Iphampu yokuqondisa amandla - ukuklama, izinhlobo, isimiso sokusebenza

Okuqukethwe

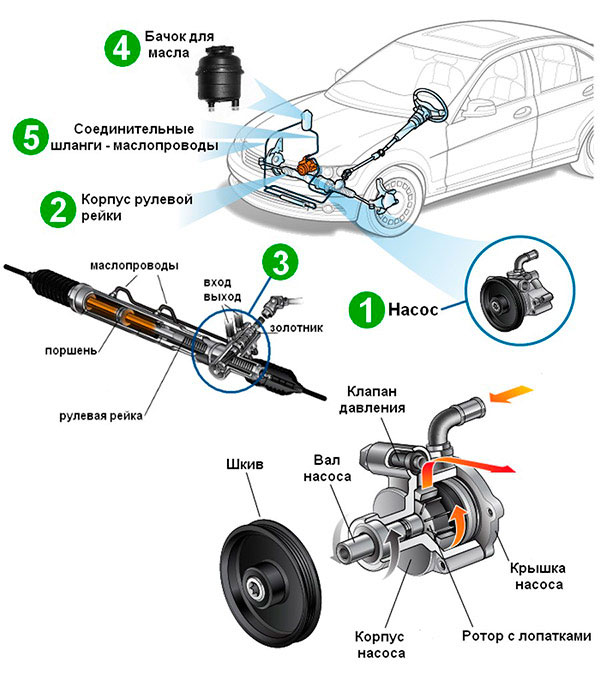

Iziqondiso zamandla ziyaqhubeka nokuthatha indawo yazo ngokuqinile ezinhlotsheni eziningi zezimoto namamodeli ngamanye ezimoto zabagibeli. I-node yabo eyinhloko yiphampu, eguqula amandla enjini abe yingcindezi ephezulu yoketshezi olusebenzayo. Umklamo usungulwe kahle futhi ufakazelwe, osivumela ukuba sicabangele ngokuningiliziwe esimweni esivamile.

Imisebenzi eyenziwe kanye nesicelo

Ngokwemvelo yayo, ipompo ye-hydraulic inikeza amandla ku-actuator ngendlela yokujikeleza koketshezi olusebenzayo lwesistimu - amafutha akhethekile, ngaphansi kwengcindezi ephezulu. Umsebenzi owenziwe unqunywa ubukhulu balokhu kucindezela kanye nezinga lokugeleza. Ngakho-ke, i-rotor yepompo kufanele ijikeleze ngokushesha ngokwanele, kuyilapho ihambisa amavolumu abalulekile ngesikhathi seyunithi.

Ukwehluleka kwephampu akufanele kuholele ekumisweni kwesiteringi, amasondo asengaphenduka, kodwa amandla esiteringini azokhuphuka kakhulu, okungamangaza umshayeli. Ngakho-ke izidingo eziphakeme zokuthembeka nokuqina, okuhlangatshezwana nazo ngenxa yedizayini efakazelwe, indlela yomjovo ekhethiwe kanye nezakhiwo ezinhle zokugcoba zoketshezi olusebenzayo.

Izinketho zokubulala

Azikho izinhlobo eziningi zamaphampu asebenza ngogesi; njengomphumela wokuziphendukela kwemvelo, kwasala amapuleti namagiya kuphela. Eyokuqala isetshenziswa kakhulu. Ukulungiswa kwengcindezi akuvamile ukunikezwa, asikho isidingo esithile salokhu, ukuba khona kwe-valve yokunciphisa ingcindezi kwanele ngokwanele.

Esiteringini samandla sakudala, idrayivu yemishini ye-pump rotor isetshenziswa kusuka ku-crankshaft pulley yenjini kusetshenziswa idrayivu yebhande. Amasistimu we-electro-hydraulic athuthuke kakhulu kuphela asebenzisa idrayivu yemoto kagesi, enikeza izinzuzo ekulawuleni ukunemba, kodwa encisha inzuzo eyinhloko yama-hydraulics - ukukhulisa amandla aphezulu.

Idizayini yepompo evamile kakhulu

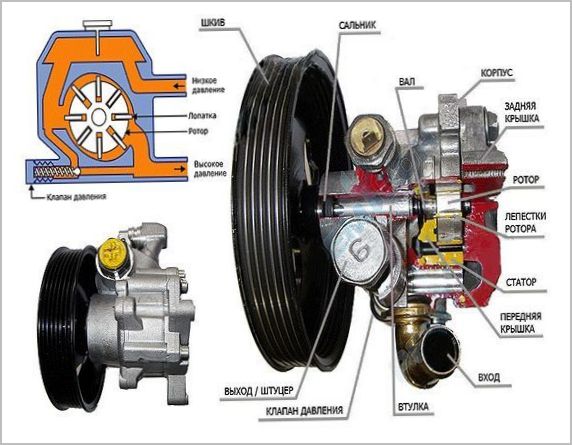

Umshini wohlobo lwe-vane usebenza ngokuhambisa uketshezi ngamavolumu amancane ngokuncipha kwawo enqubweni yokuphendula i-rotor nokukhama uwoyela epayipini lokuphuma. Iphampu iqukethe izingxenye ezilandelayo:

- shayela i-pulley ku-rotor shaft;

- i-rotor enama-lamellar blades emiseleni eduze komjikelezo;

- amabhodi kanye nezigxivizo zebhokisi ze-shaft endlini;

- i-stator enezimbotshana eziyi-elliptical kumthamo wezindlu;

- i-valve elawula imingcele;

- izindlu ezinezimbobo zenjini.

Imvamisa, i-rotor isebenzisa imigodi emibili yokusebenza, okunikeza ukwanda kokukhiqiza ngenkathi igcina ukwakheka okuhlangene. Zombili ziyafana ngokuphelele futhi zitholakala ngokuphambana ngokulingana ne-eksisi yokuzungezisa.

Ukuhleleka komsebenzi kanye nokusebenzisana kwezingxenye

Ibhande le-V noma ibhande ledrayivu elinezimbambo eziningi lizungeza i-rotor shaft pulley. I-rotor etshalwe kuyo ifakwe izikhala lapho amapuleti ensimbi ahamba ngokukhululeka. Ngesenzo samandla e-centrifugal, ahlala ecindezelwa ngokumelene ne-elliptical surface yangaphakathi ye-stator cavity.

I-liquid ingena emigodini phakathi kwamapuleti, emva kwalokho iqhubekela phambili lapho iphuma khona, lapho isuswa khona ngenxa yevolumu eguquguqukayo yemigodi. Egijima ezindongeni ezigobile ze-stator, ama-blades aphinde abuyele ku-rotor, emva kwalokho aphinde abekwe phambili, athathe izingxenye ezilandelayo zoketshezi.

Ngenxa yejubane eliphezulu lokujikeleza, iphampu inokusebenza okwanele, ngenkathi ithuthukisa ukucindezela okungaba ngu-100 bar lapho isebenza "ukuma".

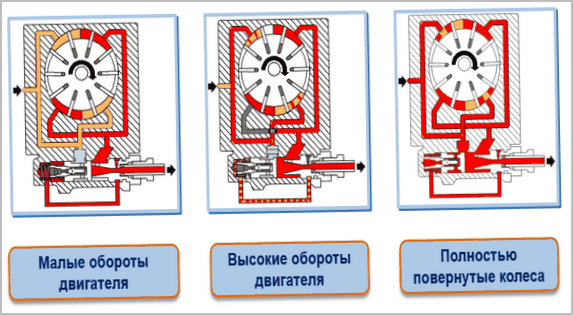

Imodi ye-dead-end pressure izoba khona ngesivinini esiphezulu senjini futhi amasondo ajika yonke indlela, lapho i-piston yesilinda sesigqila ingasakwazi ukuqhubeka. Kodwa kulezi zimo, i-valve evimbelayo elayishwe entwasahlobo ivuliwe, evula futhi iqale ukugeleza koketshezi, ukuvimbela ukucindezela ekukhuleni ngokweqile.

Amamodi epompo aklanywe ngendlela yokuthi akwazi ukuletha ukucindezela kwawo okuphezulu ngesivinini esincane sokuzungezisa. Lokhu kuyadingeka uma uhamba ngesivinini esicishe singenzi lutho, kodwa ngesiteringi esilula kakhulu. Naphezu kokuphikiswa okuningi endabeni yokuphendula amasondo esiteringi ngaso leso sikhathi. Wonke umuntu uyazi ukuthi isondo lokushayela elingenawo amandla lisinda kangakanani kuleli cala. Kuvela ukuthi iphampu ingalayishwa ngokugcwele ngesivinini esincane se-rotor, futhi ngemva kokunyuka kwejubane, ivele ilahle ingxenye yoketshezi ngokuphambene ne-valve yokulawula.

Naphezu kokuthi izindlela ezinjalo zokusebenza ngokusebenza ngokweqile zivamile futhi zihlinzekwa, ukusebenza kokuqondisa kwamandla ngamasondo kuvele ngokuphelele ebangeni eliseduze akufiseleki kakhulu. Isizathu salokhu ukushisa ngokweqile koketshezi olusebenzayo, ngenxa yokuthi lulahlekelwa izakhiwo zalo. Kukhona usongo lokukhuphuka kokuguga ngisho nokuwohloka kwephampu.

Ukwethembeka, ukwehluleka kanye nokulungiswa

Amaphampu okuqondisa amandla athembeke kakhulu futhi awawona awezinto ezisetshenziswayo. Kodwa nazo aziwona phakade. Ukungasebenzi kahle kubonakala ngendlela yomzamo owengeziwe esondweni lokuqondisa, ikakhulukazi ngesikhathi sokujikeleza okusheshayo, lapho iphampu inganikeli ngokucacile ukusebenza okudingekayo. Kukhona ukudlidliza kanye nokuduma okukhulu okunyamalalayo ngemva kokukhipha ibhande lokushayela.

Ukulungiswa kwepompo kungenzeka ngokombono, kodwa ngokuvamile kuvele kushintshwe eyoqobo noma ingxenye eyisipele evela kumakethe yangemuva. Kukhona nemakethe yamayunithi akhiwe kabusha efektri, ashibhile kakhulu, kodwa anokwethenjelwa okufanayo.