Indlela yokusabalalisa igesi - iqembu le-valve

Okuqukethwe

Inhloso nezinhlobo zesikhathi:

1.1. Inhloso yendlela yokusabalalisa igesi:

Inhloso yomshini wokulinganisa isikhathi we-valve ukudlulisa ingxube entsha kaphethiloli kumasilinda enjini nokukhipha amagesi akhipha umoya. Ukushintshaniswa kwegesi kwenziwa ngokuvuleka kwe-inlet ne-outlet, okuvalwe nge-hermetically izakhi zebhande lesikhathi ngokuhambisana nenqubo yokusebenza kwenjini eyamukelwayo.

1.2. Ukunikezwa kweqembu le-Valve:

inhloso yeqembu lama-valve ukuvala ngokusemthethweni izimbobo zokungena neziphumayo bese uzivula ngesikhathi esibekiwe sesikhathi esishiwo.

1.3. Izinhlobo zesikhathi:

ngokuya ngezitho amasilinda ezinjini axhunywe ngayo nemvelo, isikhathi yi-valve, i-spool futhi ihlanganisiwe.

1.4. Ukuqhathanisa izinhlobo zezikhathi:

isikhathi se-valve sivame kakhulu ngenxa yomklamo waso olula nokusebenza okuthembekile. Ukubeka uphawu okuhle nokuthembekile kwendawo yokusebenza, kufinyelelwe ngenxa yokuthi ama-valve ahlala emile ekucindezelweni okuphezulu kumasilinda, kunika inzuzo enkulu ngaphezu kwe-valve noma isikhathi esihlanganisiwe. Ngakho-ke, isikhathi se-valve sisetshenziswa kakhulu.

Idivayisi yeqembu leValve:

2.1. Idivayisi Valve:

Ama-valve enjini aqukethe isiqu nekhanda. Amakhanda avame ukwenziwa abe yisicaba, abe yindilinga noma amise okwensimbi. Inhloko inebhande lelincane le-cylindrical (cishe 2 mm) kanye ne-45˚ noma 30˚ yokufaka uphawu. Ibhande le-cylindrical livumela, ngakolunye uhlangothi, ukugcina ubukhulu be-valve lapho kugaywa i-chamfer yokufaka uphawu, ngakolunye uhlangothi, ukwandisa ukuqina kwe-valve futhi ngaleyo ndlela kuvimbele ukusonteka. Ama-valve asakazeke kakhulu anekhanda eliyisicaba kanye ne-chamfer yokuvala uphawu engama-45˚ (lawa kuvame kakhulu ama-valve), futhi ukwenza ngcono ukugcwaliswa nokuhlanzwa kwama-cylinders, i-valve yokudla inebubanzi obukhulu kune-valve yokukhipha. Amaphayiphu wokukhipha uvame ukwenziwa ngekhanda lebhola elibusisiwe.

Lokhu kuthuthukisa ukuphuma kwamagesi okukhipha amandla avela kumasilinda, futhi kwandisa amandla nokuqina kwe-valve. Ukuze kuthuthukiswe izimo zokukhishwa kokushisa ekhanda le-valve futhi kwandiswe ukungonakali kukonke kwe-valve, ukuguquka phakathi kwekhanda nesiqu kwenziwa nge-engeli engu-10˚ - 30˚ kanye ne-radius enkulu yokugoba. Engxenyeni engenhla ye-valve stem, ama-grooves ayenziwe nge-conical, cylindrical noma umumo okhethekile, kuye ngokuthi indlela eyamukelekile yokunamathisela intwasahlobo ku-valve. Ukupholisa i-sodium kusetshenziswa ezinjinini eziningana ukunciphisa ukucindezeleka okushisayo kuma-valve okuqhuma. Ukuze wenze lokhu, i-valve yenziwa ingenalutho, futhi i-cavity ephumela igcwele isigamu se-sodium, indawo yokuncibilika engu-100 ° C. Lapho injini isebenza, i-sodium iyancibilika futhi idlule emgodini we-valve, idlulise ukushisa kusuka ekhanda elishisayo kuya esiqwini esipholile futhi ukusuka lapho kuya ku-actuator ye-valve.

2.2. Ukuxhuma i-valve entwasahlobo yayo:

imiklamo yale yunithi ihluke ngokweqile, kepha idizayini ejwayelekile kakhulu inama-half-cones. Ngosizo lwama-cones amabili, afaka iziteshi ezenziwe ngesiqu se-valve, ipuleti licindezelwe, elibamba intwasahlobo futhi alivumeli ukuqaqa iyunithi. Lokhu kudala ukuxhumana phakathi kwentwasahlobo ne-valve.

2.3. Indawo yesihlalo se-Valve:

Kuzo zonke izinjini zesimanje, izihlalo ze-qeda zenziwa ngokuhlukile kunekhanda lesilinda. Lezi zisetshenziselwa izinkomishi zokudonsa lapho ikhanda lesilinda lenziwe nge-aluminium alloy. Lapho kwenziwa insimbi, izihlalo zenziwa kuyo. Ngokwakheka, isihlalo siyindandatho enamathiselwe ekhanda lesilinda esihlalweni somshini ngokukhethekile. Ngasikhathi sinye, ama-grooves kwesinye isikhathi enziwa engxenyeni engaphandle yesihlalo, okuthi, uma icindezelwa esihlalweni, igcwaliswe ngezinto zekhanda lesilinda, ngaleyo ndlela kuqinisekiswe ukubotshwa kwazo okuthembekile. Ngaphezu kocingo, ukubopha kungenziwa futhi ngokuswayipha isihlalo. Ukuqinisekisa ukuqina kwesikhala sokusebenza lapho i-valve ivaliwe, indawo yokusebenza yesihlalo kufanele yenziwe ngomshini nge-angle efanayo ne-chamfer yokufaka uphawu yekhanda le-valve. Ukuze wenze lokhu, izihlalo zenziwe ngomshini ngamathuluzi akhethekile anama-engeli acijile hhayi ayi-15 hhayi, ama-45˚ no-75˚ ukuze kutholwe itheyiphu yokufaka uphawu engeli ka-45˚ nobubanzi obungu-2 mm. Amanye amakhona enziwe ukuthuthukisa ukugeleza okuzungeze isihlalo.

2.4. Indawo Yemihlahlandlela Yama-Valve:

ukwakheka kweziqondisi kuhluke kakhulu. Imvamisa, kusetshenziswa imihlahlandlela enendawo ebushelelezi yangaphandle, eyenziwe ngomshini wamapayipi ongenalutho. Imihlahlandlela enentambo yokugcina yangaphandle kulula ukuyibopha kepha kunzima ukuyenza. Ngalokhu, kusizakala kakhulu ukwenza isiteshi sendandatho yokuma kumhlahlandlela esikhundleni sebhande. Imihlahlandlela yama-valve yokukhipha ivame ukusetshenziselwa ukuwavikela emiphumeleni ye-oxidative yomfudlana wegesi oshisayo oshisayo. Kulokhu, kwenziwa imihlahlandlela emide, eminye etholakala esiteshini sekhanda lesilinda sokukhipha ikhanda. Njengoba ibanga phakathi komhlahlandlela nekhanda le-valve lincipha, umgodi kusiqondisi ohlangothini lwekhanda le-valve uncipha noma uvuleke esifundeni sekhanda le-valve.

2.5. Idivayisi ye-Springs:

ezinjinini zesimanjemanje, imithombo ejwayelekile eyindilinga enephimbo elingaguquki. Ukwakha indawo esekelayo, imikhawulo yamakhoyili entwasahlobo ihlanganiswa ihlangane futhi iqweqwe ngamabunzi ayo, ngenxa yalokho inani lamakhoyili liphindwe kabili noma kathathu kunenani lemithombo yokusebenza. Amakhoyili okuphela asekelwa ohlangothini olulodwa lwepuleti nakwelinye icala lekhanda lesilinda noma ibhlokhi. Uma kunengozi yokuzwakala, iziphethu ze-valve zenziwa nge-pitch eguquguqukayo. U-gearbox onyathelwe ugoba kusuka kolunye uhlangothi lwentwasahlobo kuye kolunye, noma ukusuka maphakathi kuye emaphethelweni womabili. Lapho kuvulwa i-valve, i-windings eseduze komunye nomunye iyathinta, ngenxa yalokho inani le-windings elisebenzayo liyancipha, kanye nemvamisa yokushaywa kwamahhala kwentwasahlobo kuyanda. Lokhu kususa imibandela ye-resonance. Ngenhloso efanayo, kwesinye isikhathi kusetshenziswa iziphethu eziyindilinga, imvamisa yemvelo ehlukahluka ngobude bayo futhi nokuvela kwe-resonance kuyakhishwa.

2.6. Izinto zokwenziwa kwezinto zeqembu le-valve:

• Amavalvu - Amavalvu okumunca ayatholakala nge-chrome (40x), i-chromium nickel (40XN) nezinye izinsimbi ze-alloy. Ama-valve okukhipha umoya akhiwe ngezinsimbi ezikwazi ukumelana nokushisa ezinokuqukethwe okuphezulu kwe-chromium, i-nickel nezinye izinsimbi ezihlanganisayo: 4Kh9S2, 4Kh10S2M, Kh12N7S, 40SH10MA.

• Izihlalo zamavalvu - Izinsimbi ezimelana nezinga lokushisa eliphezulu, insimbi ekhonjiwe, ithusi le-aluminium noma i-cermet.

• Iziqondiso zamavaluvu ziyizindawo ezinzima ukuzenza futhi zidinga ukusetshenziswa kwezinto ezinokushisa okuphezulu nokungagugi kanye ne-thermal conductivity enhle, njenge-grey pearlitic cast iron kanye ne-aluminium bronze.

• Iziphethu - ezenziwe ngocingo oluvunguzayo olusuka ku-spring stoma, isb 65G, 60C2A, 50HFA.

Ukusebenza kweqembu le-Valve:

3.1. Indlela yokuvumelanisa:

indlela yokuvumelanisa ixhumeke kinematically ku-crankshaft, ihamba ngokuvumelanayo nayo. Ibhande lesikhathi livula livalwe ngamachweba okungena nawokungena amasilinda ngamanye ngokuya ngenqubo eyamukelwe yokusebenza. Le yinqubo yokushintshaniswa kwegesi kumasilinda.

3.2 Isenzo sedrayivu yesikhathi:

Idrayivu yesikhathi incike endaweni ye-camshaft.

• Nge-shaft ephansi - ngokusebenzisa ama-spur gears okusebenza okushelelayo kwenziwa ngamazinyo athambekele, futhi ekusebenzeni buthule, indandatho yegiya yenziwe nge-textolite. Igiya le-parasitic noma iketango lisetshenziselwa ukunikeza ukushayela ngebanga elide.

• Nge-shaft ephezulu - i-roller chain. Izinga lomsindo eliphansi uma kuqhathaniswa, idizayini elula, isisindo esiphansi, kodwa isifunda siyaguga futhi siyanwebeka. Ngebhande lesikhathi elisekelwe ku-neoprene eliqiniswe ngentambo yensimbi futhi elimbozwe ngelendlalelo enayiloni engagugi. Idizayini elula, ukusebenza okuthule.

3.3. Uhlelo lokusabalalisa igesi:

Indawo yokugeleza isiyonke enikezwe ukudlula kwamagesi nge-valve incike esikhathini sokuvulwa kwayo. Njengoba wazi, ngezinjini ezine ezinesifo sohlangothi, ukuze kusetshenziswe imivimbo yokudla nokukhipha, kunikezwa ukushaywa okukodwa kwe-piston, okuhambelana nokujikeleza kwe-crankshaft ngo-180˚. Kodwa-ke, okuhlangenwe nakho kukhombisile ukuthi ukugcwaliswa kangcono nokuhlanzwa kwesilinda kuyadingeka ukuthi ubude bezinqubo zokugcwalisa nokuchitha bube bude kunemivimbo ehambelana nepiston, i.e. ukuvulwa nokuvalwa kwama-valve akufanele kwenziwe ezindaweni ezifile zesifo sohlangothi lwe-piston, kodwa okunye kudlula noma kubambezeleke.

Izikhathi zokuvula nokuvala i-valve zivezwa ngama-engeli wokujikeleza kwe-crankshaft futhi zibizwa nge-valve timing. Ukuthembeka okukhulu, lezi zigaba zenziwa ngendlela yamashadi wamaphayi (I-Fig. 1).

Ivalvu yokumunca ivamise ukuvuleka nge-engeli ye-overrun φ1 = 5˚ - 30˚ ngaphambi kokuba ipiston ifike endaweni efile ephezulu. Lokhu kuqinisekisa isiphambano se-valve ethile ekuqaleni kwe-stroke yokugcwalisa futhi ngaleyo ndlela kuthuthukisa ukugcwaliswa kwe-cylinder. Ivalvu yokumunca ivalwa nge-engeli yokubambezeleka φ2 = 30˚ - 90˚ ngemva kokuba ipiston idlule indawo ephansi efile. Ukubambezeleka kokuvalwa kwevalvu yokungena kuvumela ukuthathwa kwengxube entsha kaphethiloli ukuthi isetshenziselwe ukuthuthukisa ukugcwalisa futhi ngaleyo ndlela kwandise amandla enjini.

I-valve yokukhipha umoya ivulwa nge-engeli yokudlula φ3 = 40˚ - 80˚, i.e. ekupheleni kwe-stroke, lapho ingcindezi emagesi e-cylinder iphakeme kakhulu (0,4 - 0,5 MPa). Ukukhishwa okujulile kwe-cylinder yegesi, okuqalwe kulokhu kucindezela, kuholela ekwehleni ngokushesha kwengcindezi kanye nezinga lokushisa, okunciphisa kakhulu umsebenzi wokuxosha amagesi asebenzayo. Ivalvu yokukhipha umoya ivala nge-engeli yokubambezeleka φ4 = 5˚ - 45˚. Lokhu kubambezeleka kunikeza ukuhlanzwa okuhle kwegumbi elivuthayo kusuka kumagesi okukhipha umoya.

Ukuxilonga, ukulungisa, ukulungisa:

4.1. Ukuxilongwa

Izimpawu zokuxilonga:

- •Amandla ancishisiwe wenjini yomlilo yangaphakathi:

- Ukwehliswa kwesibalo;

- Ukulingana okungapheli kwe-valve;

- Amaphayiphu abanjwe.

• Ukwanda kokusetshenziswa kukaphethiloli: - Ukwehliswa kwesibalo phakathi kwama-valve nama-lifters;

- Ukulingana okungapheli kwe-valve;

- Amaphayiphu abanjwe.

• Gqoka izinjini zomlilo zangaphakathi: - Ukugqoka kweCamshaft;

- ukuvula amakhamera we-camshaft;

- Ukwanda kwemvume phakathi kweziqu zama-valve nama-valve bushings;

- Ukuvunyelwa okukhulu phakathi kwama-valve nama-lifters;

- ukwephuka, ukwephulwa kokuqina kwemithombo ye-valve.

Inkomba yengcindezi ephansi: - Izihlalo ze-valve zithambile;

- Intwasahlobo ye-valve ethambile noma ephukile;

- I-valve eshile;

- i-gasket yekhanda elishisiwe noma elidabukile;

- Igebe lokushisa elingashintshiwe.

• Isibonisi sengcindezi ephezulu. - Ukuncipha kwekhanda;

Izindlela zokuxilonga isikhathi:

• Ukukala ingcindezi kusilinda ekugcineni kwesifo sokucindezelwa. Ngesikhathi sokulinganisa, kufanele kuhlangatshezwane nalezi zimo ezilandelayo: injini yomlilo kufanele ishiswe ekushiseni okusebenzayo; Ama-plugs enhlansi kufanele asuswe; Ikhebula lesikhungo lekhoyili yokungeniswa kufanele igcotshwe ngamafutha futhi ivalve mpintsha nevalve yomoya ivuleke. Ukulinganisa kwenziwa kusetshenziswa ama-compressors. Umehluko wengcindezi phakathi kwamasilinda ngawodwana akufanele weqe u-5%.

4.2. Ukulungisa imvume ezishisayo ebhande lesikhathi:

Ukuhlola nokulungisa igebe elishisayo kwenziwa ngokusebenzisa izingcwecwe zokucindezela ingcindezi ngokulandelana okuhambisana nokuhleleka kokusebenza kwenjini, kuqala ngesilinda sokuqala. Igebe lilungiswa kahle uma igeji yokujiya, ehambelana negebe elijwayelekile, idlula ngokukhululeka. Lapho ulungisa imvume, bamba isikulufa sokulungisa ngesikulufo, khipha ukhiye, ubeke ipuleti lokususa phakathi kwesiqu se-valve nokuhlangana, bese uvula isikulufa sokulungisa ukusetha imvume edingekayo. Bese kuqiniswa inati yokukhiya.

4.3. Ukulungiswa kweqembu le-Valve:

• Ukulungiswa kwama-valve - amaphutha amakhulu ukuguga nokushiswa kwendawo yokusebenza eyi-conical, ukuguga kwesiqu kanye nokubukeka kwemifantu. Uma amakhanda evutha noma kuvela imifantu, ama-valve ayalahlwa. Iziqu zevalve egobile ziqondiswa ngokucindezela ngesandla kusetshenziswa ithuluzi. Iziqu zama-valve ezigugile zilungiswa ngokulandelanisa isikhathi noma ngoku-ayina bese zigaywa zibe kusayizi wokukhanda omncane noma omkhulu kakhulu. Indawo yokusebenza egugile yekhanda le-valve igaywe ibe usayizi wokulungisa. Ama-valve ahlanganiswe ezihlalweni ngama-abrasive paste. Ukunemba kokugaya kuhlolwa ngokuthela i-parafini kuma-valve anama-hinged, uma ingavuzi, khona-ke ukugaya kuhle imizuzu engu-4-5. Iziphethu ze-valve azibuyiselwa, kodwa zithathelwa indawo ezintsha.

Imibuzo nezimpendulo:

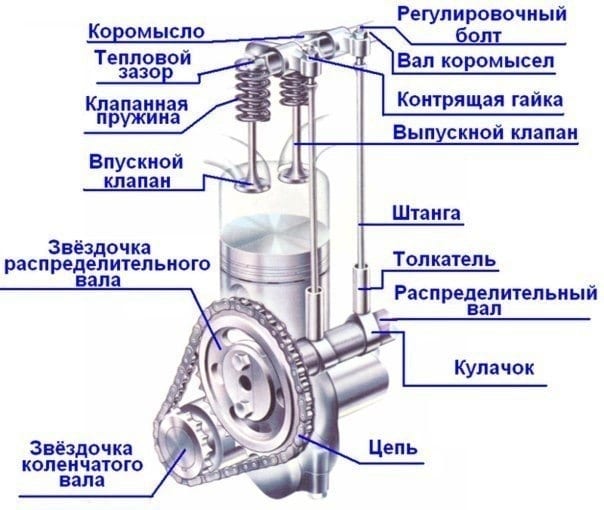

Yini efakiwe endleleni yokusabalalisa igesi? Itholakala ekhanda lesilinda. Idizayini yayo ihlanganisa: umbhede we-camshaft, i-camshaft, ama-valve, izingalo ze-rocker, ama-pusher, ama-hydraulic lifters futhi, kwamanye amamodeli, isishintshi sesigaba.

ДSiyini isikhathi senjini? Lo mshini uqinisekisa ukuhlinzekwa okufika ngesikhathi kwengxenye entsha yengxube yamafutha omoya kanye nokususwa kwamagesi okukhipha umoya. Ngokuya ngokuguqulwa, ingashintsha isikhathi sesikhathi se-valve.

Itholakala kuphi indlela yokusabalalisa igesi? Enjinini yesimanje yangaphakathi evuthayo, indlela yokusabalalisa igesi itholakala ngaphezu kwebhulokhi yesilinda ekhanda lesilinda.