Amasistimu kaphethiloli nezinjini zikadizili

Okuqukethwe

Uhlelo lwamandla luhlinzeka ngomsebenzi oyinhloko wesikhungo samandla - ukulethwa kwamandla ethangini likaphethiloli ukuya enjinini yomlilo yangaphakathi (ICE) ewaguqulela ekubeni ukunyakaza kwemishini. Kubalulekile ukuyithuthukisa ukuze injini ihlale ithola uphethiloli kaphethiloli noma udizili ngenani elifanele, hhayi ngaphezulu noma ngaphansi, kuzo zonke izindlela ezihlukene zokusebenza. Futhi uma kungenzeka, gcina imingcele yakho isikhathi eside ngangokunokwenzeka ngaphandle kokulahlekelwa ukunemba komsebenzi.

Inhloso nokusebenza kwesistimu kaphethiloli

Ngokwesisekelo esinwetshiwe, imisebenzi yohlelo ihlukaniswa ibe ezokuthutha kanye nemithamo. Imishini yokuqala ihlanganisa:

- ithangi likaphethiloli lapho kugcinwa khona uphethiloli noma udizili;

- amaphampu e-booster anezingcindezi ezahlukene zokuphuma;

- uhlelo lokuhlunga lokuhlanza okumahhadlahhadla nokucolisekileyo, ngamathangi okuhlalisa noma ngaphandle kwawo;

- izintambo zikaphethiloli ezivela kumapayipi aguquguqukayo futhi aqinile namapayipi anezixhumi ezifanele;

- imishini eyengeziwe yokungenisa umoya, ukubuyiswa komhwamuko nokuphepha uma kwenzeka kuba nezingozi.

Umthamo wenani elidingekayo likaphethiloli wenziwa ngamasistimu wamazinga ahlukene wobunzima, ahlanganisa:

- ama-carburetors ezinjini eziphelelwe yisikhathi;

- amayunithi okulawula injini anesistimu yezinzwa nama-actuator;

- ama-injector fuel;

- amaphampu aphezulu anemisebenzi yokudosa;

- izilawuli zemishini kanye ne-hydraulic.

Ukunikezwa kwamafutha kuhlobene eduze nokuhlinzeka injini ngomoya, kodwa namanje lezi ziyizinhlelo ezahlukene, ngakho-ke ukuxhumana phakathi kwazo kwenziwa kuphela ngezilawuli ze-elekthronikhi kanye nenani eliningi lokungena.

Inhlangano yokuhlinzekwa kukaphethiloli

Amasistimu amabili ahluke ngokuyisisekelo abhekene nokwakhiwa okulungile kwengxube yokusebenza - i-carburetor, lapho izinga lokunikezwa kukaphethiloli linqunywa isivinini sokugeleza komoya okufakwe ama-pistons, kanye nomjovo ngaphansi kwengcindezi, lapho uhlelo luqapha kuphela. ukugeleza komoya kanye nezindlela zenjini, ukudosa uphethiloli ngokwakho.

Carburetor

Ukunikezwa kukaphethiloli ngosizo lwe-carburetors sekuphelelwe yisikhathi, ngoba akunakwenzeka ukuhambisana namazinga emvelo nawo. Ngisho nokusetshenziswa kwe-electronic noma i-vacuum systems kuma-carburetors akuzange kusize. Manje le mishini ayisetshenziswa.

Umgomo wokusebenza kwe-carburetor bekuwukudlula kuma-diffuser ayo umfudlana womoya oqondiswe kubuningi bokudla. Ukuncishiswa okukhethekile okunephrofayili kwama-diffuser kubangele ukwehla kwengcindezi kujethi yomoya ngokuhlobene nomfutho womkhathi. Ngenxa yokwehla okwaba umphumela, uphethiloli wanikezwa ophuma ezifutheni. Ubuningi bawo bunqunyelwe ngokudalwa kwe-emulsion kaphethiloli ekubunjweni okunqunywe inhlanganisela yamafutha kanye namajethi omoya.

Ama-carburetors alawulwa izinguquko ezincane zokucindezela kuye ngokuthi izinga lokugeleza, kuphela izinga likaphethiloli ekamelweni le-float lalihlala njalo, elaligcinwa ngokupompa nokuvala i-valve yokuvala i-inlet. Kwakukhona amasistimu amaningi kuma-carburetors, ngayinye eyayinesibopho semodi yayo yenjini, kusukela ekuqaleni kuya kumandla alinganiselwe. Konke lokhu kwasebenza, kodwa izinga lokudosa lagcina lingagculisi. Kwakungenakwenzeka ukulungisa kahle ingxube, okwakudingeka kuma-converter e-exhaust gas catalytic converters.

Umjovo wephethiloli

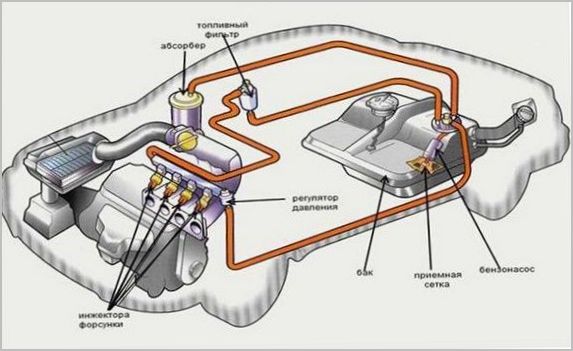

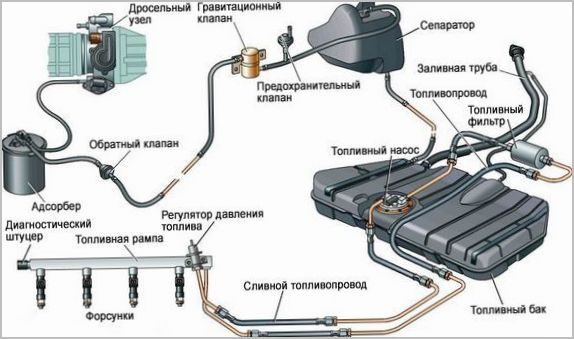

Umjovo wengcindezi engaguquki unezinzuzo ezibalulekile. Idalwe iphampu kagesi efakwe ku-tank enomlawuli ohlanganisiwe noma oqhelile futhi igcinwa ngokunemba okudingekayo. Inani layo liwuhlelo lwama-atmospheres amaningana.

Uphethiloli uhlinzekwa enjinini ngama-injection, okungamavalvu e-solenoid anama-atomizer. Ziyavuleka lapho zithola isignali ku-electronic engine control system (ECM), futhi ngemva kwesikhathi esibaliwe ziyavala, zikhiphe uphethiloli olingana ncamashí odingekayo emjikelezweni wenjini eyodwa.

Ekuqaleni, i-nozzle eyodwa yayisetshenziswa, esendaweni ye-carburetor. Uhlelo olunjalo lwalubizwa ngokuthi umjovo ophakathi noma owodwa. Akuwona wonke amaphutha asusiwe, ngakho-ke izakhiwo zesimanje eziningi zinezimbobo ezihlukene zesilinda ngasinye.

Izinhlelo zokujova ezisatshalaliswa futhi eziqondile (eziqondile) zihlukaniswa ngokuya ngendawo yama-nozzles. Esimweni sokuqala, ama-injection ahlinzeka ngophethiloli ku-multifold intake, eduze kwe-valve. Kule ndawo, izinga lokushisa liyenyuka. Indlela emfushane eya ekamelweni elivuthayo ayivumeli uphethiloli ukuba uncibilike, obekuyinkinga ngomjovo owodwa. Ngaphezu kwalokho, kwaba nokwenzeka ukuhlukanisa ukugeleza, ukukhulula uphethiloli ngokuqinile ngesikhathi kuvulwa i-valve yokungena yesilinda esithile.

Isistimu yomjovo oqondile isebenza ngempumelelo nakakhulu. Lapho ama-nozzles etholakala emakhanda futhi ethulwa ngokuqondile ekamelweni elivuthayo, kungenzeka ukusebenzisa izindlela zesimanje zokujova okuningi emjikelezweni owodwa noma emibili, ukuthungela okugqinsiwe kanye nokuzungeza okuyinkimbinkimbi kwengxube. Lokhu kwandisa ukusebenza kahle, kodwa kudala izinkinga zokwethenjelwa eziholela ezindlekweni eziphakeme zezingxenye nezincane. Ikakhulukazi, sidinga i-high-pressure pump (i-high pressure fuel pump), ama-nozzles akhethekile nokuqinisekisa ukuthi i-intake tract ihlanzwa ngokungcola nge-recirculation system, ngoba manje uphethiloli awunikezwa ekuthatheni.

Imishini yamafutha ezinjini zikadizili

Ukusebenza nge-compression ignition i-HFO inemininingwane yayo siqu ehambisana nobunzima be-atomization enhle kanye nokucindezelwa okuphezulu kukadizili. Ngakho-ke, izinto zikaphethiloli azifani neze nezinjini zikaphethiloli.

Iphampu yomjovo ehlukene kanye nezijovo zeyunithi

Ingcindezi ephezulu edingekayo ngomjovo wekhwalithi ephezulu emoyeni oshisayo ocindezelwe kakhulu udalwa amaphampu kaphethiloli anomfutho ophezulu. Ngokusho kwe-classical scheme, kuma-plungers ayo, okungukuthi, amapheya e-piston enziwe ngokuvunyelwa okuncane, uphethiloli uhlinzekwa ngepompo ye-booster ngemva kokuhlanza ngokuphelele. Ama-plunger ashayelwa injini nge-camshaft. Iphampu efanayo yenza umthamo ngokuphendula ama-plungers nge-rack yegiya exhunywe ku-pedal, futhi umzuzu womjovo unqunywa ngenxa yokuvumelanisa nezinsimbi zokusabalalisa igesi kanye nokuba khona kwezilawuli ezizenzakalelayo ezengeziwe.

Ipheya ngalinye le-plunger lixhunywe ngomugqa wamafutha ocindezela kakhulu kuma-injection, okungamavalvu alula alayishwe entwasahlobo aholelwa emakamelweni avuthayo. Ukuze kube lula ukuklama, ngezinye izikhathi kusetshenziswa okuthiwa yi-pump-injection, ehlanganisa imisebenzi yamaphampu kaphethiloli aphezulu kanye nezifutho ngenxa yedrayivu yamandla evela kumakhamera we-camshaft. Anama-plunger awo nama-valve.

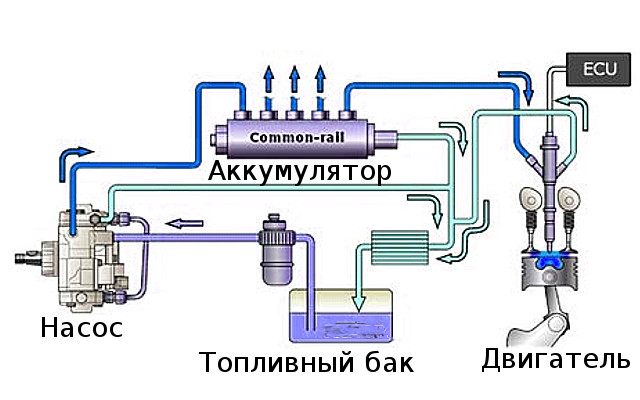

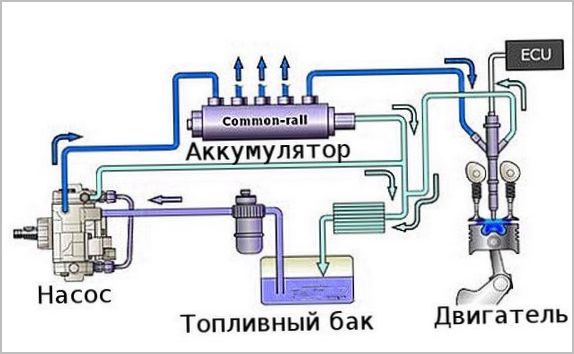

Uhlobo lomjovo oyinhloko i-Common Rail

Umgomo wokulawulwa kwe-elekthronikhi wama-nozzles axhunywe kumugqa ovamile wokucindezela okuphezulu usuphelele kakhulu. Ngamunye wabo une-valve ye-electro-hydraulic noma i-piezoelectric evula futhi ivale ngomyalo weyunithi ye-elekthronikhi. Indima yephampu yomjovo iyancipha kuphela ekugcineni ingcindezi edingekayo kumzila wesitimela, okuthi, ngalesi simiso, ilethwe ku-atmospheres engu-2000 noma ngaphezulu. Lokhu kwenze kwaba nokwenzeka ukulawula injini ngokunembe kakhudlwana futhi ifakwe ezindinganisweni ezintsha zobuthi.

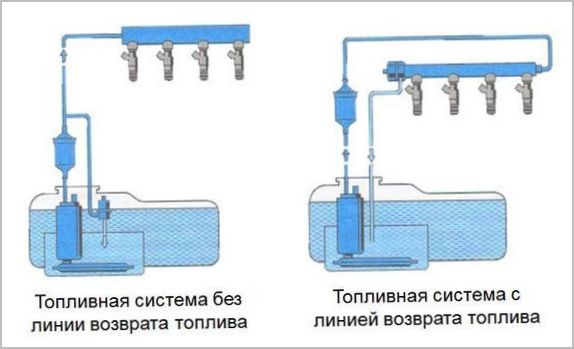

Ukusetshenziswa kwemigqa yokubuyisela uphethiloli

Ngaphezu kokunikezwa okuqondile kukaphethiloli endaweni yenjini, ngezinye izikhathi i-drain yokubuyisela ibuye isetshenziswe ngomugqa ohlukile wokubuya. Lokhu kunezinjongo ezihlukahlukene, kusukela ekusizeni ukulawulwa kwengcindezi ezindaweni ezihlukene ohlelweni, ekuhleleni ukujikeleza okuqhubekayo kukaphethiloli. Muva nje, ukugeleza okubuyela emuva ethangini akuvamile ukusetshenziswa, ngokuvamile kudingekile kuphela ekuxazululeni izinkinga zasendaweni, isibonelo, ukulawula ama-hydraulics emibhobho yomjovo oqondile.