Benziwa kanjani ababusi bobunjiniyela?

Okuqukethwe

Insimbi, insimbi eyinsimbi ne-aluminium ababusi | |

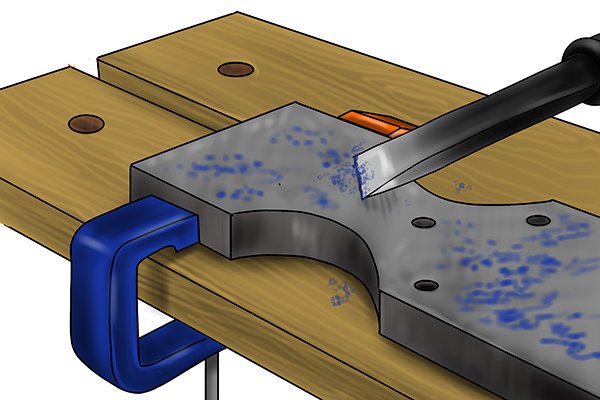

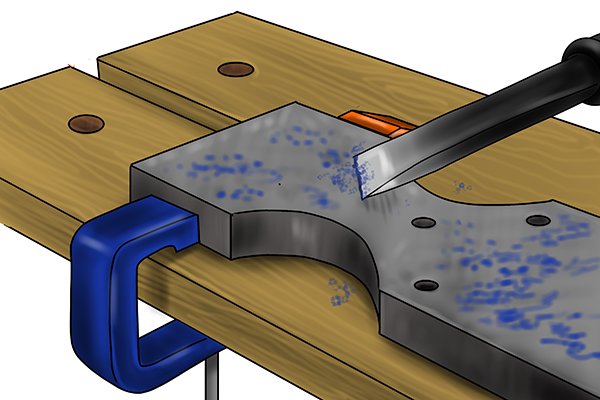

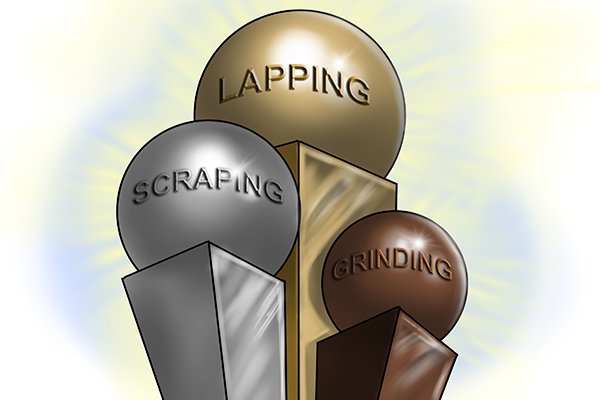

| Izinqubo eziyinhloko ezingadlula kuzo amaphethelo ensimbi ukuze awenze afaneleke kakhulu umsebenzi wawo yilezi: ukwelashwa kokushisa, ukufudumeza, ukukhuhla, ukugaya kanye nokugqwala. Imiphetho eqondile ye-cast iron ivamise ukuphonswa kusimo esifiselekayo, bese izindawo zokusebenza zazo ziqedwa ngokuklwetshwa, ukugaywa noma ukuxhawula. | |

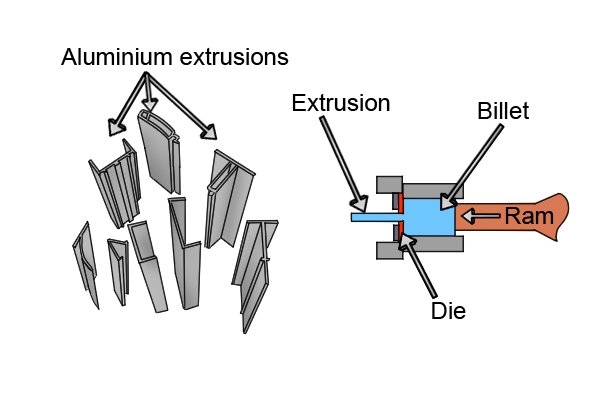

| I-aluminium ivame ukukhishwa njengoba ingaba indlela esheshayo neyongayo yokwenza izinto. Kodwa-ke, irula ye-aluminium extruded izodinga umshini ofana nerula yensimbi ecijile ukuze kuzuzwe ukunemba okudingekayo ku-countertop. |

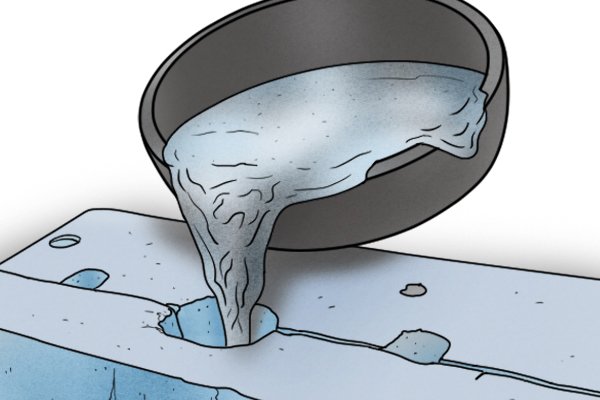

| UkusakazaI-Casting iyinqubo yokukhiqiza ehlanganisa ukuthela insimbi encibilikisiwe esikhunjeni, lapho ipholisa khona futhi ithathe isimo sesikhunta. Ngale ndlela, izimo eziningi eziyinkimbinkimbi zingenziwa. Ukulingisa kunganciphisa noma, kwezinye izimo, kuqede inani lomshini odingwa ingxenye ethile. Lokhu kuvame ukwenziwa ngensimbi, nakuba insimbi ne-aluminium nazo zingaphonswa. |

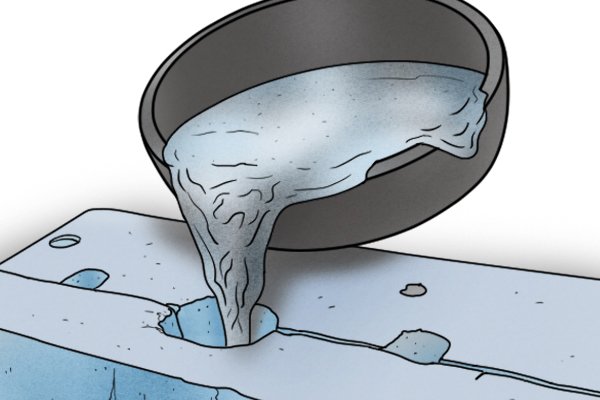

| Ukwelashwa kokushisaUkwelashwa kokushisa nokushisa kuyizinqubo zokukhiqiza ezisetshenziselwa ukushintsha izakhiwo ezibonakalayo zensimbi nezinye izinto. Ukwelashwa kokushisa kuhlanganisa ukushisa insimbi ezingeni lokushisa eliphezulu kakhulu bese uyiqinisa (ukupholisa ngokushesha). Lokhu kwandisa ubulukhuni bensimbi, kodwa ngesikhathi esifanayo kwenza kube brittle kakhudlwana. |

| ukuthukuthelaUkushisa kwenziwa ngemva kokwelashwa kokushisa futhi kuhlanganisa nokushisa insimbi, kodwa ekushiseni okuphansi kunalokho okudingekayo ngesikhathi sokwelashwa kokushisa, okulandelwa ukupholisa kancane. Ukuqina kunciphisa ubulukhuni kanye nokuqina kwensimbi, okwandisa ukuqina kwayo. Ngokulawula izinga lokushisa okushiswa ngalo insimbi ngesikhathi sokushisa, ibhalansi yokugcina phakathi kokuqina nokuqina kwensimbi ingashintshwa. |

| I-ExtrusionI-Extrusion iyindlela yokukhiqiza yokubumba umjovo lapho into ikhiwa ngesibhakela esiphoqa insimbi ngokusebenzisa idayizi. I-matrix inomumo ohlinzeka ngesimo esifiselekayo se-cross-section of the workpiece eqediwe. I-Aluminiyamu iyinto evamile kakhulu esetshenziswa ekukhiqizweni kwe-extruded. |

I-Granite imiphetho ebushelelezi | |

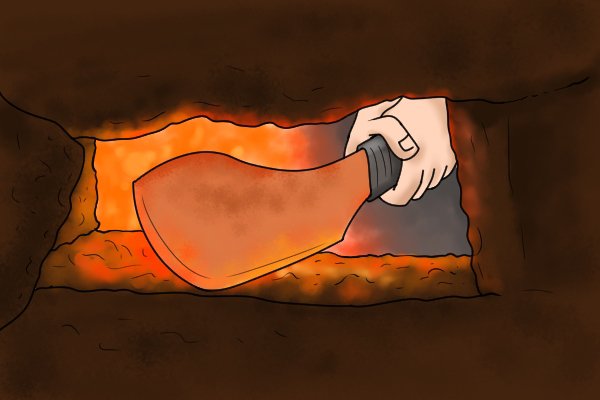

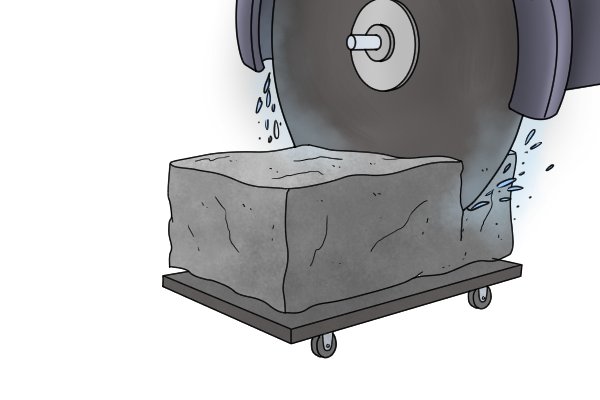

| Amarula egwadle kanjiniyela aqala ngokusika kancane ukusuka kubhulokhi enkulu yegwadle. Lokhu kwenziwa ngamasaha amakhulu apholise ngamanzi. Uma usuwonke umumo usufinyelelwe, ukuqeda nokunemba okudingekayo ukuze kusetshenziswe njengerula lobunjiniyela kufinyelelwa ngokugaya, ukuklwebha, noma ukuxhapha. |

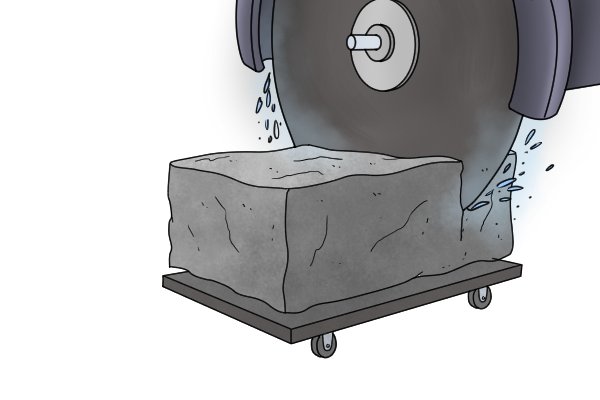

| UkugayaUkugaya kuyinqubo yokusebenzisa isondo lokugaya eliboshiwe elenziwe ngezinhlayiya ezilumayo ukuze kukhishwe into esetshenziswayo. Isondo lokugaya liyidiski elijikeleza ngesivinini esikhulu futhi ucezu lokusebenza ludlula eduze kobuso obuseceleni noma ngaphezulu kombuthano. Ukugaya kungenziwa ngama-discs anosayizi wegrit kusuka ku-8 (ama-coarse) kuya ku-250 (kakhulu kahle). Uma usayizi wokusanhlamvu ucolekile, iba ngcono ikhwalithi yangaphezulu yesiqeshana sokusebenza. |

| HlanzaUkugaya kuyinqubo lapho ingaphezulu le-workpiece lifinyezwa khona ukuze kutholwe indawo eyisicaba eqediwe. Ukugaya kungenziwa kunoma iyiphi ingxenye yensimbi edinga indawo eyisicaba. |

| IngcindeziI-Lapping iyinqubo yokuqeda esetshenziswa ekukhiqizeni ukukhiqiza indawo ebushelelezi, ngisho nangaphezulu emkhiqizweni osuphelile. I-Lapping ihlanganisa inhlanganisela ehlanganisa izinhlayiya ezilumayo kanye namafutha abekwe phakathi kwendawo yokusebenza kanye nethuluzi lokudonsa. Khona-ke ithuluzi le-lapping lihanjiswa phezu kwendawo yokusebenza. |

| Imvelo yokuluma ye-lapping paste isula ukungapheleli ebusweni bocezu lokusebenza futhi ikhiqize isiphetho esinembayo nesibushelelezi. Izinhlobo ezivame kakhulu zama-abrasives ezisetshenziswa ekugqitsheni i-aluminium oxide ne-silicon carbide, enosayizi wegrit ukusuka ku-300 kuya ku-600. |

Ukusandeni, ukuklwebha noma ukugoqa? | |

| Ukugaya akunikezi indawo ebushelelezi njengokubhuqa noma ukugcotshwa kwesihlabathi. Ukuhlunga kungenziwa kuphela ezikhaleni zensimbi, ngakho-ke ngeke kusetshenziselwe ukukhiqiza imiphetho eqondile ye-granite. Ubukhulu bonqenqema oluqondile buzonquma ukuthi ukuklwebha noma ukugoqa kukhiqiza umkhawulo oqondile wekhwalithi engcono. Njengomthetho ojwayelekile, ukukhuhla kunembe kakhudlwana kunobude obude, kodwa okuwukuphela kwendlela yokutshela ngokuqinisekile ukuthi yimuphi umbusi ozoba nembe kakhudlwana ukubuka ukubekezelelana kwabakhiqizi bobunjiniyela bobunjiniyela ohlela ukuthenga. |