukuthi kwenziwe ngaphandle kokuyikhipha emotweni.

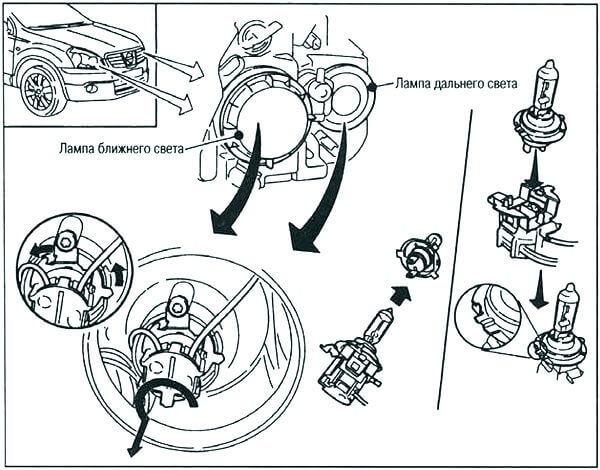

Ukushintsha i-drive gear oil seal, kufanele:

- nqamula i-cardan shaft kusuka ku-flange 14 (bheka i-Fig. 72) ye-gear shaft;

- khulula futhi ukhiphe i-nut 15, susa i-flange 14 kanye ne-washer engu-16;

- khulula amantongomane uvikela ikhava yebhokisi lokugxusha 13 bese usebenzisa amabhawodi okudiliza ukuze ususe isembozo sebhokisi lokugxusha;

- buyisela ibhokisi lokugxusha, ugcwalise izimbobo zalo zangaphakathi ngamafutha 1-13, bese uhlanganisa umhlangano ngokulandelana kwe-disassembly (ibhokisi lokugxusha licindezelwa licindezelwe ekugcineni kwekhava).

Uma kudingekile ukufaka esikhundleni sebhokisi lokugxusha 9 (bheka umdwebo 71), i-axle shaft kumele:

- khipha amafutha ku-crankcase yebhuloho ngokukhulula i-drain kanye namapulaki okugcwalisa;

- nqamula i-cardan shaft;

- susa amakhava amancane 7 (bheka umdwebo 73) wamagiya amasondo;

- khumula i-cap enkulu yokubopha ibhawudi 15 futhi, uyifake ezimbotsheni ezinentambo ekugcineni kwe-axle shafts 22, uyisuse ngokucophelela kanye namagiya elanga 11 kusuka kumagiya amasondo;

- khumula amantongomane kuma-studs avikela u-gearbox ophakathi nendawo ebhokisini le-asi (ngaphandle kwamabili aphezulu). Ngemuva kwalokho, usebenzisa i-trolley ene-lift, susa i-gearbox, ugobe amabhawodi amabili akhiphekayo ku-gearbox flange uye endaweni ye-axle, futhi ngemuva kokukhipha amantongomane amabili angaphezulu asele, buyisela uphawu lwawoyela we-axle gearbox ngesidonsa, ugcwalise umgodi ongaphakathi. ngamafutha 1-13.

I-axle yangemuva ihlanganiswa ngokulandelana, futhi ama-axle shafts kufanele afakwe ngokucophelela, uwaphendule ukuze agweme ukusonta udebe oluvalayo.

Imvamisa ukulungiswa kwebhuloho kuhlotshaniswa nokukhishwa nokuhlakazwa kwe-central gearbox noma i-wheel drive.

Ukuhlakazwa kwe-central gearbox MAZ

Ngaphambi kokukhipha i-gearbox ephakathi, kuyadingeka ukukhipha amafutha endaweni ye-axle, unqamule i-cardan shaft futhi ukhulule ibhuleki lokupaka. Bese ususa amakhava egiya lamasondo amancane, ukhulule ibhawudi lesembozo segiya lesondo elikhulu futhi, uyiphendule ngokushintshana ezihlahleni ezinentambo ekugcineni kwama-axle shafts, susa ama-axle shafts ekuhlukeni. Khulula izigxobo ezivikela u-gearbox ophakathi nendawo ukuze i-asise housing bese ukhipha u-gearbox usebenzisa unodoli.

U-gearbox ophakathi nendawo uhlakazeka kalula ku-swivel mount. Uma kungekho ukwesekwa, ibhentshi eliphansi lokusebenzela elinobude obungu-500-600 mm lingasetshenziswa.

Ukulandelana kokuqaqa i-gearbox imi kanje:

- susa i-drive gear 20 (bheka i-Fig. 72) egcwele ama-bearings;

- khulula amantongomane angama-29 no-3 kusuka kumasembozo ahlukene;

- susa ama-caps okuzala okuhlukile 1;

- khulula amantongomane ezigxotsheni zezinkomishi ezihlukanisayo bese uvula umehluko (susa ama-satellites, amagiya aseceleni, ama-washer thrust).

Geza izingxenye ezigoqayo zika-gearbox ophakathi futhi uhlole ngokucophelela. Hlola isimo se-bearings, ezindaweni zokusebenza lapho akufanele kube khona ukugoqa, ukuqhekeka, ama-dent, ukuhlunga, kanye nokubhujiswa noma ukulimala kwama-rollers kanye nabahlukanisi.

Lapho uhlola amagiya, qaphela ukungabikho kwama-chips nokuphuka kwamazinyo, ukuqhekeka, ama-chips ongqimba lukasimende ebusweni bamazinyo.

Ngomsindo okhulayo wamagiya webhokisi lebhokisi eliphakathi ngesikhathi sokusebenza, inani lokucaciswa kwecala lika-0,8 mm lingasebenza njengesisekelo sokushintsha amagiya e-bevel.

Uma kunesidingo, shintsha amagiya e-bevel oshayelayo nashayelwa njengesethi, njengoba efaniswe efekthri ngamabili ukuze athinteke futhi akhishwe eceleni futhi abe nokumaka okufanayo.

Lapho uhlola izingxenye zomehluko, naka isimo sobuso bezintamo zeziphambano, izimbobo nezindawo eziyindilinga zamasathelayithi, izindawo ezithwele amagiya aseceleni, ama-washers aphethe kanye nezindawo zokugcina zezinkomishi ezihlukanisayo, okumele kungabi nama-burrs.

Esimeni sokuguga okuphawulekayo noma ukulingana okuxekethile, buyisela i-satellite bushing. I-bushing entsha icutshungulwa ngemva kokucindezelwa ku-satellite kuya kububanzi obungu-26 ^ + 0,045 mm.

Ngokugqoka okuphawulekayo kwama-washer ane-bronze athwala ama-axle shafts, kufanele ashintshwe. Ugqinsi lwamawasha ethusi amasha luyi-1,5 mm. Ngemva kokuhlanganisa umehluko, kunconywa ukukala igebe phakathi kwegiya elihlangothini kanye newasha yethusi esekelayo, okufanele ibe phakathi kuka-0,5 no-1,3 mm. Igebe likalwa nge-feeler gauge ngefasitela ezinkomishini ezihlukanisayo, lapho amasathelayithi egijima kuma-washers asekelayo ukuze ahluleke, futhi igiya elisemaceleni licindezelwa ngokumelene namasathelayithi, okungukuthi, lihlanganyela nawo ngaphandle kokudlala. Izinkomishi ezihlukene zishintshwa njengesethi.

Hlanganisa u-gearbox omaphakathi ngokulandelana okulandelayo:

- hlanganisa igiya lokushayela, lifake endlini yokuthwala futhi ulungise ama-tapered bearings ngokulayishwa kuqala;

- hlanganisa umehluko, uwufake ku-crankcase futhi ulungise ama-bearings ahlukene ngokulayisha kuqala;

- faka igiya lokushayela endlini ye-gearbox;

- lungisa ukubandakanyeka kwamagiya e-bevel;

- jikijela isinqamuli segiya elishayelwa egiyeni lize lime, bese ulikhulula ngo-1/10-1/13 wokujika, elihambisana negebe eliphakathi kwawo elingu-0,15-0,2 mm, bese uqinisa nati lokukhiya.

Ukuhlakazwa kwedrayivu yamasondo nokususwa kwehabhu lamasondo angemuva

Ukulandelana kwe-disassembly imi kanje:

- khulula amantongomane emasondweni angemuva;

- beka ujeke ngaphansi kohlangothi olulodwa lwe-axle yangemuva futhi

- xhoma ibhakede ngamasondo, bese ulibeka esisekelweni bese ususa i-jack;

- qaqa amantongomane abambe amasondo angemuva, susa izinsimbi nesondo langaphandle, iringi yesikhala kanye nesondo langaphakathi;

- khipha amafutha egiyeni lamasondo;

- susa isembozo esikhulu 14 (bheka Fig. 73) kusukela ekuhlanganiseni kwe-wheel drive nesembozo esincane 7;

- susa igiya eli-1 eliqhutshwayo, lapho kusetshenziswa amabhawodi amabili avela kukhava enkulu njengomdonsi;

- jiya ibhawudo lekhava elikhulu embotsheni enentambo ye-half shaft 22, susa i-half shaft ngegiya eliphakathi 11 lilonke;

- khumula amabhawodi okukhiya ama-axle ama-3 kumasathelayithi, faka idonsa bese ususa ama-axle amasathelayithi ayi-5, bese ususa ama-sathelayithi aphelele ngamabheringi;

- khumula i-lock nut 27 kuma-hub bearings, susa indandatho yokugcina 26, ukhulule i-nut 25 kuma-bearings futhi ukhiphe indebe yangaphakathi engu-21 kumthwali;

- susa i-bearing spacer, faka i-hub puller bese ususa umhlangano wehabhu ngesigubhu sebhuleki.

Lapho ufaka esikhundleni se-oil seal kanye ne-hub bear, kufanele:

- khumula amabhawodi okufaka isigubhu sebhuleki bese ususa isiqoqi sothuli kanye nesembozo sebhokisi lokugxusha;

- khipha ibhokisi lokugxusha ekhavani bese ufaka ibhokisi elisha lokugxusha elinemivimbo emincane yesando;

- Usebenzisa idonsa, khipha imijaho yangaphandle neyangaphakathi yesondo elithwalayo.

Hlanza izingxenye zehabhu negiya lamasondo futhi uzihlole ngokucophelela.

Ukuchotshozwa kongqimba lwe-carburizing ebusweni bamazinyo egiya akuvunyelwe. Uma kukhona ukuqhekeka noma amazinyo aphukile, amagiya kufanele ashintshwe.

Ukufakwa kwe-nave nokufakwa kwedrayivu yesondo kwenziwa kubheke phansi. Kulesi simo, kufanele kucatshangelwe ukuthi ukuthwala kwangaphakathi kwe-tapered kabili kukhiqizwa ngokulayishwa kwangaphambili okuqinisekisiwe, okuqinisekiswa ngokufaka indandatho yesikhala. Kulo mhlangano, ukuthwala kumakwa ekugcineni kwamakheji nangaphandle kwendandatho yesikhala. Lokhu kuthwala kufanele kufakwe kuphela njengesethi ephelele ngokuhambisana nomkhiqizo.

Ukushintshwa kwezingxenye zomuntu ngamunye zekhithi akuvunyelwe, njengoba lokhu kushintsha imvume ye-axial yokuthwala, okuholela ekubhujisweni kwayo.

Ama-hub bearings awalungiseki, nokho ukuqondanisa kahle kwehabhu kuqinisekiswa ngokuqinisa imijaho yangaphakathi yalawa ma-bearings nge-nati ne-locknut. Amandla adingekayo ukuze kuqiniswe ihabhu elithwele nati kufanele alingane no-80-100 kg kusikrufu esinesikrini esiyindandatho esingu-500 mm.

Ukugcinwa kwe-asi engemuva ye-MAZ

Ukugcinwa kwe-axle yangemuva kuhlanganisa ukuhlola nokugcina izinga elidingekayo lokuthambisa ku-gearbox ophakathi nendawo namagiya amasondo, ukushintsha i-lubricant ngesikhathi, ukuhlanza izimbobo zokungenisa umoya, ukuhlola nokuqinisa izinsimbi, ukuhlola umsindo wokusebenza kanye nezinga lokushisa elingemuva le-axle.

Lapho usebenzisa i-axle yangemuva, kufanele kuqashelwe ngokukhethekile ukulungisa i-gearbox ephakathi. Ukulungiswa kwenziwa nge-gearbox esusiwe; Kulokhu, ama-conical bearings wegiya le-bevel yokushayela kanye nama-bevel ahlukile alungiswa kuqala, bese kuthi amagiya e-bevel ahambisane nesiqeshana sokuxhumana.

Ukuze ulungise ama-bevel gear we-drive bevel, kufanele:

- ukuqaqa ibhuleki yokupaka bese ususa ikhava ye-caliper 9 (bheka umdwebo 72);

- khipha amafutha;

- khulula amantongomane ezigxotsheni zendlu ephethe igiya lokushayela futhi usebenzise amabhawudi akhiphekayo 27 khipha indlu engu-9 ngomhlangano wegiya le-bevel;

- ukulungisa i-crankcase 9 ku-vice, thola imvume ye-axial yama-bearings usebenzisa inkomba;

- ngemva kokukhulula i-crankcase 9, qinisa igiya le-bevel lokushayela ku-vise (beka izinsimbi ezithambile emihlathini ye-vise). Khulula futhi unscrew flange nut 15, susa washer kanye flange. Susa ikhava ngezikulufo ezikhiphekayo. Susa i-deflector yamafutha 12, indandatho yangaphakathi ye-bearing yangaphambili kanye ne-washer yokulungisa 11;

- linganisa ubukhulu bewasha yokulungisa futhi ubale ukuthi yiliphi inani elidingekayo ukuze unciphise ukuze uqede imvume ye-axial futhi uthole ukulayisha kuqala (ukuncipha kobukhulu bewasha kufanele kulingane nesamba sokucaciswa kwe-axial shaft ngokwemibandela inkomba kanye nenani lokulayisha kuqala lika-0,03-0,05 mm);

- gaya iwasha yokulungisa ibe yinani elidingekayo, uyifake nezinye izingxenye, ngaphandle kwesembozo esingu-13 esinebhokisi lokugxusha, okungafanele lifakwe, ngoba ukungqubuzana kwebhokisi lokugxila entanyeni ye-flange ngeke kuvumele ukulungiswa ngokunembile. kala isikhathi sokumelana lapho uphendula igiya kumabheringi. Uma uqinisa i-collar nut, vula i-bearing housing ukuze ama-rollers abekwe ngendlela efanele emijahweni ethwele;

- hlola ukulayisha kuqala kwama-bearings ngokuya ngobukhulu besikhathi esidingekayo ukuze ujikeleze igiya lokushayela, okufanele lilingane no-0,1-0,3 kgm. Lo mzuzu unganqunywa ngokusebenzisa i-torque wrench ku-nut 15 noma ngokulinganisa amandla asetshenziswe emgodini we-flange we-propeller shaft mounting bolts (Fig. 75). Amandla asetshenziswa i-perpendicular ku-radius yezimbobo ku-flange kufanele abe phakathi kuka-1,3 no-3,9 kg. Qaphela ukuthi ukulayisha kuqala kakhulu kuma-roller bearings azowenza ashise futhi aguge ngokushesha. Ngokulayisha okujwayelekile okuthwalayo, susa inati ku-pinion shaft, ubheke indawo yayo, kanye ne-flange, bese ufaka kabusha ikhava 13 (bheka u-Fig. 72) ngegland futhi ekugcineni uhlanganise umhlangano.

Ukuqiniswa kwama-bearings ahlukene kulungiswa kusetshenziswa amantongomane angu-3 no-29, okumele afakwe ekujuleni okufanayo ukuze angaphazamisi isikhundla segiya kuze kube yilapho kutholakala ukulayisha kuqala okudingekayo kuma-bearings.

Ukulayisha kuqala okuthwalayo kunqunywa inani le-torque edingekayo ukuze ujikeleze umehluko, okufanele ube ku-0,2-0,3 kgm (ngaphandle kwegiya le-bevel). Lesi sikhathi sinqunywa isikrufu se-torque noma ngokulinganisa amandla asetshenziswa endaweni engaba izinkomishi ezihlukene, futhi ilingana no-2,3-3,5 kg.

Ilayisi. 75. Ukuhlola ukuqina kwe-bearing ye-drive gear shaft ka-gearbox ophakathi

Inqubo yokuhlola nokulungisa ukubandakanyeka kwegiya le-bevel imi kanje:

- ngaphambi kokufaka i-crankcase, ama-bearings angu-9 anegiya lokushayela endlini ye-gearbox, omisa amazinyo amagiya e-bevel futhi ugcobe amazinyo amathathu noma amane egiya lokushayela ngesendlalelo esincane sikapende phezu kwawo wonke;

- faka i-crankcase 9 ngegiya lokushayela ku-crankcase ye-gearbox; jikisa amantongomane kuma-studs amane awela bese uvula igiya lokushayela ngemuva kwe-flange 14 (kolunye uhlangothi kanye nolunye);

- ngokulandela imikhondo (amaphuzu okuxhumana) atholwe emazinyweni egiya elishayelwa (Ithebula 7), ukusebenzelana okulungile kwamagiya kanye nohlobo lokulungiswa kwegiya kuyasungulwa. Ukusebenzelana kwegiya kulawulwa ngokushintsha inani lama-spacers angu-18 ngaphansi kwe-flange yegiya lokushayela elinezindlu namantongomane 3 no-29, ngaphandle kokuphazamisa ukulungiswa kwama-bearings ahlukene. Ukususa igiya lokushayela kude negiya eliqhutshwayo, kuyadingeka ukuthi ubeke amashimu engeziwe ngaphansi kwe-crankcase flange, futhi, uma kunesidingo, ukuhlanganisa amagiya, susa amashimu.

Amantongomane 3 no-29 asetshenziselwa ukuhambisa igiya eliqhutshwayo. Ukuze ungaphazamisi ukulungiswa kwama-bearings 30 wokuhluka, kuyadingeka ukuqinisa (ukungafihli) amantongomane 3 no-29 nge-engeli efanayo.

Lapho kulungiswa i-clutch (eceleni kwesiqephu sokuxhumana) emazinyweni egiya, imvume eseceleni phakathi kwamazinyo iyagcinwa, inani lalo lamagiya amasha kufanele libe ngaphakathi kwama-microns angu-0,2-0,5. Ukunciphisa imvume ye-lateral phakathi kwamazinyo egiya ngokususa isiqeshana sokuxhumana endaweni enconyiwe akuvunyelwe, njengoba lokhu kuholela ekwephuleni ukuzibandakanya okulungile kwamagiya kanye nokugqoka kwawo okusheshayo.

Ngemuva kokulungisa ukuhlanganiswa kwegiya, qinisa zonke izigxobo ezivikela indawo yokuhlala endaweni ye-gearbox, setha izitobhi kumantongomane athwele, qinisa i-limiter 25 kuze kutholakale imvume encane engu-0 0,15-0,2 mm phakathi kwe-cracker negiya eliqhutshwayo. (igebe elincane libekwe ngokuzungezisa amagiya egiya elishayelwa ijika ngalinye). Ngemuva kwalokho, vala umkhawulo wegiya elishayelwayo 25 ngenati lokukhiya.

Lapho ususa i-gearbox ephakathi emotweni (yokulungisa noma ukulungisa), hlola igebe phakathi kwendiza yokugcina yebhokisi le-gearbox ne-washer yokusekela, ebekwe embonini ngaphakathi kwe-0,5-1,3 mm.

Igebe lihlolwa nge-feeler gauge emafasiteleni ezinkomishi ezihlukanisayo, lapho ama-satellites egijima kuma-washers asekelayo ukuze ahluleke, futhi igiya elihlangothini licindezelwa ngokumelene namasathelayithi, okungukuthi, lihlanganyela nawo ngaphandle kokudlala.

Ukungasebenzi kahle okungenzeka kwe-axle yangemuva nezindlela zokuziqeda kuboniswa kuthebula lesishiyagalombili.

| Ukuma kwepeshi yokuxhumana egiyeni elishayelwayo | Ungalithola kanjani igiya elifanele | |

| Emuva naphambili | ||

| Lungisa ukuxhumana kwegiya le-bevel | ||

| Hambisa igiya elishayelwa egiyeni lokushayela. Uma lokhu kubangela igebe elincane kakhulu lamazinyo, susa igiya lokushayela egiyeni elishayelwa. | ||

| Susa igiya elishayelwayo kude negiya lokushayela. Uma lokhu kuphumela ekudlaleni kwamazinyo egiya ngokweqile, hambisa igiya lokushayela endaweni yokushayelwa. | ||

| Hambisa igiya elishayelwa egiyeni lokushayela. Uma ngesikhathi esifanayo kudingekile ukushintsha i-backlash ku-hitch, dlulisela igiya lokushayela egiyeni eliqhutshwayo | ||

| Susa igiya elishayelwayo kude negiya lokushayela. Uma lokhu kudinga ukushintshwa kwe-side clearance ku-clutch, susa igiya lokushayela kude negiya elishayelwa. | ||

| Hambisa igiya lokushayela ulibhekise egiyeni elishayelwa. Uma imvume ku-clutch incane kakhulu, susa igiya elishayelwayo kude negiya lokushayela. | ||

| Susa igiya lokushayela kude negiya elishayelwa. Uma kudlalwa kakhulu, susa igiya elishayelwa ulibhekise egiyeni lokushayela. |

Funda futhi Imininingwane yewintshi ye-ZIL-131

| Imbangela yokungasebenzi kahle | resource |

| Ukwanda kokushisisa kwebhuloho | |

| Amafutha amaningi kakhulu noma amancane kakhulu ku-crankcase | Hlola futhi ugcwalise izinga likawoyela ku-crankcase |

| Ukushintsha igiya okungalungile | Lungisa igiya |

| Ukulayisha kuqala okuthwalayo | Lungisa ukungezwani |

| Umsindo webhuloho owandisiwe | |

| Ukwephulwa kokufika kanye nokuzibandakanya kwamagiya e-bevel | Lungisa igiya le-bevel |

| Ama-bearings agugile noma angahambi kahle | Hlola isimo se-bearings, uma kunesidingo, shintsha futhi ulungise ukuqina |

| Ukugqoka amagiya aqinile | Shintsha amagiya agugile futhi ulungise ukuhanjiswa |

| Ukwanda komsindo webhuloho lomgwaqo ekuhambeni | |

| Amaphutha Ahlukene | Hlukanisa umehluko kanye nokuxazulula inkinga |

| Umsindo ovela kuwo wonke amasondo | |

| Ukushintsha igiya okungalungile | Shintshanisa amagiya noma izinkomishi. |

| Ukusebenzisa amafutha okushayela isondo okungalungile | Ukushintsha uwoyela nge-crankcase flush |

| Izinga likawoyela elinganele | Engeza amafutha ku-arch yesondo |

| Ukuvuza kwamafutha ngokusebenzisa izimpawu | |

| Izimpawu ezigugile noma ezilimele | Shintsha izimvu zamanzi |

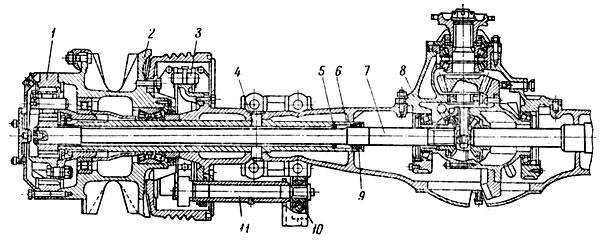

Idivayisi ye-axle yangemuva i-MAZ

I-asi yangemuva (Fig. 71) idlulisa i-torque isuka ku-crankshaft yenjini nge-clutch, u-gearbox kanye ne-cardan shaft iye emasondweni okushayela emoto futhi, ngokusebenzisa umehluko, ivumela amasondo okushayela ukuthi ajikeleze ngesivinini esihlukile.

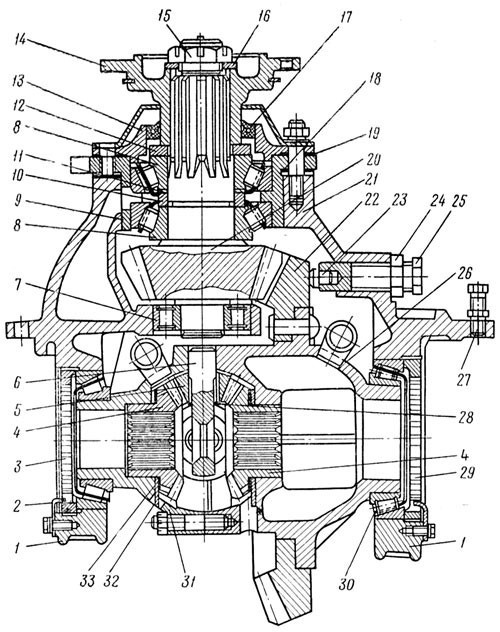

Ilayisi. 71. I-asi yangemuva MAZ:

1 - igiya; 2 - ihabhu lesondo elingemuva; 3 - amabhuleki amasondo angemuva; 4 - iphinikhodi yokukhiya yezindlu ze-axle; 5 - indandatho ye-axis yokuqondisa; 6 - i-axle yezindlu; 7 - i-axle shaft; 8 - gearbox ephakathi; 9 - i-epiploon ehlanganisiwe ye-semixis; I-10 - i-lever yokulungisa; 11 - khulula isibhakela sebhuleki

Izikimu ezamukelwe zesakhiwo kanye ne-kinematic zokudlulisa i-torque zenza kube nokwenzeka ukuhlukanisa i-gearbox ephakathi, iqondise kumagiya amasondo, ngaleyo ndlela ithulule ama-shaft ahlukene kanye ne-axle kusuka ku-torque eyengeziwe, edluliselwa ngohlelo lwezigaba ezimbili ukusuka ku- igiya main ye-axle ezingemuva (ezifana, isibonelo, ngemoto MAZ-200). Ukusetshenziswa kwama-sprockets futhi kuvumela, ngokushintsha kuphela inani lamazinyo we-sprocket cylindrical gears nokugcina ibanga eliphakathi kwama-sprockets, ukuthola izilinganiso zegiya ezihlukene, okwenza i-axle yangemuva ifanele ukusetshenziswa ekulungisweni okuhlukahlukene kwezimoto.

U-gearbox ophakathi nendawo (Fig. 72) uyisiteji esisodwa, uhlanganisa amagiya e-bevel anamazinyo ayi-spiral kanye ne-interwheel differential. Izingxenye zika-gearbox zifakwe ku-crankcase 21 eyenziwe nge-ductile iron. Isikhundla se-crankcase esihlobene nesigxobo sinqunywa yikhola egxilile ku-flange yezindlu ze-gearbox futhi ngaphezu kwalokho ngezikhonkwane.

I-drive bevel gear 20, eyenziwe ngocezu olulodwa nge-shaft, ayinakho i-cantilevered, kodwa ine, ngaphezu kwamabhorethi amabili angaphambili ane-tapered roller 8, ukusekelwa okwengeziwe okungemuva, okuyi-cylindrical roller ephethe 7. Umklamo wamabhere amathathu kuhlangene kakhulu, kuyilapho umthwalo omkhulu we-radial kuma-bearings wehliswa kakhulu Uma kuqhathaniswa nokufakwa kwe-cantilever, umthamo wokuthwala kanye nokuzinza kokufakwa kwe-bevel gear meshing kuyanda, okwandisa kakhulu ukuqina kwayo. Ngasikhathi sinye, amathuba okusondela kuma-roller ama-tapered emqhele wegiya le-bevel drive anciphisa ubude be-shaft yayo, ngakho-ke, ikuvumela ukuthi ukhuphule ibanga phakathi kwe-gearbox flange ne-gearbox flange, okubaluleke kakhulu. ngesisekelo senqola esincane sendawo engcono ye-cardan shaft. Amasongo angaphandle ama-roller bearings akhiwe ku-crankcase 9 futhi acindezelwa esitobhini ehlombe elenziwe ku-crankcase. I-flange ye-bearing housing iboshelwe ku-gearbox we-axle yangemuva. Lawa ma-bearings athatha imithwalo ye-radial ne-axial eyenzeka lapho i-bevel gears mesh ekudluliselweni kwe-torque.

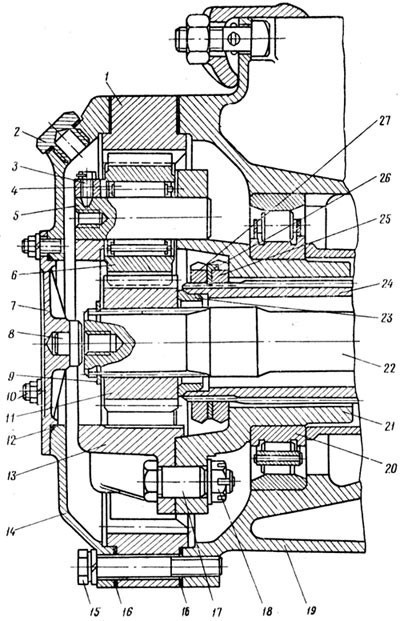

Ilayisi. 72. Central gearbox MAZ:

I-1 - i-cap yokuzala; I-2 - ikhava ye-nut; 3 - nut of the bear left; 4 - shaft gear; 5 - satellite umehluko; 6 - umehluko wesiphambano; 7 - ukuthwala i-cylindrical yegiya lokushayela; I-8 - i-conical bearing drive gear; 9 - ukuthwala izindlu zegiya lokushayela; 10 - indandatho yesikhala; 11 - ukulungisa i-washer; 12 - i-deflector yamafutha; I-13 - ikhava yebhokisi lokugxusha; 14 - flange; 15 - flange nut; 16 - washer; I-17 - ibhokisi lokugxila; 18 - ama-wedges; 19 - gasket; 20 - drive gear; 21 - gearbox; 22 - igiya eliqhutshwayo; 23 - amakhukhi; 24 - i-locknut; 25 - umkhawulo wegiya oshayelwa; 26 - indebe yokuhlukanisa kwesokudla; 27 - ibhawodi lokususwa kokudluliselwa; I-28 - i-thrust ring bushing; 29 - nut of the right bear; 30 - i-tapered bear; 31 - inkomishi yokuhluka kwesobunxele; 32 - iwasha yensimbi; 33 - iwasha yethusi

I-internal bearing inokulingana okuqinile ku-shaft futhi ibhere yangaphandle ine-slip fit evumela ukulungiswa kokulayisha kuqala kulawa ma-bheringi. Phakathi kwamasongo angaphakathi ama-roller bearings acijile, kufakwe iringi yesikhala engu-10 kanye newasha yokulungisa engu-11. Ukulayisha kuqala okudingekayo kwamabheringi ane-tapered roller kunqunywa ngokukhetha ubukhulu bewasha yokulungisa. I-Cylindrical roller ephethe u-7 wegiya le-bevel yokudlulisela ifakwe emgodini we-axle wangemuva we-axle gearbox eduze nendawo ehambayo futhi ilungiswa ngokususwa kwe-axial enendandatho ebambayo engena esikhaleni ehlathini ekupheleni kwegiya lokushayela. .

Engxenyeni engaphambili ye-bevel gear shaft yokudlulisela, intambo engaphezulu ye-diameter encane kanye nobubanzi obukhulu obuphezulu be-splines esikiwe, lapho kufakwa khona i-deflector kawoyela 12 kanye ne-propeller shaft flange 14. Zonke izingxenye eziku-pinion shaft ziqiniswe nge-castle nut 15.

Ukuze kube lula ukukhishwa kwezindlu ezithwalayo, i-flange yayo inezimbobo ezimbili ezinezintambo lapho ama-bolts okubopha angafakwa khona; uma efakwe phakathi, amabhawodi ahlala phezu kwendlu ka-gearbox, ngenxa yokuthi i-bearing housing iphuma ku-gearbox. Amabhawodi enhloso efanayo, afakwe ku-flange yendlu ye-gearbox, angasetshenziswa njengama-bolts okudiliza.

Igiya le-bevel 22 elishayelwa lihlehliselwe enkomishini elungile yokuhlukanisa. Ngenxa yomkhawulo ophakathi kwephini kanye nomphathi ku-gearbox wezindlu ukuze kunikeze ukwesekwa okwengeziwe kwegiya lokushayela i-axle yangemuva, ama-rivets axhuma igiya elishayelwa enkomishini ehlukanisayo ngaphakathi anekhanda eliyisicaba.

Igiya elishayelwayo ligxile endaweni engaphandle yeflange yenkomishi ehlukile. Ngesikhathi sokusebenza, igiya eliqhutshwayo lingase licindezelwe lisuke egiyeni lokushayela ngenxa yokuguqulwa, ngenxa yalokho ukubandakanyeka kwegiya kuzophulwa. Ukuze unciphise i-deformation ecacisiwe futhi uqinisekise ukuthintana okufanele ekuxhumaneni kwamagiya e-bevel, i-gearbox inomkhawulo wegiya oqhutshwayo 25, owenziwe ngendlela ye-bolt, ekugcineni lapho kufakwa i-cracker yethusi. I-limiter ifakwe ku-gearbox housing kuze kube yilapho isitobhisi saso sithinta ubuso bokugcina begiya le-bevel elishayelwa, ngemuva kwalokho i-limiter ikhululiwe ukuze kwakhiwe imvume edingekayo futhi amantongomane avaliwe.

Ukuzibandakanya kwamagiya amakhulu e-bevel gear kungalungiswa ngokushintsha isethi yama-shim 18 yobukhulu obuhlukahlukene enziwe ngensimbi ethambile futhi ifakwe phakathi kwendlu yokuthwala kanye nendlu ye-axle ye-axle yangemuva. Ipheya lamagiya e-bevel efekthri likhethwa kusengaphambili (likhethiwe) ukuze lithintane nomsindo. Ngakho-ke, lapho ushintsha igiya elilodwa, elinye kufanele lishintshwe.

Umehluko we-axle wangemuva u-tapered, unamasathelayithi amane angu-5 namagiya amabili aseceleni 4. Amasathelayithi agibele izikhonkwane eziphambanayo zensimbi ezinamandla aphezulu futhi aphathwe ngokushisa abe lukhuni kakhulu. Ukunemba kokwenziwa kwesiphambano 6 kuqinisekisa isikhundla esifanele samasathelayithi akuso kanye nokuzibandakanya kwayo okufanele namagiya aseceleni. Amasathelayithi asekelwa ezintanyeni ze-transom ngokusebenzisa izihlahla ezenziwe nge-tape yethusi enezingqimba eziningi. Phakathi kwamasathelayithi nezisekelo zama-crossheads, kufakwe izindandatho zensimbi ezingama-28, ezilungisa ngokuphepha ama-bushings amasathelayithi.

Umkhawulo ongaphandle wamasathelayithi ancikene nenkomishi ehlukanisayo ugoqelwe endaweni eyindilinga. Ukusekelwa kwamasathelayithi enkomishini iwasha yethusi enesitembu, nayo eyindilinga. Amasathelayithi angamagiya e-spur bevel enziwe ngensimbi eqinile ye-carburized alloy.

I-crossbar enamaphuzu amane ingena emigodini eyi-cylindrical eyakhiwe endizeni yezinkomishi ezihlukanayo phakathi nokucubungula kwazo ngokuhlanganyela. Ukucubungula okuhlangene kwezinkomishi kuqinisekisa indawo eqondile yesiphambano kuzo. I-centering yezindebe itholakala ngokuba khona kwehlombe kwelinye lazo, kanye nezikhala ezihambisanayo nezikhonkwane kwenye. Iqoqo lezinkomishi limakwe ngezinombolo ezifanayo, okumele zifane ngesikhathi sokuhlangana ukuze kugcinwe ukunemba kwendawo yezimbobo nezindawo ezitholakala ngesikhathi sokucubungula ngokuhlanganyela. Uma kudingekile ukufaka inkomishi eyodwa yokuhlukanisa, eyesibili, okungukuthi ephelele, inkomishi nayo kufanele ishintshwe.

Izinkomishi ezihlukene zenziwe nge-ductile iron. Emigodini eyi-cylindrical yamahabhu wezinkomishi ezihlukanisayo, amagiya aqondile-bevel semi-axial afakiwe.

Izindawo zangaphakathi zama-hubs ama-semi-axial gears zenziwe ngendlela yezimbobo ezine-involute splines zokuxhuma nama-semi-axes. Phakathi kwegiya elihlangothini nendebe kunesikhala esihambisana nokulungiswa kwe-stroke ebanzi, okudingekayo ukuze kugcinwe ifilimu yamafutha ezindaweni zabo futhi kuvimbele ukuguga kwalezi zindawo. Ngaphezu kwalokho, ama-washers amabili afakwe phakathi kwezindawo ezithwalayo zokuphela kwe-semiaxes nezinkomishi: insimbi 32, ukuphenduka okuhleliwe, ne-bronze 33, uhlobo oluntantayo. Lesi sakamuva sitholakala phakathi kwewashi lensimbi negiya elisemaceleni. Ama-blade ashiselwe ezinkomishini zokuhlukanisa, ahlinzeka ngokutholakala okuningi kokugcoba ezingxenyeni zomehluko.

Izembozo zesikhundla sazo esifanele uma kuqhathaniswa nezindlu ze-gearbox zigxile kuwo ngosizo lwama-bushings futhi zigxilwe kuwo ngama-studs. Izimbobo ze-crankcase kanye namakepisi okuthwala ahlukene ahlanganiswa ngomshini.

Ukulayishwa kuqala kwama-roller bearings we-tapered of the differential kulungiswa ngamantongomane 3 no-29. Ukulungisa amantongomane enziwe nge-ductile iron ane-turnkey protrusions endaweni yangaphakathi ye-cylindrical, lapho amantongomane ahlanganiswe futhi agxilwe endaweni oyifunayo ngentshebe yokukhiya. 2, enamathiselwe endaweni engaphambili eyenziwe ngomshini yekepisi elithwalayo.

Izingxenye ze-gearbox zigcotshwe ngamafutha afuthwe ngegiya lendandatho yegiya le-bevel elishayelwa. Isikhwama sikawoyela sithelwa endlini ye-gearbox, lapho kukhishelwa khona uwoyela ofuthwe ngegiya le-bevel elishayelwa, bese kuthi uwoyela awehle ezindongeni zezindlu ze-gearbox azinze.

Kusukela esikhwameni samafutha, uwoyela uphakelwa ngesiteshi ukuya endaweni ene-pinion. Ihlombe lale ndlu ehlukanisa ama-bearings linembobo lapho uwoyela ugeleza kuwo womabili ama-roller bearings. Ama-bearings, afakwe ama-cones abheke komunye nomunye, agcotshwa ngamafutha angenayo futhi, ngenxa yesenzo sokumpompa ama-conical rollers, awapompa ngezindlela ezihlukene: i-back bear ibuyisela amafutha ku-crankcase, futhi i-front bear iyayibuyisela. ku-cardan shaft flange.

Kukhona i-baffle yensimbi eqinile eqinile phakathi kwe-flange ne-bearing. Endaweni yangaphandle, i-washer inentambo yesokunxele ene-pitch enkulu, okungukuthi, isiqondiso sentambo siphambene nokuqondisa kokujikeleza kwegiya; ngaphezu kwalokho, i-washer ifakwe ngegebe elincane ekuvuleni kwebhokisi lokugxusha. Konke lokhu kuvimbela i-lubricant ukuthi ingagelezi isuka ekuthwaleni ingene ebhokisini lokugxusha ngenxa yokuvaleka kobuso obungaphandle be-flange.

Ehlangothini le-flange, izindlu ezithwalayo zivaliwe ngesembozo se-iron-cast, lapho i-gasket ye-rubber eqinisiwe enezinsimbi ezimbili ezisebenzayo ezixutshwe nokuphela kwangaphandle zicindezelwa. I-slot yenziwa ehlombe elikhuphukayo lekhava, elihambisana nembobo ethambekele endlini yokuthwala. I-gasket phakathi kwesembozo kanye nezindlu ezithwala kanye nama-wedges angu-18 afakwe ngendlela yokuthi ama-cutouts kuwo ahambisane ne-groove esembozweni kanye nomgodi endlini yokuzala, ngokulandelana.

Uwoyela oweqile ongene emgodini wekhava ubuyiselwa ku-gearbox ngesikhala esisesembozweni kanye ne-valve egobile endaweni yokuthwala. Isigxivizo senjoloba esiqinisiwe sicindezelwa ngemiphetho yaso yokusebenza ngokumelene nendawo ephucuziwe futhi lukhuni endaweni yokuqina okuphezulu kwe-flange 14, eyenziwe nge-carbon steel.

Igiya lesibili eliphethe i-cylindrical roller lifakwe i-splash lubricated kuphela. Ama-roller bearings ane-tapered ezinkomishini ezihlukene agcotshwa ngendlela efanayo.

Ukuba khona kwamagiya amasondo, nakuba kwehlisa umthwalo ezingxenyeni ze-different, kodwa kuholele ekwenyukeni kwesivinini sokuphenduka kwamagiya uma ujika noma ushibilika. Ngakho-ke, ngaphezu kwezinyathelo ezithathiwe ukuvikela izindawo zokungqubuzana (ukwethulwa kwama-washers asekelayo nama-bushings), kuphinde kuhlelwe ukuthuthukisa uhlelo lokugcoba lwezingxenye ezihlukene. Ama-blades ashiselwe enkomishini ehlukanisayo athatha okokugcoba ku-gearbox yezindlu futhi akuqondise ezingxenyeni ezitholakala ezinkomishini ezihlukene. Ubuningi be-lubricant engenayo bunomthelela ekupholiseni kwezingxenye zokuhlikihla, ukungena kwazo ezikhaleni, okunciphisa ithuba lokubamba nokugqoka kwezingxenye.

Funda futhi Ukugcinwa kwemishini kagesi ye-KAMAZ

U-gearbox ophakathi nendawo ohlanganiswe ngokugcwele ufakwe embotsheni enkulu e-axle yangemuva futhi uboshelwe endizeni yawo emile enama-studs namantongomane. Ama-flange okukhwelana engxenye emaphakathi ye-axle yangemuva ne-gearbox avaliwe nge-gasket. Ku-crankcase ye-axle yangemuva, izimbobo ezinentambo zezigxivizo ezifakwayo ze-crankcase aziboni, okuthuthukisa ukucinana kwalokhu kuxhumana.

Indlu ye-axle yangemuva yenziwe ngensimbi ekhonjiwe. Ukuba khona kwezimbobo endizeni eqondile akuthinti ukuqina kwezindlu ze-axle yangemuva. Ukuxhunywa kwayo no-gearbox kuqinile futhi akushintshi ngesikhathi sokusebenza kwemoto. Ukuqiniswa okunjalo endizeni eqondile kunenzuzo enkulu uma kuqhathaniswa nokuxhumeka kwebhokisi le-gearbox enezindlu ze-axle zangemuva endizeni enezingqimba, isibonelo, emotweni ye-MAZ-200, lapho ukuguqulwa okuphawulekayo kwe-crankcase evulekile kusuka phezulu kwephula ukuxhumana kwayo. indawo ye-asi yangemuva.

I-axle yangemuva igcina kuzo zombili iziphetho ngama-flange lapho ama-brake caliper amasondo angemuva agijinyiswa khona. Ohlangothini olungenhla, amapulatifomu entwasahlobo ahlangana nawo abe yinto eyodwa, futhi amagagasi enziwa kulawa mapulatifomu asuka ngezansi, okuyiziqondiso zezitebhisi zasentwasahlobo ezingemuva kanye nokusekela amantongomane alezi zitebhisi.

Eduze kwama-spring pads kunamaphedi amancane okugcina irabha. Ngaphakathi kwe-crankcase, izingxenye ezimbili zenziwa ohlangothini ngalunye; emigodini yalezi zihlukanisi zeziphetho ze-cylindrical ze-crankcase, zicindezelwa yi-casing 6 (bheka i-Fig. 71) yama-axle shafts 7.

Amabhokisi e-Semi-axle ngenxa yokuba khona kwamagiya amasondo, ngaphezu kwesikhathi sokugoba kusuka emandleni esisindo somthwalo kanye nesisindo semoto, nawo alayishwa umzuzu osebenzayo ozwakala izinkomishi zamasondo. , enamathiselwe ngokuqinile ekugcineni kukathayela we-casing. Kulokhu, izidingo eziphakeme zibekwe emandleni ohlaka. Umzimba wenziwe ngeshubhu yensimbi enezindonga eziwugqinsi eselashwe ngokushisa ukuze ikhulise amandla. Amandla okucindezela endlu eya endlini ye-axle yangemuva akwanele ukuvimbela ukujikeleza kwayo, ngakho-ke indlu ivaliwe ngaphezu kwendlu ye-axle yangemuva.

Ezingxenyeni ze-crankcase eziseduze namapulatifomu entwasahlobo, ngemva kokucindezela umzimba, izimbobo ezimbili ziyabhobozwa, ngasikhathi sinye zidlule endaweni ye-axle yangemuva kanye nendlu ye-axle shaft. Kufakwe kulezi zimbobo izikhonkwane zokukhiya eziyinsimbi eziqinile ezingu-4 ezishiselwe endaweni ye-asi engemuva. Izikhonkwane zokukhiya zivimbela ukuzungezisa kwendlu endaweni ye-asi engemuva.

Ukuze ungenzi buthaka i-crankcase nezindlu ngaphansi kwesenzo semithwalo yokugoba eqondile, izikhonkwane zokukhiya zifakwe endizeni enezingqimba.

Emaphethelweni angaphandle ama-crankcases ama-semi-axs, ama-splines angahleliwe asikwa lapho kubekwa khona inkomishi yegiya lamasondo. Ngakolunye uhlangothi lomzimba, kunqunywa intambo ukuze kuhlanganiswe amantongomane ama-wheel hub bearings. Izimbobo ze-shaft seals 9 7 kanye nezindandatho zokuqondisa i-centering 5 zenziwa kusukela ekugcineni kwangaphakathi kwezindlu. Izigxivizo ze-Shaft ziyizimpawu zenjoloba ezizikhiyayo ezimbili ezihlukene ezifakwe ekhejini lensimbi elinesitembu nezindebe zazo ezivalayo zibhekane.

Ukuze ukhiphe amathuba okwanda kwengcindezi emigodini yama-crankcase amagiya okunciphisa isondo amaphakathi lapho uwoyela ushisisiwe, kufakwa ama-valve amathathu okungenisa umoya engxenyeni engenhla yendlu ye-axle yangemuva, eyodwa ngakwesokunxele engxenyeni engenhla ye-axle. i-axle yangemuva ye-ekseli ye-semi-axle yokunwetshwa okuphakathi nezimbili eduze nezindawo zasentwasahlobo. Lapho ingcindezi emigodini ye-crankcase ikhuphuka, ama-valve okuphefumula ayavuleka futhi axhumane le migodi nomkhathi.

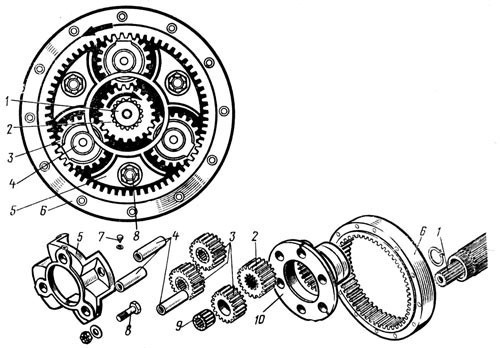

I-wheel drive (Fig. 73) iyisigaba sesibili ku-gearbox we-axle yangemuva.

Ukusuka egiyeni le-bevel lokushayela le-gearbox ephakathi, ngegiya le-bevel elishayelwa kanye nomehluko, i-torque idluliselwa ku-axle shaft 1 (Fig. 74), enikeza isikhathi egiyeni eliphakathi, elibizwa nge-satellite 2 yesondo. cindezela. Kusukela egiyeni lelanga, ukuzungezisa kudluliselwa kumasathelayithi amathathu 3, ahlukaniswe ngokulinganayo azungeze isiyingi esizungeze igiya lelanga.

Amasathelayithi azungeza ezimbazweni ezingu-4, ezigxilwe emigodini yokwesekwa okungaguquki, ehlanganisa izinkomishi ezi-5 zangaphandle neziyi-10 zangaphakathi, zibheke ohlangothini oluphambene nendawo yokuzungezisa igiya lelanga. Kusuka kumasathelayithi, ukuzungeza kudluliselwa egiyeni le-ring 6 legiya langaphakathi, elifakwe kuhabhu yamasondo angemuva. Igiya le-ring 6 lizungeza ohlangothini olufanayo namasathelayithi.

Isilinganiso segiya le-wheel drive kinematics scheme sinqunywa isilinganiso senani lamazinyo asegiyeni leringi nenani lamazinyo egiyeni lelanga. Amasathelayithi, ajikeleza ngokukhululekile kuma-axle awo, akuthinti isilinganiso segiya, ngakho-ke, ngokushintsha inani lamazinyo amagiya esondo ngenkathi ugcina ibanga lawo phakathi kwama-axles, ungathola inani lezilinganiso zegiya, okuthi, noma okufanayo. amagiya e-bevel ku-gearbox omaphakathi, anganikeza ibhuloho elingemuva lokukhetha isilinganiso segiya.

Ilayisi. 73. Ukushayela amasondo:

I-1 - igiya lendandatho (eliqhutshwa); 2 - ipulaki yokugcwalisa; 3 - umgcini we-axis yesathelayithi; 4 - inkambo yesathelayithi; 5 - i-axis yesathelayithi; 5 - satellite; 7 - ikhava encane; 8 - ukuqhuma okuqhubekayo kwe-axle shaft; 9 - indandatho yokugcina; 10 - hairpin; I-11 - igiya lelanga (eliholayo); 12 - indandatho yokufaka uphawu; 13 - ingilazi yangaphandle; 14 - ikhava enkulu; 15 - ibhawudi lekhava elikhulu kanye negiya lendandatho; 16 - gasket; 17 - inkomishi yebhawodi lokuqala; 18 - nut; 19 - ihabhu lamasondo; 20 - ukuthwala kwangaphandle kwehabhu; 21 - inkomishi yangaphakathi eqhutshwa; 22 - i-axle shaft; 23 - drive gear stop; 24 - izindlu ze-axle; I-2S - ihabhu eliphethe nut; 26 - indandatho yokugcina; 27 - isondo elithwele i-locknut

Ngokwesakhiwo, igiya lamasondo lenziwa kanje. Wonke amagiya ano-cylindrical, i-spur. I-Sun gear 11 (bheka i-Fig. 73) nama-satellites 6 - igiya langaphandle, umqhele - igiya langaphakathi.

Igiya lelanga linembobo enama-involute splines ahlangana nama-splines ekugcineni okuhambisanayo kwe-axle shaft. Uhlangothi lwangaphakathi oluphambene lwe-axle shaft luphinde lube nama-splines asontekile ahlangana nama-splines ku-hub bore yamashafti ahlukene. Ukunyakaza kwe-axial kwe-central shaft ku-axle shaft kunqunyelwe indandatho yokukhiya i-spring 9. Ukunyakaza kwe-axial kwe-axial shaft 22 ukuya ku-gearbox emaphakathi kunqunyelwe iplanethi emaphakathi egxilwe kuyo. Ngakolunye uhlangothi, ukunyakaza kwe-axle shaft kuvinjelwa ukuqhekeka okuqhubekayo okungu-8 okucindezelwe kumkhono wekhava encane engu-7 yegiya lesondo. Amasathelayithi afakwe ku-shafts egxilwe kubakaki abakhiphekayo abahlanganisa izinkomishi ezimbili. Isitsha sangaphakathi esingu-21 sakhiwe ngensimbi ye-carbon, sinehabhu eliyisilinda ngaphandle kanye nembobo ebolekile ngaphakathi. Inkomishi yangaphandle engu-13 inokucushwa okuyinkimbinkimbi futhi yenziwe ngensimbi ekhonjiwe. Izindebe ezithwalayo zixhunywe ngamabhawudi amathathu.

Ilayisi. 74. Uhlelo lokushayela amasondo nemininingwane yalo:

1 - i-axle shaft; 2 - igiya lelanga; 3 - satellite; 4 - i-axis yesathelayithi; 5 - indebe yangaphandle; 6 - igiya lendandatho; 7 - i-axis yokugcina yesathelayithi; 8 - umshudo wokuhlanganisa wendebe yenkampani; 9 - inkambo yesathelayithi; 10 - umnikazi wenkomishi yangaphakathi

Ezinkomishini eziqoqiwe zomphathi, izimbobo ezintathu zicutshungulwa ngasikhathi sinye (zabholwa) ze-axis yamasathelayithi, njengoba ukunemba kwesikhundla esihlobene samasathelayithi maqondana nelanga namagiya omqhele kunquma i-clutch yokudlulisela efanele, amagiya, kanye. nokuqina kwamagiya. Amahabhu amasondo enziwe ngomshini awashintsheki namanye amahabhu ngakho amakwa ngenombolo yomkhiqizo. Amalugi ezinkomishi zangaphandle zezimbobo ze-axle yesathelayithi anezimbobo ezinentambo zamabhawodi okukhiya ama-axle amathathu esathelayithi.

Izingilazi ezihlanganisiwe (izibambi zamasondo) zifakwe engxenyeni engaphandle ehlukanisiwe yezindlu ze-asi. Ngaphambi kokutshala isithwali, ihabhu elingaphakathi lamasondo 19 lifakwa ku-crankcase ye-axle shaft kuma-bearings amabili. I-double tapered roller bear yehabhu yangaphakathi ifakwe ngqo ku-axle housing, kuyilapho i-roller eyi-cylindrical yangaphandle ifakwe esiphathini samasondo. Kufakwe i-spacer phakathi kwe-double tapered roller bear kanye nesithwali samasondo. Khona-ke ubakaki ohlangene ugxilwe ku-axle shaft housing usebenzisa i-nut 25 kanye ne-lock nut 27. Indandatho yokugcina i-26 ifakwe phakathi kwe-nut ne-lock nut, okufanele ingene emseleni wezindlu ze-axle nge-protrusion yangaphakathi.

Izinkomishi ezihlanganisiwe zamagiya amasondo zakha izimbobo ezintathu lapho amasathelayithi afakwa khona ngokukhululeka. Amasathelayithi anezimbobo eziyisilinda ngomshini ngokucophelela ukuze kufakwe ama-4 cylindrical roller bearings angenawo amaringi angaphandle noma angaphakathi. Ngakho-ke, imbobo ye-cylindrical yangaphakathi yesathelayithi iyibhande eligoqayo lama-roller asekelayo. Ngokufanayo, ubuso be-satellite shaft budlala indima yendandatho yangaphakathi yokuthwala. Njengoba ukuphila okuzalayo kuhlobene ngokuqondile nobulukhuni bemigwaqo yomjaho, imishayo yesathelayithi yenziwe ngensimbi ye-alloy kanye nokushisa okuphathwe ukuze kutholakale ubulukhuni obuphezulu bobuso (HRC 60-64.

Lapho uhlanganisa i-wheel drive, okokuqala, ama-bearings afakwe emgodini we-satellite, bese, ukwehlisa igiya emgodini owenziwe izinkomishi, i-shaft ye-satellite ifakwa ekuthwaleni. I-shaft ye-satellite ifakwe ezinkomishini ngesikhathi sokulungiswa futhi igxilwe kuzo ngokujikeleza nokuhamba kwe-axial ngosizo lwe-bolt yokukhiya 3, induku ye-conical engena emgodini we-conical ekupheleni kwe-satellite shaft. Ukuze kube lula ukuhlakazeka kwalo shaft, kunembobo enentambo endaweni yayo engaphambili. Ngokufaka ibhawudi kule mbobo ngomkhono, uncike enkomishini yangaphandle yesiphathi, ungasusa kalula i-shaft kusathelayithi.

Amagiya ahambisana negiya lelanga kanye neringi.

I-torque idluliselwa egiyeni elikhulu ngamagiya amathathu ahlanganiswe nawo, ngakho amazinyo egiya leringi awalayishiwe kangako uma kuqhathaniswa namazinyo egiya lamasondo. Isipiliyoni sokusebenza siphinde sikhombise ukuthi igiya elihambisana nerimu langaphakathi yilona elihlala isikhathi eside. Igiya eliyindandatho lifakiwe futhi ligxiliswe phakathi nehlombe emseleni wehabhu lamasondo angemuva. Kufakwe i-gasket phakathi kwegiya nehabhu.

Ohlangothini olungaphandle, maphakathi nehlombe legiya leringi, kunekhava enkulu engu-14 evala igiya. I-gasket yokuvala iphinde ifakwe phakathi kwekhava negiya. Isembozo kanye negiya lendandatho kuboshwe ngamabhawodi ajwayelekile ngo-15 kuya kuhabhu yamasondo angemuva, agibele ibhere ebekwe ohlakeni lwamasondo, okunikeza ukunemba okudingekayo kwendawo yamasathelayithi ngokusekelwa ku-axle, izimbobo ezinembayo. yenkampani yenethiwekhi efanayo ebekwe ngesikhathi somshini kanye nokusebenzisana okulungile kwamasathelayithi nekhanda lewashi. Ngakolunye uhlangothi, igiya lelanga alinakho ukwesekwa okukhethekile, okungukuthi "lintanta" futhi ligxile emazinyweni egiya leplanethi, ngakho-ke umthwalo emagiyeni eplanethi uyalingana, ngoba ahlukaniswe ngokulinganayo nxazonke ngokunemba okwanele. .

Igiya lelanga le-wheel drive namasathelayithi enziwe ngensimbi ye-alloy yekhwalithi ephezulu engu-20ХНЗА ngokwelashwa kokushisa. Ukuqina kobuso bamazinyo egiya kufinyelela ku-HRC 58-62, futhi umnyombo wamazinyo uhlala u-ductile nobulukhuni be-HRC 28-40. Igiya lendandatho elilayishwe kancane lenziwe ngensimbi engu-18KhGT.

Amagiya nama-bearings amagiya okwehlisa amasondo agcotshwa ngamafutha e-spray athelwe emgodini wegiya lokunciphisa isondo. Ngenxa yokuthi igumbi legiya liqukethe ikhava enkulu kanye nehabhu lamasondo angemuva elizungeza kumabheringi acijile, uwoyela osegunjini legiya ahlala enyakaziswa ukuze ahlinzeke ngokugcobisa kuwo wonke amagiya namabheringi amasondo egiya. Amafutha athululelwa ngekepisi elincane elingu-7, elinamathiselwe kusivalo esikhulu samasondo esinamaphini amathathu futhi livalwe ngekhola emaphakathi ngendandatho yerabha evala 12.

Uma ikhava encane isusiwe, unqenqema olungezansi lwembobo esembozweni esikhulu lunquma izinga likawoyela elidingekayo esitimeleni esinamasondo. Ipulaki enkulu yokukhipha uwoyela inembobo evalwe ngepulaki yomphongolo. Ukuvimbela uwoyela ukuthi ungagelezi usuka emgodini wegiya lesondo ungene ku-gearbox ophakathi nendawo, njengoba kuphawuliwe ngenhla, kufakwa uphawu lukawoyela oluphindwe kabili ku-axle shaft.

Uwoyela ophuma endaweni yokushayela isondo nawo ungena endaweni yehabhu lamasondo angemuva ukuze ugcobe ama-double tapered nama-cylindrical roller bearings amasondo.

Kusukela ohlangothini lwangaphakathi lwehabhu kuya ebusweni bayo bokuphela, ngokusebenzisa i-gasket yerabha, isembozo sebhokisi lokugxusha siyafinywa, lapho kubekwa khona ibhokisi lokuzikhiya lerabha-metal. Unqenqema olusebenzayo lwebhokisi lokugxusha luvala umgodi wehabhu eduze nendandatho ekhishwayo ecindezelwe endaweni ye-asili. Ingaphezulu lendandatho ligaywe ngezinga eliphakeme lokuhlanzeka, liqiniswe kubunzima obuphezulu futhi liphucuziwe. Isembozo sebhokisi lokugxusha kuhabhu yesondo sigxile ehlombe, okuthi ngesikhathi esifanayo sincike endandeni yangaphandle ye-axial bear bear, ikhawulela ukunyakaza kwayo kwe-axial.

Esembozweni se-gland, i-flange, enobukhulu obukhulu, isebenza njenge-deflector yamafutha, njengoba kukhona igebe elincane phakathi kwayo nendandatho ye-gland ekhishwayo. Futhi, endaweni eyi-cylindrical ye-flange, ama-grooves agubha uwoyela ayasikwa, abe nokuthambekela ohlangothini oluphambene nesiqondiso sokujikeleza kwehabhu. Ukuvimbela amafutha ukuthi angangeni ezigubhu zamabhuleki, uphawu lukawoyela luvalwa nge-deflector yamafutha.