Isikhathi sokujova isibaseli kusengaphambili

Okuqukethwe

- Inhloso yedivayisi yomjovo kusengaphambili

- Ukucindezela kwesilinda

- Idizayini yedivayisi ethuthukisiwe yomjovo

- Umgomo wokusebenza komjovo kusengaphambili idivayisi

- Ubukhulu bedivayisi yomjovo kusengaphambili

- Iphampu yomjovo kasayizi ongu-M

- Usayizi wephampu yomjovo A

- Iphampu yomjovo kasayizi we-WM

- Iphampu yomjovo wosayizi we-P

Izinqubo ezibaluleke kakhulu zokuthuthukisa ukusebenza kwenjini ye-diesel yilezi:

- ubuthi obuphansi begesi yokukhipha;

- izinga eliphansi lomsindo wenqubo yomlilo;

- ukusetshenziswa kukaphethiloli othize okuphansi.

Isikhathi lapho iphampu yomjovo iqala ukunikeza uphethiloli ibizwa ngokuthi ukuqala kokunikezwa (noma ukuvala isiteshi). Leli phuzu ngesikhathi likhethwa ngokuya kwesikhathi sokulibaziseka kwamandla (noma nje ukubambezeleka kokukhanyisa). Lawa amapharamitha aguquguqukayo ancike kumodi ethile yokusebenza. Isikhathi sokulibaziseka komjovo sichazwa njengenkathi ephakathi kokuqala kokunikezwa kanye nokuqala komjovo, futhi isikhathi sokulibaziseka sokuthungela sichazwa njengenkathi ephakathi kokuqala komjovo nokuqala kokusha. Ukuqala komjovo kuchazwa njenge-engeli yokuzungezisa i-crankshaft esifundeni se-TDC lapho umjovo ejova khona uphethiloli egumbini elivuthayo.

Ukuqala kokusha kuchazwa njengesikhathi sokuthungela sengxube yomoya/yamafutha, engathinteka ngokuqala komjovo. Kumaphampu kaphethiloli anengcindezi ephezulu, kungcono ukulungisa ukuqala kokunikezwa (ukuvalwa kwesiteshi) kuye ngenani lama-revolution kusetshenziswa idivayisi engaphambi komjovo.

Inhloso yedivayisi yomjovo kusengaphambili

Njengoba idivayisi ethuthukisiwe yomjovo ishintsha ngokuqondile isikhathi sokuqala komjovo, ingachazwa njengesilawuli sokuqala komjovo. Idivayisi ethuthukisiwe yomjovo wohlobo lwe-eccentric (ebuye ibizwe ngokuthi i-injection advance clutch) iguqula i-torque yenjini enikezwe iphampu yomjovo, kuyilapho yenza imisebenzi yayo yokulawula. I-torque edingwa yiphampu yomjovo incike kusayizi wephampu yomjovo, inani lamapheya episton, inani likaphethiloli elijovwe, ingcindezi yomjovo, ububanzi be-plunger kanye nokuma kwekhamera. Iqiniso lokuthi i-torque yenjini inomthelela oqondile ekusebenzeni kwesikhathi komjovo kumele licatshangelwe ekwakhiweni kanye nokuphuma kwamandla okungaba khona.

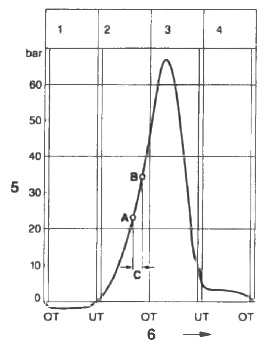

Ukucindezela kwesilinda

Ilayisi. Ukucindezela kwethangi: A. Ukuqala komjovo; B. Ukuqala kokusha; C. Ukubambezeleka komlilo. 1. Umjaho oyisingeniso; 2. Ukucindezelwa unhlangothi; 3. Umsebenzi womsebenzi; 4. Khipha i-OT-TDC, UT-NMT; 5. Ukucindezela kusilinda, ibha; 6. Isikhundla sepiston.

Idizayini yedivayisi ethuthukisiwe yomjovo

Idivayisi yomjovo yangaphambi kwesikhathi yepompo yomjovo ekulayini igxunyekwe ngqo ekugcineni kwe-camshaft yepompo yomjovo. Kunomehluko obalulekile phakathi kwamadivayisi athuthukisiwe omjovo wohlobo oluvulekile noluvaliwe.

Idivayisi yohlobo oluvaliwe lomjovo olungaphambili lunendawo yalo yokugcina uwoyela wokugcoba, okwenza idivayisi izimele ohlelweni lokugcotshwa kwenjini. Umklamo ovulekile uxhumeke ngokuqondile ohlelweni lokugcotshwa kwenjini. Umzimba wedivayisi unamathiselwe ku-gearbox ngezikulufo, futhi ama-eccentrics anxephezela futhi alungisayo afakwa emzimbeni ukuze ajikeleze ngokukhululeka. I-eccentric yesinxephezelo nokulungiswa iqondiswa iphinikhodi exhunywe ngokuqinile emzimbeni. Ngaphezu kokushibhile, uhlobo "oluvulekile" lunenzuzo yokudinga indawo encane futhi lugcoba kahle kakhulu.

Umgomo wokusebenza komjovo kusengaphambili idivayisi

Umshini osetshenziswa ngaphambili womjovo ushayelwa isitimela segiya esifakwe endaweni yokubeka isikhathi injini. Uxhumano phakathi kokokufaka nokuphumayo kwedrayivu (ihabhu) lwenziwa ngamapheya ezinto ze-eccentric ezihlanganisiwe.

Okukhulu kunawo wonke, ama-eccentrics alungisayo (4), atholakala emigodini ye-stop disc (8), yona ejikijelwa kusici sedrayivu (1). Izingxenye ze-eccentric ezinxephezelayo (5) zifakwe ku-eccentrics elungisayo (4) futhi iqondiswa yizo kanye nebhawodi kumahabhu (6). Ngakolunye uhlangothi, i-hub bolt ixhunywe ngqo kuhabhu (2). Izisindo (7) zixhunywe ku-eccentric elungisayo futhi zibanjwe endaweni yazo yasekuqaleni yimithombo yokuqina okuguquguqukayo.

Ilayisi a) endaweni yokuqala; b) isivinini esiphansi; c) isilinganiso sokushintshwa; d) indawo yokugcina ngesivinini esiphezulu; a i-engeli engaphambili yomjovo.

Ubukhulu bedivayisi yomjovo kusengaphambili

Usayizi wedivayisi ethuthukisiwe yomjovo, enqunywa ububanzi obungaphandle nokujula, futhi inquma isisindo sezisindo ezifakiwe, ibanga phakathi kwezikhungo zamandla adonsela phansi kanye nendlela engenzeka yokunyakaza kwezisindo. Lezi zici ezintathu futhi zinquma ukuphuma kwamandla nokusebenza.

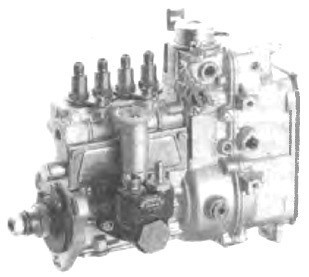

Iphampu yomjovo kasayizi ongu-M

Ilayisi. Iphampu yomjovo kasayizi ongu-M

Ilayisi. 1. Ivalvu yokuphepha; 2. Umkhono ; 7 i-camshaft; 8. Kam.

Iphampu yomjovo wosayizi ongu-M iphampu encane kakhulu kulayini wamaphampu omjovo osemgqeni. Inomzimba we-alloy okhanyayo futhi ifakwe nge-flange enjinini. Ukufinyelela ngaphakathi kwepompo kungenzeka ngemva kokususwa kwe-base plate kanye nesembozo eseceleni, ngakho-ke usayizi wepompo we-M uchazwa njengepompo yomjovo evulekile. Ingcindezi yomjovo ephezulu ikhawulelwe kumabha angama-400.

Ngemva kokukhipha isembozo eseceleni sepompo, inani likaphethiloli elihlinzekwa amapheya e-plunger lingalungiswa futhi libekwe ezingeni elifanayo. Ukulungiswa komuntu ngamunye kwenziwa ngokuhambisa izingxenye zokubopha ku-control rod (4).

Ngesikhathi sokusebenza, ukufakwa kwama-plunger wepompo futhi, kanye nawo, inani likaphethiloli elinikeziwe lilawulwa yinduku yokulawula ngaphakathi kwemingcele enqunywe ukuklama kwepompo. Induku yepompo yomjovo ongu-M iyinduku yensimbi eyindilinga eneflethi, lapho kufakwa khona izinsimbi ezifakwayo (5). Izinsimbi (3) zixhunywe ngokuqinile kumkhono wokulawula ngamunye, futhi induku egobile ekugcineni kwayo ingena emseleni wesibambi senduku yokulawula. Lo mklamo waziwa ngokuthi i-lever control.

Ama-plunger epompo yomjovo axhumene ngqo nama-roller tappets (6), futhi i-stroke ilungiswa kuqala ngokukhetha amarola anobubanzi obufanele be-tappet.

Ukugcoba kwepompo yomjovo kasayizi M kwenziwa ngokunikezwa okujwayelekile kwamafutha enjini. Amaphampu omjovo kasayizi we-M atholakala ngamapheya e-piston angu-4,5 noma angu-6 (amaphampu omjovo angu-4-, 5- noma angu-6-cylinder) futhi aklanyelwe uphethiloli wedizili kuphela.

Usayizi wephampu yomjovo A

Ilayisi. Usayizi A Iphampu yomjovo

Amaphampu omjovo we-in-line A-frame anebanga elibanzi lokulethwa alandela ngokuqondile iphampu yomjovo we-M-frame. Le furemu futhi ine-alloy casing ekhanyayo futhi ingafakwa kumotho ene-flange noma uhlaka. Iphampu yomjovo yoHlobo A iphinde ibe nomklamo “ovulekile”, futhi amalayini epompo yomjovo (2) afakwa ngokuqondile ukusuka phezulu endlini ye-aluminium, kuyilapho ukuhlanganiswa kwe-wastegate (1) kucindezela ku-casing yepompo yomjovo kusetshenziswa isibambi sevalvu. Ingcindezi yokuvala, ephakeme kakhulu kunomfutho wokuhlinzeka ngamanzi, kufanele imuncwe yindlu yephampu yomjovo. Ngalesi sizathu, ingcindezi yomjovo ephezulu ikhawulelwe kumabha angama-600.

Ngokungafani nephampu yomjovo yohlobo lwe-M, iphampu yomjovo yohlobo lwe-A ifakwe isikulufu sokulungisa (enenadi lokukhiya) (7) kuthephu yerola ngayinye (8) ukuze kulungiswe i-prestroke.

Ukuze ulungise inani likaphethiloli olethwa isitimela sokulawula (4), iphampu yomjovo yohlobo lwe-A, ngokungafani nephampu yomjovo wohlobo lwe-M, ifakwe isilawuli segiya, hhayi i-lever. Ingxenye enamazinyo egxilwe kumkhono wokulawula (5) we-plunger isebenzisana nerack yokulawula futhi ukuze ulungise amapheya ama-plunger emthonjeni ofanayo, kuyadingeka ukukhulula izikulufu ezihleliwe bese uphendulela umkhono wokulawula uhambe newashi ngokuhlobene ingxenye enamazinyo futhi ngaleyo ndlela ihlobene nesitimela sokulawula.

Wonke umsebenzi wokulungisa lolu hlobo lwepompo lomjovo kufanele wenziwe ngepompo efakwe phezu kokusekelwa kanye ne-casing evulekile. Njengephampu yomjovo we-M, iphampu yomjovo yoHlobo A inesembozo eseceleni esilayishwe intwasahlobo okufanele isuswe ukuze kufinyelelwe ngaphakathi kwephampu yomjovo.

Ukuze kugcotshwe, iphampu yomjovo ixhunywe ohlelweni lokugcoba injini. I-high pressure fuel futha uhlobo A luyatholakala ngezinguqulo ezifika kumasilinda ayi-12 futhi, ngokungafani ne-high pressure fuel futha uhlobo lwe-M, ilungele ukusebenza ngezinhlobo ezahlukene zikaphethiloli (hhayi udizili kuphela).

Iphampu yomjovo kasayizi we-WM

Ilayisi. Usayizi we-HPFP WM

Iphampu yomjovo we-MW ekumugqa we-in-line yakhelwe ukuhlangabezana nemfuneko yengcindezi ephezulu. Iphampu yomjovo we-MW iwuhlobo oluvaliwe lomjovo wephampu ekulayini enengcindezi yomjovo ephezulu ekhawulelwe kumabha angama-900. Iphinde ibe nomzimba we-alloy okhanyayo futhi ixhunywe enjinini ngohlaka, isisekelo esiyisicaba noma i-flange.

Idizayini yephampu yomjovo we-MW ihluke ngokuphawulekayo ekuklanyweni kwamaphampu omjovo angu-A no-M. Umehluko omkhulu ukusetshenziswa kwepheya lama-plunger, okuhlanganisa ibhushi (3), ivalvu yokukhipha kanye nesibambi sevalvu yokukhipha. Ifakwa ngaphandle kwenjini futhi ishuthekwa phezulu endaweni yephampu yomjovo. Empompini yomjovo we-MW, isibambi sevalvu yokucindezela sijikijelwa ngqo esihlahleni esiphumela phezulu. I-pre-stroke ilawulwa amashimu afakwa phakathi komzimba nomkhono ngokuhlangana kwevalvu. Ukulungiswa kokunikezwa okufanayo kwamapheya e-plunger ngamanye kwenziwa ngaphandle kwepompo yomjovo ngokuphendula amapheya e-plunger. Ama-piston flange afakwayo (1) ahlinzekwa ngezikhala zale njongo.

Ilayisi. 1. I-Flange yokubopha ama-plungers; 2. Ivalvu yokuphepha; 3. Umkhono ; 4. Plunger; 5. Umzila wesitimela; 6. Lawula umkhono; 7. I-roller pusher; 8 i-camshaft; 9. Kam.

Indawo yephampu yepompo yomjovo ihlala ingashintshile lapho ukuhlangana komkhono nevalvu yokukhipha (2) kuzungeziswa. Iphampu yomjovo we-MW iyatholakala ngezinguqulo ezinemikhono eyi-8 (amasilinda ayi-8) futhi ilungele izindlela zokukhweza ezahlukahlukene. Isebenzisa udizili futhi igcotshwa nge-lubrication system yenjini.

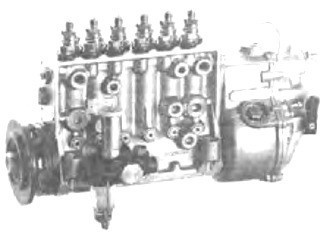

Iphampu yomjovo wosayizi we-P

Ilayisi. Iphampu yomjovo wosayizi we-P

Ilayisi. 1. Ivalvu yokuphepha; 2. Umkhono ; 3. Ukulawula ukudonsa; 4. Lawula umkhono; 5. I-roller pusher; 6 i-camshaft; 7. Ikhamera.

Usayizi we-P (uhlobo) wephampu yomjovo osemugqeni nawo uklanyelwe ukunikeza ingcindezi ephezulu yomjovo. Njengephampu yomjovo we-MW, lena ipompo yohlobo oluvaliwe exhunywe enjinini ngesisekelo noma i-flange. Endabeni yamaphampu omjovo wohlobo lwe-P, aklanyelwe ukucindezela komjovo ophakeme webha engu-850, umkhono (2) ufakwa kumkhono we-flange, osevele ucushwe umbambi wevalvu yokukhipha (1). Ngale nguqulo yokufakwa kwemikhono, amandla okuvala awalayishi isikhwama sepompo. I-pre-stroke isethwe ngendlela efanayo neyephampu yomjovo we-MW.

Amaphampu kaphethiloli omfutho we-in-line aklanyelwe ukucindezela komjovo ophansi asebenzisa ukugcwaliswa okuvamile kolayini kaphethiloli. Kulokhu, uphethiloli udlula emigqeni kaphethiloli ye-bushings ngayinye ngokulandelana futhi ibheke ku-axis longitudinal yepompo yomjovo. Uphethiloli ungena kulayini bese uphuma ngesistimu yokubuyisela uphethiloli.

Ukuthatha iphampu yomjovo wenguqulo ye-P8000 njengesibonelo, elinganiselwe ukucindezela komjovo kuze kufike kubha ye-1150 (uhlangothi lwepompo lomjovo), le ndlela yokugcwalisa ingabangela umehluko omkhulu wokushisa kukaphethiloli (kufika ku-40 ° C) ngaphakathi kwephampu yomjovo phakathi ipayipi lokuqala nelokugcina. Njengoba ukuminyana kwamandla kaphethiloli kuncipha ngokukhuphuka kwezinga lokushisa likaphethiloli futhi ngenxa yalokho ngokwevolumu ekhuphukayo, lokhu kuzoholela emananini ahlukene wamandla ajovwe emagumbini avuthayo enjini. Kulokhu, amaphampu kaphethiloli anjalo aphezulu asebenzisa ukugcwaliswa okuphambene, okungukuthi, indlela lapho imigqa yamafutha e-hoses ngayinye ihlukaniswa komunye nomunye ngokusebenzisa izimbobo zokudonsa).

Le futha yomjovo iphinde ixhunywe ohlelweni lokugcoba injini ukuze igcobe. Iphampu kaphethiloli yohlobo lwe-P high iyatholakala futhi ngezinguqulo ezinama-liner afinyelela kwangu-12 (amasilinda) futhi ilungele kokubili udizili namanye amafutha.