Isigaba: Amaphedi, ama-linings, izicathulo zamabhuleki - Izinkinga ezivame kakhulu ngezinhlelo zemigqomo

Ukuxhaswa: I-Fomar. Uhlelo lokubhuleka olusebenzayo luwucezu oluyisisekelo lwanoma iyiphi imoto futhi luthinta ngqo ukuphepha komsebenzisi.

Ukuxhaswa: I-Fomar. Uhlelo lokubhuleka olusebenzayo luwucezu oluyisisekelo lwanoma iyiphi imoto futhi luthinta ngqo ukuphepha komsebenzisi.

Umnyango: Amaphedi, omalayini, amabhuleki

Umnyango: Amaphedi, omalayini, amabhuleki

Ukuxhaswa: I-Fomar

Izinkinga eziningi ngezinhlelo zezigubhu zibangelwa ukulungiswa okungalungile kokushintsha ama-brake pads kanye nokufakwa okungalungile kwamaphedi kuma-brake pads. Ukuze unciphise ingozi yezinkinga, gwema amaphutha alandelayo.

Ukujiya kolayini okungalungile

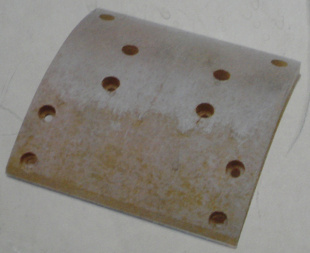

Ungakhohlwa ukukhetha ukujiya okufanele kwama-lining kuye ngenani lokuguga kwesigubhu. Umehluko phakathi kwalawa mapharamitha uholela ekugqokeni okungalingani kwama-linings (isithombe 1) kanye nokwehla kokusebenza kahle kwamabhuleki (hhayi yonke indawo yolwelwesi eseduze nendawo yesigubhu).

Isigubhu asilungiselelwanga kahle ulwelwesi olusha.

Ngaphambi kokuqala isigubhu esine-lining entsha, kufanele sifakwe. I-roller kufanele ilungise i-radius yesigubhu endaweni engaphandle ye-lining futhi ithole indawo yokusebenza eyisicaba futhi ebushelelezi, okudingekayo ukuze kusebenze kahle i-friction pair. Ukulungiswa okungalungile kwendawo kungaholela ekugugeni okungalingani futhi okusheshayo kwama-lining, futhi okubaluleke kakhulu, ekwehleni kokusebenza kahle kwamabhuleki.

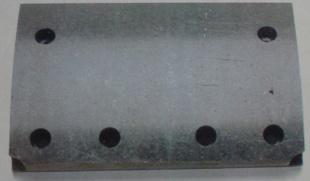

Qaphela! Ngemuva kokugoqa, ungakhohlwa ukugeza izigubhu nge-degreaser. Lesi senzo sizosusa isendlalelo se-graphite phezulu, esigeleza ngesikhathi sokugoqa. Ukwehluleka ukususa ungqimba oluwumphumela kuzoholela ekucwebezeni kwendawo yolwelwesi (Isithombe 2) futhi, ngenxa yalokho, ekwehleni kokusebenza kahle kwamabhuleki.

Ukubekwa okungalungile kwephedi yomhlathi

Ukufakwa kwamaphedi emhlathini kufanele kwandulelwe ukuhlanza indawo yokuxhumana. Noma yikuphi ukungcola kusheshisa ukuguga kwama-linings futhi kunomthelela ekunciphiseni ukusebenza kahle kwamabhuleki. Esimeni esibi kakhulu, ukungcola phakathi kwesipontshi nolayini kungabangela ukuqhekeka komugqa.

Enye indaba ebalulekile ukukhethwa kobubanzi obufanele, ubude kanye nokuma kwekhanda kwama-rivets asetshenzisiwe. Imikhiqizo ye-Fomar inikezwa iphelele nesethi ekhethwe kahle yama-rivets. Ukukhethwa kwamadivaysi e-riveting nakho kunendima ebalulekile. Ububanzi be-rivet mandrel obungalungile bungabangela ukuqhekeka kwe-rivet flange (isithombe 3) noma ukulingana okunganele kolimi emhlathini. Kuzo zombili izimo, lokhu kuholela ekuxhumekeni okuxekethile kolwelwesi lwamakhamera futhi kungaholela ekwephukeni kolwelwesi lapho ubhuleka.

Ukuntuleka kokuqapha ngezikhathi ezithile izinga lokuguga kwezingqimba

Ukusetshenziswa kwamaphedi angaphansi komkhawulo wokuguga (isithombe 4) kunciphisa ukusebenza kahle kwamabhuleki futhi kulimaze izigubhu.

Ngokugwema amaphutha ashiwo ngenhla, sizoba nomthelela omuhle empilweni yesevisi nokusebenza kahle kwalo lonke uhlelo lokubhuleka, ngaleyo ndlela sibe nesandla ekuphepheni kwabasebenzisi bezimoto.