Injini yenjini yomlilo yangaphakathi yomlilo

Okuqukethwe

- Imisebenzi yekhanda lesilinda

- Ukwahlukaniswa kwamakhanda amasilinda

- Isilinda ekhanda gasket

- Ikhava yekhanda lesilinda

- Izici eziyinhloko ze-cylinder head of a-stroke engine

- Izici eziyinhloko ze-cylinder head of four-stroke engine

- Igumbi lokushisa

- Inlet futhi esidayisa

- Imihlahlandlela ye-Valve

- Amaphayiphu ekhanda lesilinda lenjini

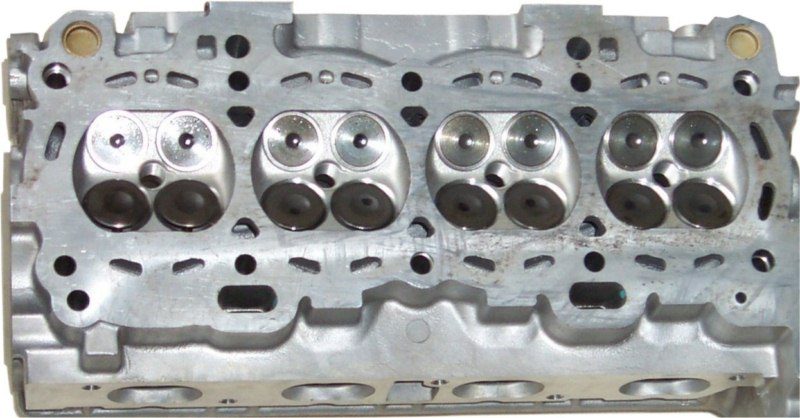

- Ikhanda lesilinda elinama-valve amabili

- Ikhanda lesilinda elinama-valve amathathu

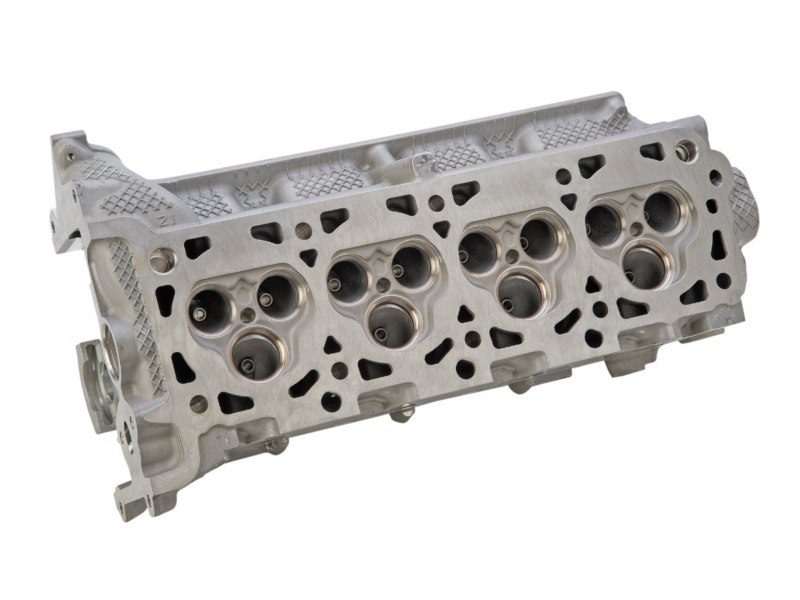

- Ikhanda lesilinda elinama-valve amane

- Ikhanda lesilinda elinama-valve amahlanu

Igama elithi "cylinder head" alizange libe khona ngengozi. Njengasekhanda lomuntu, izenzo eziyinkimbinkimbi kakhulu futhi ezibalulekile zenjini evuthayo yangaphakathi zenzeka ekhanda le-cylinder. Ngakho-ke i-cylinder head iyingxenye yenjini evuthayo yangaphakathi, etholakala engxenyeni yayo engaphezulu (engaphezulu). Ihlanganiswe nemigudu yomoya ye-intake kanye ne-exhaust tracts, iqukethe izingxenye zendlela ye-valve, ama-injection nama-spark plugs noma amapulaki akhanyayo. Ikhanda le-cylinder livala phezulu kwesilinda block. Ikhanda lingaba elilodwa layo yonke injini, ngokwehlukana isilinda ngasinye noma ngokwehlukana umugqa ohlukile wamasilinda (injini emise okwe-V). Iboshelwe kusilinda ngezikulufo noma amabhawudi.

Igama elithi "cylinder head" alizange libe khona ngengozi. Njengasekhanda lomuntu, izenzo eziyinkimbinkimbi kakhulu futhi ezibalulekile zenjini evuthayo yangaphakathi zenzeka ekhanda le-cylinder. Ngakho-ke i-cylinder head iyingxenye yenjini evuthayo yangaphakathi, etholakala engxenyeni yayo engaphezulu (engaphezulu). Ihlanganiswe nemigudu yomoya ye-intake kanye ne-exhaust tracts, iqukethe izingxenye zendlela ye-valve, ama-injection nama-spark plugs noma amapulaki akhanyayo. Ikhanda le-cylinder livala phezulu kwesilinda block. Ikhanda lingaba elilodwa layo yonke injini, ngokwehlukana isilinda ngasinye noma ngokwehlukana umugqa ohlukile wamasilinda (injini emise okwe-V). Iboshelwe kusilinda ngezikulufo noma amabhawudi.

Imisebenzi yekhanda lesilinda

- Yakha indawo yomlilo - yenza indawo yokucindezela noma ingxenye yaso.

- Inikeza ukushintshwa kwe-cylinder charge (4-stroke engine).

- Inikeza ukupholisa kwekamelo lomlilo, ama-spark plugs nama-valve.

- Kuvalwa ikamelo lokushisa igesi eliqinile nokungangenwa manzi.

- Inikezela ngokubekwa kwe-spark plug noma i-injector.

- Ibamba futhi iqondise umfutho ovuthayo - i-voltage ephezulu.

Ukwahlukaniswa kwamakhanda amasilinda

- Amakhanda ayisilinda wezinjini ezishaywa unhlangothi ezimbili nezishaywa unhlangothi ezine.

- Izinhlamvu zesilinda zezinjini zokushisa.

- Amakhanda apholile omoya noma amanzi.

- Hlukanisa amakhanda ngesilinda esisodwa, ikhanda le-in-line noma elenziwe ngo-V.

- Ikhanda lesilinda nesikhathi se-valve.

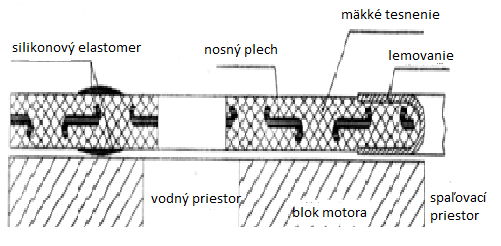

Isilinda ekhanda gasket

Kunophawu phakathi kwekhanda lesilinda nebhulokhi elivala ikamelo lomlilo ngokweqile futhi livimbele uwoyela nesipholisi ekubalekeni (ekuxubeni). Sihlukanisa izimvu zamanzi zibe okubizwa ngokuthi yinsimbi futhi kuhlanganisiwe.

Izinsimbi, okusho ukuthi izimpawu zethusi noma i-aluminium, zisetshenziswa ezinjinini ezincane, ezinejubane eliphezulu, ezipholile emoyeni (ama-scooter, izithuthuthu ezinhlangothi zombili ezifika ku-250 cc). Izinjini ezipholile ngamanzi zisebenzisa uphawu oluqukethe imicu e-graphite ecebile ephilayo eboshelwe kupulasitiki esekelwa kusekelo lwensimbi.

Ikhava yekhanda lesilinda

Ingxenye ebalulekile yekhanda lesilinda futhi ikhava emboza isitimela se-valve futhi ivimbele uwoyela ukuthi ungangeni endaweni yenjini.

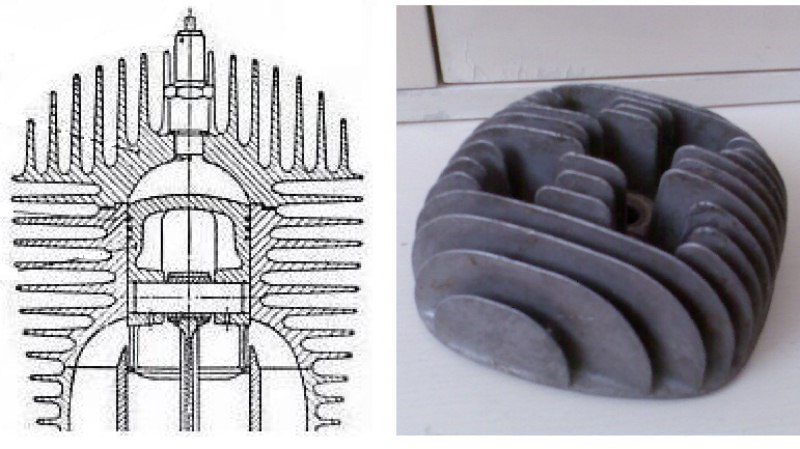

Izici eziyinhloko ze-cylinder head of a-stroke engine

Inhloko yesilinda yezinjini ezinama-stroke amabili ngokuvamile ilula, ipholile ngomoya (inezimbambo ebusweni) noma i-liquid. Igumbi lokushisa lingalingana, libe yi-biconvex noma libe yindilinga, imvamisa kunegebe lokulwa nokungqongqoza. Intambo ye-spark plug itholakala ku-cylinder axis. Kungenziwa nge-grey cast iron (amadizayini enjini endala) noma i-aluminium alloy (esetshenziswa njengamanje). Ukuxhuma kwekhanda lenjini eshaywa onqenqemeni olubili ku-cylinder block kungacushwa, kufakwe i-flanged, kuhlanganiswe nokuqinisa ngezikulufo, noma nekhanda eliqinile.

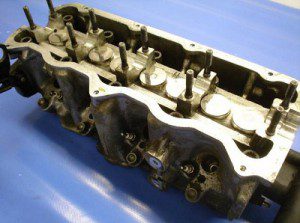

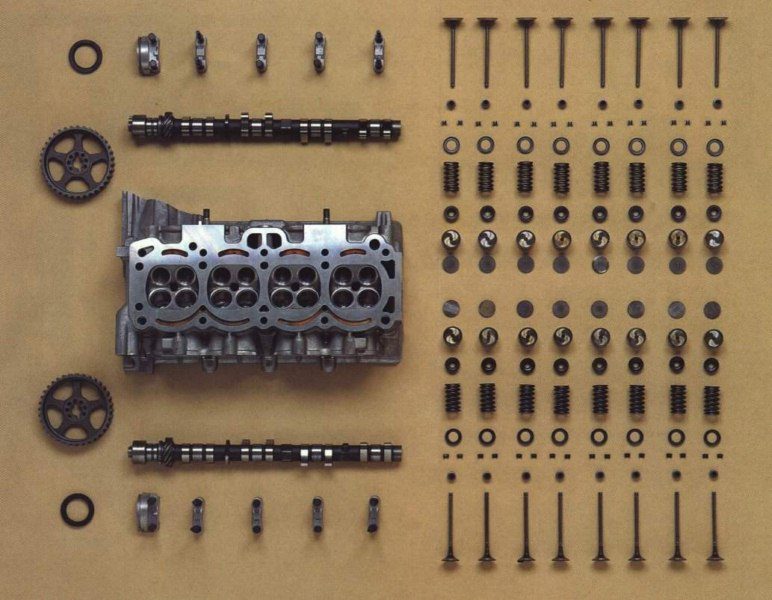

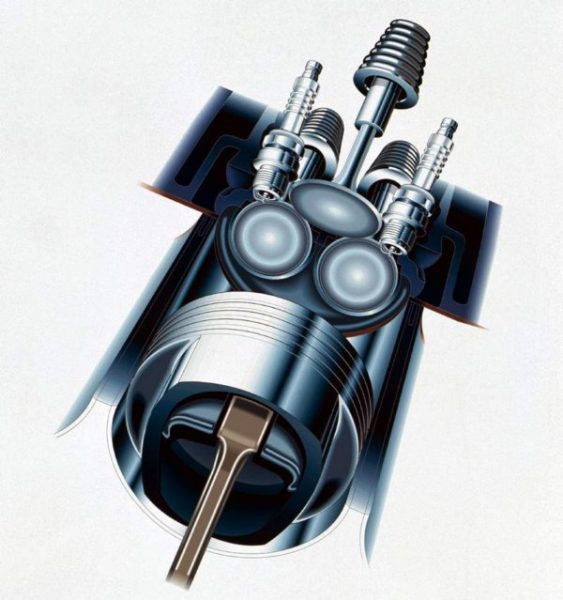

Izici eziyinhloko ze-cylinder head of four-stroke engine

Ukwakhiwa kwekhanda lezinjini ezine-stroke kumele futhi kuhlinzeke ngoshintsho ekugudluzweni kwamasilinda enjini. Iqukethe iziteshi zokungena neziphumayo, izingxenye zendlela yokusabalalisa igesi elawula ama-valve, ama-valve ngokwawo, kanye nezihlalo zawo neziqondiso, izintambo zokulungisa i-spark plug nama-nozzles, iziteshi zokugeleza kwemidiya yokugcoba nokupholisa. Iphinde ibe yingxenye yegumbi lomlilo. Ngakho-ke, inkimbinkimbi ngokungenakuqhathaniswa ekwakhiweni nasekubunjweni kwayo uma iqhathaniswa nekhanda lesilinda lenjini enama-stroke amabili. Ikhanda le-cylinder lenjini enama-four-stroke lenziwa nge-iron cast iron empunga, noma i-alloyed cast iron, noma insimbi ebunjiwe - okuthiwa yi-cast steel noma ama-alloys e-aluminium ezinjini ezipholiswe uketshezi. Izinjini ezipholiswe ngomoya zisebenzisa ama-alloys e-aluminium noma insimbi yokusansimbi. I-cast iron cishe ayikaze isetshenziswe njengenhloko futhi ithathelwe indawo yi-aluminium alloy. Isici esinqumayo sokukhiqizwa kwezinsimbi ezikhanyayo akusona isisindo esiphansi njenge-conductivity enhle kakhulu yokushisa. Njengoba inqubo yokuvutha yenzeka ekhanda lesilinda, okuholela ekushiseni okukhulu kule ngxenye yenjini, ukushisa kufanele kudluliselwe kusipholisi ngokushesha ngangokunokwenzeka. Futhi-ke i-aluminium alloy iyimpahla efanelekile kakhulu.

Igumbi lokushisa

Igumbi lokushisa futhi liyingxenye ebaluleke kakhulu yekhanda lesilinda. Kumele ibe sesimeni esifanele. Izidingo eziyinhloko zekamelo lomlilo yilezi:

- Ubumbano obukhawulela ukulahleka kokushisa.

- Vumela ukusetshenziswa kwenani eliphakeme lama-valve noma usayizi owanele we-valve.

- Ukuvulwa kahle kokugcwaliswa kwesilinda.

- Beka ikhandlela endaweni ecebe kakhulu ekugcineni kokukhama.

- Ukuvimbela ukungqongqoza kokungqongqoza.

- Ukucindezelwa kwezindawo ezidla lubi.

Lezi zidingo zibaluleke kakhulu ngoba ikamelo lomlilo linomthelela ekwakhiweni kwama-hydrocarbon, linquma inkambo yomlilo, ukusetshenziswa kukaphethiloli, umsindo wokushisa kanye ne-torque. Igumbi lokushisa futhi linquma isilinganiso sokucindezela esiphezulu futhi linomthelela ekulahlekelweni ukushisa.

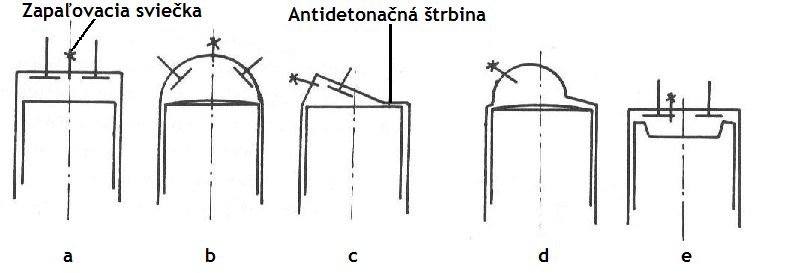

Umumo wegumbi lokushisa

a - bathroom, b - i-hemispherical, c - uhlaka, d - i-asymmetric hemispherical, e - Izindwandwe ku-piston

Inlet futhi esidayisa

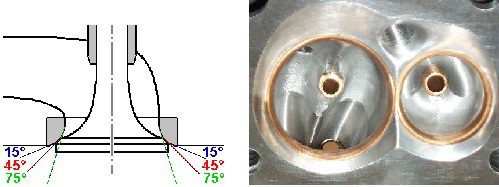

Kokubili amachweba okungena nawokukhipha aphela ngesihlalo se-valve ngqo ekhanda lesilinda noma ngesihlalo esifakiwe. Isihlalo se-valve esiqondile sakhiwa ngqo ezintweni zekhanda noma singabizwa kanjalo. isihlalo se-inthanethi esenziwe ngezinto zensimbi esezingeni eliphakeme. Izindawo okuxhunyanwa nazo zinenhlabathi ngqo ngosayizi. I-bevel angle yesihlalo se-valve imvamisa ingu-45 °, ngoba leli nani lifinyelela ukuqina okuhle lapho i-valve ivaliwe futhi isihlalo siyazihlanza. Amaphayiphu okudonsa kwesinye isikhathi atshekiswa ku-30 ° ukuze kugeleze kangcono endaweni yesihlalo.

Imihlahlandlela ye-Valve

Ama-valve ahamba kumhlahlandlela we-valve. Imihlahlandlela ye-valve ingenziwa ngensimbi yensimbi, i-aluminium-bronze alloy, noma yenziwe ngqo entweni yekhanda lesilinda.

Amaphayiphu ekhanda lesilinda lenjini

Bahamba ngemihlahlandlela, futhi ama-valve uqobo ahlala ezihlalweni. I-valve njengengxenye ye-valve yokulawula ukuphindisela izinjini zangaphakathi zomlilo ibhekene nengcindezi yomshini neyokushisa ngesikhathi sokusebenza. Ngokombono womshini, ikakhulu kulayishwe ingcindezi yamagesi okususa egumbini lokushisa, kanye namandla okulawula aqondiswe kwikham (i-jack), amandla angenawo amandla ngesikhathi sokunyakaza okuphindayo, kanye ukungqubuzana kwemishini. mina. Ukucindezela okushisayo kubalulekile ngokufanayo, ngoba i-valve ithonywe kakhulu izinga lokushisa ekamelweni lomlilo kanye nezinga lokushisa elizungeze amagesi e-flue ashisayo (ama-valve wokuqeda). Yimiphimbo yokukhipha amanzi, ikakhulukazi ezinjinini ezisetshenziswa kakhulu, evezwa yimithwalo eshisayo eyedlulele, kanti izinga lokushisa lendawo lingafinyelela ku-900 ° C. Ukushisa kungadluliselwa esihlalweni i-valve ivaliwe nasesiqu se-valve. Ukudluliswa kokushisa kusuka ekhanda kuya esiqwini kungakhuphuka ngokugcwalisa umgodi ngaphakathi kwe-valve ngento efanelekile. Imvamisa, kusetshenziswa igesi eline-sodium, eligcwalisa isiqu kuphela phakathi, ukuze kuthi lapho i-valve ihamba, ingxenye yangaphakathi igxishwe kakhulu uketshezi. Isiqu sesiqu sezinjini ezincane (zabagibeli) senziwa ngokubhola imbobo; esimweni sezinjini ezinkulu, ingxenye yekhanda le-valve nayo ingahle ibe yize. Isiqu se-valve sivamise ukufakwa nge-chrome. Ngakho-ke, umthwalo wokushisa awufani nama-valve ahlukile, futhi kuya ngenqubo yokushisa uqobo futhi kubangele izingcindezi ezishisayo ku-valve.

Amakhanda evalve yokungena ngokuvamile amakhulu ngobubanzi kunamavalvu okukhipha umoya. Ngenombolo eyinqaba yamavalvu (3, 5), maningi amavalvu okungena isilinda kunamavalvu okukhipha umoya. Lokhu kungenxa yesidingo sokufeza ubuningi obunokwenzeka - amandla athile akhethekile futhi, ngakho-ke, ukugcwaliswa okungcono kakhulu kwesilinda ngenhlanganisela evuthayo yamafutha nomoya.

Ekhiqizweni kwamaphayiphu okudonsa, kusetshenziswa insimbi enesakhiwo se-pearlite, ehlanganiswe ne-silicon, i-nickel, i-tungsten, njll. Kwesinye isikhathi kusetshenziswa ingxubevange ye-titanium. Amaphayiphu okukhipha adalulwe ekucindezelekeni okushisayo enziwa ngezinsimbi eziphakeme (i-chromium-nickel) ezakhiwe ngesakhiwo se-austenitic. Insimbi yethuluzi eliqinile noma enye impahla ekhethekile ifakwe esihlalweni sesihlalo. i-satellite (i-alloy oluthambile ye-cobalt ene-chromium, i-carbon, i-tungsten noma ezinye izinto).

Ikhanda lesilinda elinama-valve amabili

Ikhanda lesilinda elinama-valve amathathu

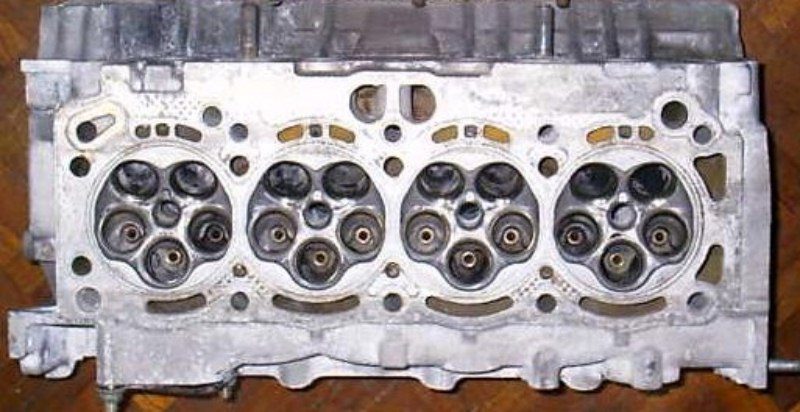

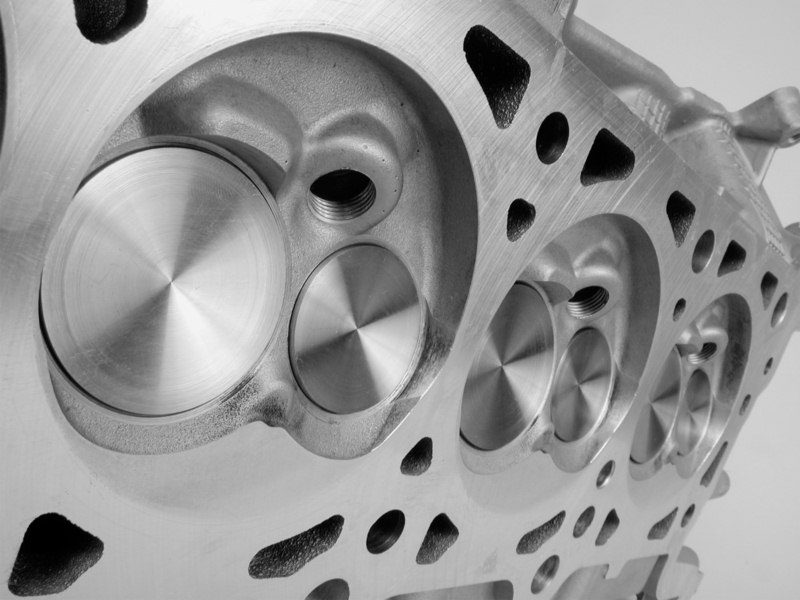

Ikhanda lesilinda elinama-valve amane

Ikhanda lesilinda elinama-valve amahlanu