I-Hydraulic booster MAZ

Ukulungiswa kokuvunyelwa kokuhlangana kwebhola kwe-hydraulic booster MAZ.

Ukubonakala kwezikhala ezikhonkwane zebhola kuthinta kakhulu ukudlala jikelele kwama-headphone. Ngokuvamile, igebe ku-pin yebhola 9 liyakhula (bheka u-Fig. 94), lapho induku ye-longitudinal ixhunywe khona, ngoba amandla amaningi adluliselwa ngale phini yebhola kunokuba ngephini lebhola le-lever yokuqondisa.

Ukulungisa izikhala zezikhonkwane zebhola, i-hydraulic booster ihlakazwa kancane. Ngakho-ke, kungcono ukwenza ukulungiswa kwe-hydraulic booster ekhishwe emotweni.

Inqubo yokusetha imi kanje.

Hudula ukulungiswa kwegebe elihlanganyelwe:

- khipha amapayipi;

- qinisa i-hydraulic booster ku-vise futhi ukhulule nati lokukhiya kusilinda;

- khumula umzimba wehinge kusilinda;

- lungisa imizimba ye-hinge ku-vice, ukhulule isikulufa sokukhiya ku-nut 7 (bheka u-Fig. 94);

- qinisa i-nut 7 kuze kube yilapho ima, bese uqinisa isikulufa sokukhiya ngokuqinile;

- Hlanganisa umzimba wamabhola ngesilinda. Qinisa kuze kufike lapho izohamba khona futhi ukhulule endaweni evumela ukuthi amapayipi axhumeke.

Ukulungiswa kokudlala okuhlangene kwe-Pivot:

- lungisa i-hydraulic booster ku-vice;

- susa ikhava engu-12 kumsabalalisi, khulula futhi ukhulule nati;

- qaqa izikulufu ezibambe ikhoyili yendlu bese ususa indlu kanye nekhoyili;

- khumula isikulufu sokukhiya 29;

- screw ikepisi 29 yonke indlela bese uyibuyisela emuva kuze kube yilapho imbobo yesikulufu sokukhiya iqondana nembobo eseduze enkomishini 36;

- qinisa isikulufu sokukhiya size siyeke;

- faka futhi uvikele umzimba wekhoyili;

- faka i-spool emkhonweni womzimba, gqoka i-cap 32, qinisa i-nati ukuze umise, uyivule ngokujika kwe-1/12 bese usika intambo;

- faka futhi uvikele ikhava engu-12 namapayipi;

- faka i-hydraulic booster emotweni.

Ukungasebenzi kahle okungenzeka kokulawula nezindlela zokuziqeda kunikezwa kuthebhu yeshumi nanye.

| Imbangela yokungasebenzi kahle | resource |

| Ukukhulisa okunganele noma okungalingani | |

| Ukungezwani okunganele kwebhande le-pump drive | Lungisa ukungezwani kwebhande |

| Izinga likawoyela eliphansi endaweni yephampu yokuqondisa amandla | Faka amafutha |

| Igwebu likawoyela ethangini, ukuba khona komoya ohlelweni lwe-hydraulic | Khipha umoya ohlelweni. Uma kungekho moya owophayo, hlola konke ukuxhumana ukuze uthole ukuvuza. |

| Ukuntuleka okuphelele kwenzuzo ngesivinini senjini ehlukahlukene | |

| Ukuvinjwa kwepayipi lokukhipha kanye nokukhipha amanzi ohlelweni lwe-hydraulic | Hlukanisa imigqa bese uhlola i-patency yamapayipi namapayipi afakwe kuwo |

| Awukho umfutho lapho ujikela ohlangothini olulodwa | |

| Ukubanjwa kwe-spool yokusabalalisa isiteringi samandla | Hlukanisa umsabalalisi, thola futhi uqede imbangela ye-jamming |

| Ukuma kwenkomishi eyindilinga yomunwe we-hydraulic servomotor | Hlukanisa i-hydraulic booster futhi uqede imbangela yokuminya kwenkomishi |

| Ukuhlehla emuva ekuxhumekeni kwe-spool ngengilazi yephini lebhola le-lever yokuqondisa | Susa ikhava yangaphambili ye-distributor, susa umdlalo ngokuqinisa i-nati kuze kukhethwe igebe phakathi kwe-nati ne-spool, bese kuba iphinikhodi ye-cotter. |

Ukulungiswa kwe-MAZ hydraulic booster

Ukukhipha i-hydraulic booster emotweni. Ukuze uyisuse udinga:

- nqamula i-pressure kanye ne-drain hoses kusuka ku-hydraulic booster;

- khumula inadi lebhawodi elihlanganisayo elibambe iphinikhodi ekhanda le-hydraulic servomotor rod, bese ungqongqoza ibhawudi liphume kubakaki;

- hit the stud of the head of the hydraulic booster rod;

- qaqa futhi ukhulule amantongomane avikela i-hydraulic booster esiqondisweni sokuqondisa kanye nasengalweni elandela ngemuva;

- usebenzisa i-punch, cindezela iminwe yakho iphume emigodini engalweni yokuqondisa kanye nesixhumanisi sokulandela. Susa i-hydraulic booster. Inqubo yokuhlakaza i-hydraulic booster imi kanje: susa amapayipi nokufakwa;

- khulula ukuxhumana okucushiwe kwekhanda lesiqu nesiqu bese uqaqa ikhanda. Susa iwasha yokulungisa yangaphandle; isivalo;

- lapho i-rubber bushing igugile, hlakaza ikhanda, lapho uvula i-nut bese ucindezela i-steel bushing, bese kuba i-rubber bushing;

- khipha i-clamp ebambe ikhava, ikhava kanye newasha yangaphakathi entabeni;

- qaqa izikulufu ezibambe ikhava yesilinda sokuqondisa amandla, susa iwasha, khipha indandatho ebambayo ngokushelela ikhava yesilinda emuva, susa isembozo;

- khipha ipiston ngentonga futhi uyiqaqe;

- khumula nati lokukhiya lesilinda bese uvula isilinda ngaphandle;

- susa izinsimbi zokubopha izindlala zebhola kanye nezindlala ngokwazo;

- khumula isikulufu sokukhiya, qaqa i-nati yokulungisa 7 (bheka umdwebo 94), susa i-pusher 8, intwasahlobo, ama-crackers kanye ne-ball pin 9;

- khumula izikulufo zokubopha ikhava 12 bese ususa isembozo; khumula i-coil fastening nut bese uyiqaqa, susa i-cap 32;

- qaqa izikulufu ezibamba umzimba wekhoyili, khipha umzimba, khipha ikhoyili;

- khumula isikulufu sokukhiya, qaqa ipulaki 29, khipha ibhawodi, ipusher 8, intwasahlobo, ama-crackers kanye nophini 10;

- susa ingilazi 36;

- qaqa ikepisi yevalve yokuhlola 35 bese ukhipha isiphethu sebhola i.

Ngemuva kwe-disassembly, hlola ngokucophelela izingxenye ze-hydraulic booster.

Ukuklwebheka nama-nick akuvunyelwe endaweni ye-spool, ingilazi yephini lokuqondisa lever yebhola kanye nemizimba yabo. Izindawo ezigijimayo zezigxobo zebhola kanye ne-rocker kumele zingabi namazinyo nokuguga ngokweqile, futhi izindandatho zenjoloba kufanele zibonise umonakalo obonakalayo nokuguga.

Uma umonakalo utholakele, shintsha lezi zingxenye ufake ezintsha.

Faka i-hydraulic booster ngohlelo lokuhlehla lokususwa. Ngaphambi kokuhlangana, izindawo zokuhlikihla zekhoyili, ingilazi neminwe; gcoba ngongqimba oluncane lwe-lubricant futhi uqiniseke ukuthi ikhoyili nenkomishi kuhamba ngokukhululekile ezindlini zabo, ngaphandle kokuphazamiseka.

Lungisa imvume yokuhlangana kwebhola njengoba kuchazwe ngenhla.

Ngemuva kokuhlanganiswa, gcoba ama-ball bearings nge-oiler 18.

Faka i-hydraulic booster emotweni ngohlelo lokuhlehla lokususwa.

Lapho ufaka i-hydraulic booster, qinisa amantongomane uvikela izikhonkwane ngokuqinile futhi uwafinye ngokucophelela.

Ukugcinwa kwe-hydraulic booster MAZ

Ngesikhathi sokusebenza kwemoto, hlola ngokuhlelekile ukuqiniswa kwe-hydraulic booster kubakaki wohlaka lwemoto, ukuqiniswa kwe-hydraulic booster pump pulley, ngezikhathi ezithile qinisa amantongomane ezigxobo zebhola zokusabalalisa.

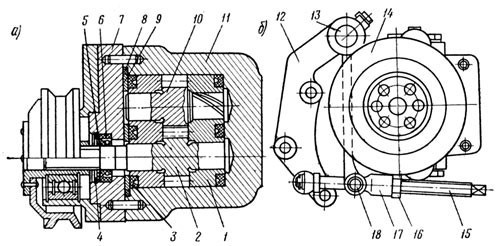

Hlola ukushuba kwebhande le-pump drive kukho konke ukunakekelwa. Ukuqina kwebhande kulungiswa nge-screw 15 (Fig. 96, b). Ngokucindezela okulungile, ukuphambuka phakathi kwebhande ngaphansi kwamandla angama-4 kg kufanele kube ngaphakathi kuka-10-15 mm. Ngemuva kokulungiswa, vala isikulufu nge-nut 16.

Funda futhi 8350 kanye 9370 Ukugcinwa Kwe-Trailer

Ngezikhathi ezithile, ngesikhathi esiboniswe eshadini lokuthambisa, hlola izinga likawoyela ku-hydraulic booster pump reservoir, shintsha uwoyela ohlelweni lwe-hydraulic booster, futhi ugeze isihlungi se-reservoir.

Nsuku zonke hlola ukucinana kokuxhuma kanye nezigxivizo ze-hydraulic booster, futha, amapayipi namapayipi ohlelo.

Kusistimu yesiteringi samandla, sebenzisa kuphela amafutha ahlanzekile, ahlungiwe njengoba kucaciswe eshadini lokuthambisa. Thela uwoyela endaweni yepompo engu-10-15 mm ngaphansi konqenqema olungaphezulu lwe-reservoir ngokusebenzisa ifaneli enemeshi ephindwe kabili. Uma uthela amafutha, ungawanyakazi noma uwaxube esitsheni.

Ukusetshenziswa kwamafutha angcolile kuholela ekugugeni ngokushesha kwesilinda sokuqondisa amandla, i-distributor kanye nezingxenye zepompo.

Lapho uhlola izinga likawoyela endaweni yokugcina amanzi ekunakekeleni ngakunye (TO-1), amasondo angaphambili emoto kufanele afakwe aqonde.

Ku-TO-2 ngayinye, susa isihlungi ethangini bese ugeza. Uma isihlungi sivaleke kakhulu ngamadiphozithi aqinile, sigeze ngesinqamuli sikapende wemoto. Ngaphambi kokukhipha isihlungi, hlanza kahle isivalo sethangi lemfucumfucu.

Lapho ushintsha uwoyela, okwenziwa izikhathi ezi-2 ngonyaka (ngokugcinwa kwesizini), phakamisa i-axle yangaphambili yemoto ukuze amasondo angathinti phansi.

Ukukhipha uwoyela ohlelweni:

- nqamula ithangi futhi, ngemva kokukhipha ikhava, khipha amafutha;

- nqamula imibhobho ekuphumeni nasekukhipheni amapayipi okusabalalisa bese ukhipha uwoyela empompini ngawo;

- uphendulela kancane i-flywheel kwesokunxele nakwesokudla ize ime, khipha amafutha kusilinda samandla.

Ngemva kokukhipha uwoyela, shayela isigcinamandla sokuqondisa:

- khipha isihlungi ethangini, ugeze njengoba kuchazwe ngenhla;

- hlanza kahle ithangi ngaphakathi, ususe iminonjana yamafutha angcolile;

- faka isihlungi esigeziwe ethangini;

- uthele uwoyela omusha ethangini ngokusebenzisa ifaneli enemeshi emihle kabili futhi ulinde aze aphume ngemibhobho.

Uma ugcwalisa amafutha amasha, qiniseka ukuthi ususa ngokuphelele umoya ohlelweni. Ukuze wenze lokhu udinga:

- engeza amafutha ethangini ezingeni oyifunayo futhi ungathinti uhlelo cishe imizuzu emibili;

- qala injini futhi uyivumele isebenze ngesivinini esiphansi imizuzu emibili;

- phendula kancane isondo lokuqondisa izikhathi ezi-2 ukuya kwesokudla nakwesokunxele kuze kube amabhamuza omoya endaweni yokuma. Uma kunesidingo, engeza amafutha ezingeni eliboniswe ngenhla; faka kabusha ikhava yethangi kanye nezinsimbi zayo;

- jikisa amasondo kwesokudla nakwesokunxele, uhlole ukuthi isiteringi silula yini kanye nokuvuza kwamafutha.

Hlola ukucaciswa kwezikhonkwane zebhola ngenjini egijima ku-TO-1 ngayinye, ijika ngokucijile isiteringi sibheke kwewashi nangokuphikisana newashi.

Akumele kube khona ukudlalwa endaweni ehlangene ye-tie rod. Ku-hinge ye-lever yokuqondisa enenjini imisiwe, umdlalo akufanele udlule u-4 mm, kanti injini isebenza - kufika ku-2 mm.

Idivayisi kanye nokusebenza kwe-hydraulic booster

I-hydraulic booster (Fig. 94) iyiyunithi ehlanganisa umsabalalisi kanye nomhlangano wamasilinda wamandla. I-hydraulic system ye-booster ihlanganisa iphampu yegiya ye-NSh-10E efakwe enjini yemoto, ithangi likawoyela namapayipi.

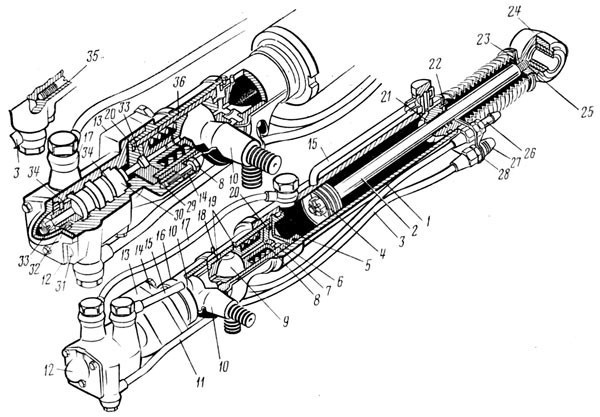

Ilayisi. 94. GUR MAZ:

I-1 - isilinda samandla; 2 - izinduku; 3 - ipayipi yokukhipha; 4 - ipiston; 5 - ukhokho; 6 - umzimba webhola lebhola; 7 - ukulungiswa kwe-backlash ye-nati ye-longitudinally-stop ball joint; 8 - pusher; 9 - iphinikhodi yebhola yokusalungiswa kwe-longitudinal; 10 - bopha iphini lebhola lenduku; 11 - ipayipi yokukhipha; 12 - ikhava; 13 - izindlu zokusabalalisa; 14 - flange; I-15 - ipayipi yegatsha emgodini ongaphezu kwepiston yesilinda samandla; I-16 - ikhola yokubopha i-sealant; I-17 - ipayipi yegatsha emgodini we-piston yesilinda samandla; 18 - i-oiler; 19 - izikhonkwane zokulungisa ama-crackers; 20 - isikulufa sokukhiya; 21 - ikhava yesilinda samandla; 22 - isikulufa; I-23 - i-washer yangaphakathi yokubopha ikhava; 24 - ukuphonsa ikhanda; 25 - iphinikhodi ye-cotter; 26 - ukuqiniswa komugqa wokukhipha; 27 - ukuhlanganiswa komugqa wokukhipha; 28 - umnikazi we-hose; 29 - lungisa isethi yamakhanda okuhlangene kwebhola yengalo yokuqondisa; 30 - ikhoyili; 31 - ukhokho; 32 - i-spool cap; 33 - umshudo wokuhlanganisa; 34 - isiteshi sokuxhuma; 35 - hlola i-valve; 36 - ingilazi

Umsabalalisi unomzimba ongu-13 kanye ne-spool 30. Ama-spool bushings avaliwe ngezindandatho zokuvala zenjoloba, eyodwa ngqo emzimbeni, enye kupulaki 32 efakwe emzimbeni futhi ivalwe ngekepisi 12.

Kunemifantu emithathu ye-annular ebusweni obungaphakathi bomzimba wekhoyili. Okudlulele kakhulu kuxhunywe ngesiteshi komunye nomunye kanye nomugqa wokukhipha wepompo, ophakathi - ngokusebenzisa umugqa wokudonsa kuya ku-tank yepompo. Ebusweni besigubhu kunemifantu emibili yama-annular exhunywe ngokuxhuma iziteshi 34 ezinevolumu evaliwe ebizwa ngokuthi ama-reactive chambers.

Umzimba wekhoyili unamathiselwe ku-flange yomzimba ngamahinge angu-6. Kunezikhonkwane ezimbili zebhola ezindlini ezingu-6: 10, lapho induku yokuqondisa ifakwe khona, futhi i-9, ixhunywe ku-longitudinal rod rod. Yomibili iminwe ibanjwa phakathi kwamabhisikidi ayindilinga ngepulaki 29 kanye nenati elilungisa u-7 kusetshenziswa iziphethu. Ukuqiniswa kwamabhisikidi kunqunyelwe ama-pusher 8. Amahinge avikelwe ekungcoleni yizigxivizo zenjoloba ezigxilwe emzimbeni ngezinsimbi.

Iminwe engaphakathi kwemingcele ethile ingajikeleza kumabhisikidi, aphethwe izikhonkwane eziphukile 19, ezifakwe emigwaqweni yamabhisikidi.

Funda futhi izici zobuchwepheshe zesistimu ye-brake yama-trailer GKB-8350, OdAZ-9370, OdAZ-9770

I-bipod 36 igxilwe enkomishini engu-10, engahamba endaweni engu-6 endaweni ye-axial phakathi kuka-4 mm. Lokhu kunyakaza kunqunyelwe ikhola kakhokho 29 esongwe engilazini. Ihlombe elisezindaweni ezidlulele lincike ekupheleni kwendlu engu-13 yokusabalalisa futhi ngokumelene nokuphela kwezindlu ezingu-6 zamabhola amabhola. I-spool 30 nayo ihamba nenkomishi engu-36, njengoba ixhunywe ngokuqinile kuyo ngebhawodi namantongomane.

Isilinda samandla 1 sixhunywe komunye umkhawulo wehinge body 6 ngoxhumano olunentambo futhi ikhiywe ngenadi. I-Piston 4 ihamba ku-cylinder, exhunywe yinati endongeni 2. I-piston ivalwe ngezindandatho ezimbili zensimbi. I-cylinder cavity ivaliwe ngakolunye uhlangothi nge-plug 5, ivalwe ngendandatho yenjoloba, ngakolunye, ikhava engu-21, ivalwe ngendandatho efanayo futhi ivikelekile ngendandatho yokugcina kanye ne-washer, lapho ikhava iboshwe khona. Isiqu sivalwe kukhava ngendandatho yerabha evikelwe i-scraper. Ngaphandle, isiqu sivikelwe ekungcolisweni yibhuthi yenjoloba enothayela. Ekupheleni kwenduku, ikhanda le-24 lilungiswe ngoxhumano lwentambo, lapho kufakwa khona i-rubber ne-steel bushings.

I-rubber bushing igxiliwe ekugcineni ngekholomu yensimbi ye-bushing kanye ne-nut. I-cavity yesilinda samandla ihlukaniswe yi-piston ibe izingxenye ezimbili: i-under-piston ne-over-piston. Lezi zimbobo zixhunywe ngamapayipi egatsha 15 kanye ne-17 aneziteshi emzimbeni wokusabalalisa, aphethe ngamashaneli avuleka emgodini womzimba phakathi kwemigodi ye-annular.

Izimbobo ezingaphansi nangaphezulu kwepiston yesilinda samandla zingaxhunywa ngevalvu yokuhlola engu-35, equkethe ibhola nesiphethu esicindezelwa ipulaki.

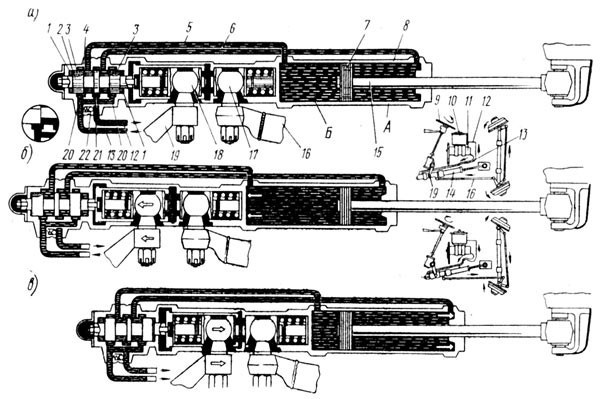

I-hydraulic booster isebenza kanje (Fig. 95). Lapho injini yemoto isebenza, iphampu 11 ihlinzeka ngokuqhubekayo uwoyela ku-hydraulic booster 14, okuthi, ngokuya ngesiqondiso semoto, ibuyele ethangini 10 noma ifakwe komunye wemigodi yokusebenza (A noma B) isilinda samandla 8 ngamapayipi 5 no-6. Esinye imbobo lapho sixhunywa ngomugqa wokukhipha amanzi 12 nethangi le-10.

Ingcindezi kawoyela ngokusebenzisa iziteshi 3 ku-spool 2 ihlale idluliselwa emakamelweni asebenzayo 1 futhi ijwayele ukuhambisa i-spool endaweni engathathi hlangothi ngokuphathelene nomzimba.

Lapho imoto isendleleni eqondile (Fig. 95, a), iphampu inikeza uwoyela nge-hose yokukhipha 13 kuya emigodini eyedlulele engu-20 ye-distributor, futhi ukusuka lapho ngokusebenzisa izikhala phakathi kwemiphetho ye-grooves ye-spool. kanye nendlu eya endaweni emaphakathi ye-annular 21 kanye nokuqhubekela phambili ngakulayini wokudonsa amanzi we-12 ukuya ethangini le-10.

Lapho isondo lokuqondisa liphendukela kwesokunxele (Fig. 95, b) futhi kwesokudla (Fig. 95, c), i-lever steering 19 ngokusebenzisa iphini lebhola 18 isusa i-spool endaweni engathathi hlangothi kanye ne-drain cavity 21 in. umzimba we-valve uyahlukana, futhi uketshezi luqala ukugeleza emgodini ohambisanayo we-cylinder yamandla , ukuhambisa isilinda 8 ngokuhlobene ne-piston 7, egxilwe endongeni 15. Ukunyakaza kwe-cylinder kudluliselwa emasondweni aqondisayo ngebhola. pin 17 kanye nenduku yokuqondisa eyi-longitudinal XNUMX ehlotshaniswa nayo.

Uma uyeka ukuzungezisa i-flywheel 9, ikhoyili iyama futhi umzimba uya ngakuyo, uya endaweni engathathi hlangothi. Amafutha aqala ukugeleza ethangini futhi amasondo ayeke ukujikeleza.

I-hydraulic booster inokuzwela okuphezulu. Ukuze uvule amasondo emoto, kubalulekile ukuhambisa i-spool ngo-0,4-0,6 mm.

Ngokunyuka kokumelana nokuguqula amasondo, ingcindezi kawoyela endaweni yokusebenza yesilinda samandla nayo iyanda. Lokhu kucindezela kudluliselwa emakamelweni okusabela futhi kuvame ukuhambisa i-spool endaweni engathathi hlangothi.

Ilayisi. 95. Uhlelo lomsebenzi GUR MAZ:

I-1 - igumbi elisebenzayo; 2 - ikhoyili; 3 - iziteshi; 4 - izindlu zokusabalalisa; 5 no-6 - amapayipi; 7 - ipiston; 8 - isilinda samandla; 9 - isondo lokuqondisa; 10 - ithangi; 11 - ibhomu; I-12 - ipayipi yokukhipha; 13 - i-hose yokucindezela; 14 - i-hydraulic booster; 15 - induku ye-piston; I-16 - i-longitudinal thrust; 17 no-18 - iminwe yebhola; I-19 - i-lever yokuqondisa; 20 - umgodi wokucindezela; 21 - umgodi wokudonsa amanzi; 22 - hlola i-valve

Ilayisi. 96. Iphampu yesiteringi samandla MAZ:

ibhomu; b - idivayisi ye-tension; 1 - umkhono wesokudla; 2 - igiya elishayelwa; 3 - indandatho yokuvala; 4 - indandatho yokugcina; 5 - indandatho yokusekela; 6 - umkhono; 7 - ikhava; 8 - indandatho yokuvala; 9 - drive gear; 10 - umkhono wesokunxele; 11 - izindlu zokupompa; I-12 - ukwesekwa okungaguquki; 13 - i-eksisi; 14 - i-pulley; 15 - ukulungisa isikulufa; 16 - i-locknut; 17 - imfoloko; 18 - umunwe

Ngenxa yomphumela wokukhulisa we-hydraulic booster, amandla esiteringini ekuqaleni kokuphenduka kwamasondo awadluli ama-5 kg, futhi amandla amakhulu angaba ngu-20 kg.

I-hydraulic booster system ine-valve yokuphepha efakwe kusilinda samandla. I-valve isethwe efektri ingcindezi yesistimu engu-80-90 kg/cm2. Ukulungiswa kwe-valve akuvunyelwe kuzindiza.

Kufanele kukhunjulwe ukuthi ukusebenza kwesikhashana kuphela kokuqondisa kuvunyelwe lapho i-amplifier ingasebenzi, njengoba lokhu kwandisa kakhulu umzamo esindweni futhi kwandisa ukudlala kwayo mahhala. Ijubane lokungenzi lutho lemoto akumele lidlule ku-20 km/h.

Iphampu yegiya lokuqondisa lamandla e-NSh-10E (Fig. 96) ifakwe ohlangothini lwesobunxele lwenjini futhi ishayelwa ku-crankshaft yenjini kusetshenziswa i-V-belt. I-reservoir yamanzi esebenzayo ifakwe kuhlaka lwerediyetha.