Yenza ngokwakho i-plastic welding - indlela yokuxhuma izakhi zepulasitiki ngomshini wokushisela?

Okuqukethwe

- Ukuhlanganisa amapulasitiki nezinye izindlela zokuhlanganisa izinto

- i-plastic welding lokushisa

- Uhlobo lwe-binder kanye nama-electrode welding

- Imishini yokushisela endaweni yokusebenzela

- Izesekeli zokushisela i-thermoplastic

- Amakhono namakhono

- Welding plastic isinyathelo ngesinyathelo

- Amaphutha Welding Wepulasitiki Okufanele Ugweme

- Ikuphi ukushisela ipulasitiki okuvame ukusetshenziswa kakhulu?

- Intengo yokushisela ipulasitiki - kubiza malini?

- Welder Plastic namandla ahlangene

Ingabe ipulasitiki yokushisela izwakala iyinqaba? Nakuba uma uthi nhlá lokhu kungase kumangaze, le nhlanganisela yezakhi ihambisana ngokugcwele ne-Art. Le ndlela isetshenziswa kwezokwakha, ezezimoto nezimboni. Ungakwazi futhi ukushisela lezi zinto egalaji lasekhaya noma indawo yokusebenzela. Sikunikeza okudingayo ukuze uqalise. Bheka ukuthi yini okudingeka uyenze isinyathelo ngesinyathelo ukushisela izinto zemoto yakho!

Ukuhlanganisa amapulasitiki nezinye izindlela zokuhlanganisa izinto

Izingxenye zepulasitiki zivame ukunamathiselwa ndawonye. Lokhu kuyiqiniso ikakhulukazi ezintweni ezincane ezingekho ngaphansi kokugcwala okukhulu. Izinamatheliso nazo zisetshenziselwa izinto ezingadingi ukuthi ziminyene kakhulu noma zithandeke ngobuhle. Indlela yokunamathisela ipulasitiki ngezinye izindlela? Kulokhu, imishini yokushisela enama-clamps ingasetshenziswa, ebekwe phakathi kwezinto ezimbili ezihlukene. Ngaphansi kwesenzo samanje esigelezayo, isiqeshana esingaphakathi siyancibilika futhi kudalwe uxhumano olungunaphakade.

I-Welding kanye ne-plastic welding

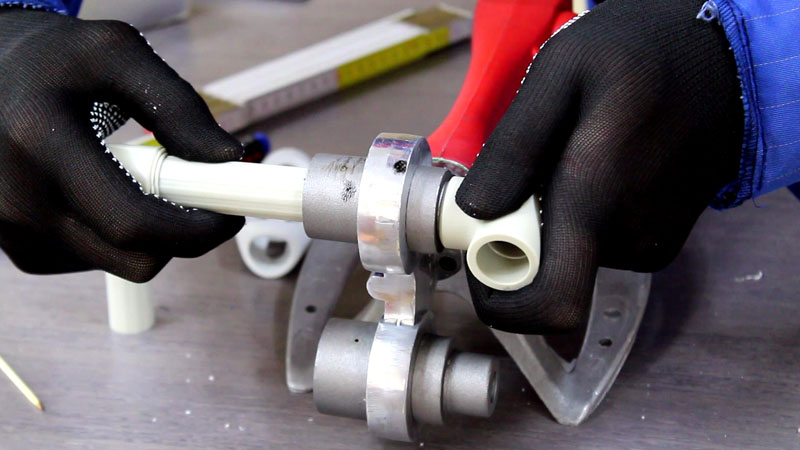

Kubuye kube wumkhuba ojwayelekile (isb ekufakeni amapayipi) ukushisela ipulasitiki. Kuyinqubo yokushisisa izinto ezimbili nokuzihlanganisa ngaphansi kwengcindezi. Ngale ndlela, isibonelo, amapayipi e-PP noma e-PVC axhunywe komunye nomunye noma ezindololwaneni noma amapayipi egatsha. Isixazululo sokugcina ukushisela ipulasitiki. Akuhlukile ekuxhumekeni kwezinsimbi ngokwesiko. I-plastic binder ikuvumela ukuthi udale inhlanganisela ehlala njalo yezinto ezimbili noma ngaphezulu. Futhi kukule ndlela lapho sizogxila khona esihlokweni sethu.

i-plastic welding lokushisa

Okubaluleke kakhulu ukukhethwa kwemingcele yokusebenza kwedivayisi ye-anastomosis ephezulu. Ukuze wenze lokhu, udinga ukwazi ipulasitiki eshiselwe kanye nendawo yayo yokuncibilika. Ezidume kakhulu zibalwe ngezansi:

- I-PE (i-polyethylene) - 110 ° С-180 ° С;

- I-PP (i-polypropylene) - 160 ° C;

- I-PVC (i-polyvinyl chloride) - 180 ° C-270 ° C;

- I-PC (i-polycarbonate) - 230 ° С;

- I-ABS (acrylobutylstyrene) - 240 ° С;

- I-PA (i-polyamide) - 255 ° C;

- I-PTFE - 325°С.

Uhlobo lwe-binder kanye nama-electrode welding

I-electrode kumele yenziwe njalo ngezinto ezifanayo nezinto zepulasitiki okufanele zishiselwe. Uma kungenjalo, wonke umsebenzi uzomoshakala futhi umphumela ngeke wenziwe ngendlela efanele. Uma ufuna ukushisela, kufanele futhi ukhethe ububanzi bensimbi obufanele bokugcwalisa ukuze ugcine ilunga liqinile futhi liqinile. Le parameter iphinde ihlobane nobukhulu bombhobho wokushisela wejubane eliphezulu.

Imishini yokushisela endaweni yokusebenzela

Imuphi umshini wokushisela ofanelekile? Konke kuncike ezingeni lobuchwepheshe bomqhubi kanye nemvamisa ye-welding. Amadivayisi alula, angabuye abizwe ngezibhamu zokushisa, akufanele abize ngaphezu kwama-euro angu-10, ngokuvamile afakwe ama-nozzles ezinhlobonhlobo ze-binder futhi anikwe amandla yinethiwekhi. Ingaphinde ifakwe ngemishini yokushisela igesi ye-cartridge. Kukhona nezinto ezisebenza ngamabhethri kanye neziteshi zokushisela ezisebenzayo ezizosetshenziswa emabhizinisini esevisi. Ukushisela kwabo kudinga ukuzijwayeza. Intengo yalezi zisetshenziswa ifinyelela izinkulungwane ezimbalwa zamazloty.

Futhi hlola ulwazi mayelana nezinsimbi zokushisela i-aluminium lapha: https://spawam.pl/spawanie-felg-aluminiowych

Izesekeli zokushisela i-thermoplastic

Sikhuluma ngani kuleli cala? Ukulungisa ipulasitiki, akudingeki umshini wokushisela kuphela, kodwa futhi namathuluzi okugaya angaphezulu. Ngokuvamile ama-scrapers amancane futhi abanzi anele, kanye ne-grinder kagesi enamacebiso epulasitiki. Ngosizo lwabo, uzosusa indawo ene-oxidized futhi uyilungiselele ukushisela.

Amakhono namakhono

Kunzima kuwe ukwenza umkhuba wokushisela uma ungakaze usebenze nomshini wokushisela ngaphambili. Kodwa-ke, awunakho ukukhathazeka ngakho, ngoba ngemuva kokufunda lo mhlahlandlela, uzokwazi ukuthi yimaphi amaphutha okufanele uwagweme nokuthi ungenza kanjani ama-welds. Ukuze uthole ukuqeqeshwa, uzodinga amadivaysi alula kakhulu angasetshenziswa ukushisela amapulasitiki.

Welding plastic isinyathelo ngesinyathelo

Kunezinto ezimbalwa okufanele uzinqume ngaphambi kokuba uqale ukwenza i-plastic weld yakho yokuqala. Hlola lokho okudingeka ukwenze isinyathelo ngesinyathelo uma usunqume ukuqalisa.

Welding of ABS nezinye plastic - ukulungiswa base

Akunakwenzeka ukuxhuma izakhi kahle ngaphandle kokuhlanza kuqala. Lokhu akusebenzi kuphela kumapulasitiki, kodwa nasezinsimbi. Ngakho-ke, qala ukushisela ngokuhlanza indawo. Ungakwazi ngisho ukuwasha uma udinga. Lokhu kungase kubaluleke kakhulu endabeni yezinto lapho amafutha noma uketshezi bekukhona. Ngemuva kokumisa ngokuphelele, ama-oxide angaphezulu nawo kufanele asuswe esakhiweni. Ukugaya kanye nezinto ezifiphele kancane kuzovumela isici ukuthi sishiselwe ukuze sixhumeke ngempumelelo ku-weld. Sebenzisa ama-scrapers kanye ne-grinder kulokhu. Okokugcina, susa ngokucophelela ubuso.

Ipulasitiki yokushisela nge-soldering iron kanye ne-welder - ukuhlanganisa okuyinhloko kwezinto

Uma ama-elementi engakaze ahlanganiswe ndawonye, kunconywa ukuthi wenze ukuhlanganisa kokuqala kuqala. Ukuze wenze lokhu, sebenzisa i-nozzle yangaphambi kwe-weld ene-wedge ekhethekile ezodlula phakathi kwezinto eziseduze. Lokhu kuzoqale kusimamise imikhiqizo futhi kulungiselele isiteshi sokushisela okuyinhloko kusetshenziswa i-plastic binder. Ngaphambi kokushisela izakhi zepulasitiki, setha idivayisi ekushiseni okuncibilikayo kwepulasitiki oyifunayo bese ulinda kuze kube yilapho ithiphu lishisa. Kuhle ukushisela ngokunyakaza okukodwa, ngaphandle kokudabula i-elementi ezintweni okumele zishiselwe. Zama ukugcina i-welder isendaweni engashintshi, okungcono kakhulu engu-45°.

Ibhondi yepulasitiki eshisayo - ukushisela okuyisisekelo

Manje sekuyisikhathi sokwenza i-main weld.

- Linganisa ubude obudingekayo bokubopha ngomphetho wamasentimitha ambalwa. Kuyoba kuhle uma unethiphu yokushisela esheshayo, ngoba ngale ndlela ukusetshenziswa kwe-putty kuyoba okunembe kakhulu.

- Fudumeza idivayisi bese ufaka i-elementi ngaphakathi. Ungakhulula isibophezelo ngaphandle kancane kwekhonta ukuze ipulasitiki ikwazi ukuxhumana kahle nezindawo ezizohlanganiswa endaweni lapho kungekho ukuxhumana.

- Bese, ngokunyakaza okuhamba kancane kodwa okuqinisekile, sebenzisa i-welder eduze komfafa.

Ukulungiswa kwepulasitiki nge-pendulum welding

Uma ungenayo ithiphu ye-welding yejubane eliphezulu noma uma ingafaneleki indlela yokushisela, indlela ye-pendulum iyisinqumo esingcono kakhulu. Ama-Seam sealants lapha kufanele asetshenziswe futhi afakwe ipulasitiki ngesandla. Ungakhohlwa ukushisela ama-elementi phansi ukuze izindawo ezingaphezulu zihlangane. Kule ndlela yokulungisa, kuyadingeka futhi ukucabangela ukucindezela okulungile kwe-binder, ngaphandle kwalokho i-weld izophuka.

Ukuqeda ama-welds

Ngemva kokuba zonke izingxenye sezipholile, ungaqala ukuzigaya. Ukuze wenze lokhu, sebenzisa ama-scrapers noma i-grinder kagesi futhi ulahle ama-welds amaningi. Uma uzama ukwenza lokhu kuma-welds ashisayo, angase aphule ukuqhubeka kwawo. Ngakho-ke kungcono ukulinda kuze kuphole.

Amaphutha Welding Wepulasitiki Okufanele Ugweme

Kunamaphutha ambalwa ayisisekelo ngisho nama-welders anolwazi awenzayo. Bakhona:

- ipulasitiki engabonakali kahle;

- indawo engahlanjululwa kahle;

- amandla okuphoqa okungalungile;

- ukushisisa i-elementi eyodwa kuphela.

Ipulasitiki Engaxilongwanga kahle

Kulokhu, kuzoba nzima kuwe ukusetha izinga lokushisa elifanele emshinini wokushisela. Futhi lokhu kungaholela ekuncibilikeni ngokushesha okukhulu kwezakhi kanye nokushiswa kwe-weld. Ipulasitiki yokushisela ngezinto ezikhonjwe ngokungalungile iveza ubungozi bokukhethwa okungalungile kwesici sokuxhuma. Futhi-ke wonke umsebenzi uzoba yize, ngoba izinto ngeke zixhumane.

Indawo engaphezulu ayihlanzwanga kahle

Ipulasitiki inamathela kahle komunye nomunye, kodwa ngaphandle kokubamba iqhaza kokungcola okuqinile. Ngakho-ke, ngaphambi kokuqala umsebenzi, zama ukuhlanza nokukhuhla ubuso bemikhiqizo ezoshiselwa kahle. Uma kungenjalo, ngisho nezinga lokushisa elifaniswe ngokuphelele ne-binder ngeke lisebenzise. I-weld izophuma emizuzwini embalwa, futhi esimweni esinethemba lokhu kuzokwenzeka emizuzwini embalwa.

Amandla okubamba angalungile

Lokhu kungenzeka ikakhulukazi ekuqaleni kokuqeqeshwa kwe-plastic welding. Uzoshisa izinto eziningi, ngaphambi kokuthi uzizwe, ngamandla angakanani ukuwacindezela phezulu. Uma ingcindezi ilula kakhulu, izakhi ngeke zixhumane. Amandla amaningi angabangela ukuthi ithiphu le-welding licwile endaweni yokusebenza.

Ukushisisa i-elementi eyodwa kuphela

Izinga lokuxhuma libuye lincike ekutheni uzishisa kanjani izingxenye. Ngesikhathi senqubo yokushisela, zama ukushisa insimbi yokugcwalisa kanye nezinto ezizohlanganiswa ngokulinganayo. Uma wenza okuhlukile futhi ushise eyodwa kuphela yazo, zizonamathela kancane komunye nomunye. Ngemva kwesikhashana, uzokwazi kalula ukuphula lezi zingcezu ngaphandle komzamo omkhulu.

Ikuphi ukushisela ipulasitiki okuvame ukusetshenziswa kakhulu?

Kumsebenzisi wemoto, ukushiselwa kwalolu hlobo lwento ngokuvamile kuyazuzisa uma obhampa bonakele. Yiqiniso, uma izingxenye zihlakazekile, akunakwenzeka ukuphinda zihlanganiswe ngendlela yokugcina isimo sazo kanye nomsebenzi wazo. Kodwa-ke, ngemuva komthelela ozodala ukuqhekeka okude ngaphandle kokulimala okukhulu, ukushisela okukhulu kunengqondo. Kungashiwo okufanayo mayelana nabakaki abalungisa izibani nezinye izinto zemishini yemoto, ukushintshwa kwayo kubiza kakhulu.

Intengo yokushisela ipulasitiki - kubiza malini?

Uma ungeke ukwazi ukuzilungisela ngokwakho, ukushisela ubhampa wepulasitiki kungakubiza okungenani ama-euro angu-20. Uma imoto indala, kuba nenzuzo encane ukwenza ukulungisa okunjalo. Izindleko zokushintshwa kwensimbi ethandwayo zingase zingadluli ngisho nenani lentengo yokushisela, futhi khumbula ukuthi intengo kufanele ihlanganise umdwebo wesici. Ezimweni eziningi, i-welding izobiza kakhulu kunokuthenga ingxenye entsha. Kodwa-ke, ukuthi kuzoba njani esimweni sakho, kufanele uzinqumele.

Welder Plastic namandla ahlangene

I-Welding iyindlela evamile yokuxhuma izakhi. Ngale ndlela, izinto zasendlini zihlangene, kanye nemishini yezimboni kanye nemishini. Ukuqina kwe-weld kuzokwanelisa uma ugwema amaphutha esiwashilo lapho sishisela ipulasitiki ekushiseni okuphezulu. Udinga ukuzijwayeza okuningi ekusebenziseni umshini wokushisela, ukukhetha izinga lokushisa nokusebenzisa izesekeli ukwenza umphumela unomphela. Ukuhlanganiswa kwamapulasitiki nge-welding kusetshenziswa, isibonelo, kuma-hydraulics, namapayipi ahlanganisiwe anezindleko eziphakeme ahlala iminyaka.

Uma ufuna ukushisela i-bumper ngokwakho, kungase kungafaneleki ukuthenga zonke izingxenye. Enye into ukuthi uma esikhathini esizayo ufuna ukwenza lolu hlobo lwenkonzo, okungenani ngezikhathi ezithile. Khona-ke kunengqondo ukushisela izinto zepulasitiki uwedwa futhi uthenge izinto zokusebenza. Uma ungenawo amathuluzi, isipiliyoni nesikhathi, kungcono ukuyisa into eyonakele endaweni yokusebenzela ekhethekile.