Ukushisela nokulungisa amapulasitiki ezimotweni

Okuqukethwe

- Izindlela zokulungisa amapulasitiki

- Izinketho zokulungisa ipulasitiki

- Ukulungiswa kwamapulasitiki ngokushisela

- Lungisa nge-Uni-Weld ne-fiberflex tape

- Ilungisa ukudla okuyisisekelo okuphukile

- Ukulungiswa kwepulasitiki ngeglue esheshayo

- Ukulungiswa kwamapulasitiki ane-resin epoxy enezinto ezimbili

- Uhlelo lokusebenza lwe-Putty

- Ukwelashwa komhlaba nge-primer ngaphambi kokufaka ijazi eliphezulu

- Uhlelo lokusebenza lokupenda oluguquguqukayo

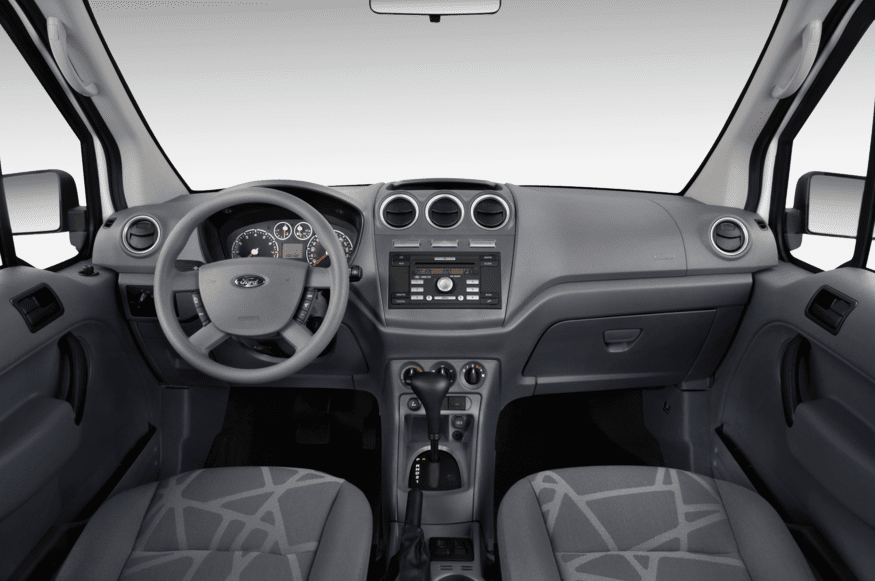

Ezimotweni eziningi zanamuhla, izingxenye zensimbi zishintshwa ngepulasitiki. Isizathu isisindo esiphansi semoto, ukusetshenziswa kukaphethiloli okuphansi, ukugqwala futhi, yiqiniso, intengo ephansi. Lapho ulungisa izingxenye zemoto yepulasitiki, kuyadingeka ukucabangela uhlangothi lwezomnotho lokulungisa enye noma enye into kanye nokusebenza kwepulasitiki ngemva kokulungiswa.

Ezimotweni eziningi zanamuhla, izingxenye zensimbi zishintshwa ngepulasitiki. Isizathu isisindo esiphansi semoto, ukusetshenziswa kukaphethiloli okuphansi, ukugqwala futhi, yiqiniso, intengo ephansi. Lapho ulungisa izingxenye zemoto yepulasitiki, kuyadingeka ukucabangela uhlangothi lwezomnotho lokulungisa enye noma enye into kanye nokusebenza kwepulasitiki ngemva kokulungiswa.

Izindlela zokulungisa amapulasitiki

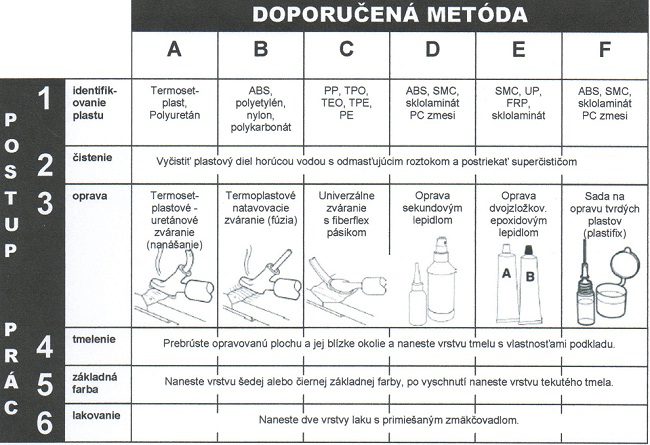

Ukuhleleka komsebenzi ukuhlonza ipulasitiki, ukuhlanza, inqubo yokulungisa ngokwayo, ukubeka uphawu, upende wesisekelo, ukudweba.

Umazisi wePulasitiki

Indlela elula yokubona ipulasitiki ukuliphendula bese ubheka ngaphakathi ukuze uthole uphawu lomenzi. Bese ubheka lolu phawu kuthebula elinamathiselwe (Ishadi Lereferensi Lokulungiswa Kwepulasitiki) futhi, esimweni sezindlela ezimbalwa zokulungisa eziphakanyisiwe, khetha leyo ekufanele kakhulu. Uma kungenakwenzeka ukukhomba ipulasitiki ngesibonakaliso, kunzima kakhulu ukucacisa indlela yokulungisa, lokhu kudinga ochwepheshe abanolwazi kakhulu emkhakheni abangakhetha indlela efanele yokulungisa ingxenye.

Ithebula Lereferensi Lokulungisa Amaplastiki

Ukuhlanzwa kwendawo ngaphambi kokulungiswa

Ukuthola amandla okulungisa okuphezulu kanye nempilo ende yokusebenza kwengxenye elungiswayo, kubalulekile ukuthi uhlanze kahle ubuso kusuka kokungcola okuhlukahlukene, ikakhulukazi endaweni yokulungisa okuhlelwe.

Isinyathelo cha. 1: Geza izinhlangothi zombili zengxenye ngensipho namanzi bese womile ngephepha noma ngomoya.

Isinyathelo cha. 2: Futha indawo elungisiwe nge-super cleaner (i-degreaser) bese usula ngendwangu eyomile. Njalo hlanganisa ithawula ngengxenye entsha. Sula njalo ohlangothini olulodwa. Le nqubo igwema ukungena kokungcola engxenyeni ezohlanzwa.

Izinketho zokulungisa ipulasitiki

Ukulungiswa kwe-Overhang

Uma ingaphezulu limboziwe, sisebenzisa isibhamu esishisayo ukulungisa izindawo ezilimele. Lapho kufudunyezwa ipulasitiki, kubalulekile ukuyifudumeza ngokuphelele. Ukushisa okuhle kusho ukubamba isibhamu sokushisa ngakolunye uhlangothi kuze kube yilapho uhlangothi oluphambene lushisa kakhulu kangangokuba ubuso balo abunakubanjwa esandleni sakho. Ngemuva kokushisa kahle kwepulasitiki, cindezela ingxenye eyonakele ngokhuni endaweni efanele bese upholisa futhi uhlanze indawo (ungayipholisa ngomfudlana womoya noma ngendwangu emanzi).

Amapulasitiki e-Thermosetting - i-polyurethanes (i-PUR, i-RIM) - amapulasitiki anenkumbulo, ngenxa yokuthi abuyela ngokuzenzakalelayo endaweni yawo yasekuqaleni ngemva kokushisa ngesibhamu sokushisa noma esitsheni sikapende.

Ukulungiswa kwamapulasitiki e-thermosetting avela kuplastiki be-uranium.

I-urethane yezimoto noma i-PUR iyinto ekwazi ukumelana nokushisa. Ekukhiqizeni kwayo, ukusabela kusetshenziswa okufana nalokho okusetshenziswa lapho kuhlanganiswa i-sealant ne-hardener - okungukuthi, izingxenye ezi-2 ze-liquid ndawonye kanye nengxenye eyodwa eqinile yakhiwe ngaphandle kokubuyela esimweni sayo sokuqala. Ngenxa yalesi sizathu, ipulasitiki ayikwazi ukuncibilika. Akunakwenzeka ukuncibilikisa ipulasitiki nge-welder. Indlela ethembeke kakhulu yokusho ukuthi i-bumper iyi-polyurethane ukufaka ithiphu le-welder elishisayo ngemuva kwebhampa. Uma kuyi-urethane, ipulasitiki izoqala ukuncibilika, ibhamule, futhi intuthu (i-welder idinga ukushisa kakhulu ukwenza lokhu). Ngemva kokuba indawo eqoshiwe isipholile, ipulasitiki ihlala iqinile lapho ithintwa. Lokhu kuwuphawu lokuthi izinga lokushisa liye lalimaza ukwakheka kwama-molecule epulasitiki. I-Thermoset urethanes ingalungiswa kalula nge-welder engenawo umoya, kodwa ukulungiswa kuzoba ngaphezulu ngeglue eshisayo kunokwelding (ukuhlanganisa induku nokusekela).

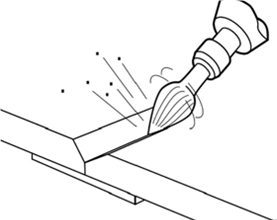

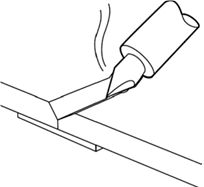

Ukulungiswa kwama-V-grooves endaweni eyonakele

Siqondisa futhi sinamathisela izingxenye ezilimele nge-aluminium tape. Ezindaweni ezinkulu, kuvikelekile ngezibopho zokucindezelwa. Ungajoyina futhi izingxenye nge-glue esheshayo (isb. Uhlobo 2200). Ngemuva kwengxenye ezolungiswa, sigaya i-V-groove emshinini wokugaya onamathele. Asikwazi ukusebenzisa ithiphu efudumele esikhundleni somshini wokugaya wale nqubo njengoba okubhaliwe kungangeneki. Sanda i-V-groove nge-sandpaper (z = 80) noma i-coarser. Ngokufaka isihlabathi ngaphezulu, sithola ama-groove amaningi endaweni egayiwe. Futhi endaweni ye-V-groove, susa i-varnish bese uthambisa imiphetho ye-V-groove ukuze ushintsho phakathi kobuso ne-V-groove lubushelelezi.

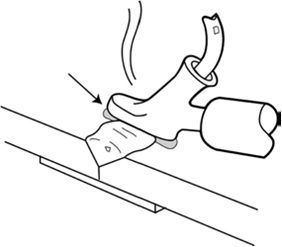

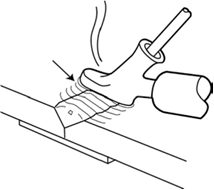

Ukuphonsa induku ku-V-groove

Izinga lokushisa emshinini wokushisela kufanele lisethwe kusetshenziswa umlawuli ohambelana nenduku esobala (R1). Sisebenzisa induku yensimbi engu-5003R1, siphumelele iqiniso lokuthi ekuphumeni kwesicathulo se-welding, induku kufanele iphume esimweni soketshezi, eguquguqukayo ngaphandle kwamabhamuza. Bamba isicathulo sokushisela ngaphezu kobuso ukuze ushiselwe bese ucindezela induku enezikhala ungene ku-V-groove ngayo. Asishisi kakhulu okokusebenza okuyinhloko, kepha sithela induku yokushisela ebusweni bayo. Musa ukudida isiqu nobhampa. Masingakhohlwa ukuthi i-urethane ayincibiliki. Ungangezi izinti ezingaphezu kuka-50 mm ngasikhathi. Sikhipha induku esicathulweni futhi ngaphambi kokuba induku encibilikisiwe epholini ipholile, sibushelele ubuso bayo ngesicathulo esishisayo.

Ukulungiswa kwama-V-grooves ohlangothini oluhlukile

Ngemuva kokuthi i-weld ohlangothini lwangemuva selupholile phansi, phinda wenze i-V-groove, sanding kanye ne-welding kolunye uhlangothi.

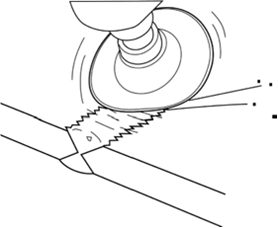

Ukugaya i-weld endaweni ebushelelezi

Usebenzisa iphepha eliqatha, sandisa i-weld endaweni ebushelelezi. Ijoyini le-urethane alikwazi ukugoqwa ngokuphelele, ngakho-ke ijazi le-sealant lizodinga ukufakwa ebusweni ukuze lilungiswe. Susa kancane okokusebenza okuningana kwi-weld ngokufaka isihlabathi ukuze i-sealant imboze yonke indawo ngokulinganayo.

Ukulungiswa kwamapulasitiki ngokushisela

Ngaphandle kwe-urethane, wonke ama-bumpers namapulasitiki amaningi ezimoto enziwe nge-thermoplastics. Lokhu kusho ukuthi zingancibilika lapho zishiswa. Izingxenye ze-Thermoplastic zenziwa ngokuncibilikisa ubuhlalu bepulasitiki futhi zijove izinto eziwuketshezi zibe isikhunta lapho zipholile futhi ziqine. Lokhu kusho ukuthi i-thermoplastics i-fusible. Iningi lamabhampa akhiqizwayo enziwe ngezinto ze-TPO. I-TPO isiphenduke into ethandwayo ngokushesha ekukhiqizweni kwezingxenye zangaphakathi nezinjini. I-TPO ingashiselwa kusetshenziswa ubuchwepheshe be-fusion noma i-fibreflex fibre rod ekhethekile eyenza i-weld iqine kakhudlwana. Impahla yesithathu ethandwa kakhulu yi-Xenoy, eshiselwe kangcono.

Ukulungiswa kwama-V-grooves endaweni eyonakele

Siqondisa futhi sinamathisela izingxenye ezonakele nge-aluminium tape. Ezindaweni ezinkulu, zivikele nge-clamp clamp. Futhi singajoyina izingxenye ngohlobo lwesibili lweglu engama-2200. Ngemuva kwengxenye elungisiwe, sigaya i-V-groove emshinini wokugaya ocijile. Ngale nqubo, singasebenzisa ithiphu efudumele esikhundleni somshini wokugaya, ngoba indaba iyinto fusible. Susa upende ezungeze ukulungiswa okuhleliwe ngesandla sesihlabathi bese ususa i-chamfer phakathi kobuso ne-V-groove.

Ukuxubana nomongo nento eyisisekelo

Sibeka izinga lokushisa emshinini wokushisela ukufanisa induku ye-welding ekhethiwe, esiyinqume ngesikhathi senqubo yokuhlonza. Ezimweni eziningi, induku ye-weld enamapads kufanele iphume ihlanzekile futhi ingapendiwe. Okuwukuphela kokuhlukile kungaba yinyiloni, ejika iguqule ibe nsundu ngokukhanyayo. Beka isicathulo sokushisela esisekelweni bese ufaka kancane induku ku-V-groove. Siphusha kancane induku ephambi kwethu ukuze sikwazi ukubona ngemuva kwethu umsele omise okwe-V ogcwele le nto. Ubuningi bensimbi engu-50 mm yokushisela ngenqubo eyodwa. Sikhipha induku esicathulweni futhi, ngaphambi kokuba induku iphole, sicindezele ngokucophelela futhi sihlanganise izinto ndawonye. Ithuluzi elihle unqenqema lwesicathulo, esifaka ngalo imifula entweni eyisisekelo bese siyayihlanganisa. Smooth surface ngobumnene nge-tip eshisayo. Shiya ithiphu ishisa kuyo yonke inqubo yokuxuba.

Ukulungiswa kwe-V-groove kanye ne-side side welding

Ngemuva kokuthi uhlangothi lwangemuva selupholile ngokuphelele, siphinda inqubo yokulungisa ama-V-shaped grooves, ukugaya nokushisela uhlangothi olungaphambili.

Izinsimbi zokugaya

Usebenzisa iphepha eliqatha, sandisa i-weld endaweni ebushelelezi. Susa kancane okokusebenza okuningana kwi-weld ngokufaka isihlabathi ukuze i-sealant imboze yonke indawo ngokulinganayo.

Lungisa nge-Uni-Weld ne-fiberflex tape

I-Universal Welding Rod iyimpahla yokulungisa eyingqayizivele engasetshenziswa kunoma iyiphi ipulasitiki. Akuyona induku yangempela yokushisela, ingaphezulu kohlobo lweglue elishisayo. Lapho silungisa le nduku, sizosebenzisa ukushisa kwe-welder, esikhundleni sezindawo zayo zokunamathisela. Induku efana ne-Fiberflex strip inesakhiwo esiqine kakhulu. Iqiniswa nge-carbon ne-fiberglass ukuze uthole amandla engeziwe. I-Fiberflex iyisixazululo esingcono kakhulu sokulungiswa kwe-TPO (futhi i-TEO, PP/EPDM) i.e. izinto ezisetshenziswa kakhulu amabhampa. I-Fiberflex ingasetshenziswa ukulungisa zonke izinhlobo zamapulasitiki. Ingakwazi ukunamathela kuma-urethanes kanye nama-xenos. Uma singaqiniseki ukuthi iyiphi ipulasitiki esiyishiselayo, simane sisebenzisa i-Fiberflex. Enye inzuzo ye-Fiberflex ukuhlakazeka kwayo. Isakhiwo esihle se-weld sinciphisa ukusetshenziswa kwe-sealant.

Ukulungiswa kwama-V-grooves endaweni eyonakele

Siqondisa futhi sinamathisele izingxenye ezonakele nge-aluminium tape, sizilungise ngocingo lokuminyanisa ezindaweni ezinkulu.Ungaxhuma futhi izingxenye ngohlobo lweglu yesibili engu-2200. Ububanzi besikhonkwane esime ngo-V kufanele bube ngu-25-30 mm. Kubaluleke kakhulu ukumboza ingaphezulu ngaphandle kwe-V-groove nge-sandpaper (grit size approx. 60) ukuze uthole indawo eyengeziwe kuma-micro-grooves. Uma sisebenzisa i-rotary vibration sander ekugayeni, sizonciphisa isivinini sibe sincane ukuvimbela ukuncibilika kwento i-thermoplastics ebucayi kuyo. Usebenzisa i-sandpaper (z = 80), susa i-varnish kuyo yonke indawo ezolungiswa bese usika onqenqemeni phakathi kwe-V-groove nobuso. Lokhu kusivumela ukuthi sisakaze kangcono futhi sicindezele itheyiphu yeFiberflex endaweni yokulungisa.

Ukuncibilika kwe-fiberflex

Setha umshini wokushisela emazingeni okushisa aphakeme kakhulu bese ufaka isicathulo sokushisela ngephedi yokuncibilika (ngaphandle kwethubhu yomhlahlandlela). Kungcono ukusula uhlangothi olulodwa lomucu we-Fiberflex ngendawo eshisayo ukuze uyincibilikise kancane bese usebenzisa ngokushesha kwi-substrate. Hlukanisa ingxenye ehlanganisiwe nomphetho wepuleti elishisayo kusuka kulo lonke ikhoyili. Bese uncibilikisa umucu ku-V-groove. Asizami ukuxuba izinto eziyisisekelo neFiberflex. Le ndlela ifana nendlela eshisayo yeglue.

Ukulungiswa kwama-V-grooves kanye ne-welding ye-facade

Ngemuva kokuthi iFiberflex ngemuva isipholile phansi (singaphinde sisheshise inqubo ngamanzi abandayo), phinda inqubo yokugaya, yokugaya neyokushisela. Ungafaka futhi ungqimba olungaphezulu kancane lweFiberflex njengoba igaya kahle.

Ukugaya

Lapho i-fiberflex weld isipholile phansi, qala ngokufaka isihlabathi (z = 80) nesivinini esihamba kancane. Qedela inqubo yesihlabathi nge-sandpaper (z = 320). Konke okungahambi kahle kufanele kugcwaliswe nge-sealant.

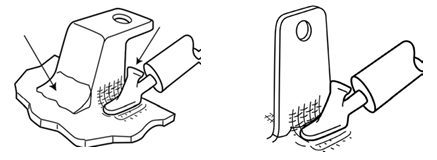

Ilungisa ukudla okuyisisekelo okuphukile

Obhampa abaningi be-TEO banabakaki okudingeka bavumelane nezimo ukuze ukufakwa kube lula. Lesi sakhiwo singalungiswa kahle kakhulu ngegridi yensimbi engagqwali kanye ne-fiberflex. Okokuqala, lungisa ubuso nge-sander ejikelezayo. Kusuka ku-stainless steel mesh, sizosika ingxenye elungele ukuxhuma ikhonsoli kanye nesisekelo nhlangothi zombili. Ngethiphu elishisayo, cindezela lezi zingcezu epulasitikini. Ngemva kokuncibilika nokupholisa, gcoba ingaphezulu ngephepha ukuze ususe izindawo ezicwebezelayo. Faka induku ye-Fiberflex endaweni ephathwayo. Ngalokhu kulungisa, i-mesh iqinisekisa amandla nokuguquguquka, futhi i-fiber rod iwukunamathela kwezimonyo kuphela.

Ukulungiswa kwepulasitiki ngeglue esheshayo

Njengoba izinto zokunamathisela zesibili zakha amabhondi aqinile, zikhethwa ukulungisa amapulasitiki afana ne-ABS, i-PC, i-SMC, ama-plastiki aqinile. Zifanele izingxenye zokujoyina indawo ngokuzilungisa ngaphambi kokushisela.

Ukulungiswa okusheshayo kwemifantu

Okusemqoka kokujoyina izingxenye ukufafaza kancane izingxenye ezizohlanganiswa nesisebenzisi. Sifaka futhi sixhume izingxenye. Sebenzisa itheyiphu ye-aluminium engu-6481. Ezingxenyeni ezinkulu, sebenzisa izibopho ukuqinisekisa ukuthi izingxenye zigcinwa zisebenza ngesikhathi sokubopha. Beka inani elincane le-glue esheshayo ukugcwalisa ukuqhekeka. Imiphumela emihle ifinyelelwa ngenani elincane lokunamathisela elisetshenziswe kujoyini. Ingcina incane ngokwenele ukungena esikhaleni. Futha umthamo owengeziwe wesisebenzisi ukuqedela inqubo nezimbobo eziphakathi nendawo.

Ukugcwalisa ama-grooves nezimbobo

Sivala umgodi ngezansi nge-aluminium tape. Lungisa i-V-notch ezungeze yonke ipherimitha lomgodi bese uyisanda kanye nezindawo ezizungezile ngokukhipha uthuli. Futha indawo ezolungiswa kancane nge-activator. Gcwalisa umgodi nge-putty bese usebenzisa amaconsi ambalwa weglue. Silinganisela futhi sicindezele i-glue ku-sealant ngethuluzi elibukhali. Ngemuva kwamasekhondi angu-5-10, sebenzisa ungqimba olulula lwe-activator. Ubuso bungafakwa ngesihlabathi ngokushesha futhi buhlolwe.

Ukulungiswa kwamapulasitiki ane-resin epoxy enezinto ezimbili

Sandla ngemuva kwendawo elungisiwe nge-sandpaper (z = 50 noma ngaphezulu). Ama-grooves ajulile ngemva kokugaya ayisisekelo esihle kakhulu soxhumano oluqinile. Bese ugcoba kancane indawo ngephepha (z = 80), okubuye kube nomthelela ekuxhumaneni okungcono. Uma kusetshenziswa i-TEO, TPO noma i-PP impahla, kufanele sisebenzise i-adhesive esekelayo yohlobo lwe-1060FP. Sabalalisa umkhiqizo ngebhulashi endaweni enesanti bese uyeke. Sibeka i-fiberglass kubo bonke ubude bengxenye eyonakele. Uma ingxenye ye-SMC igoqwe phezu komfantu nenye ingxenye esele nayo eyenziwe nge-SMC, qinisekisa ukuthi lesi sigaba sokugqagqana sidlula indawo yomonakalo ohlangothini ngalunye okungenani ngo-0,5mm. Sizokhetha i-adhesive efanelekile enezingxenye ezimbili efana kakhulu nengxenye ezonanyathiselwa:

- I-Filler 2000 Flex (grey) iyaguquguquka

- I-2010 filler semi-flexible filler eguquguqukayo emaphakathi (ebomvu)

- 2020 SMC Hardset Filler (Okumpunga) Okuqinile

- 2021 Ukugcwalisa kanzima (okuphuzi) kanzima

Hlanganisa i-epoxy eyanele. Faka isendlalelo ukumboza itheyiphu ngemicu bese uyivumela ukuthi yome okungenani imizuzu eyi-15. Ku-SMC, sakha ungqimba lweglu yengcezu yokuqinisa, esiyicindezela embhedeni olungisiwe. Kulokhu, vumela iglue lome okungenani imizuzu engama-20. Sanda ubuso bengxenye eyonakele ngephepha (z = 50) bese uyisanda i-V-groove esikhaleni. Uma isikhathi eside futhi sijula le groove, kunamandla ukuxhumana. Chamfer emaphethelweni omsele we-V, sandza ingaphezulu ngephepha (z = 80). Hlanganisa futhi usebenzise ungqimba lwe-epoxy adhesive bese uyilolonga ukuze idlulele ngale kwendawo ezungezile. Vumela omile okungenani imizuzu engama-20. Kungaleso sikhathi kuphela lapho sizoqala ukugaya khona. Sisebenzisa i-SMC, sifaka izingcezu zendwangu ye-fiberglass eguquguqukayo ku-V-groove naphakathi kwezingqimba ezithile zokunamathela. Sisebenzisa iroli ejikelezayo, sicindezela ngokucophelela indwangu ku-glue bese sikhiphela ngaphandle amagwebu omoya angafuneki. Silungisa indawo eyomile nge-sandpaper (z = 80, bese-ke = 180).

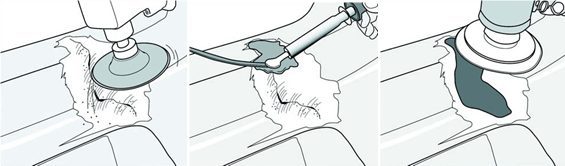

Uhlelo lokusebenza lwe-Putty

Sanda ingaphezulu ukuze lisandwe ngephepha eliqinile. Lungisa i-V-groove encane endaweni yomonakalo. Zonke izingxenye ezicwebezelayo kufanele zisuswe ngaphambi kokufaka i-sealant, ngaphandle kwalokho ukunamathela okuhle ngeke kwenzeke. Uma ngabe impahla i-polyolefin (i-PP, i-PE, i-TEO noma i-TPO epulasitiki esekwe ngo-oyili), sisebenzisa isinamathelisi esisekelayo esinomoya onomoya. Sikhetha i-epoxy sealant efanelekile ehambelana nokuguquguquka kwento eyisisekelo. Uma uguquguquka, sebenzisa i-2000 Flex Filler 2 noma i-Adhesive Semi-flexible Adhesive 2010. Uma kunzima, sebenzisa i-2020 SMC Rigid Kit noma i-2021 Rigid Filler. Hlanganisa inani elibekiwe le-epoxy sealant. Sizokwakha ungqimba we-sealant ophakeme kancane kunendawo ezungezile. Asiqali ukugxuma ngaphambi kwemizuzu engama-20, ukuze sanding sisebenzisa iphepha ngosayizi wokusanhlamvu (z = 80, bese kuba ngu-180).

Ukwelashwa komhlaba nge-primer ngaphambi kokufaka ijazi eliphezulu

Uma ngabe okokusebenza kuyi-semi-olefin (TEO, TPO noma i-PP), faka isinamathelisi sokusekela kuzo zonke izingxenye ezidwetshiwe ngokwenqubo ekhonjisiwe kwilebula yomkhiqizo. Ebusweni obuzolungiswa, gcoba isifutho esiyisisekelo sombala ompunga noma omnyama ezingqimbeni ezincanyana. Ngemuva kokomisa, sandisa ingaphezulu nge-sandpaper (z = 320-400).

Uhlelo lokusebenza lokupenda oluguquguqukayo

Ngemuva kokufaka isihlabathi phansi, phephula uthuli, faka umkhiqizo obhebhethekisa yonke imihuzuko ebusweni ezolungiswa. Hlanganisa umkhiqizo nopende ongagayiwe. Ngemuva kwalokho sixuba upende ngesinciphisi, sisebenzise yonke indawo yepaneli ngokuya ngemiyalo yomkhiqizi, gwema ukufafaza indawo. Ukufeza ukubukeka okujwayelekile kwengxenye yepulasitiki, sisebenzisa isifutho esimnyama esiguquguqukayo esimnyama.

Lapho silungisa opulasitiki bezimoto, kufanele sinake, okokuqala, uhlangothi lobuchwepheshe lokuthi kungenzeka kulungiswe futhi kuhlolwe ukulungiswa okwenziwe ngombono wezomnotho. Kwesinye isikhathi kuyashesha, kulula futhi kushibhile ukuthenga ingxenye yepulasitiki esetshenzisiwe isesimweni esihle.