Ukupenda, ukulwa nokugqwala kanye nokwelashwa okubonakalayo kwezidumbu zemoto

Okuqukethwe

- Ukudweba ngemuva kokuvuselelwa

- Ukugaya

- ukuhlanza

- Ukubekwa uphawu

- Izimbangela nokuvinjelwa kwamaphutha okugcwalisa

- ukusebenza

- Sifihle

- Ukudweba

- Izimbangela nokuvinjelwa kwamaphutha lapho ufaka isicelo sama-primers acc. imibala

- Izimbangela nokuvinjelwa komshado opendwe kabili nongqimba abathathu

- Izinhlobo zemibala

- Futha umdwebo

- Ukulungisa umzimba

Imidwebo yemoto inemisebenzi emibili eyinhloko. Ngokombono wokusebenza, ukuvikela kubaluleke kakhulu lapho upende uvikela ubuso bomzimba emathonyeni angathandeki angaphandle (izinto ezinolaka, amanzi, ukushaywa kwamatshe ...). Kodwa-ke, kubashayeli abaningi, umbono wobuhle bepende ubaluleke kakhulu, ngakho-ke umbala wemoto ungenye yezindlela ezibalulekile lapho uyikhetha.

Imidwebo yemoto inemisebenzi emibili eyinhloko. Ngokombono wokusebenza, ukuvikela kubaluleke kakhulu lapho upende uvikela ubuso bomzimba emathonyeni angathandeki angaphandle (izinto ezinolaka, amanzi, ukushaywa kwamatshe ...). Kodwa-ke, kubashayeli abaningi, umbono wobuhle bepende ubaluleke kakhulu, ngakho-ke umbala wemoto ungenye yezindlela ezibalulekile lapho uyikhetha.

Ukufaka i-varnishing njengokwelashwa komhlaba kwavela eChina futhi kwafinyelela esicongweni sayo e-East Asia. Inqola edonswa ngamahhashi ibe neqhaza elikhulu ekwandiseni indawo yesitolo sopende iye ezimotweni. Ngaleso sikhathi (ngekhulu le-18), kwakuthathwa njengezithuthi zomphakathi, okwathi kamuva kwadlula ezigabeni ezahlukahlukene zentuthuko. Isikhathi eside, kwakuyisisekelo sezimoto zokuqala. Kuze kube yikhulu lama-XNUMX AD, izinhlaka zomzimba zemoto zazenziwe ngohlaka lwokhuni, olwalumbozwe ngesikhumba sokwenziwa. Ama-hood nama-fenders kuphela kwakuyinsimbi eshisiwe eyayidinga ukupendwa.

Phambilini, izimoto bezipendwa ngesandla ngebhulashi, elidinga isikhathi nekhwalithi yomsebenzi womdwebi. Umdwebo wesandla wenziwe isikhathi eside kakhulu ekukhiqizeni izidumbu zemoto ebhande lokuhambisa. Izindlela zanamuhla zokulungisa i-varnishing nezinto ezintsha zisize ukukhulisa okuzenzakalelayo, ikakhulukazi kwezimboni, i-batch varnishing. Ukuguqulwa okuyisisekelo kwenziwa kubhavu wokucwilisa olandelwa ukusebenza komuntu ngamunye wokufafaza kusetshenziswa amarobhothi alawulwa ngogesi.

Ukushintshela kuma-metal hulls kubonise enye inzuzo ekudwebeni - isikhathi sokucubungula nokomisa sincishiswe kakhulu. Indlela yokudweba nayo isishintshile. Baqala ukuyipenda nge-nitro-lacquer, eyandisa inani lezingxenye ezikhiqizwayo. Nakuba i-synthetic resin varnish yasungulwa ngawo-30, ukusetshenziswa kwe-nitro varnish emafektri nezitolo zokulungisa kwaqhubeka kwaze kwaba ngawo-40. Kodwa-ke, womabili amafomu kancane kancane ahlehliselwa ngemuva ngenqubo entsha - ukudubula.

Umsebenzi omkhulu wokudweba ngezandla umsebenzi wezimoto ukulungisa, ngandlela-thile umdwebo omusha, kanye nokudweba okukhethekile nokumaka. Ubungcweti obunamakhono kufanele buhambisane nentuthuko yezobuchwepheshe ekukhiqizeni izimoto, ikakhulukazi ngokushintshwa kwezinto zokwakha umzimba (ipulasitiki eningi, i-aluminium, ubujamo obuhlukahlukene, insimbi eshisiwe) noma izinguquko kupende (imibala emisha, izinto ezisuselwa emanzini) nentuthuko ehlobene emkhakheni wezindlela zokulungisa nokudweba.

Ukudweba ngemuva kokuvuselelwa

Kulesi sihloko, sizogxila kakhulu ekudwebeni izindawo ezivele zidwetshiwe, i.e. ngaphandle kokudweba izingxenye ezintsha, acc. imizimba yemoto. Ukudweba izingxenye ezintsha kuwulwazi lwawo wonke umkhiqizi wezimoto, futhi kungashiwo ukuthi inqubo yokudweba njengaleyo ifana kakhulu, ngaphandle kwezinyathelo zokuqala ezihilelekile ekuvikeleni insimbi "eluhlaza" ekugqwaleni, njengokucwilisa umzimba. kwisisombululo se-zinc.

Abasebenzisi bokugcina bezimoto baqonda kangcono amasu okudweba ngemuva kokulungisa ingxenye eyonakele noma efakwe esikhundleni. Lapho upenda imoto yakho ngemuva kokulungiswa, khumbula ukuthi ukubukeka kokugcina kuncike ezintweni eziningi. Hhayi kuphela ekukhetheni kwekhwalithi yengubo yokuqedela, kodwa futhi kusuka kuyo yonke inqubo, eqala ngokulungiswa okulungile nokuphelele kweshidi.

Ukudweba, i-acc. Umsebenzi wokulungiselela uqukethe izigaba eziningana:

- ukugaya

- ukuhlanza

- uphawu

- ukusebenza,

- sifihle,

- varnishing.

Ukugaya

Ukunakekelwa okukhethekile kufanele kukhokhwe ekusandeni ishidi nezendlalelo zomuntu ngamunye eziphakathi, noma kwesinye isikhathi lokhu kubonakala kungasho lutho noma kungukusebenza okuncane lapho kudingeka khona indawo eyisicaba kuphela.

Cabanga ngalokhu okulandelayo lapho usanda:

- Ukukhetha okulungile kwe-sandpaper kuya ngendawo yesanda, noma ngabe sihlwaya insimbi endala / entsha yensimbi, ishidi lensimbi, i-aluminium, ipulasitiki.

- Lapho usanda ungqimba ngalunye olulandelayo, usayizi we-grit we-sandpaper kufanele ube muhle ngokwedlula ama-degree amathathu kunalawo owedlule.

- Ukuze uzuze isihlabathi esifanele, linda kuze kube yilapho izincibilikisi sezihwamuke ngokuphelele nefilimu isomile, ngaphandle kwalokho okubhaliwe kuzogingqika ngaphansi kwephepha.

- Ngemuva kokufaka isihlabathi, indawo kumele ihlanzwe ngokuphelele, zonke izinsalela zesihlabathi, usawoti kanye namafutha kufanele zisuswe. Ungayithinti indawo ebusweni ngezandla.

ukuhlanza

Ngaphambi kokupenda, i-acc. futhi ngaphambi kokufaka isicelo se-sealant, noma Kubalulekile ukususa konke ukungcola okufana nezinsalela zesihlabathi, izinsalela zikasawoti emanzini kanye ne-sandpaper, i-sealant eyeqile uma kungenzeka kubekwe uphawu noma ukuvikelwa okwengeziwe, uwoyela ovela ezandleni, yonke insalela (kufaka phakathi iminonjana) yemikhiqizo ehlukahlukene ye-silicone , uma kukhona okusetshenzisiwe.

Ngakho-ke, indawo kumele ihlanzeke ngokuphelele futhi yomile, ngaphandle kwalokho kungenzeka amaphutha amaningi; ama-craters nokusabalalisa upende, ngokuhamba kwesikhathi kupenda nokuqhekeka namabhamuza. Ukuqedwa kwala maphutha ngokuvamile akunakwenzeka futhi kudinga ukugaya okuphelele komhlaba. Ukuhlanza kwenziwa nge-cleaner esetshenziswa ngaphezulu endaweni eyomile ehlanzekile, isibonelo. futhi nethawula lephepha. Ukuhlanza kuphindwa kaningana ngesikhathi sokulungiselela ukugqoka.

Ukubekwa uphawu

Ukubeka uphawu kuyindlela ejwayeleke kakhulu yokukala izingxenye zemoto ezihlehlisiwe nezinesici. Isithombe esingezansi sibonisa ukuhlangana kombusi nomzimba, okumele kugcwaliswe nge-sealant. Ngokuvamile, indawo ezungeze i-overhang imakwe ngepensela, lapho kudingekile ukusebenzisa i-filler sealant.

I-putty isetshenziswa ebusweni nge-spatula yakudala endaweni esike sayimaka ngaphambili ngepensela. I-sealant isetshenziselwa insimbi engenalutho, ihlanzwa ngokugaya, ukuhlinzeka ubulukhuni namandla anele, yize ama-sealant anamuhla okunamathela kufanele abambelele ngokuqinile kunoma iyiphi i-substrate. Esithombeni esilandelayo, indawo ilungele ukufaka isicelo, ngokulandelana. inqubo yalokho okubizwa ngokuhambisa.

Izimbangela nokuvinjelwa kwamaphutha okugcwalisa

Amachashaza kusendlalelo esiphezulu

Izizathu:

Izizathu:

- i-hardener eningi kakhulu ku-polyethylene sealant,

- i-hardener exutshwe ngokwanele ku-polyethylene sealant.

Ukulungiswa okungaphelele:

- isihlabathi kupuleti siphinde sivalwe.

Izimbobo ezincane

Izizathu:

Izizathu:

- ukubekwa uphawu okungafanele (ubukhona bomoya noma izingqimba eziwugqinsi)

- i-substrate ayomile ngokwanele,

- ungqimba oluncane kakhulu lwe-primer.

Ukuvimbela okungalungile:

- ifosholo kufanele licindezelwe amahlandla amaningi kule ndawo ukukhipha umoya,

- uma sigcina ngogqinsi olukhulu, kuyadingeka ukufaka izingqimba ezimbalwa,

- zomisa izinto zokwakha kahle.

Ukulungiswa okungaphelele:

- isihlabathi kupuleti siphinde sivalwe.

Ukumaka

Izizathu:

Izizathu:

- sanding sealant nge-sandpaper engafanele (kakhulu)

- sanding upende wakudala nge-sandpaper engafanele.

Ukuvimbela okungalungile:

- sebenzisa i-sandpaper kasayizi osanhlamvu osinikiwe (roughness),

- Sanda ama-grooves amakhulu ngephepha elihle le-emery.

Ukulungiswa okungaphelele:

- isihlabathi kupuleti siphinde sivalwe.

ukusebenza

Ukuthulula kuwukuhamba komsebenzi okubalulekile ngaphambi kokufaka ijazi eliphezulu. Inselele iwukumboza nokufaka ungqimba oluncane lwamaqhubu nemihuzuko emincane kakhulu kodwa ebonakalayo, nokuvala nokuhlukanisa izindawo ezinyathelisiwe.

Izinhlobo ezahlukahlukene zokugcwalisa zisetshenziselwa izinhloso ezahlukahlukene:

- 2K polyurethane / acrylate okugcwalisa okusekelwe,

- amafilimu aminyene (ama-compact)

- okugcwalisa ngamanzi,

- okugcwaliswa kumanzi kumanzi,

- ukugcwalisa i-toning,

- okugcwalisa okusobala (Ukugcwalisa).

Sifihle

Zonke izingxenye ezingapendiwe kanye nezindawo zezimoto kufanele zimbozwe, kufaka phakathi imichilo yokuhlobisa, engaboli noma ibole.

Izidingo:

- amateyipu wokunamathisela nawokumboza kumele amelane nomswakama futhi ngasikhathi sinye amelane nokushisa,

- iphepha kumele lingangeneki ukuze uyinki angangeni kulo.

Ukudweba

- Fudumeza imoto ekamelweni lokushisa (18˚C) ngaphambi kokupenda.

- Umbala nezinto ezihambisana nawo (i-hardener ne-thinner) kufanele futhi kube sezingeni lokushisa.

- Ubulukhuni bamanzi wokugaya kufanele bube phansi ngangokunokwenzeka. Amanzi okusila asalayo kufanele asulwe ngokucophelela, ngoba izinsalela zikasawoti zingadala ukushaywa komhlaba.

- Umoya ocindezelweyo kumele womile futhi uhlanzeke. Isihlukanisi samanzi kufanele sikhishwe njalo.

- Uma singenayo idokodo lokufafaza futhi sipenda egalaji, sidinga ukuqaphela ikakhulukazi umswakama womoya (ngokwesibonelo, unganiseli phansi bese uvulela ama-radiator phezulu). Uma umswakama uphakeme kakhulu, amagwebu akha kahle. izibopho acc. upende wokugaya. Kuyafana nangothuli. Izitezi kufanele zihlanzeke futhi zome futhi ukugeleza komoya kufanele kube phansi ngangokunokwenzeka.

- Amadokodo okupenda namakhabethe owomayo kufanele afakelwe umoya ohlanzekile, izihlungi zothuli nezindawo zokushisa umusi ukuvimbela ukugcoba upende noma ukuqongelela uthuli kupende.

- Zonke izindawo ezinesihlabathi kufanele zivikelwe kabusha ekugqobeni.

- Iphakethe ngalinye lineziyalezo zokusetshenziswa ngendlela yama-pictograms. Yonke idatha inikezwa ukushisa kohlelo lokusebenza okungama-20 ° C. Uma izinga lokushisa liphakeme noma liphansi, umsebenzi kufanele uvumelane nezimo zangempela. Lokhu kubaluleke kakhulu empilweni yebhodwe nokomiswa, okungancishiswa emazingeni okushisa aphezulu, ngokulandelana. ezingeni lokushisa eliphansi isikhathi eside kunokuyalelwa.

- Umswakama ohlobene nawo ubaluleke kakhulu, okungafanele ube ngaphezu kuka-80%, ngoba lokhu kubambezela kakhulu ukomisa futhi kungaholela nokomiswa okungaphelele kwefilimu kapende. Ngakho-ke, kuma-sealants e-PE, kuzoba nokuhlangana noma. ukuvimba i-sandpaper, ekugqokeni kwe-2K bese kuqhuma ngenxa yokusabela ngamanzi. Uma usebenzisa ukumbozwa kwezinto eziningi futhi usebenzisa uhlelo oluphelele lokulungisa, imikhiqizo kuphela evela kumkhiqizi oyedwa okufanele isetshenziswe futhi nemiyalo kufanele ilandelwe, ngoba le ukuphela kwendlela yokufeza ukusebenza okufunwayo. Uma kungenjalo, indawo ingase ibe nemibimbi. Lokhu kukhubazeka akubangelwa yikhwalithi enganele yezinto zokwakha, kodwa ngenxa yokuthi izinto ezisezingeni azivumelani. Kwezinye izimo, imibimbi ayiveli ngokushesha, kodwa kuphela ngemuva kwesikhathi esithile.

Izimbangela nokuvinjelwa kwamaphutha lapho ufaka isicelo sama-primers acc. imibala

Ukwakhiwa kwe-bubble

Izizathu:

Izizathu:

- isikhathi esifushane kakhulu somoya omncane phakathi kwezendlalelo,

- izingqimba zokuqala kakhulu

- izinsalela zamanzi ngemuva kokufaka isihlabathi emakhoneni, emaphethelweni, emajikeni,

- amanzi anzima kakhulu ukugaya,

- umoya ocindezelwe ongcolile,

- ukufingqa ngenxa yokushintshashintsha kwezinga lokushisa.

Ukuvimbela okungalungile:

- isikhathi somoya phakathi kwamajazi kufanele okungenani sibe imizuzu eyi-10 kuma-20 ° C,

- ungavumeli izinsalela zamanzi ngemuva kokumiswa kwesihlabathi, kufanele zisulwe,

- umoya ocindezelweyo kumele womile futhi uhlanzeke.

Ukulungiswa okungaphelele:

- isihlabathi ukufaka ipuleti bese uphinde ufake isicelo.

Okubi, i-acc. ukunamathela okunganele ku-substrate

Izizathu:

Izizathu:

- substrate engalungiselelwe kahle, iminonjana yegrisi, izigxivizo zeminwe, uthuli,

- ukuncibilikiswa kwento enokuncipha okungafanelekile (okungekhona okwangempela).

Ukulungiswa kwamaphutha:

- hlanza indawo kahle ngaphambi kokupenda,

- ukusetshenziswa kwezidakamizwa ezibekiwe.

Ukulungiswa okungaphelele:

- isihlabathi ukufaka ipuleti bese uphinde ufake isicelo.

Ukuqothula i-substrate

Izizathu:

Izizathu:

- umdwebo wangaphambilini ongafakwanga,

- izingqimba zikapende wakudala ziwugqinsi kakhulu.

Ukuvimbela okungalungile:

- ukuhambisana nesikhathi esimisiwe sokomisa

- ukunamathela enqunweni enamathela ukushuba

Ukulungiswa okungaphelele:

- isihlabathi ukufaka ipuleti bese uphinde ufake isicelo

Izimbangela nokuvinjelwa komshado opendwe kabili nongqimba abathathu

Ukubona

Izizathu:

Izizathu:

- inqubo engagculisi yokusebenza (umlomo wombhobho, ingcindezi),

- isikhathi esifushane kakhulu somoya omncane,

- usebenzisa okungalungile okuncane,

- indawo edwetshiwe ayikho ezingeni lokushisa elifanele (kubanda kakhulu, kufudumele kakhulu).

Ukuvimbela okungalungile:

- usebenzisa inqubo enqunyiwe yokufaka isicelo,

- usebenzisa i-thinner enqunyiwe,

- ukuqinisekisa ukushisa kwamakamelo afanele kanye nobuso okufanele bupendwe (18-20 ° C) kanye nomswakama omkhulu ongu-40-60%.

Ukulungiswa okungaphelele:

- isihlabathi phansi bese upenda futhi.

Ukuvuza

Izizathu:

Izizathu:

- i-viscosity engafanele ye-HYDRO Base,

- I-HYDRO Substrate iqine kakhulu,

- isibhamu sokufafaza esingafanelekile (umlomo wombhobho), ingcindezi,

- izinto ezibandayo kakhulu, isisekelo esiphansi kakhulu noma ithempelesha yegumbi,

- usebenzisa okunganciphisi.

Ukuvimbela okungalungile:

- ukuhambisana nemiyalelo yobuchwepheshe yokusetshenziswa,

- usebenzisa isibhamu sokufafaza esifanelekile,

- into nempahla kushiswa ekamelweni lokushisa + 20 ° C,

- usebenzisa i-diluent enqunyiwe.

Ukulungiswa okungaphelele:

- isihlabathi phansi bese upenda futhi.

Izinhlobo zemibala

Imibala e-Opaque imibala eyinhloko esetshenziswa yodwa noma exutshwe neminye imibala ukudala ama-shades amasha noma njengengubo eyisisekelo yama-shades akhethekile nemiphumela. Zivame ukusetshenziswa kakhulu ngemibala ebonakalayo, enikeza imibala e-opaque umthunzi okhanyayo ngokuya ngezidingo nemibono, ngqo ngokuxuba le mibala noma ngokusebenzisa izingqimba ezisobala ngqo kumbala opaque. Ububanzi bombhobho obunconyiwe lapho usebenzisa upende opaque ungu-0,3 mm noma ngaphezulu. Uma upende uhlanjululwe kakhulu, kungasetshenziswa umlomo wombhobho ongu-0,2 mm.

Imibala engabonakali imibala ekhanyayo enomphumela we-semi-gloss. Zingaxutshwa nezinye izinhlobo zamapende noma zifakwe ngqo kwezinye izinhlobo zamapende. Ziyahlukahluka futhi zisetshenziselwa ukufeza inani elikhulu lemiphumela. Ukuxuba nezinye izinhlobo, ungakwazi ukufeza umthunzi oyifunayo. Ngokwesibonelo. Ngokuxuba upende obala ngopende lwe-aluminium, i-metallization yanoma yimuphi umthunzi ifinyelelwa. Ukuze udale umbala ocwebezelayo ocwebezelayo, imibala ekhanyayo nemibala ye-Hot Rod (okukhulunywe ngezansi) iyaxutshwa. Imibala ekhanyayo ingase futhi yengeze i-tint encane emibaleni e-opaque, idale i-hue entsha ngokuthanda kwakho. Amapende angaxutshwa ngokuqondile ndawonye noma asetshenziswe ngendlela esobala noma e-opaque. Ububanzi bombhobho onconywayo uma usebenzisa opende abakhanyelayo bungu-0,3 mm noma ngaphezulu. Uma amapende ehlanjululwe kakhulu, i-nozzle enobubanzi obungu-0,2 mm ingasetshenziswa.

Amapende we-fluorescent translucent, imibala ye-neon enomphumela we-semi-gloss. Afuthwe kupende ongemuva omhlophe noma kungemuva elikhanyayo elidalwe ngopende opaque noma obala. Opende be-Fluorescent abazweli kancane emisebeni ye-UV evela elangeni kunopende abavamile. Ngakho-ke, badinga i-varnish enokuvikelwa kwe-UV. Ububanzi bomlomo obunconyiwe bopende be-fluorescent bungu-0,5 mm noma ngaphezulu. Ububanzi beNozzle 0,3 resp. Ungasebenzisa u-0,2 mm uma imibala ihlanjululwe kakhulu.

Pearl imibala zingasetshenziswa zodwa ngomphumela we-pearly shimmer noma neminye imibala. Ngokuxuba nemibala ekhanyayo, ungakha imibala ecwebezelayo emthunzini wakho. Asetshenziswa futhi njengamajazi ayisisekelo opende be-Candy, okuholela kumbala we-pearlescent ogqamile emithunzi ehlukahlukene. Ukwakha umphumela ocwebezelayo, upende lwe-Candy lusetshenziswa kumajazi amabili kuya kwamane ngokuqondile kupende we-pearlescent. Ububanzi bombhobho onconywayo bopende be-pearlescent bungu-0,5 mm noma ngaphezulu. Ububanzi beNozzle 0,3 resp. Ungasebenzisa u-0,2 mm uma imibala ihlanjululwe kakhulu.

Metallic esetshenziswa iyodwa noma ihlanganiswe neminye imibala. Le mibala igqama kangcono kunengemuva elimnyama (omnyama umbala o-opaque). Angasetshenziswa futhi njengejazi eliyisisekelo lamapende acacile noma amaswidi ukuze kwakheke ama-metallic shades angokwezifiso adalwe ngokufaka amajazi amabili kuya kwamane opende ocacile/oswindi ngqo ku-metallic. Ububanzi bomlomo obunconywayo bopende bensimbi bungu-0,5 mm noma ngaphezulu. Ububanzi beNozzle 0,3 resp. Ungasebenzisa u-0,2 mm uma imibala ihlanjululwe kakhulu.

Imibala yemvula zingasetshenziswa ngokwazo ukuze zenze umphumela we-rainbow ocashile obangela ukushintsha kombala lapho kuvezwe ekukhanyeni, noma njengesisekelo sezinye izinhlobo zemibala. Zivame ukusetshenziswa njengejazi lesisekelo semibala ecacile noma ye-candy, abangakha ngayo imibala yabo yomphumela we-rainbow (ngokusebenzisa amajazi amabili kuya kwamane ombala ocacile/uswidi ngqo kumbala wothingo). Ububanzi bombhobho onconywayo wemibala yothingo ngu-0,5 mm noma ngaphezulu. Ububanzi beNozzle 0,3 resp. Ungasebenzisa u-0,2 mm uma imibala ihlanjululwe kakhulu.

Imibala ye-Hi-Lite zingasetshenziswa ngokumelene nanoma yisiphi isizinda esinemibala ukufeza umphumela ohlukile wokukhulisa umbala. Zenzelwe ukuthi zisetshenziswe ngamanani amancane ngejazi elilodwa kuya kwamathathu. Umphumela wokushintsha umbala awubonakali kangako emibala ye-Hi-Lite kunasechungechungeni lwe-emerald. Imibala ye-Hi-Lite ikulungele ukudala umphumela ogqamile wokugqamisa obonakala kahle emini noma ekukhanyeni okuqondile okufakelwayo. Imibala ingaxubaniswa ngqo nemibala ebonakalayo. Ngenxa yalokhu, umbala uzoshintsha kalula. Ukuxuba ngokweqile imibala kuzolahlekelwa yilo mphumela futhi imibala izothatha umphumela wobisi we-pastel. Imibala ye-Hi-Lite ivelele kahle uma iqhathaniswa nezizinda ezimnyama ezifana nomnyama opaque. Ububanzi bombhobho obunconyiwe bopende be-Hi-Lite ngu-0,5 mm noma ngaphezulu. Nozzle ubukhulu 0,3 resp. Ungasebenzisa u-0,2 mm uma imibala ihlanjululwe kakhulu.

Imibala ye-Emerald Lawa ngopende abane-pigment ekhethekile esebenza ngesisekelo sama-engeli ekhefu, okuholela ekuguqukeni okuqinile emthunzini wombala. Imibala ye-Emerald ishintsha umbala wayo ngokuphawulekayo kuye nge-angle yokukhanyisa. Le mibala ivelele kahle uma iqhathaniswa nesizinda esimnyama (omnyama opaque). Lo mthunzi wenziwa ngokusebenzisa eyodwa noma amabili amajazi amancane ompende wesisekelo esimnyama alandelwe amajazi amabili kuya kwamane opende we-emerald. Ukuncipha kwalolu pende akunconyiwe, kepha uma kunesidingo, ukuncipha kufakwa kuphela ngemithamo emincane ukugwema ukuncipha kwepende ngokweqile. Ububanzi bombhobho obunconyiwe be-Emerald Paint bungu-0,5 mm noma ngaphezulu.

Imibala ikhanya kukhona amapende ane-pigment ekhethekile esebenza ngesisekelo se-engeli yokuphumula, okuholela ekushintsheni okunamandla emthunzini wombala. Ukushintsha kombala kwale mibala kuyashelela futhi kubonakala ngokucacile ngisho nasekukhanyeni okuphansi, futhi umphumela ubonakala nakakhulu ezintweni ezingalingani ezinama-crease abukhali. Imibala egqamile igqama kangcono kunengemuva elimnyama (umbala ongemuva omnyama). Umphumela ofisa ukuwufeza utholakala ngokusebenzisa ijazi elilodwa kuya kwamabili amancane kapende wesisekelo omnyama namajazi amabili kuya kwamane opende we-Flair. Ukunciphisa lawa kapende akunconywa, kodwa engeza omncane kuphela ngamanani amancane uma kunesidingo ukuze ugweme ukunciphisa kakhulu upende. Ububanzi bomlomo obunconyiwe be-Emerald Paints bungu-0,5 mm noma ngaphezulu.

Imibala ekhazimulayo le yimibala enokucwebezela okuncane. Usayizi wezinhlayiyana zawo mncane kunopende we-Hot Rod. Le mibala iyakhanya ngokubonakala okucwebezelayo. Zigqame kakhulu ngokuqhathanisa nesizinda esimnyama (umbala ongemuva omnyama). Ukufaka amajazi ama-black primer owodwa kuya kwamabili nezingubo ezimbili kuya kwezine zepende le-glitter kuzofeza umphumela oyifunayo. Ububanzi bombhobho obunconyiwe bamapende akhazimulayo ngu-0,5 mm noma ngaphezulu. Nozzle ubukhulu 0,3 resp. Ungasebenzisa u-0,2 mm uma imibala ihlanjululwe kakhulu.

Imibala ye-cosmic lena imibala enomphumela we-stardust emihle. Usayizi wabo wezinhlayiyana mncane kunopende we-Hot Rod. Le mibala iyashintshashintsha futhi ibukeka njenge-semi-gloss. Zigqama kakhulu uma kuqhathaniswa nengemuva elimnyama (umbala ongemuva omnyama). Umphumela ofisa ukuwufezwa ngokufaka ijazi elilodwa kuya kwamabili amancane kapende wesisekelo omnyama namajazi amabili kuya kwamane opende we-Cosmic. Ukuze kuzuzwe umbala ocwebezelayo, imibala ye-Cosmic ixutshwa nemibala ecacile noma ye-candy. Ukuze upende upende ovelayo, amajazi amabili kuya kwamahlanu anoma yimuphi upende osobala kufanele asetshenziswe kusisekelo sikapende we-Cosmic. Imibala yesikhala nayo ingaxutshwa nomunye ukuze kuzuzwe umphumela wombala ogqamile. Ungasebenzisa futhi umphumela wazo ocwazimulayo futhi usebenzise ku-substrate yanoma yimuphi umbala opaque. Ububanzi bomlomo obunconyiwe bopende be-Cosmic bungu-0,5 mm noma ngaphezulu. Ububanzi beNozzle 0,3 resp. Ungasebenzisa u-0,2 mm uma imibala ihlanjululwe kakhulu.

Hotrod upenda bavuselela okubizwa nge- "Retro colours" yezimoto ezingama- 50-60. iminyaka, kwakheka umphumela ocwebezelayo ocwebezelayo ovuthayo futhi ocwebezelayo ngokukhanya okuqondile. Le mibala ivelele kahle uma iqhathaniswa nesizinda esimnyama (umbala ongemuva omnyama). Umphumela owufunayo utholakala ngokusebenzisa ijazi elilodwa noma amabili amancane kapende omnyama olandelwa amajazi amabili kuya kwamane kapende kaHot Rod. Ukufeza ukukhanya, imibala ye-Hot Rod kufanele ixutshwe ngqo nopende ocacile noma woswidi. Ukuthinta upende ovelayo, faka eyodwa kumajazi amane anoma yimuphi upende ocacile kusisekelo se-Hot Rod. Imibala ye-Hot Rod nayo ingaxubaniswa nomunye nomphumela wombala ogqame kakhudlwana. Ububanzi bombhobho obunconyiwe ngopende we-Hot Rod ungama-0,5 mm noma ngaphezulu. Nozzle ubukhulu 0,3 resp. Ungasebenzisa u-0,2 mm uma imibala ihlanjululwe kakhulu.

Imibala yamaswidi ngopende obunjiwe obuphezulu obucwebezelayo, okuthi, noma ngemuva kokumiswa okuphelele, kubukeke njengopende osanda kufuthwa (umphumela ogcwele ocwebezelayo uvele kuphela ngemuva kokuthi kufakwe ungqimba ophezulu). Yize imibala ye-Candy isetshenziswa njengesisekelo sokuqala, yehluka ngezindlela eziningi kusuka kumbala wesisekelo wakudala. Upende wamaswidi ngaphandle kwe-varnish uthinteka kakhulu ekulimaleni futhi akumele uboshwe ngqo (kufanele omile ngokuphelele futhi upende ngaphambi kokufihla ubuso). Uma usebenzisa upende weCandy kuyadingeka ukufaka ijazi eliphezulu ngokushesha okukhulu, njengoba livikela upende ezintweni ezingcolile kanye nasezigxivizelweni zeminwe, okuyinto le penti ethinteka kakhulu kuyo. Lapho ufafaza izindawo ezinkulu, kunconywa ukuxuba upende wamaCandy ngesisekelo esibonakalayo ngenxa yokugxila kwawo okuphezulu. Kuyadingeka ukuthi upende lome ngokuphelele, emoyeni ovulekile kungathatha amahora ambalwa. Ububanzi bombhobho obunconyiwe bopende bamaPipi bungu-0,5 mm noma ngaphezulu. Nozzle ubukhulu 0,3 resp. Uma imibala ihlanjululwe kakhulu, kungasetshenziswa u-0 mm.

Umbala we-Aluminium itholakala ngamabanga amathathu ahlukene kuye ngosayizi wokusanhlamvu: kuhle, okuphakathi, okumahhadlahhadla. Ibonakalisa kakhulu futhi ihloselwe ikakhulukazi njengesisekelo sezimbali zikaswidi. Ingasetshenziswa iyodwa ukudala i-aluminium noma i-metallic effect, noma njengejazi eliyisisekelo lamapende abonisa ngale ukuze kwakheke noma yimuphi umthunzi onomphumela okhanyayo. Okunye okungenziwa wukufafaza izinhlobo ezahlukene zopende be-aluminium (abacolile, abaphakathi, abamahhadla) bese usebenzisa noma yimuphi upende weCandy. Umphumela uba upende ocwebezelayo onenguquko phakathi kwezinhlamvu ze-aluminium ezinosayizi abahlukene. Upende we-aluminium umboza kahle futhi ijazi elilodwa ngokuvamile lanele kuwo wonke umdwebo. Ububanzi bomlomo obunconyiwe bopende be-aluminium bungu-0,5 mm noma ngaphezulu. Ububanzi beNozzle 0,3 resp. Ungasebenzisa u-0,2 mm uma imibala ihlanjululwe kakhulu.

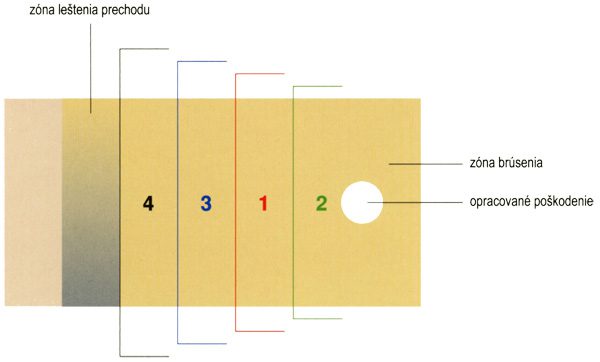

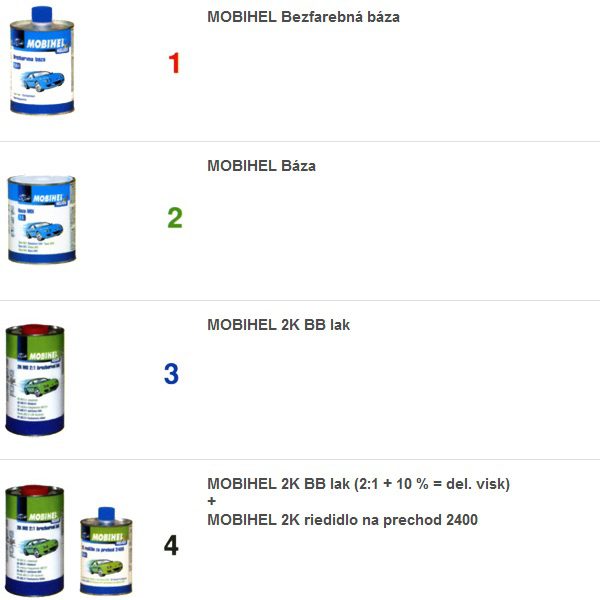

Futha umdwebo

Izikhathi zokushesha zamanje ziphoqa abanikazi bezimoto ukuthi basebenzise ngokugcwele abalingani babo bezimoto futhi bazisebenzise ngokugcwele. Futhi kwandisa ingcindezi izinga lokulungisa, kuhlanganise ukudweba. Uma lokhu kungumonakalo omncane, kusetshenziselwa ukunciphisa isikhathi nokunciphisa izindleko zalokho okubizwa ngokuthi ukulungiswa okuyingxenye yokudweba - spray. Kunezinkampani ezikhethekile emakethe ezithuthukise izinhlelo ezikuvumela ukuthi usebenze ngale ndlela.

Lapho sipenda iBase, sibhekene nezinkinga ezintathu:

- Ukuphambuka komthunzi wesisekelo esisha ngokuhlobene nokugqoka kwangempela - kuthinteka cishe zonke izici: izinga lokushisa, i-viscosity, ingcindezi, ukushuba kwezingqimba, njll.

- Ukuvela kochungechunge olulula lwesisekelo ezingxenyeni lapho sifutha khona (i-powder) bese sizama ukudala isifutho.

- Ukuhlanganisa upende omusha ocacile nopende omdala, ongalimele.

Le nkinga imvamisa ingagwenywa ngokulandela imiyalo yokulungiswa kwendawo efanele ngaphambi kokupenda nokusebenzisa izinto ezihloselwe ukudweba okunjalo.

Futha isikimu sokupenda

Ukulungisa umzimba

Ukulungiswa komzimba ngendlela ye-PDR (ngaphandle kokudweba imidwebo)

Usebenzisa indlela ye-PDR, kungenzeka ukuvumelanisa amakhaza wezitho zomzimba wensimbi nomonakalo omncane obangelwe yisibonelo, ukwethuka ngenkathi kupakwa, omunye umnyango wemoto, ukucekelwa phansi kwempahla, isichotho, njll. lungisa lo monakalo ngezindleko eziphansi, kodwa ngaphezu kwakho konke ukugcina upende wokuqala nopende ngaphandle kwesidingo sokufaka isihlabathi, ukuhlaba usayizi nokupenda kabusha kwendawo eyonakele.

Umsuka wendlela ye-PDR ihlehlela emuva eminyakeni yama-80s, lapho uchwepheshe weFerrari alimaza umnyango wenye yamamodeli akhiqizwayo futhi engenayo imali edingekayo yokulungiswa okulandelayo. Ngakho-ke, wazama ukubuyisa umnyango ngokukhama ishidi nge-lever yensimbi. Wabe esesebenzisa le ndlela kaningana futhi ngaleyo ndlela wayithuthukisa waze wabona ukuthi kungenzeka ukuthi kube khona okuzenzekelayo, ngokulandelana. Ukusetshenziswa kabanzi kwale ndlela futhi wanquma ukuya e-United States futhi asebenzise lobu buchwepheshe ukuthola imali, kanti ngasikhathi sinye ayibe nelungelo lobunikazi. Kuphela eminyakeni engamashumi amabili eyalandela lapho le ndlela yasakazekela ezwenikazi laseYurophu, lapho, njengaseMelika, yaba nempumelelo enkulu futhi yasetshenziswa kabanzi kakhulu.

Преимущества:

- Ukugcina upende wangempela, ungenawo ama-putty, ama-aerosol nokunye, kubaluleke kakhulu, ikakhulukazi ezimotweni ezintsha nezintsha. Isizathu sisobala: ezimweni eziningi kungenzeka ukugcina upende wangempela kusuka efektri ngaphambi kokufafaza, okubaluleke kakhulu ezimotweni ezintsha, ezingakathengiswa.

- Ukwehliswa okuphawulekayo kwesikhathi sokulungisa, uma kuqhathaniswa nomdwebo ojwayelekile, le ndlela yokulungisa yenziwa kaningana ngokushesha.

- Izindleko Zokulungisa Ezincishisiwe - Isikhathi esincane esichithwa ukulungiswa kanye nezinto ezimbalwa ezisetshenzisiwe kunciphisa izindleko zokulungisa.

- Ngemuva kokulungiswa, ngeke kube khona imikhondo esele - ngemva kokuqedwa kokulungiswa okunjalo, ubuso bengxenye buyoba njengento entsha.

- Ayikho i-sealant esetshenzisiwe, ngakho-ke indawo ezolungiswa iyamelana nezinye izingxenye zengxenye emithwalweni ehlukahlukene, ngaphandle kwengozi yokuqhekeka kwe-sealant.

- Ithuba lokwenza ukulungiswa ngqo endaweni yekhasimende. Njengoba ukulungiswa kudinga kakhulu izandla ezinekhono zomakhenikha kanye namathuluzi ambalwa, indawo eyonakele ingalungiswa cishe noma kuphi nanoma yisiphi isikhathi.

Inqubo yokulungisa

Inqubo yokulungisa isuselwa ekukhipheni kancane kancane insimbi eshisiwe ngaphakathi komzimba ngaphandle kokulimaza umsebenzi wokupenda. Uchwepheshe uqapha ingaphezulu lomzimba wemoto ekukhanyeni kwesibani sokulungisa. Ukungahambi kahle komhlaba kuhlanekezela ukukhanya, ngakho uchwepheshe anganquma indawo ngqo nezinga lokuchichima. Ukuphrinta uqobo kwenzeka kancane kancane, kudinga ikhono nokusetshenziswa kwamathuluzi akhethekile namadivayisi wezimo ezahlukahlukene.